Milling machine for wrench opening

A wrench and milling machine technology, applied in the field of wrench wrench milling machines, can solve the problems of the surface flatness of the wrench wrench not meeting the requirements, the operation of the traverse device is not stable, the wrench is easy to loosen and shift, etc., and the milling effect is good, The effect of stable wrench and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

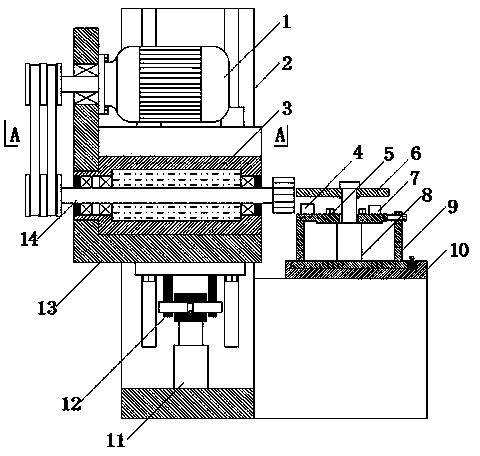

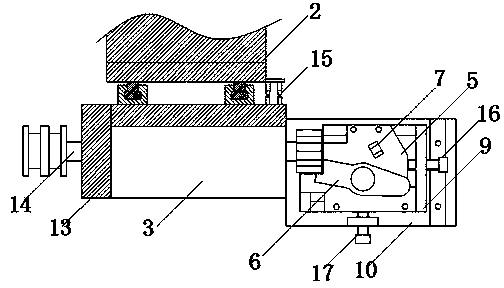

[0016] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

[0017] like figure 1 , figure 2 As shown, the wrench wrench milling machine of the present invention includes a transmission device, a fixed frame 13, a hydraulic cylinder 11, a wrench clamp and a workbench 2. The transmission device includes a motor 1 and a cutter shaft 14, the motor 1 and the cutter shaft 14 are respectively fixed on the fixed frame 13 through bearings, and one end of the motor 1 and the cutter shaft 14 is connected by a synchronous wheel and a synchronous belt transmission, and the other end of the cutter shaft 14 is connected to an adaptable The high-speed rotating alloy milling cutter is fixedly connected. The side wall of the fixed mount 13 is slidably connected with the side wall of the workbench 2, so that the fixed mount 13 can slide up and down along the side wall of the workbench to move. The hydraulic cylinder 11 is plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com