Cutting Combination Tool

A technology of combining cutting tools and cutting parts, which is applied in the direction of milling cutters, drilling tool accessories, manufacturing tools, etc., can solve the problems of error accumulation, product failure, and lower processing efficiency, so as to reduce errors, facilitate manufacturing, and improve processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

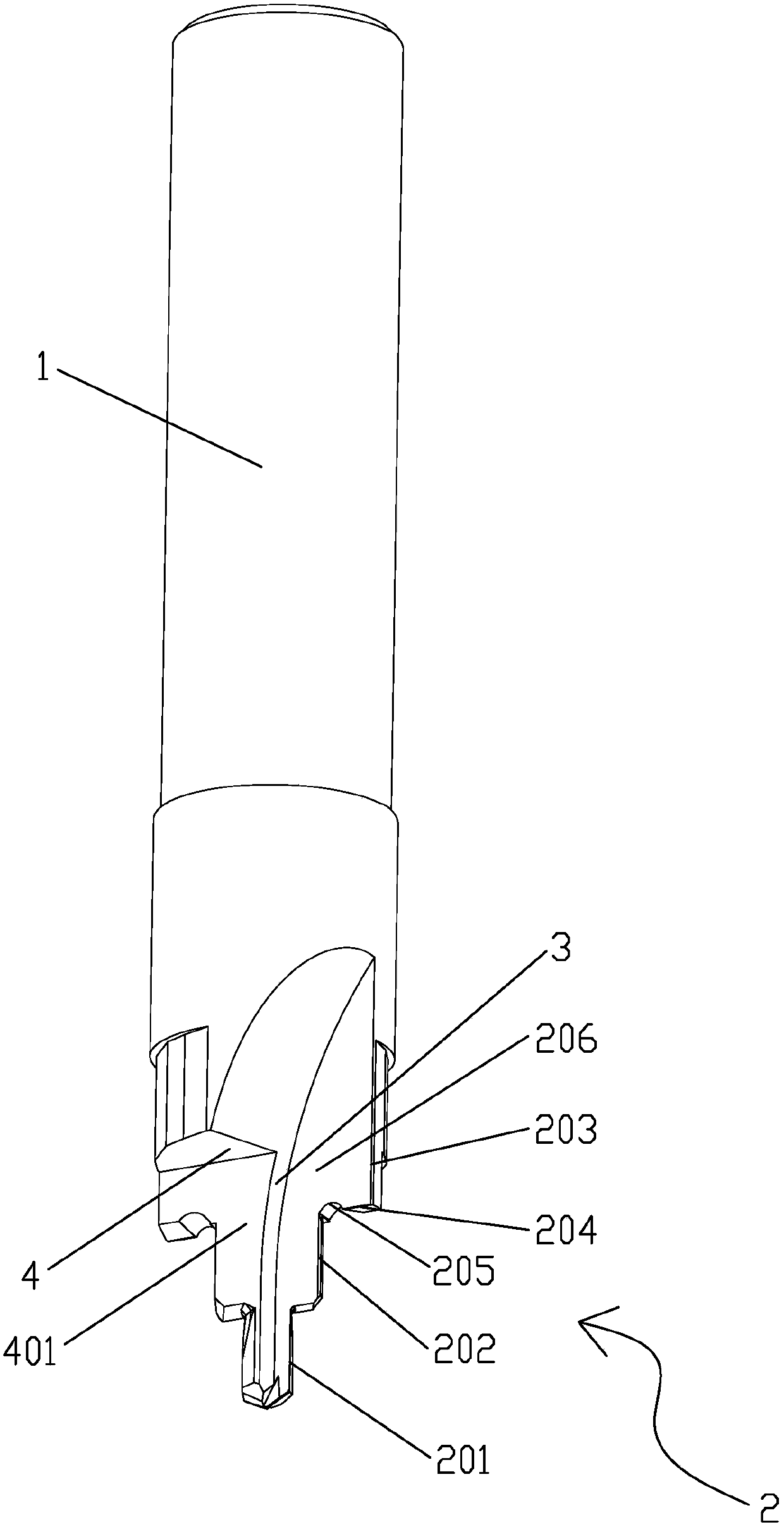

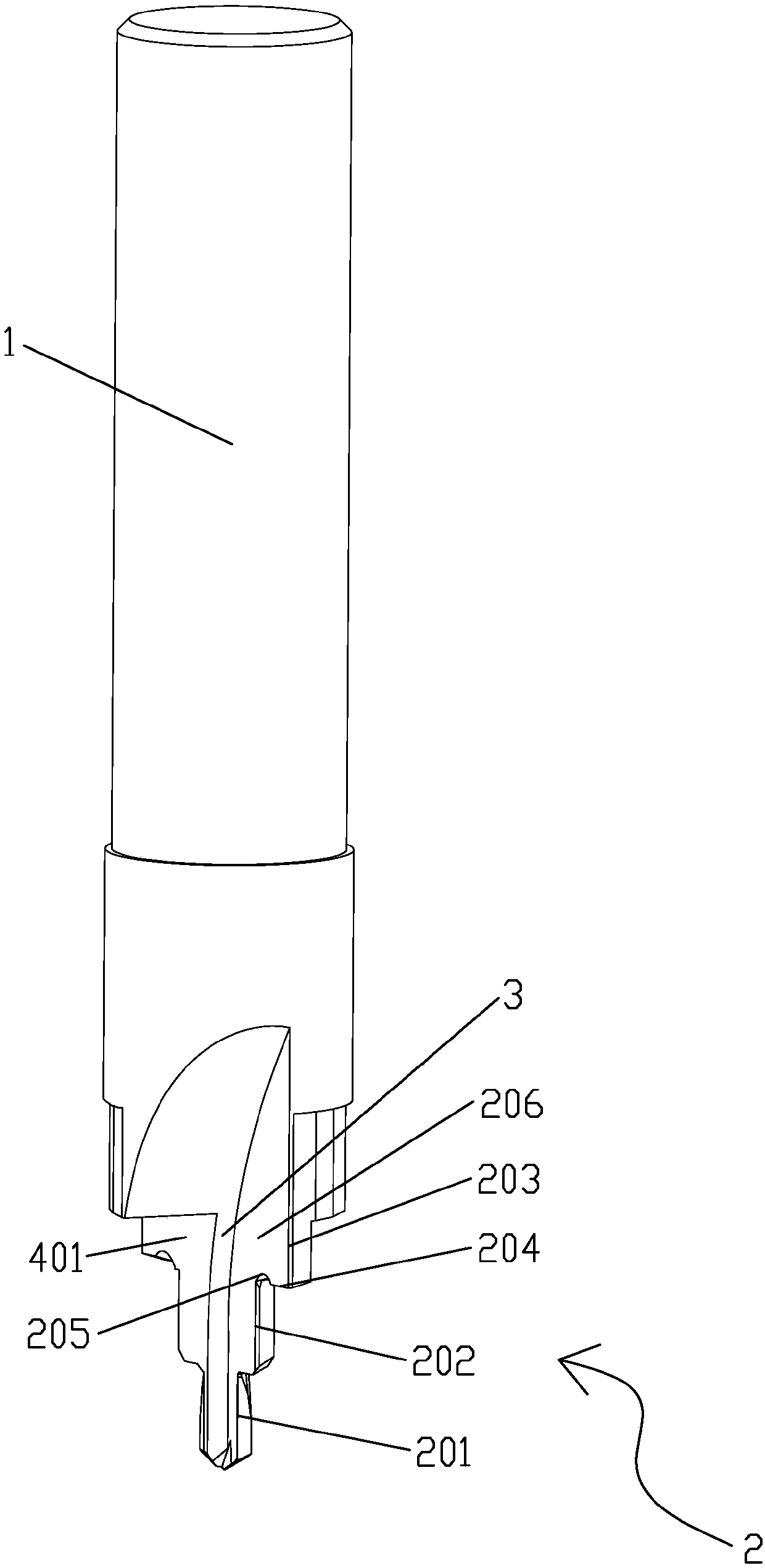

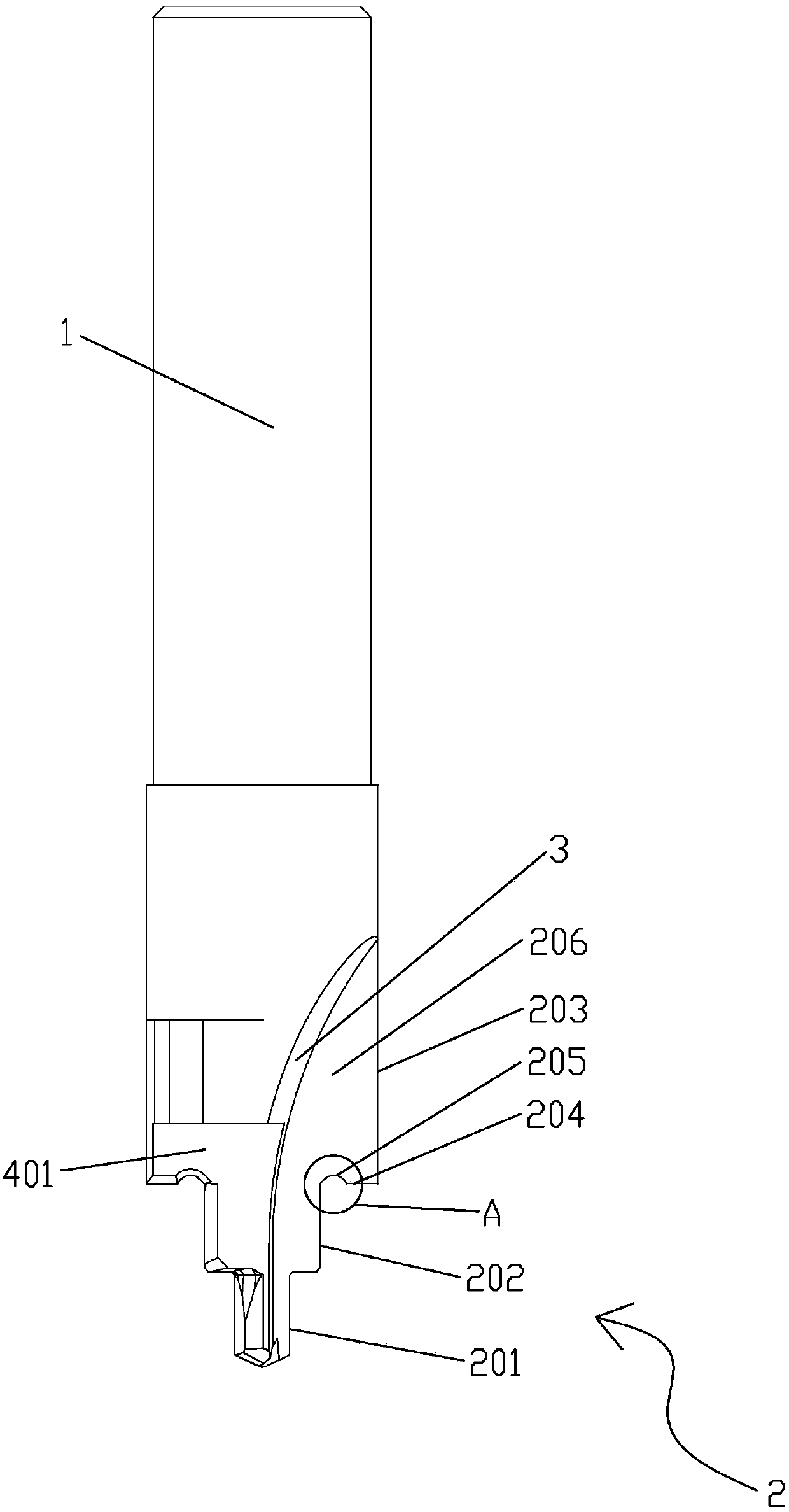

[0027] The combined cutting tool includes a body 1 that can be connected with processing equipment at one end, and the body 1 is provided with a cutting structure 2 that rotates with it, and the cutting structure 2 includes a first cutting portion 201 at its end, The first cutting part 201 is provided with a second cutting part 202 connected with it and the cutting range is larger than the first cutting part 201, and the second cutting part 202 is provided with a second cutting part 202 connected with it and the cutting range is larger than the first cutting part 202. The third cutting part 203 of the second cutting part 202, the third cutting part 203 is provided with a milling part 204, between the milling part 204 and the second cutting part 202 Be provided with the chamfering cutting part 205 that can chamfer the rear edge of the workpiece milling groove, the first cutting part 201, the second cutting part 202, the third cutting part 203 and the chamfering cutting part 205 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com