Memory card rotary disk and processing method thereof

A processing method and turntable technology, applied in metal processing equipment, manufacturing tools, details of milling machine equipment, etc., can solve problems such as reducing fluidity, difficulty in opening molds, reducing product qualification rate and performance, and reducing mold opening costs. , The difficulty of opening the mold is reduced, and the milling effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

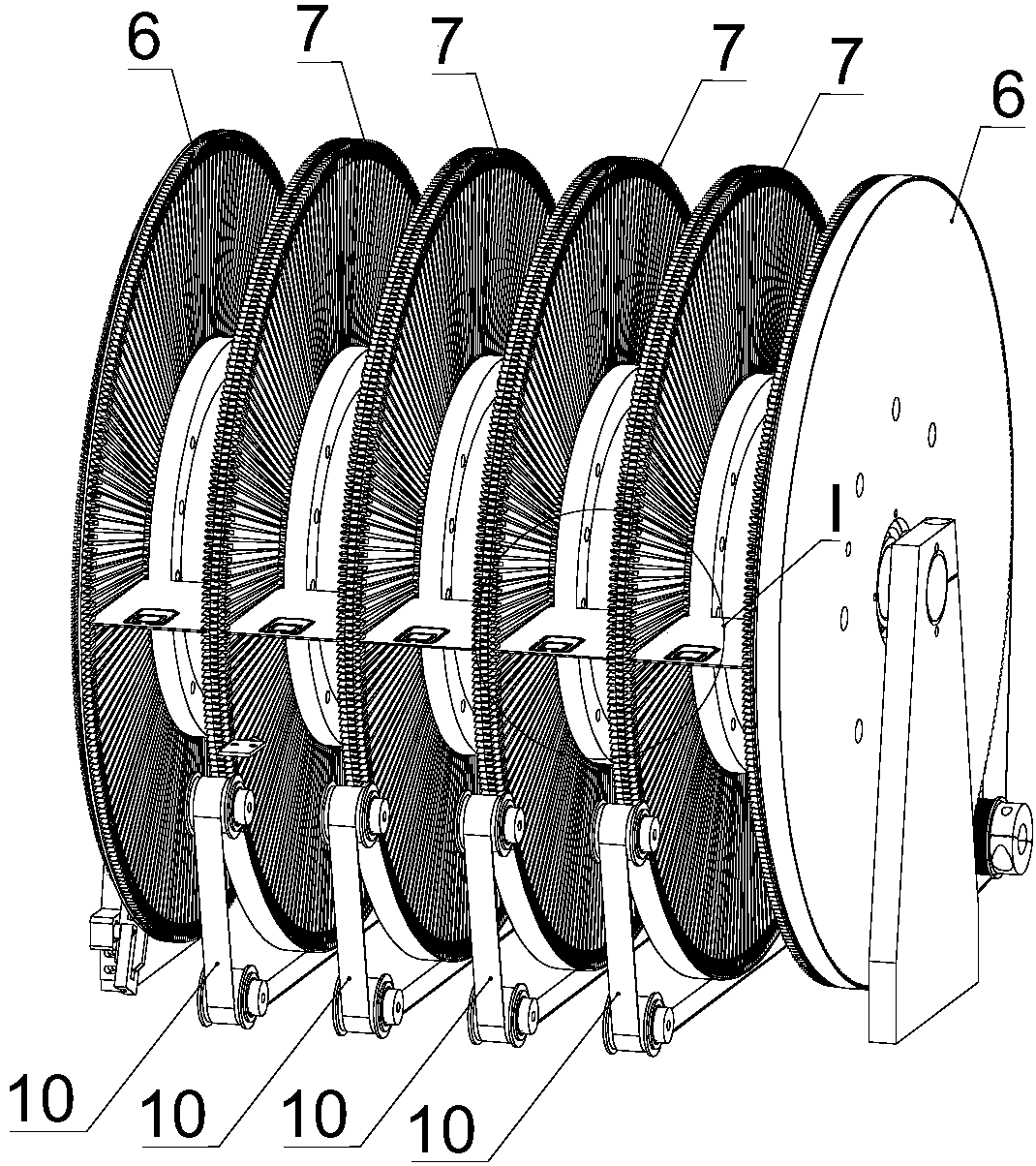

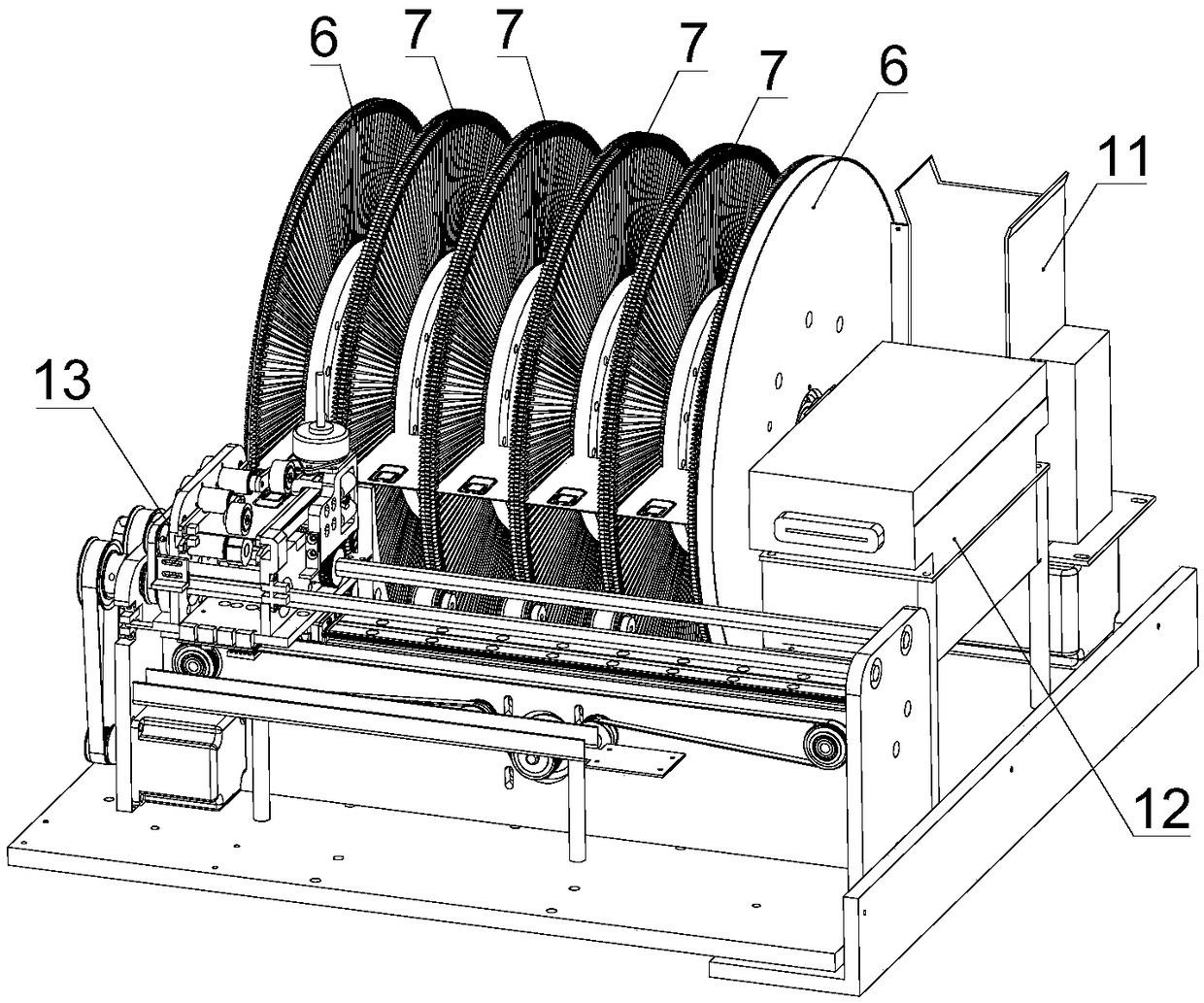

[0038] see figure 2 , a card storage carousel of the present invention cooperates with the card storage device 11, the card reading device 12 and the access card trolley 13 to jointly complete the task of accessing the card. Wherein, when depositing the card, the access card trolley 13 is responsible for The card of the card storage device 11 is stored in the card storage carousel, and when the card is taken out, the card storage device is responsible for taking out the card from the card storage carousel and sending it to the card opening position of the card collection machine.

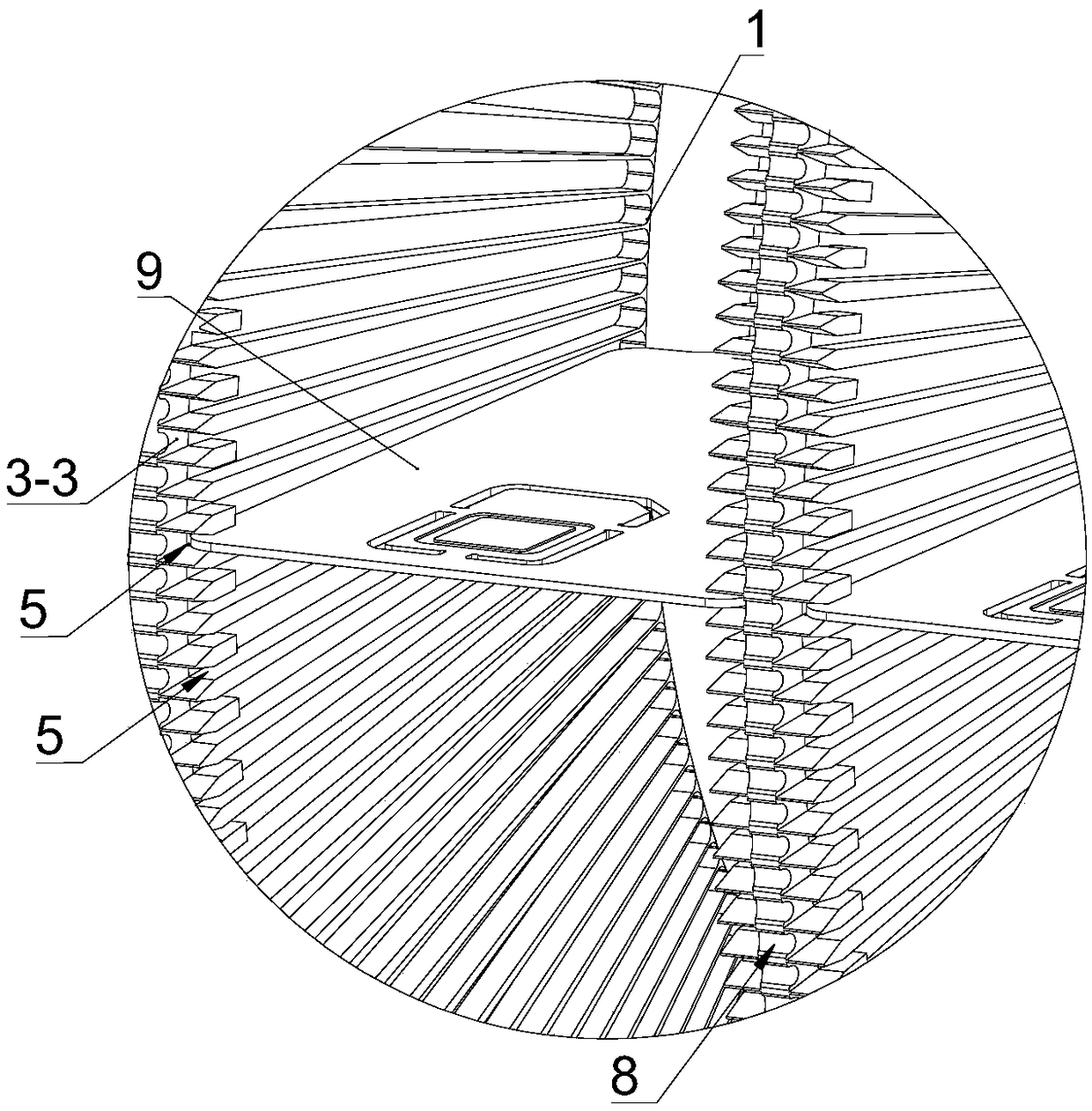

[0039] see Figure 1-Figure 5 , a card storage carousel of the present invention includes a carousel main body 1, on which a plurality of accommodating grooves 2 for accommodating smart card...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com