Efficient and novel PCD cutter set

A new type of tool set technology, which is applied in the direction of milling cutters, manufacturing tools, metal processing equipment, etc., can solve the problems of affecting work efficiency, service life, easy formation of chip layers, and low precision, so as to save the number of tool changes and processing time, improved productivity, and high precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

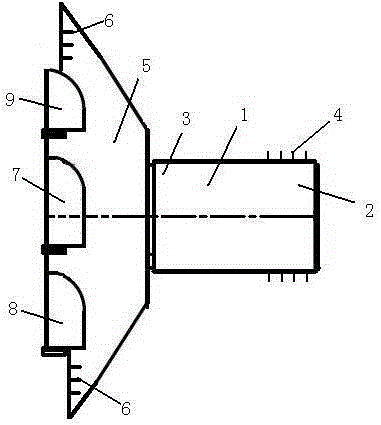

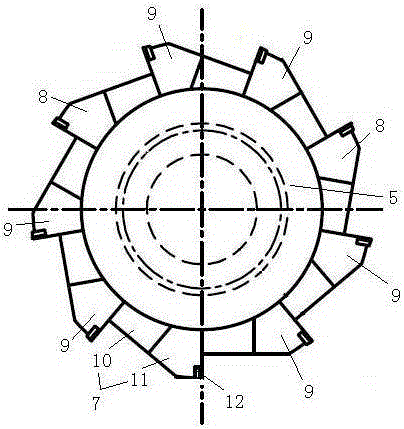

[0012] As shown in the figure, a high-efficiency new PCD knife set includes a connecting rod 1, one end of the connecting rod 1 is a connecting end 2, and the other end is a cutting end 3, and the connecting end 2 is provided with a lock nut 4. A milling cutter disc 5 is provided on the cutting end 3, and a plurality of chip removal grooves 6 are uniformly arranged around the milling cutter disc 5, and the width of the chip removal grooves 6 is 0.2-0.5 mm. The cutter head 5 is a circular structure, the milling cutter head 5 is provided with a first blade 7, a second blade 8 and a third blade 9, the first blade 7 is one, and the second blade 8 is two , there are six third blades 9, the first blade 7 is 0.5mm higher than the second blade 8, the third blade 9 is 1mm higher than the second blade 8, the first blade 7 and the second The blades 8 are used in conjunction to separate the third blade 9 in pairs. The first blade 7, the second blade 8 and the third blade 9 have the same s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com