Hydraulic-mechanical combined rock-breaking milling wheel and double-wheel slot milling machine

A hydraulic machinery and double-wheel milling technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problem of inability to deal with rocks in the blind area of milling, loss of milling tooth life, and slot milling machine Reduced work efficiency and other problems, to achieve the effect of reducing rock breaking energy consumption, reducing wear of milling teeth, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In order to make the purpose, technical solution and advantages of the present application clearer, the implementation manners of the present application will be further described in detail below in conjunction with the accompanying drawings.

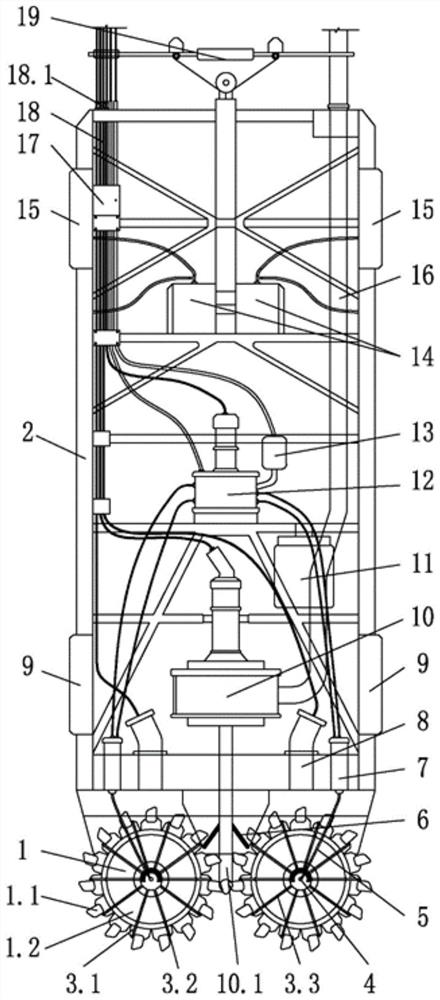

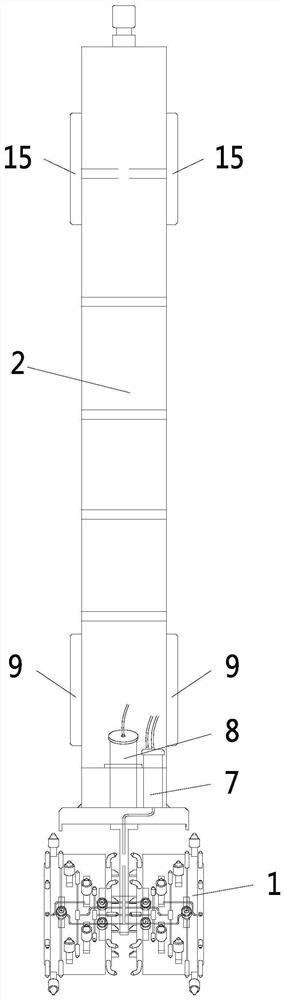

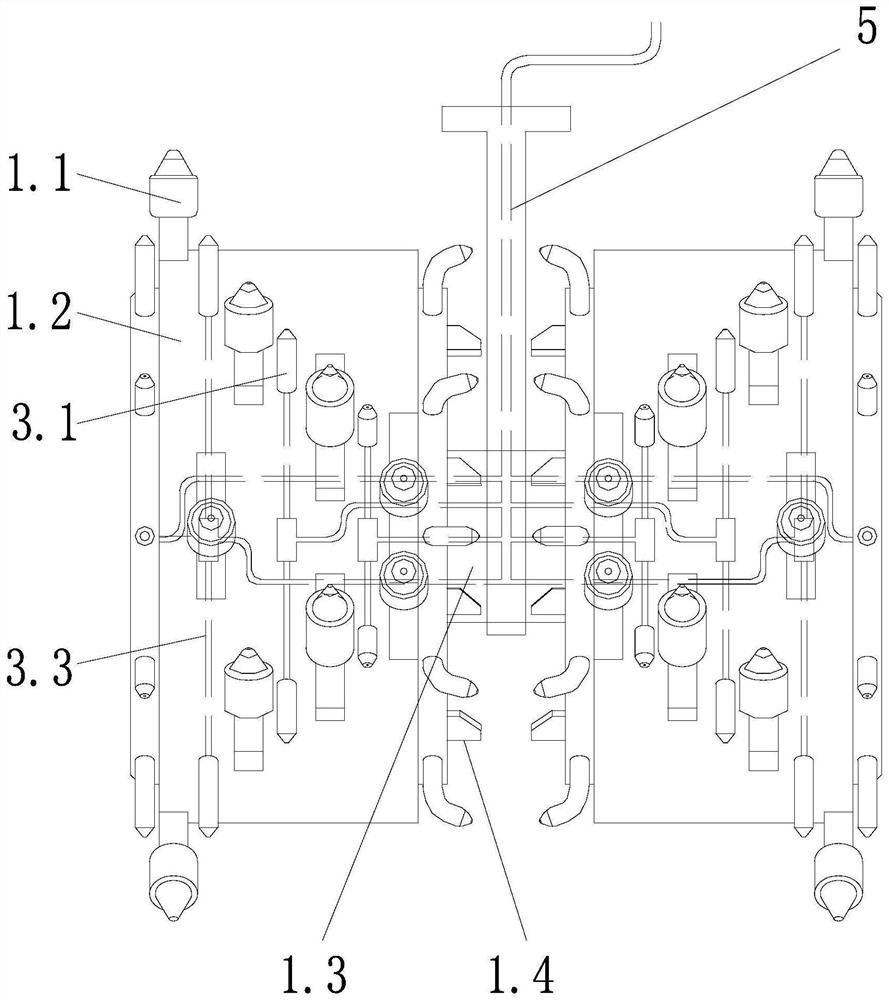

[0065] See attached Figure 1-8 , The hydromechanical combined rock-breaking milling wheel 1 of the present application includes a milling wheel main body 1.2, a plurality of milling teeth 1.1, a plurality of picks 1.4, a milling wheel spindle 1.3 and a high-pressure water jet device 3.

[0066] See attached Figure 3-5 , the milling teeth 1.1 are arranged on the milling wheel main body 1.2; the milling teeth 1.1 are arranged at intervals, and the shape formed by connecting the center points of each milling tooth 1.1 is the function image shape of the sine function y=sinωx, wherein the value of ω is measured according to the test , or take the engineering experience value, where the value of ω is measured according to the test, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com