A pharmaceutical and chemical raw material powder making device

A pulverizing device and a technology of chemical raw materials, which are applied in the field of pharmaceutical and chemical raw material pulverizing devices, can solve the problems of poor pulverizing effect, no combined effect, single longitudinal rolling or horizontal rubbing, etc., to achieve the pulverizing effect better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

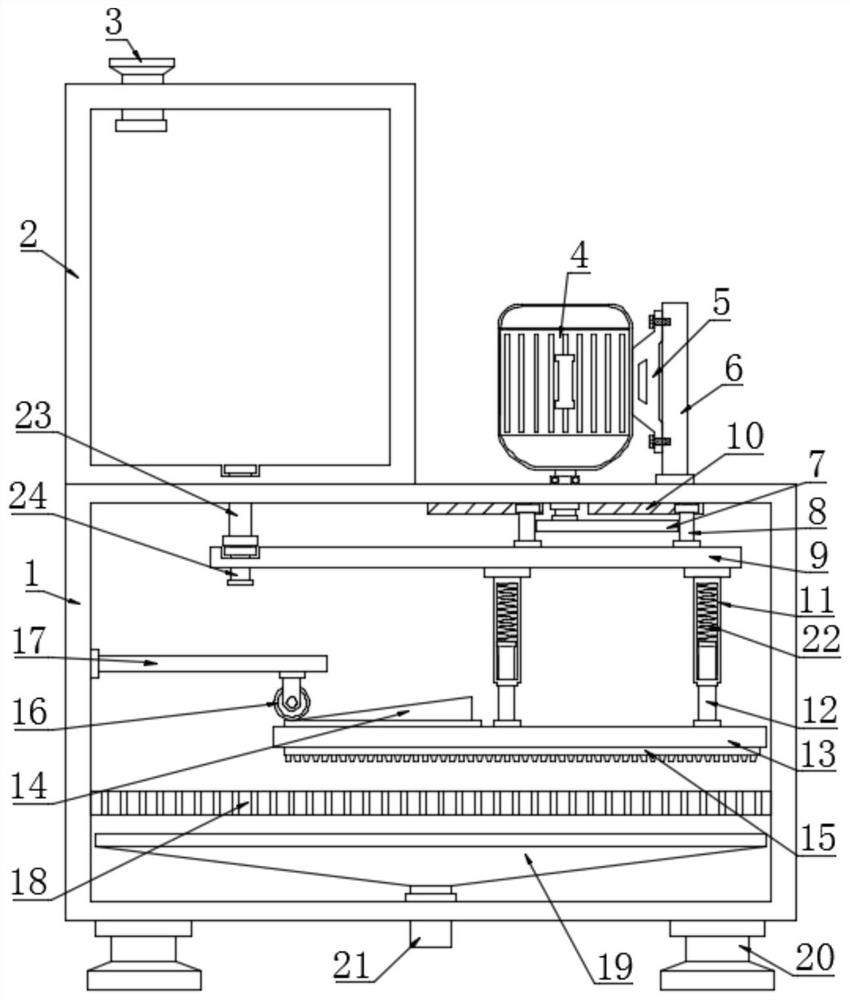

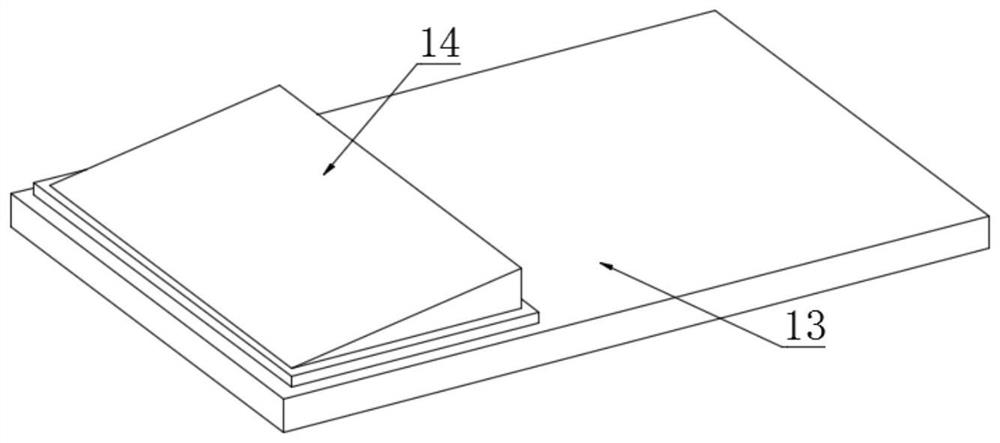

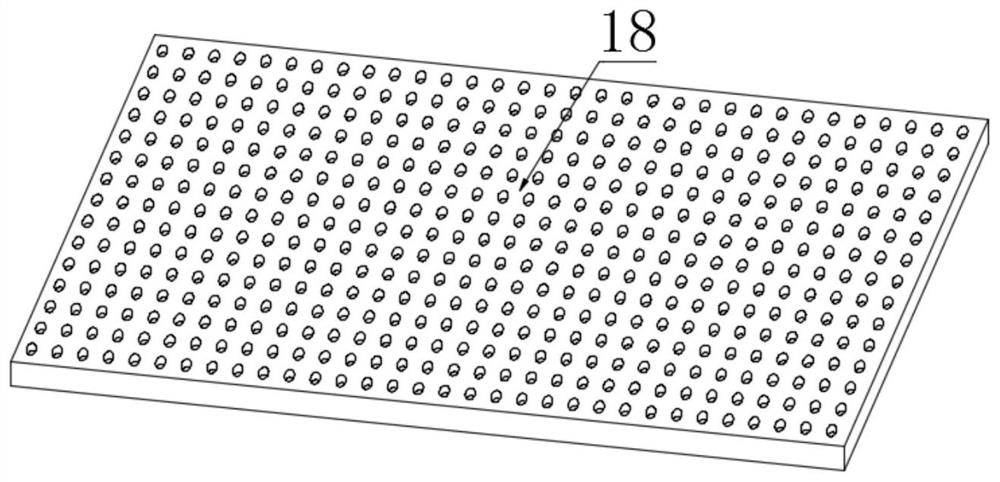

[0020] see Figure 1~3 , in an embodiment of the present invention, a pharmaceutical and chemical raw material powder making device includes a device housing 1, a material box 2, a drive motor 4, a top plate 9, a movable plate 13, a wear-resistant tooth plate 15 and a filter plate 18; the device The upper left side of the casing 1 is fixedly installed with a material box 2, and the upper side of the material box 2 is fixedly connected with a hopper 3, and the upper right side of the device casing 1 is fixedly installed with a drive motor 4, and the lower part of the drive motor 4 is connected to the output shaft through rotation. The device housing 1 is rotatably connected with the bearing. It should be noted that the right side of the drive motor 4 is fixedly connected to the motor base 5, the motor base 5 is fixedly connected to the mounting frame 6 by bolts, and the lower end of the mounting frame 6 is fixedly connected to the device housing 1. The wires of the drive motor ...

Embodiment 2

[0023] In order to make the technical solutions in this application more detailed and complete, now some supplements and explanations are made on the basis of the above-mentioned embodiment 1, so that the disclosure of the technical means adopted in this application is more sufficient, specifically, the supplements and explanations Part of the technical feature is that the center of the bottom of the material box 2 is fixed and communicated with a through pipe 23, the lower end of the through pipe 23 is attached to the top plate 9, the left end of the top plate 9 is connected with and fixed with a discharge pipe 24, and the top plate 9 that moves back and forth left and right makes the discharge The pipe 24 reciprocates through the through pipe 23 to discharge the material in the material box 2 to achieve the function of intermittent blanking.

[0024] The working principle of the present invention is: press the switch so that the drive motor 4 is energized to drive the output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com