Special efficient grinding shoe for drift-diameter bridge plugs

A bridge plug and high-efficiency technology, applied in the direction of wellbore/well components, earthwork drilling and production, etc., can solve the problems of low drilling efficiency, debris and sediment in the lower part of the bridge plug can not be cleaned in time, to improve drilling efficiency, Improve the milling effect and keep the effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

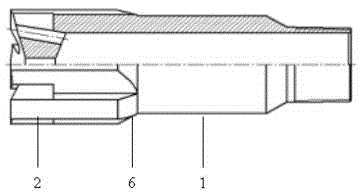

[0020] In order to overcome the problems of low efficiency of existing drilling, grinding and drilling, and the inability to clean the debris and sediments in the lower part of the bridge plug in time, the present invention provides such figure 1 , figure 2 , image 3 , Figure 4 A special high-efficiency grinding shoe for bridge plugs is shown. It is suitable for the drilling and milling needs of fast drilling bridge plugs with larger diameters. It can greatly improve the grinding shoe and drilling efficiency of the fast drilling bridge plug.

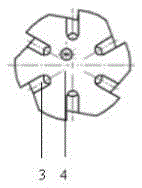

[0021] A special high-efficiency flat-bottomed grinding shoe for bridge plugs, including a main body 1, a six-petal milling italic body 2, a YG carbide block 5 and a reverse-guided milling body 6, one end of the body 1 is connected to a reverse-guided milling body Body 6, the reverse guide milling body 6 is connected to the six-lobe milling italic body 2; there are seven channels for liquid circulation at the bottom of the six-lob...

Embodiment 2

[0024] Based on Embodiment 1, in this embodiment, the bottom of the six-lobed milling oblique body 2 is provided with an eccentric flushing water eye 4 .

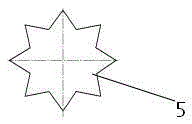

[0025] The cross-section of the YG cemented carbide block 5 is equilateral and multi-rhombic, and each part has the same geometric shape to ensure that there are cutting points in multiple directions.

[0026] The YG hard alloy block 5 is evenly laid and welded on the six-lobe milling oblique body 2 of the milling shoe. Regardless of the shape or position of the milling bridge plug fish head, there are sharp cutting angles and cutting points where it meets the fish head.

[0027] 4-6 layers of YG hard alloy blocks 5 are evenly laid and welded between the six-petal milling italic body 2 and the reverse-guided milling body 6 .

[0028] The hardness of YG cemented carbide block 5 is HRA91.

[0029] There are 7 channels for liquid circulation at the bottom of the flat grinding shoe, of which 6 ring-shaped milling water holes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com