Patents

Literature

40results about How to "Improve processing rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing process for high-curvature full-profile thin-wall part

ActiveCN103639655ASolve Vibration ProblemsGuaranteed sizeAircraft componentsWorkpiecesMaterial removalNatural aging

The invention provides a manufacturing process for a high-curvature full-profile thin-wall part so as to solve the problem of processing deformation and vibration of an ultra-complex spatial thin-wall curved surface. By reasonable process layout, a segmented layer-by-layer processing mode is adopted, an appropriate cutter and a cutter handle are selected, working allowance of every process is set, natural aging time is set, cutting process parameters and feeding strategies are optimized, the uniform material removal amount of the part is guaranteed, an adding cushion block location and gypsum filling method is adopted simultaneously, the problem of clamping difficulty and vibration in part processing is solved, processing rigidity and clamping stability of the part are improved, deformation in the part processing process is controlled, and the part size and precision are guaranteed.

Owner:江西洪都航空工业股份有限公司

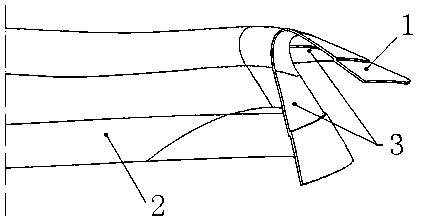

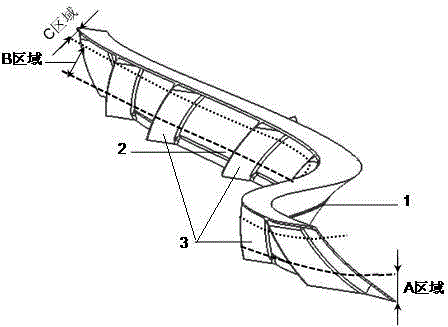

Double-S-shaped double-curve thin-walled part manufacturing process

ActiveCN104526270AImprove clamping stabilityImprove processing rigidityMachining deformationVibration Problem

The invention relates to the technical field of mechanical machining, in particular to a double-S-shaped double-curve thin-walled part manufacturing process. A five-coordinate high-speed mill is adopted to conduct rough machining on an inner curve and an outer curve with ribs and conduct semi-finish machining and finish machining on the inner curve and the outer curve with ribs, and a step cushion block positioning and gypsum filling method is adopted to perform clamping and positioning. The part clamping and positioning problems are solved, and part clamping stability and machining rigidity are improved. Regional segmented and layered machining is adopted for parts, machining deformation of ultra-complicated thin-walled curved surfaces is effectively controlled, the vibration problem in the machining process is avoided, and part size and accuracy are ensured.

Owner:JIANGXI HONGDU AVIATION IND GRP

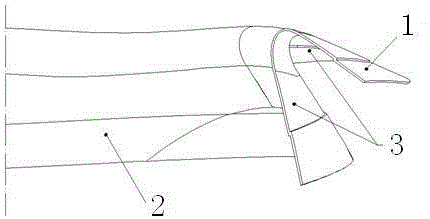

Method for milling and vibration-damping blisk

InactiveCN101912990AEliminate milling distortionEliminate ChatterMilling equipment detailsMaintainance and safety accessoriesEngineeringChatter mark

The invention belongs to the technical field of machining and discloses a method for milling and vibration-damping a blisk. The method comprises the following specific process steps of: (1) preparing a filling material according to the proportion; (2) melting the filling material; (3) mounting a pouring clamp; (4) pouring a filling agent; (5) condensing the filling agent at normal temperature, secondarily condensing the filling agent and checking the condensing state of the filling agent; (6) mounting a filtering clamp; and (7) carrying out the abutted milling processing and chip removal processing. By pouring the filling agent between the blisk and vanes in the milling processing of vane profile five coordinates of the blisk, the method enhances the rigidity of parts in the milling processing of the vanes, eliminates the chatter marks generated at the vent tip part of the vanes during milling and reduces the roughness of the surfaces of the vanes. Meanwhile, the rigidities of the parts and a clamping system thereof are enhanced, so that the milling feed rate is increased and the milling speed can be improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

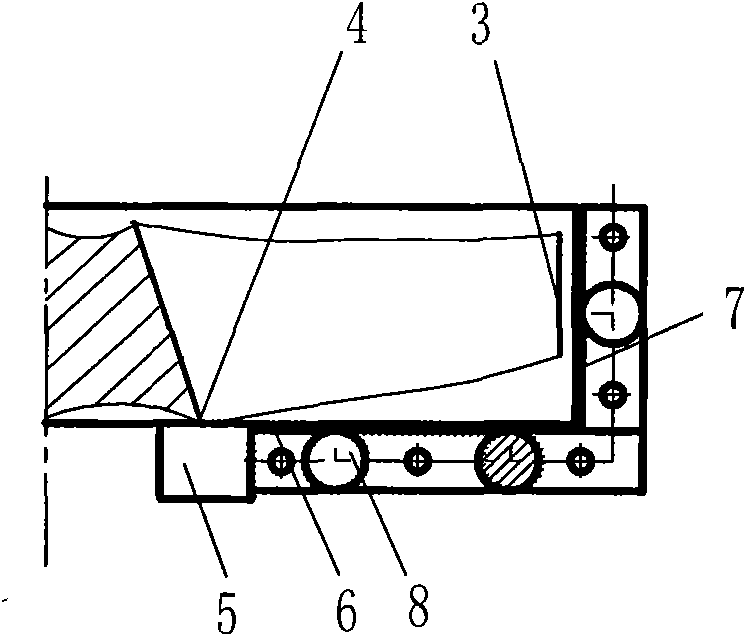

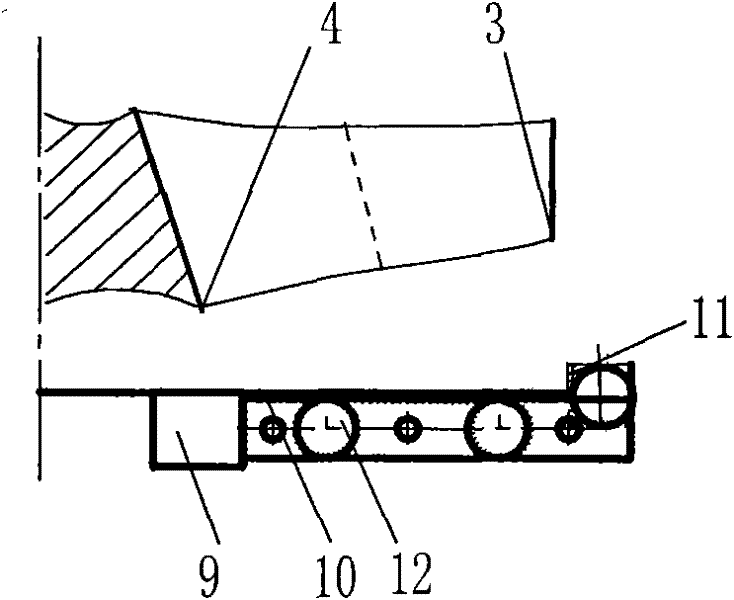

Rotary milling fixture device for machining guide vane of air compressor

ActiveCN102922313AImprove versatilityImprove processing rigidityPositioning apparatusMetal-working holdersInstabilityEngineering

Owner:WUXI TURBINE BLADE

Machining method of slender shaft made of17-4PH stainless steel material

The invention belongs to the technical field of material machining and particularly relates to a machining method of a slender shaft made of a 17-4PH stainless steel material. The machining method of the slender shaft made of the 17-4PH stainless steel material at least includes the steps of firstly, stress relief annealing heat treatment, secondly, slender shaft end face machining and drilling, thirdly, determination of the grinding benchmark of the slender shaft, fourthly, rough turning, semi-finish turning and penetration flaw detection, fifthly, solid solution and aging thermal treatment, sixthly, grinding treatment, seventhly, surface quenching and annealing heat treatment and eighthly, obtainment of the slender shaft, wherein the slender shaft obtained in the seventh step is subjected to finish grinding, a plug is removed, the following conventional shaft end fine dressing or end cut-off is conducted, and the finished slender shaft is obtained. By the adoption of the method, the defect that the machining rejection rate of the slender shaft made of the 17-4 PH stainless steel material is high at present can be effectively overcome, the high-precision shape of the slender shaft and the surface roughness machining of the slender shaft are guaranteed, the machining efficiency of the slender shaft is improved, and the yield is increased.

Owner:HEFEI UNIV OF TECH +1

Composite cutter for drilling and boring hole and processing end surface annular groove

PendingCN107931636AHigh drilling forceProcessing lightTransportation and packagingTurning toolsEngineeringProcessing cost

The invention belongs to the field of part processing and particularly relates to a composite cutter for drilling and boring a hole and processing an end surface annular groove. A tool holder is installed on the top of a non-standard cutter body; drill blades are installed at the bottom of the non-standard cutter body; one drill blade is installed in a manner of passing through an axis of the non-standard cutter body, and the other drill blade is installed on the outer side of the non-standard cutter body; rough boring blades and radius boring blades are symmetrically installed on the outer side of the non-standard cutter body sequentially; a regulation cutter clamp is arranged above the radius boring blade on one side and is provided with a finish boring blade; chamfer blades are symmetrically installed on the outer side of the non-standard cutter body; and non-standard groove blades are arranged on the outer sides of the chamfer blades in a staggering manner respectively. By adoptingthe composite cutter provided by the invention, the cutter changing time and the cutter cost are saved, the processing efficiency is improved, and the processing cost is lowered; larger drilling force can be acquired at the same time, so that processing is lighter, the danger of drop-dead halt of the cutter is avoided, and the processing efficiency is improved; the inside and outside diameter sizes of the annular groove are more easily controlled, the quality is more reliably ensured, and the quality stability of parts is high when the parts are produced in batch.

Owner:WUXI WEIFU PRECISION MACHINERY MFG

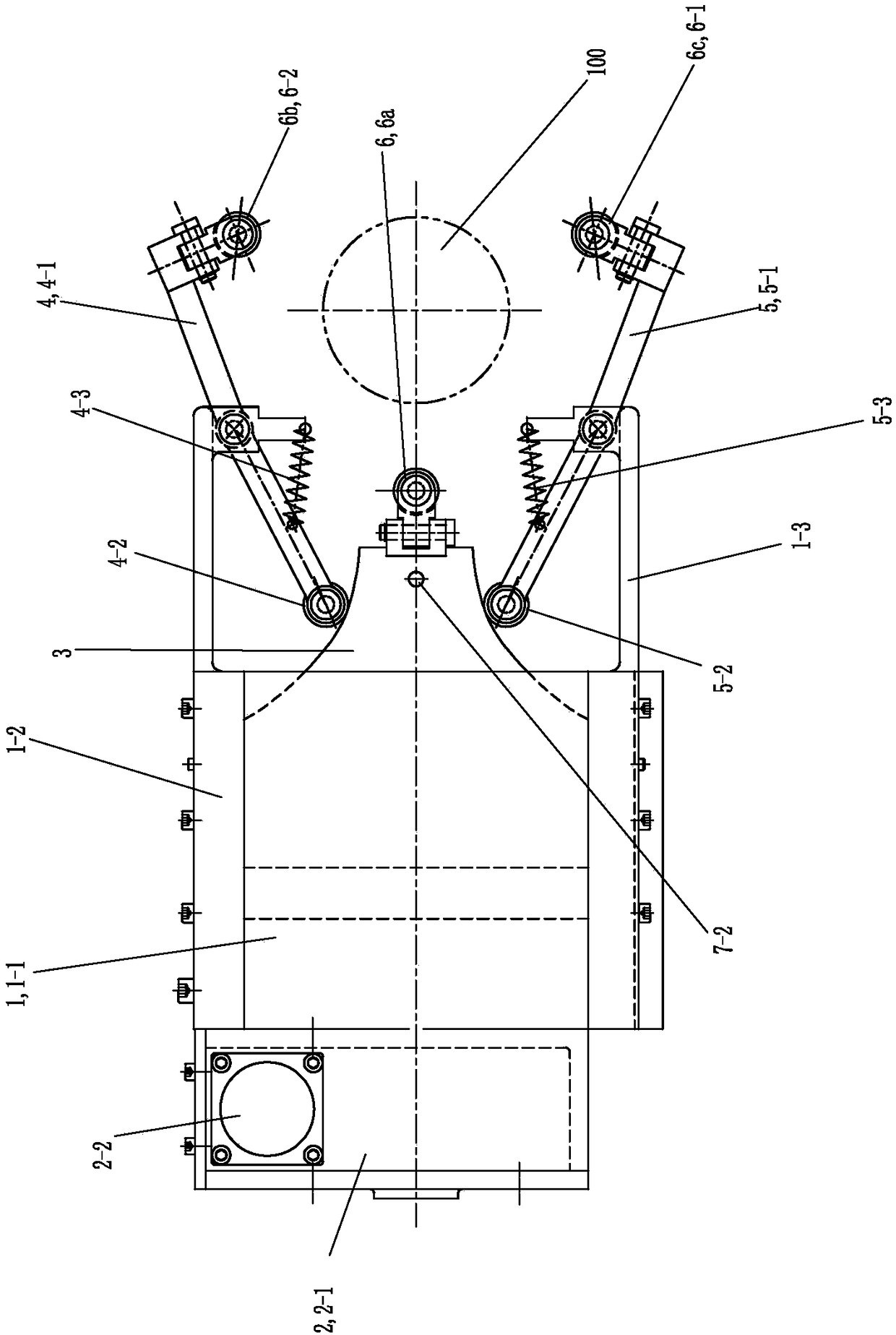

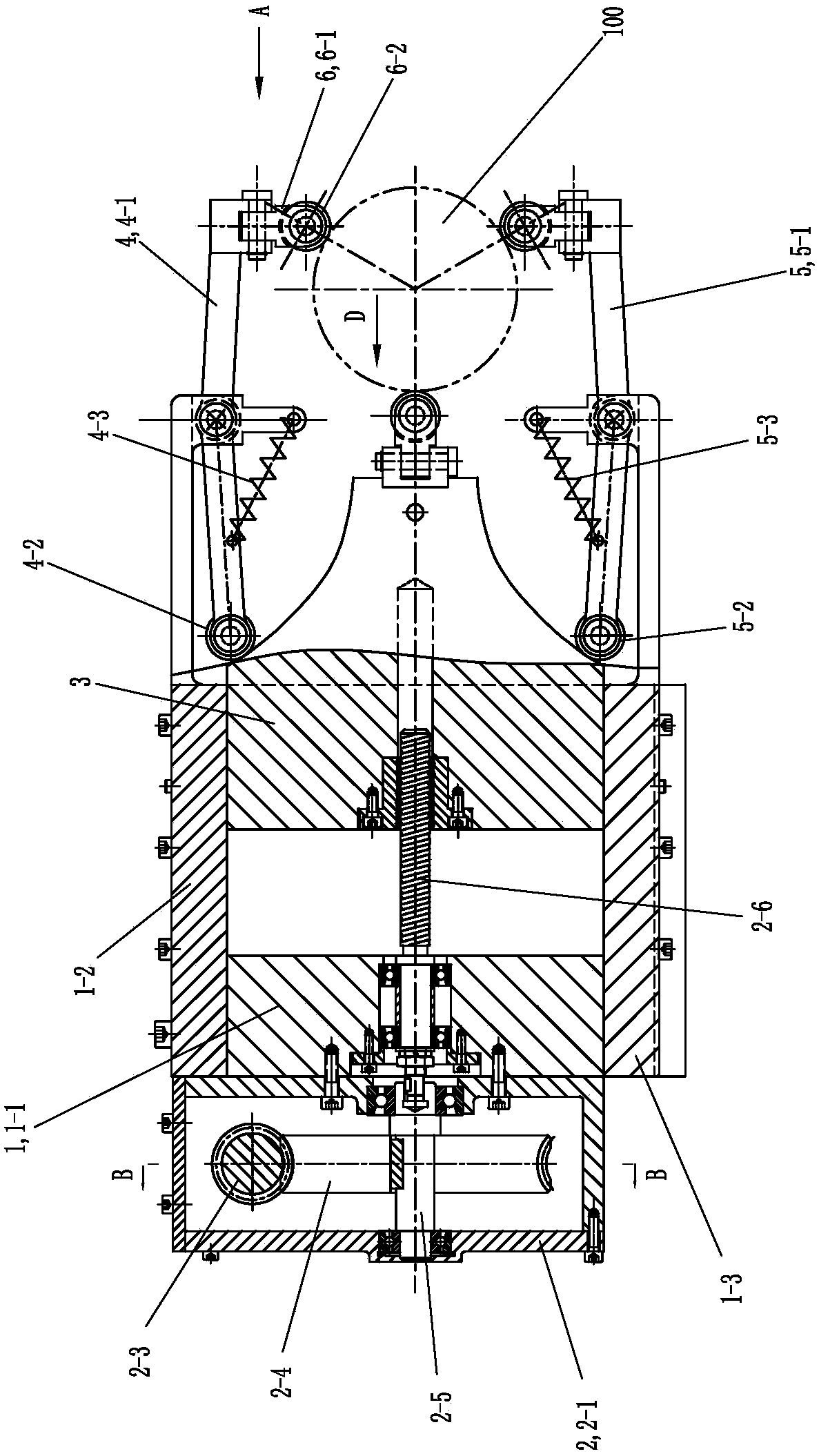

Automatic alignment center rack

InactiveCN108481018ASimple structureEasy to install and disassemble the workpieceLarge fixed membersGrinding work supportsEdge surfaceEngineering

The invention discloses an automatic alignment center rack. The automatic alignment center rack is characterized by comprising a machine box, a driving device, a translation cam, an upper pressing rodcomponent, a lower pressing rod component and pressing head components, the translation cam is arranged inside the machine box in a left and right sliding manner and is driven by the driving device to move left and right, an upper pressing rod on the upper pressing rod component and a lower pressing rod are made to swing by the translation cam to make the pressing head components located on the upper pressing rod and the lower pressing rod and the pressing head component on the translation cam be simultaneously closed to the axis of a workpiece to be machined, so that the workpiece to be machined is supported, wheel support racks of the pressing head components automatically rotate according to the shape of the outer edge surface of the workpiece to be machined, and two support wheels ofeach wheel support rack are guaranteed to be pressed tightly against the workpiece to be machined simultaneously.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Machining tool for die forging rotor blade

InactiveCN109128902AImprove processing rigidityImprove pressure consistencyPositioning apparatusMetal-working holdersEngineeringFlow management

The invention discloses a machining tool for a die forging rotor blade. The machining tool comprises a base and a fixing device arranged on the upper surface of the base. The fixing device comprises apressing plate, a positioning pin, a positioning block, an adjusting screw and a baffle. The pressing plate is connected with the positioning block. The positioning block is connected with the baffle. The positioning pin is arranged on the positioning block. The adjusting screw and the pressing plate are in threaded connection. The machining tool further comprises a positioning tensioning sheet arranged on the lower surface of the base and a chip hole formed in the side edge of the base. The machining tool adopts integral structure design and is simple in structure and convenient to operate;and meanwhile, the machining rigidity of the tool is improved, and the qualified rate of parts is further increased. The base and machine tools are connected through the positioning tensioning sheet,interchangeability between the machine tools is high, the machining tool can be used on the machine tools of different brands, the positioning accuracy of a clamp and the interchangeability of the tool are improved, and management is facilitated. A chip capable of being encoded is mounted the base through the chip hole, thus automatic integration engineering is achieved advantageously, part data flow management is achieved, the serial number of each part is accurately tracked, and the machining efficiency of the parts is improved.

Owner:AECC AVIATION POWER CO LTD

Method for milling and vibration-damping blisk

InactiveCN101912990BImprove processing rigidityHigh milling feed rateMilling equipment detailsMaintainance and safety accessoriesFilling materialsEngineering

The invention belongs to the technical field of machining and discloses a method for milling and vibration-damping a blisk. The method comprises the following specific process steps of: (1) preparing a filling material according to the proportion; (2) melting the filling material; (3) mounting a pouring clamp; (4) pouring a filling agent; (5) condensing the filling agent at normal temperature, secondarily condensing the filling agent and checking the condensing state of the filling agent; (6) mounting a filtering clamp; and (7) carrying out the abutted milling processing and chip removal processing. By pouring the filling agent between the blisk and vanes in the milling processing of vane profile five coordinates of the blisk, the method enhances the rigidity of parts in the milling processing of the vanes, eliminates the chatter marks generated at the vent tip part of the vanes during milling and reduces the roughness of the surfaces of the vanes. Meanwhile, the rigidities of the parts and a clamping system thereof are enhanced, so that the milling feed rate is increased and the milling speed can be improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

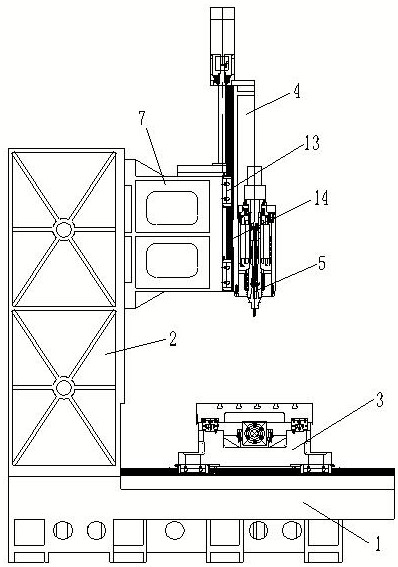

Parallel-driven four-degree-of-freedom series-parallel mechanical wrist swing head

ActiveCN110450136AGuaranteed machining accuracyGuaranteed stiffnessProgramme-controlled manipulatorJointsCircular coneDegrees of freedom

The invention relates to a parallel-driven four-degree-of-freedom series-parallel mechanical wrist swing head. A circular guide hole is formed in an extension body, and the extension body is arrangedin a mounting frame; and an extension cylinder is arranged in the circular guide hole of the extension body; a conical sleeve is arranged on the conical surface of the extension cylinder, the inner conical surface of the conical sleeve is attached to the conical surface of the extension cylinder, the outer cylindrical surface of the conical sleeve is further attached to the circular guide hole ofthe extension body, and the conical sleeve can rotate relatively and axially move relatively in the circular guide hole of the extension body; an adjusting block is arranged on the extension cylinderthrough a threaded pair and is tightly attached to the end face of the conical sleeve; one end of a connecting rod is connected with the extension cylinder through a ball pair, and the other end of the connecting rod is connected with a movable platform through a revolute pair; the movable platform is further connected with the extension body through a universal hinge; a U seat is arranged on themovable platform and can rotate relatively around the axis of the movable platform on the movable platform, and an electric spindle is arranged on the U seat and rotate relatively on the U seat.

Owner:YANSHAN UNIV

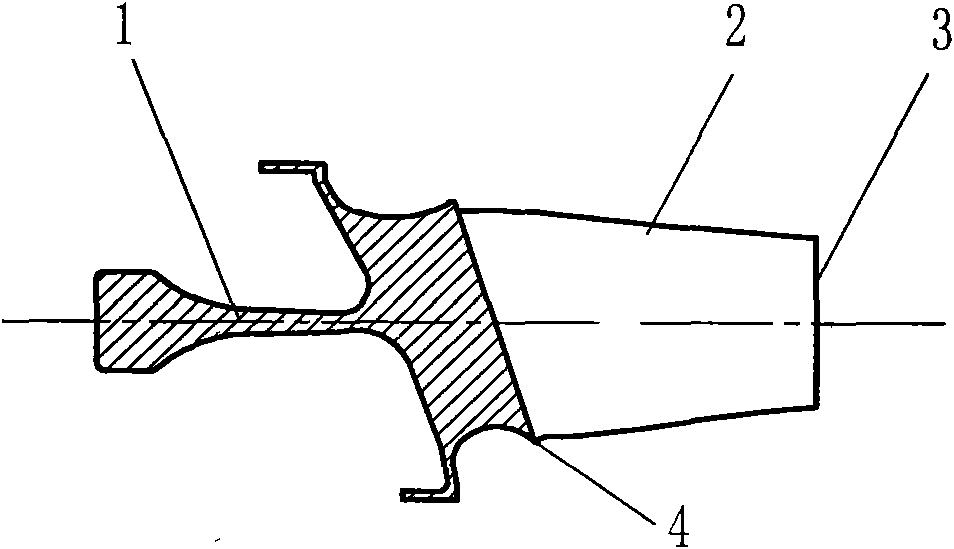

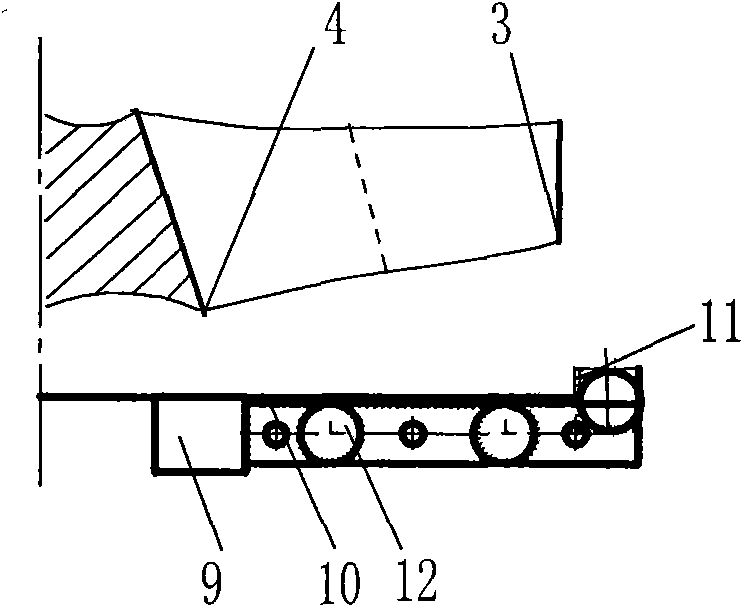

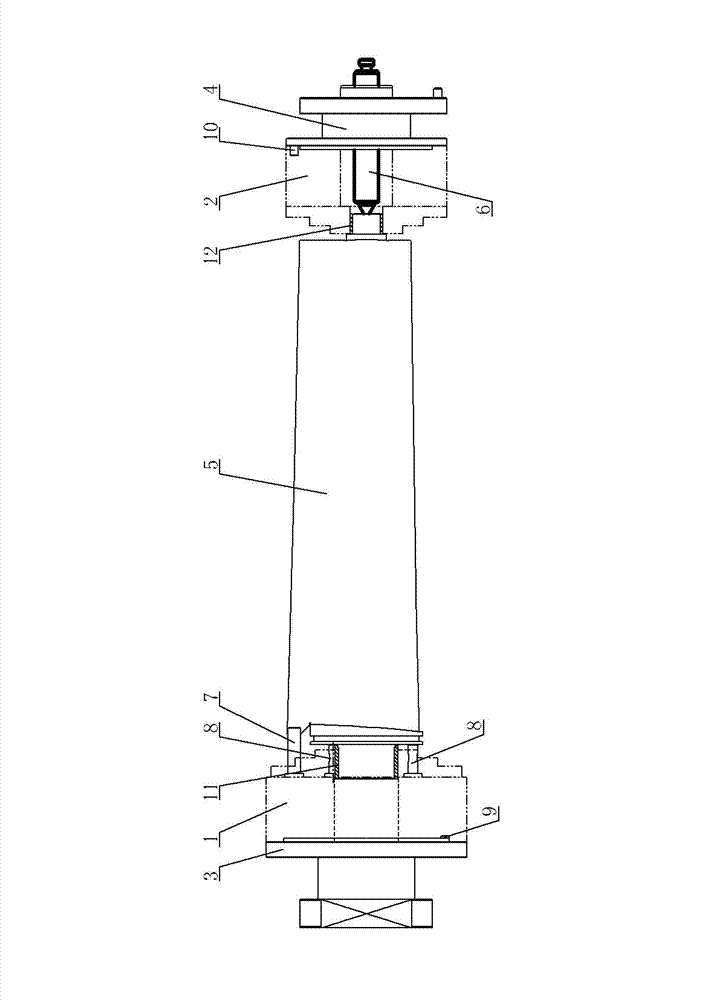

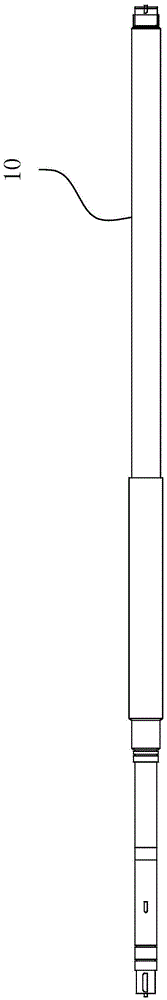

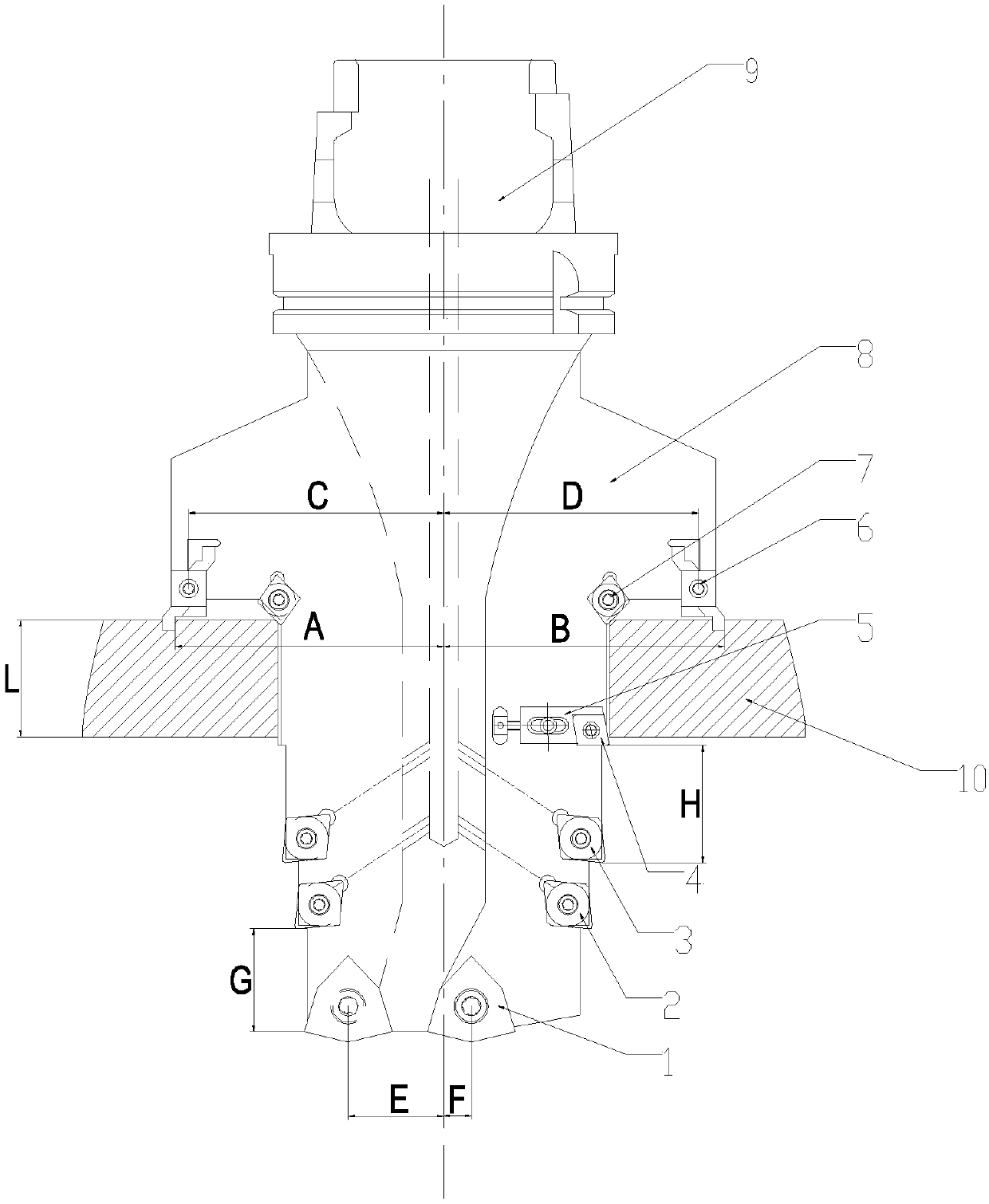

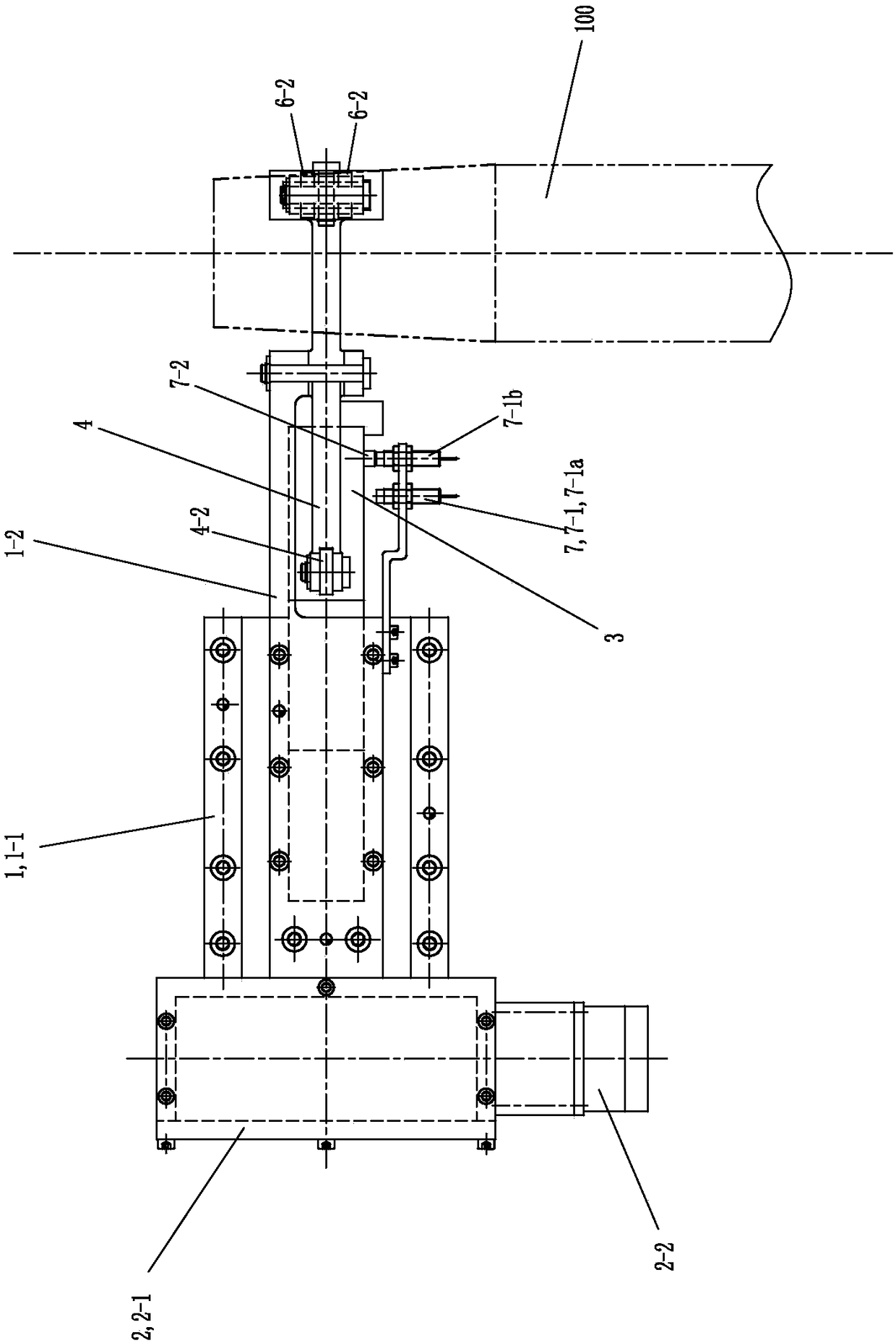

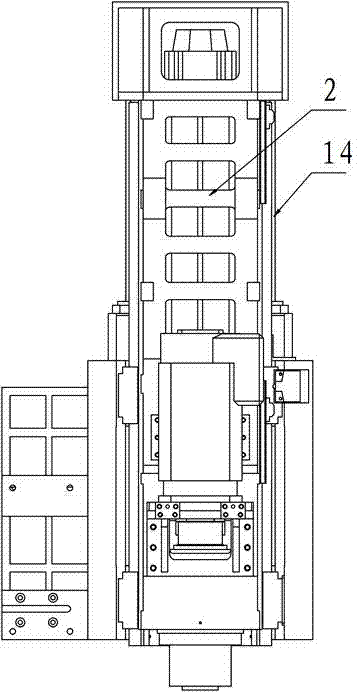

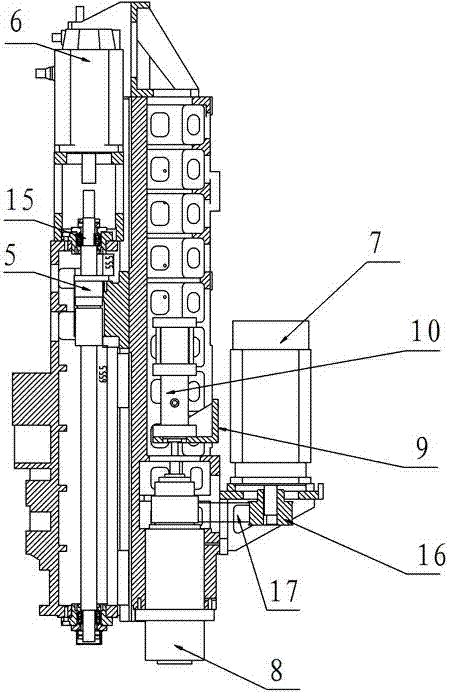

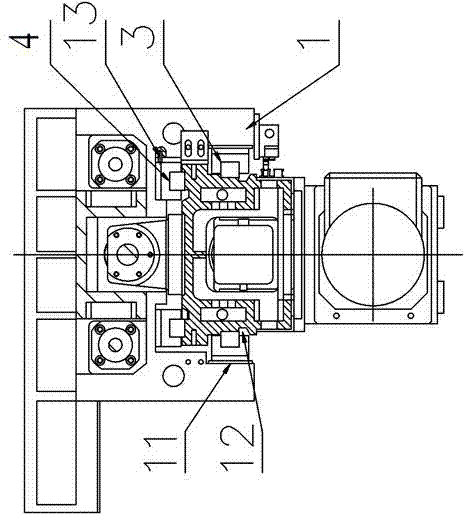

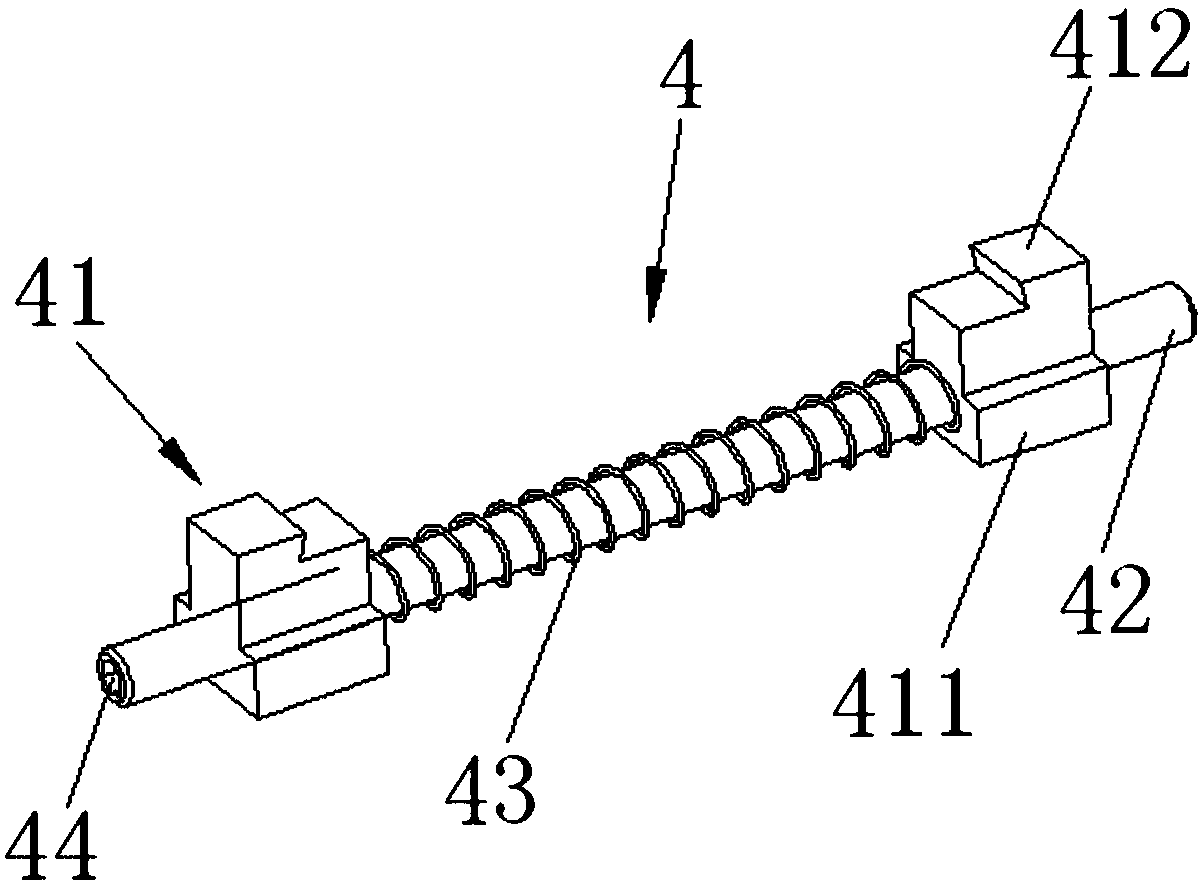

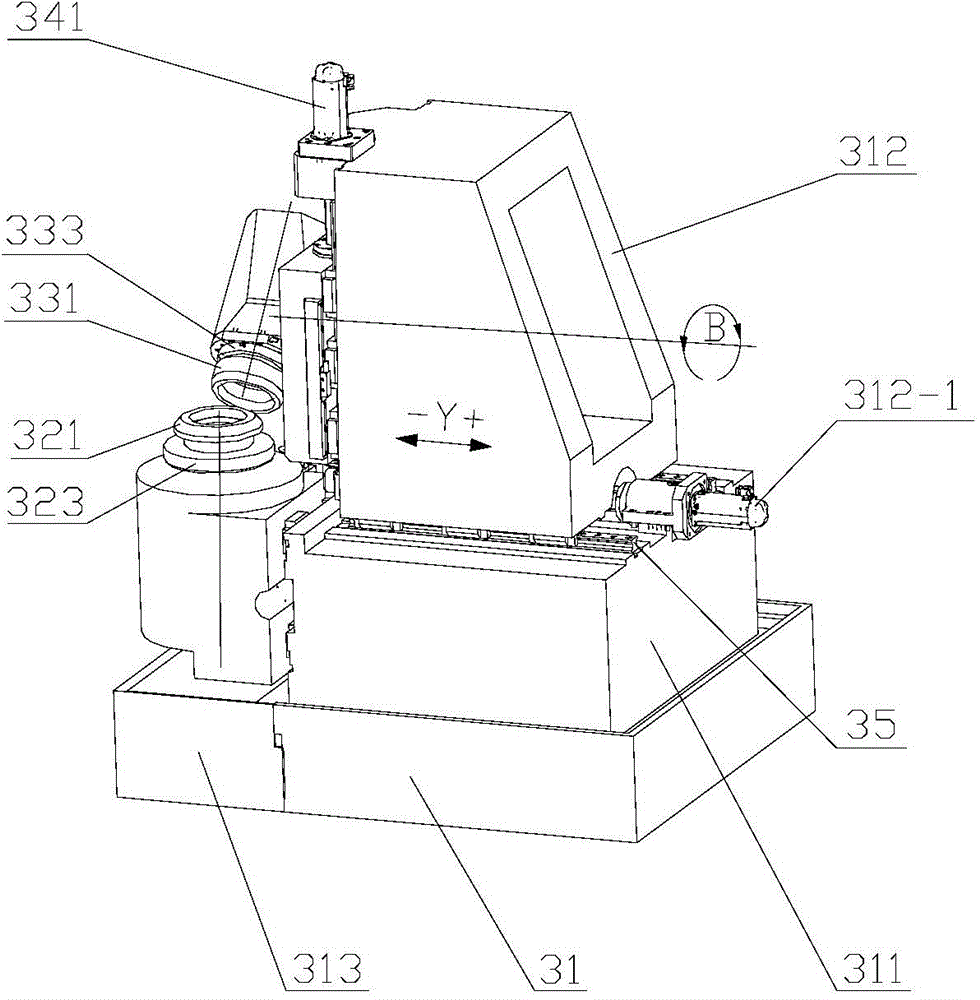

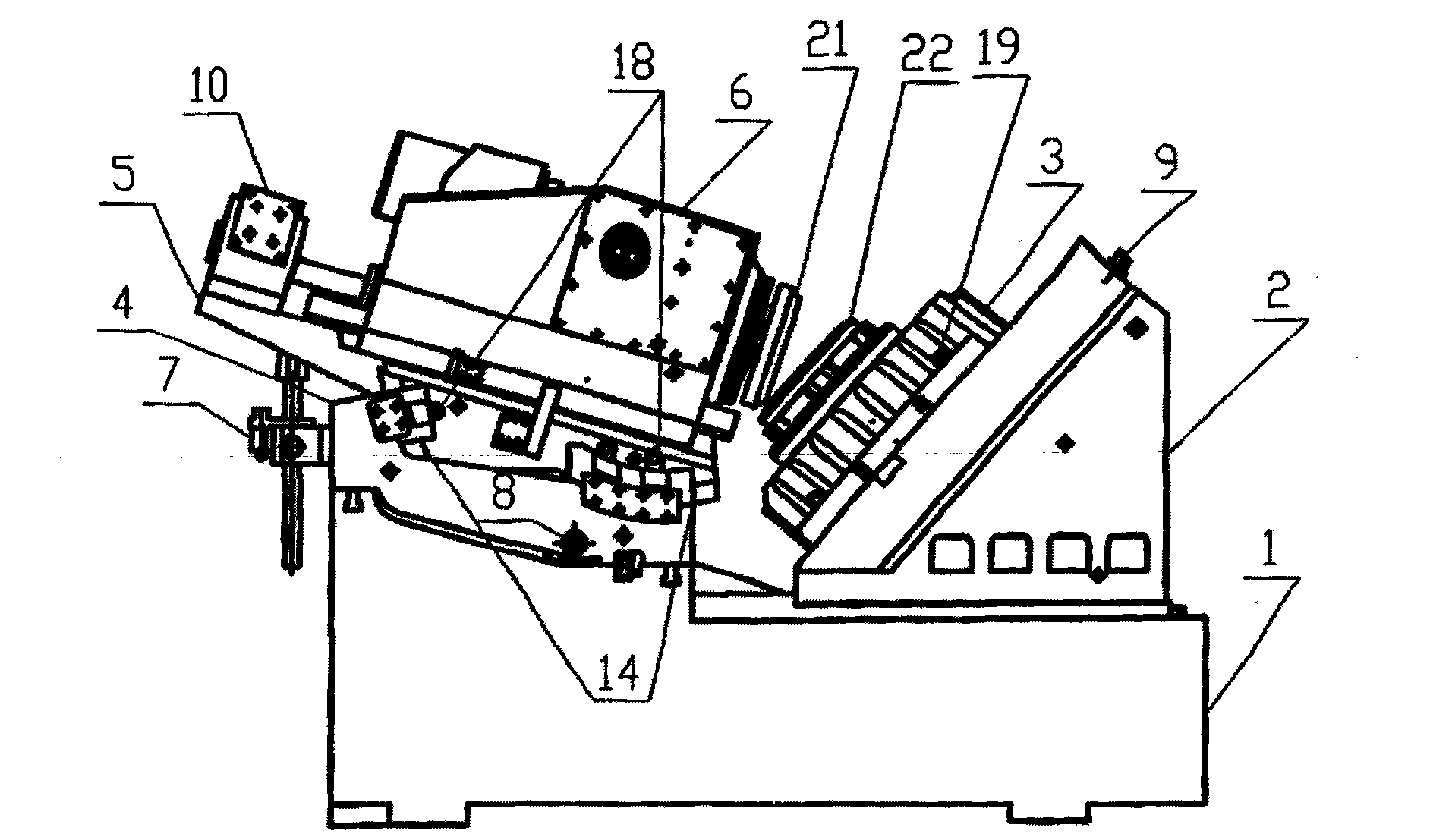

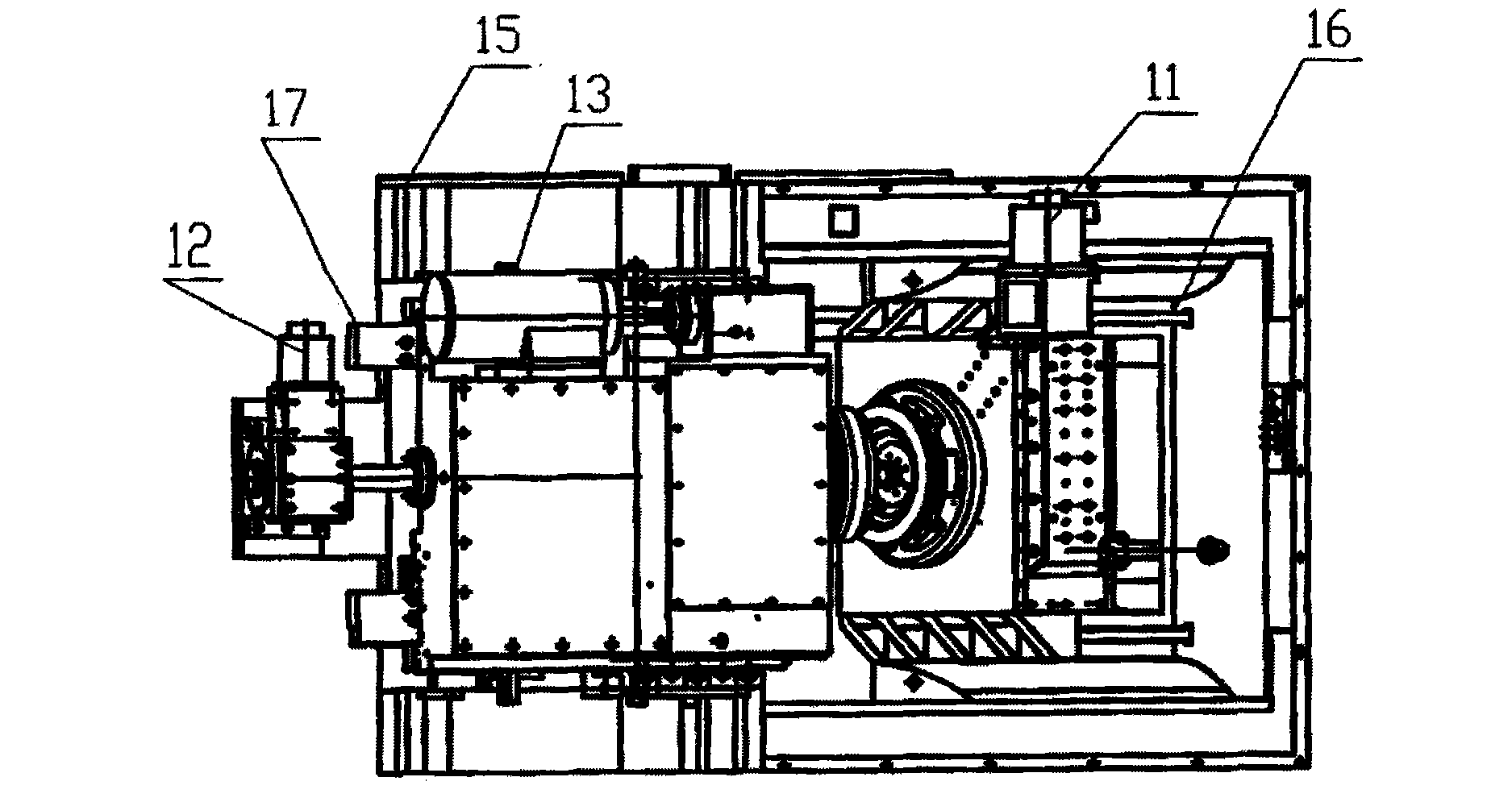

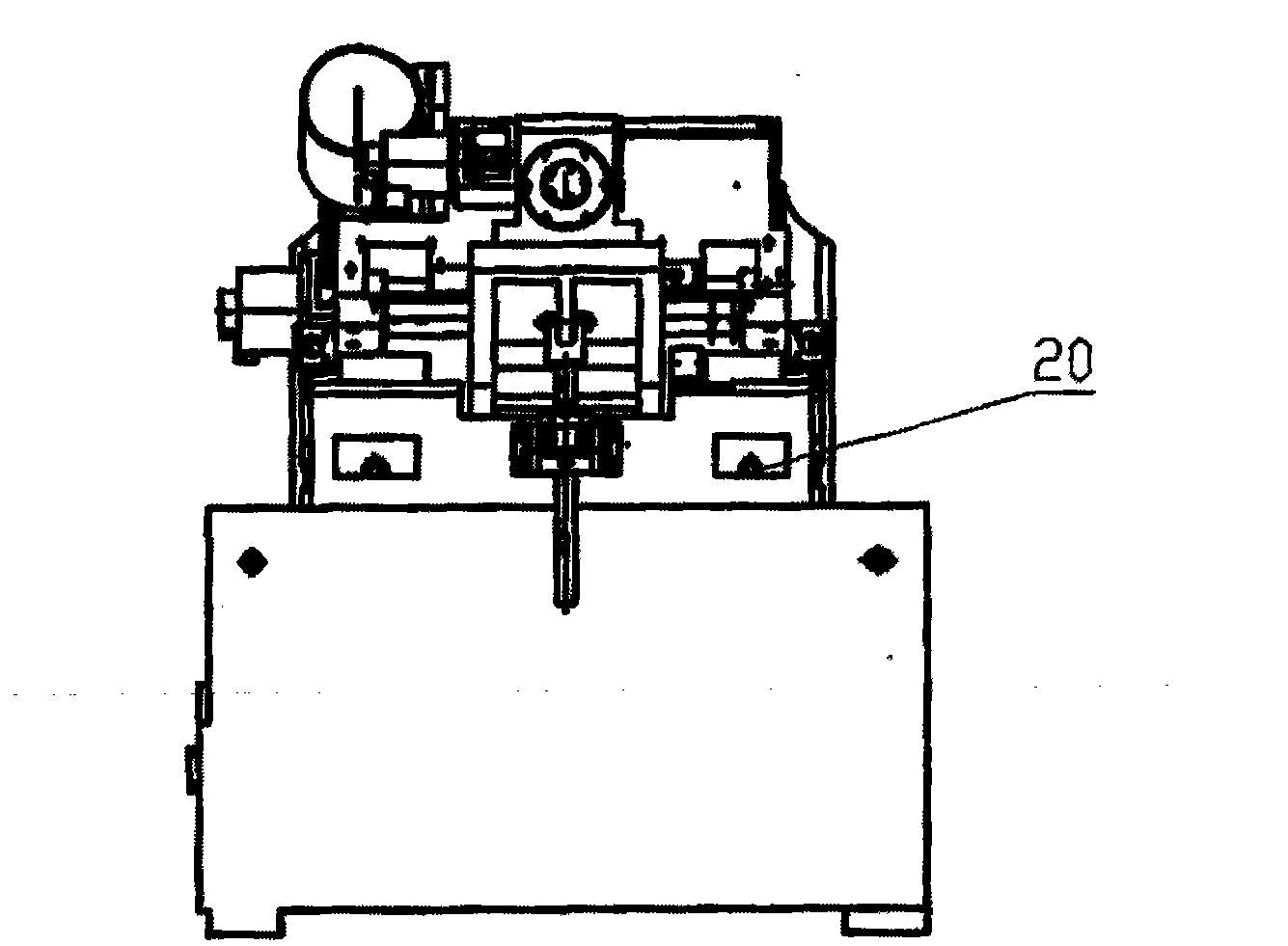

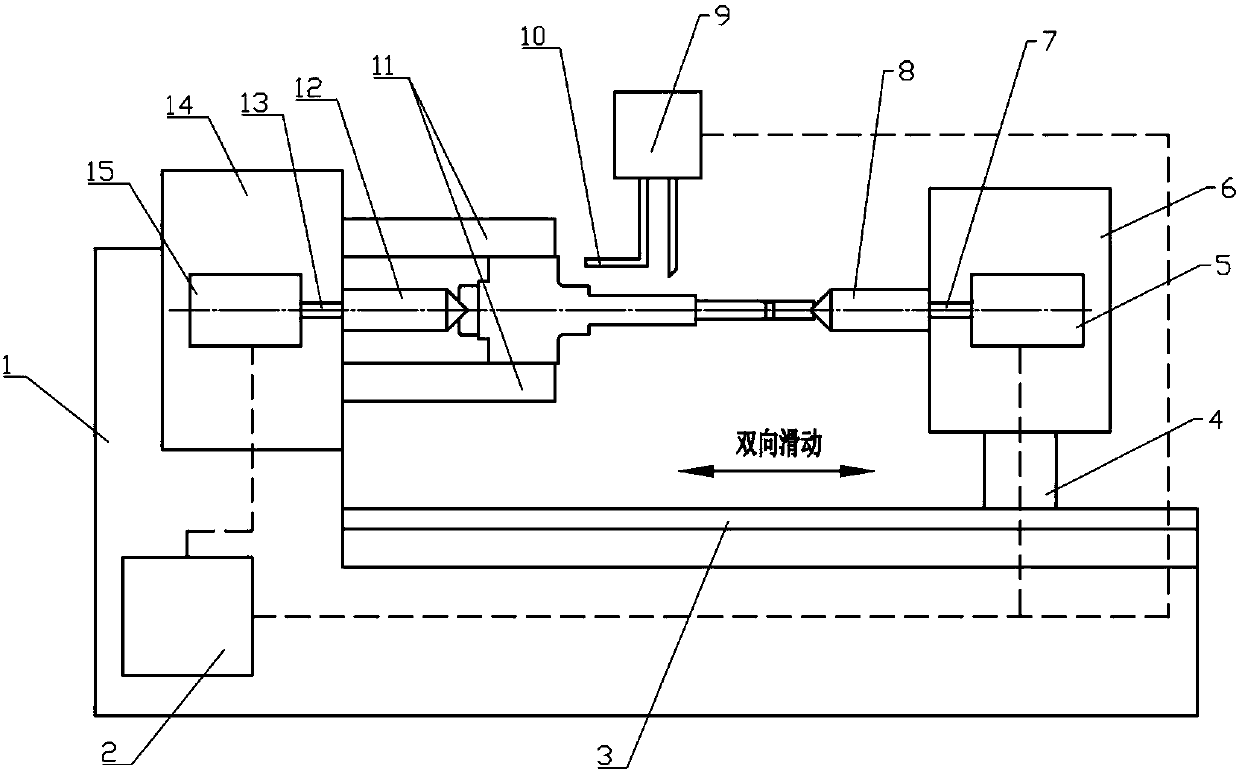

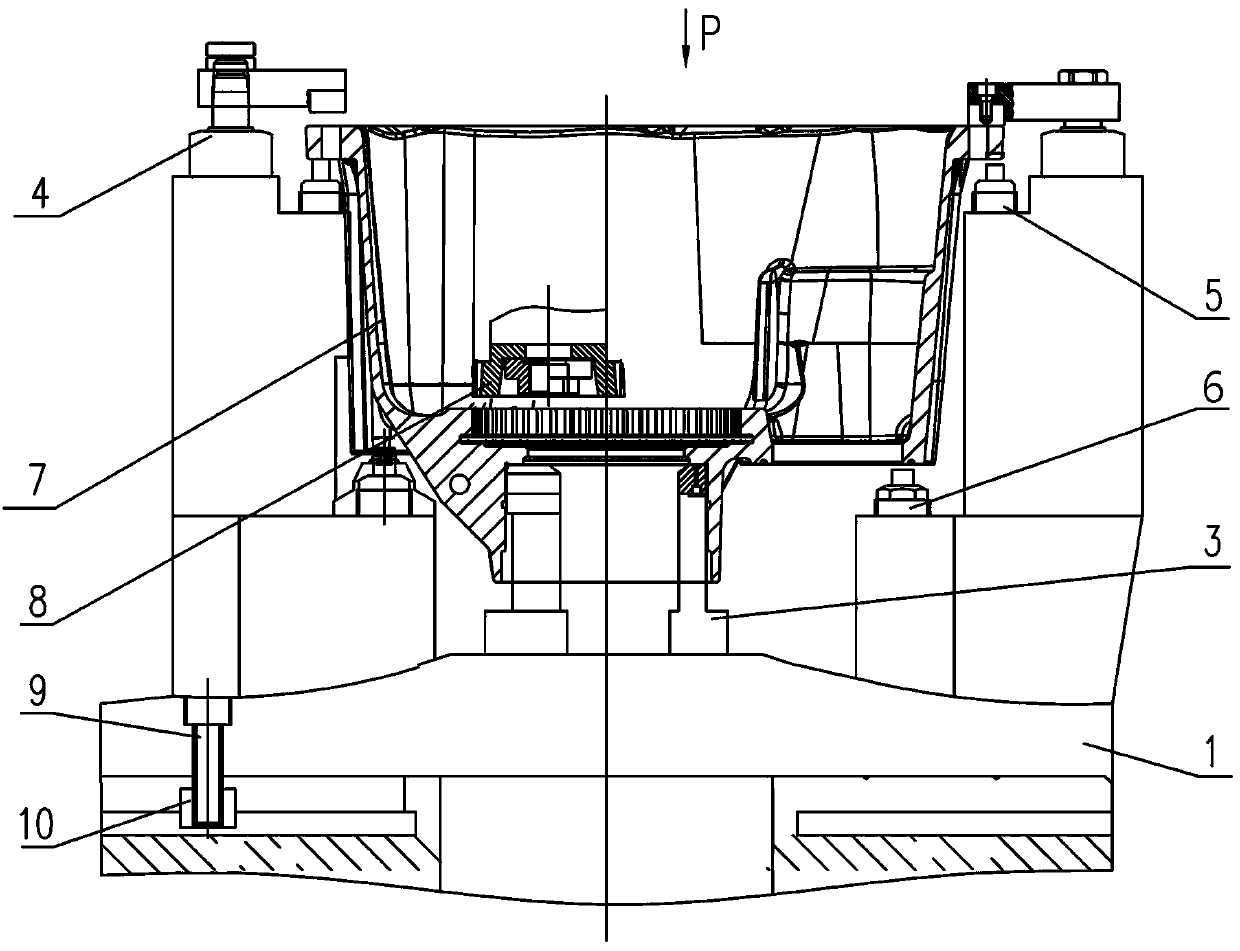

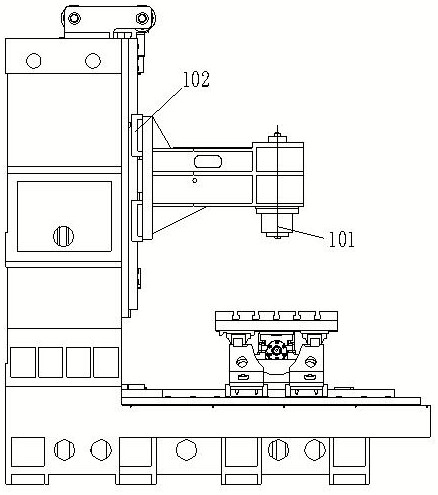

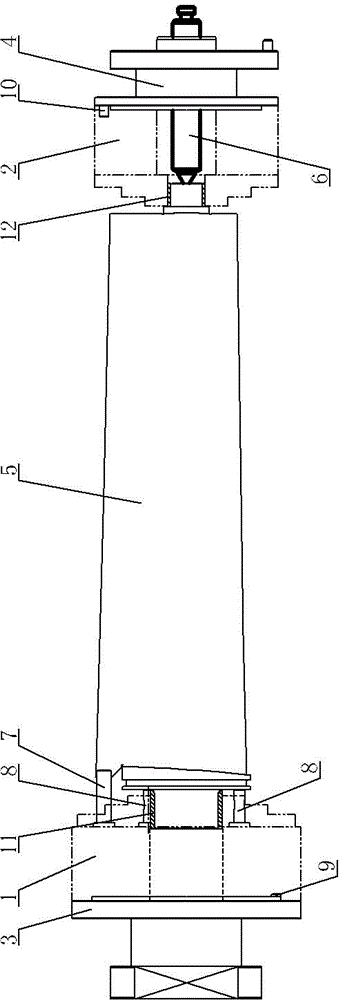

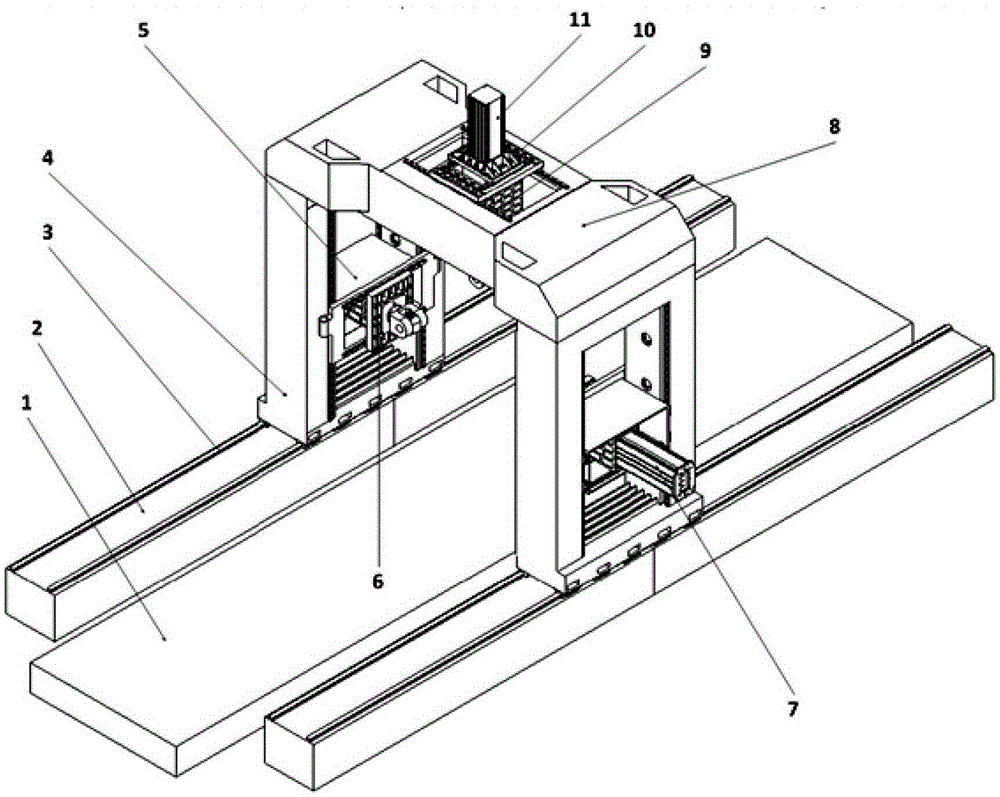

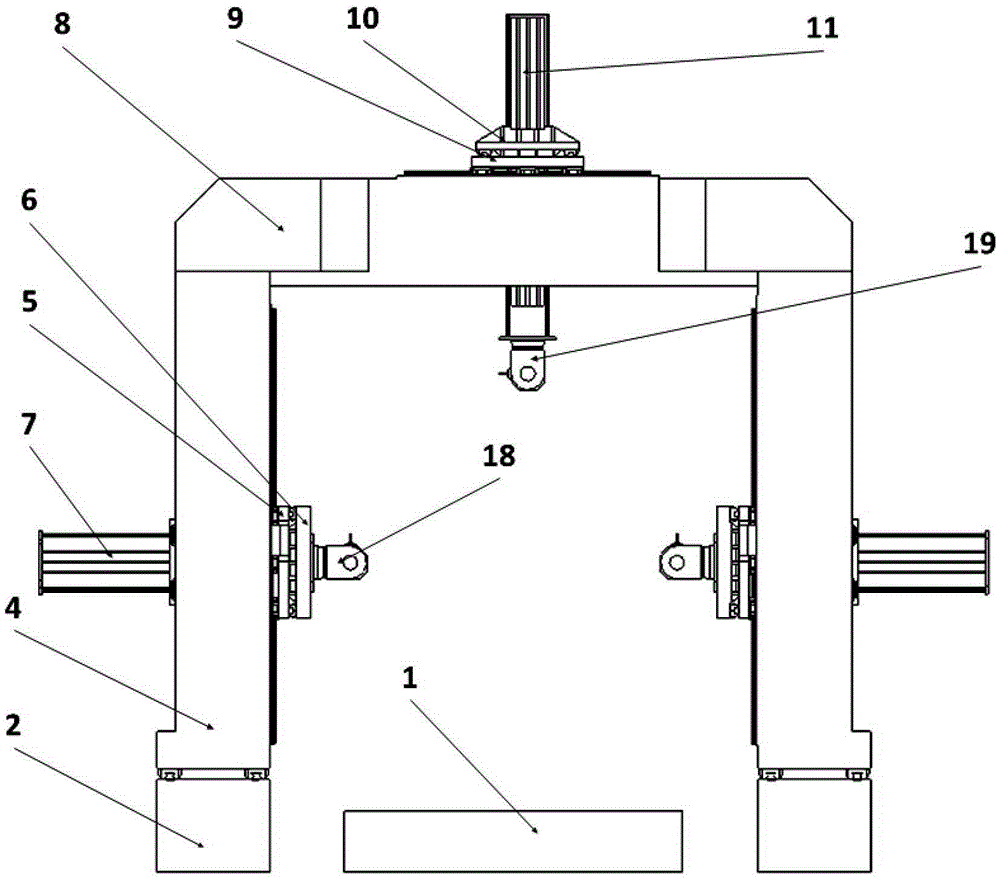

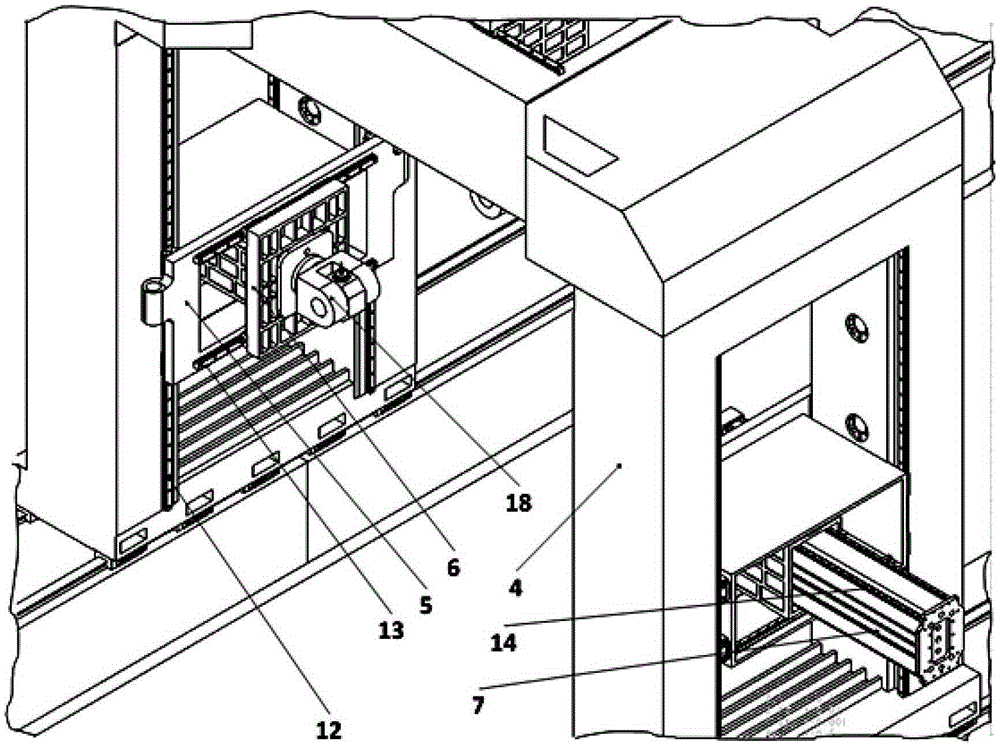

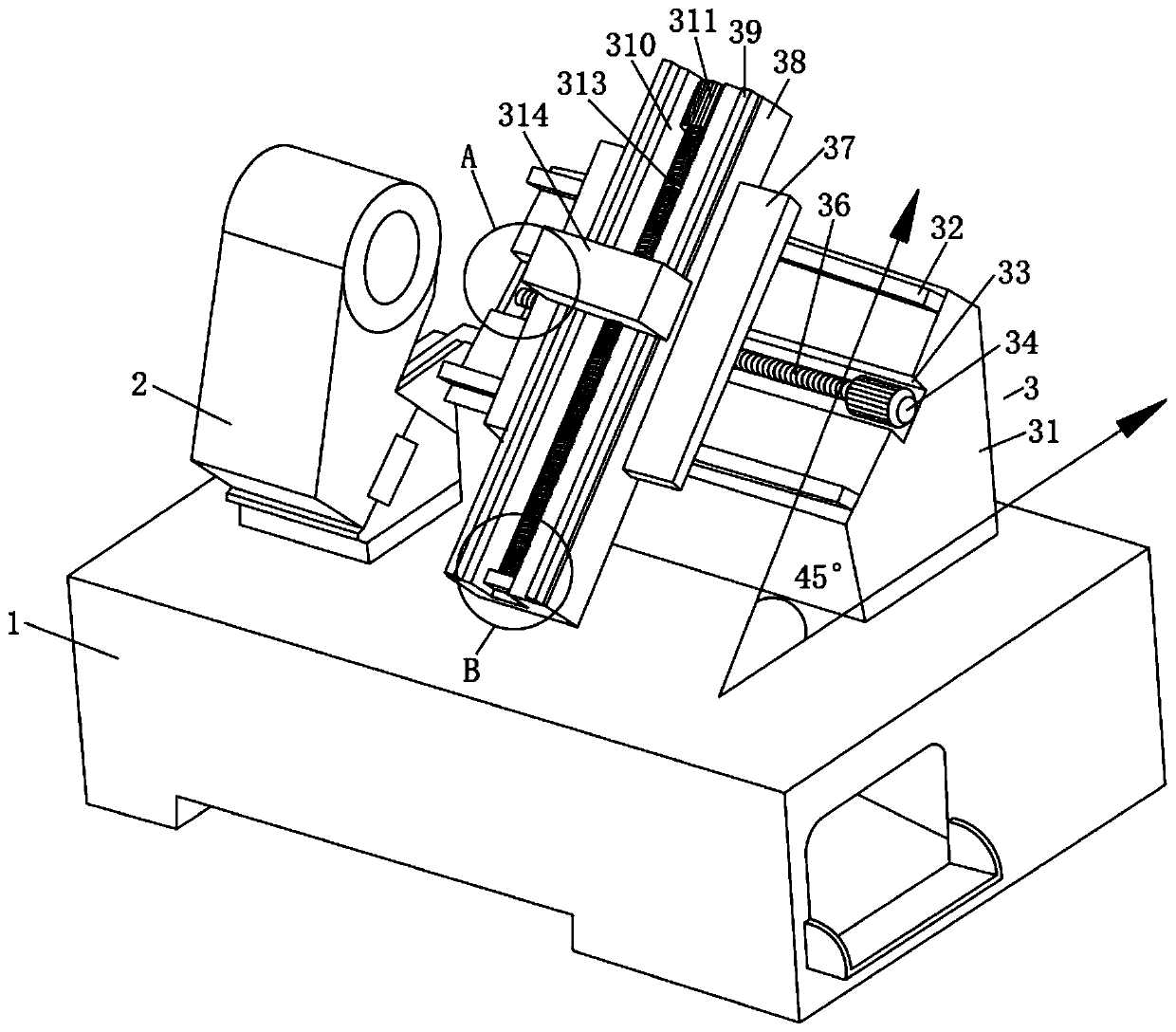

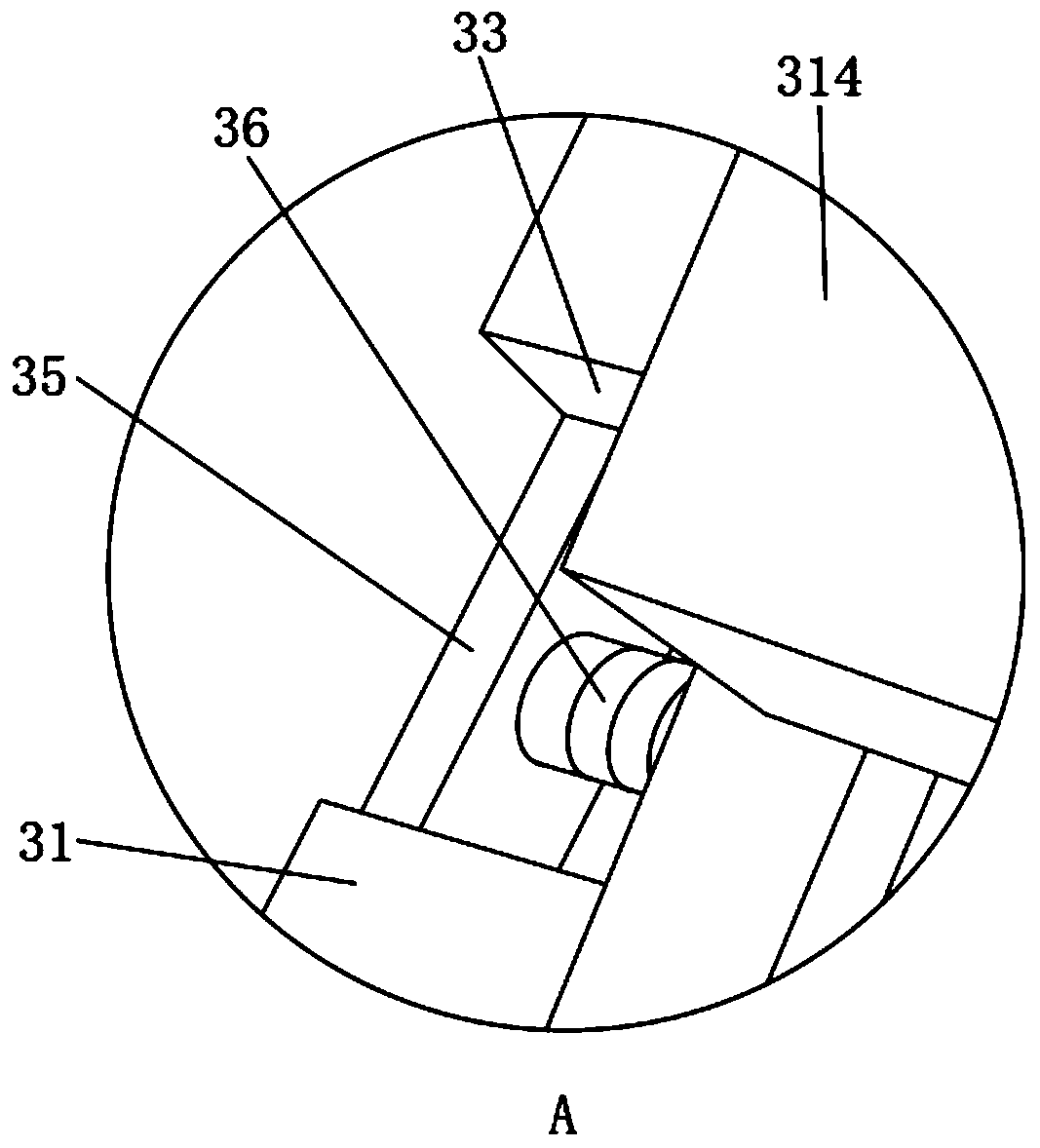

Machining center for gantry with four linear rails and ram

InactiveCN103586698ASmooth slidingImprove processing rigidityFeeding apparatusLarge fixed membersMachine toolEngineering

The invention relates to a machining center, in particular to a machining center for a gantry with four linear rails and a ram. The machining center comprises a saddle (1), and is characterized in that the vertically slidable ram (2) is arranged on the saddle (1), the left and right linear rails (3) are arranged on the saddle and are positioned on two sides of the ram, the rear linear rails (4) are arranged on the saddle and are positioned at the rear of the ram, a lead screw (5) is connected to the ram and is connected with a servo motor (6), a main motor (7) is arranged on the ram and is connected with a spindle (8) by a transmission, a tool impact cylinder support (9) is arranged on the upper portion of the spindle, and a tool impact cylinder (10) is arranged on the tool impact cylinder support. The machining center has the advantage that technical problems of poor workpiece machining rigidity and precision and the like of a spindle due to the fact that a machine tool in the prior is only provided with two linear rails and a ram is poor in rigidity when sliding can be solved.

Owner:HANGZHOU DATIAN CNC MACHINE TOOL

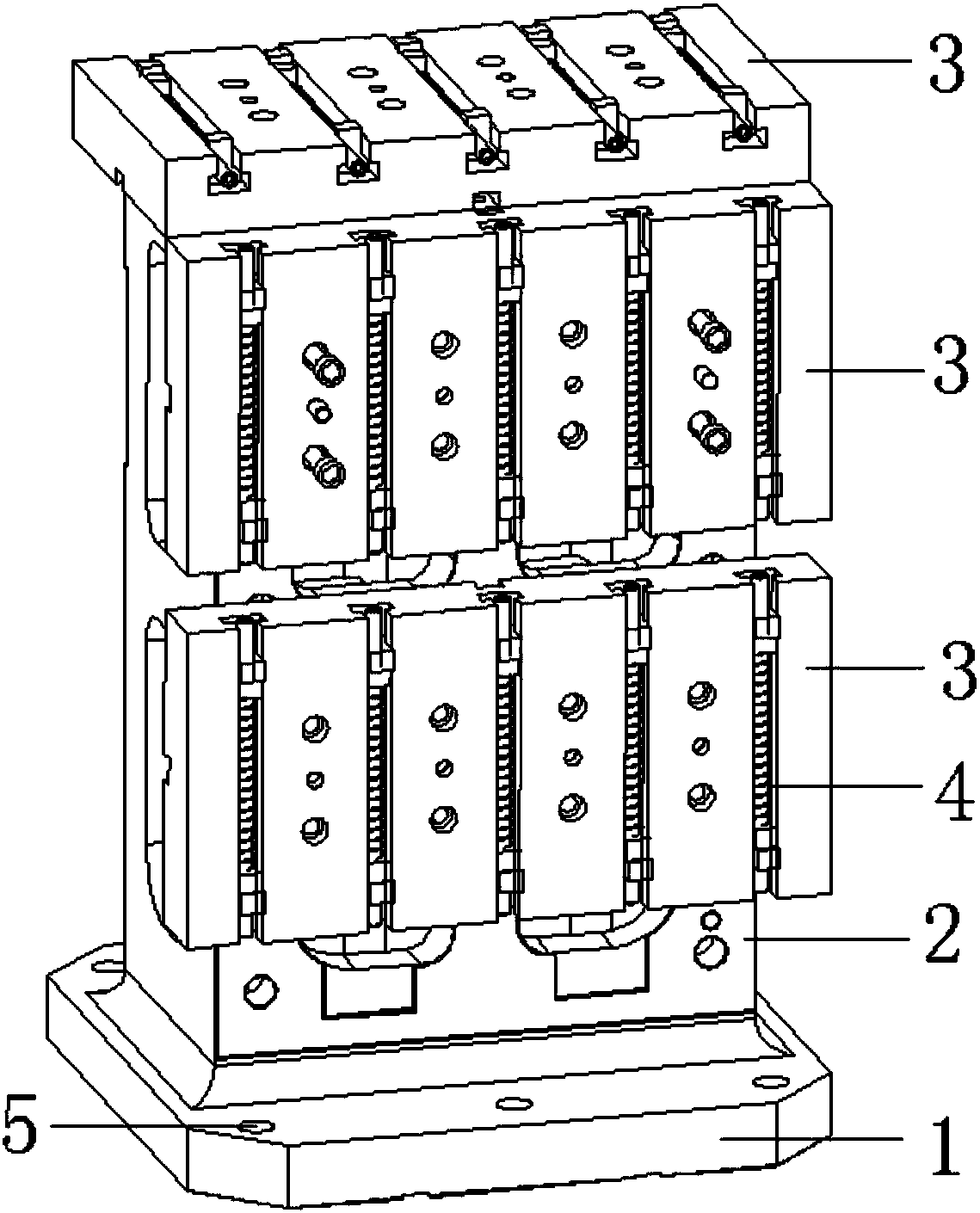

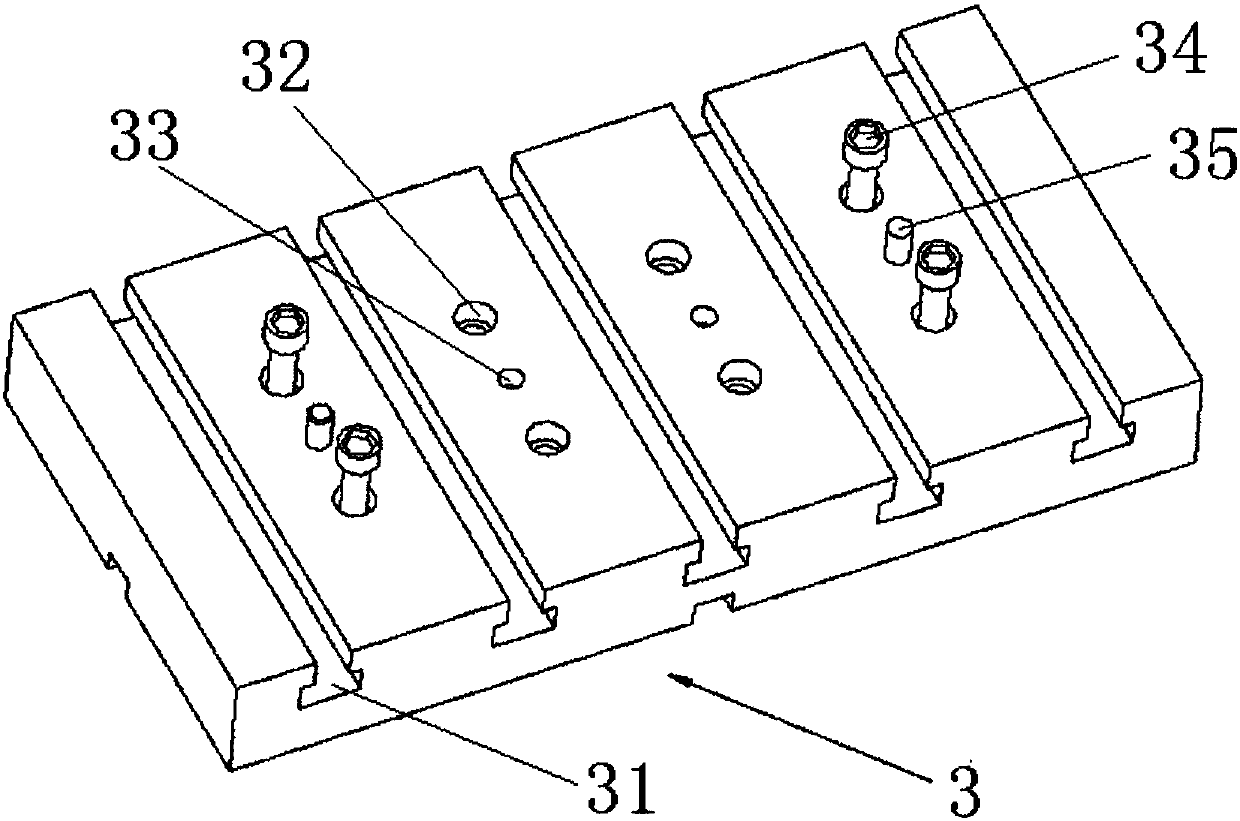

Fast clamping system

ActiveCN107803680AFit tightlyImprove machining accuracyPositioning apparatusPhotovoltaic energy generationClassical mechanicsEngineering

The invention discloses a fast clamping system. The fast clamping system comprises a pedestal with a hanger, clamp fixing bases and clamps, wherein the clamp fixing bases and the clamps are movably fixed to the hanger. The clamp fixing bases are provided with mounting grooves matched with the corresponding clamps. Each clamp comprises a fastening screw rod with the two ends being provided with threads and dovetail clamping blocks located at the two ends of the fastening screw rod. The dovetail clamping blocks comprise positioning parts which are matched with the mounting grooves in the clamp fixing bases for positioning and clamping parts with dovetail structures. The positioning parts of the dovetail clamping blocks are screwed at the two ends of the corresponding fastening screw rods separately. By adoption of the fast clamping system, the multi-operation, multi-position and multi-part machining requirements can be met, and clamping rigidity is good; moreover, clamping force is evenly distributed, predeformation of parts is reduced and machining precision is improved; and the adaptability is high, the parts and the surfaces of the fixing bases can be tightly attached easily through the clamping blocks, and there is no need for workers to inspect the fitness of the bottom faces of the parts.

Owner:ZHEJIANG XIZI AVIATION IND

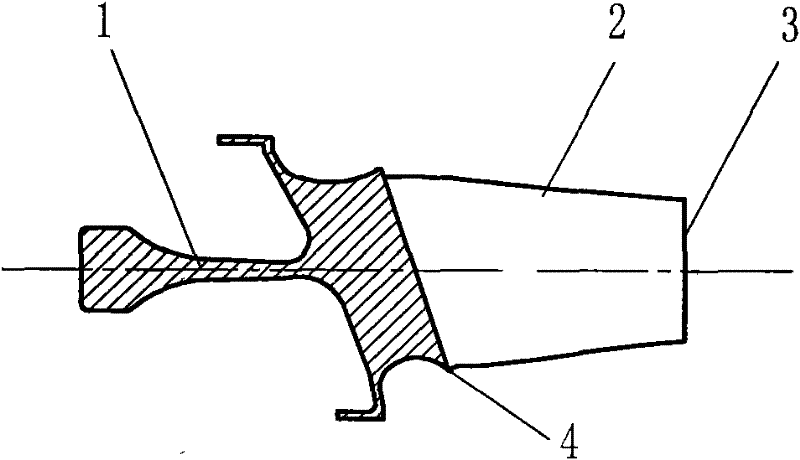

Double-bearing positioning fixture

ActiveCN106826550ASimple structureImprove processing rigidityRevolution surface grinding machinesGrinding work supportsBall bearingEngineering

The invention discloses a double-bearing positioning fixture, which comprises a fixture body (1), a first supporting knuckle bearing (2), a second supporting knuckle bearing (3), a taper sleeve (5), a ball bearing (7), a gland (9), a compression knuckle bearing (10) and a mandrel (11). The taper sleeve (5) is arranged on the fixture body (1) through the ball bearing (7); the first supporting knuckle bearing (2) and the second supporting knuckle bearing (3) are oppositely arranged up and down so as to form a supporting knuckle bearing outer ring; a large excircle of the fixture body (1) is a convex spherical surface so as to form a supporting knuckle bearing inner ring; a convex spherical surface used as a compression knuckle bearing inner ring is arranged on the surface of the mandrel (11); a matched end of the gland (9) and the mandrel (11) is a concave spherical surface; and the compression knuckle bearing (10) and the concave spherical surface of the gland (9) are partially matched so as to jointly form a compression knuckle bearing outer ring. According to the double-bearing positioning fixture provided by the invention, the cost is effectively reduced, a fixture structure is simplified, and up-propping lower-pulling type floating compression is utilized, so that the characteristics of high processing rigidity, high accuracy and the like are realized.

Owner:WENLING MINGHUA GEAR

Center frame

InactiveCN108500652ASimple structureEasy to install and disassemble the workpieceLarge fixed membersGrinding work supportsEngineeringCam

The invention discloses an automatic-centering center frame. The automatic-centering center frame is characterized by comprising a machine box, a driving device, a translation cam, an upper pressing rod assembly, a lower pressing rod assembly and pressing head assemblies. The translation cam is arranged in the machine box in a left-right sliding mode and driven by the driving device to move left and right. An upper pressing rod of the upper pressing rod assembly and a lower pressing rod are made to swing through the translation cam, so that the pressing head assemblies located on the upper pressing rod and the lower pressing rod and the pressing head assembly on the translation cam are gathered towards the axis of a workpiece to be machined at the same time, the workpiece to be machined issupported, a supporting wheel frame of each pressing head assembly can be automatically rotated according to the shape of the outer edge face of the workpiece to be machined, and it is ensured that two supporting wheels located on each supporting wheel frame are pressed on the workpiece to be machined at the same time.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

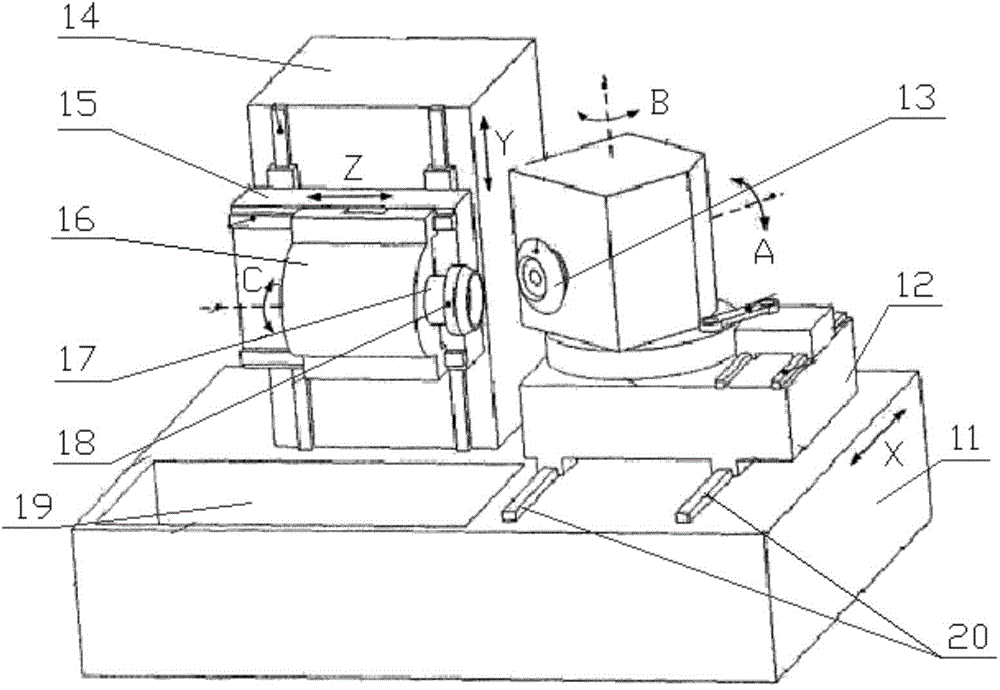

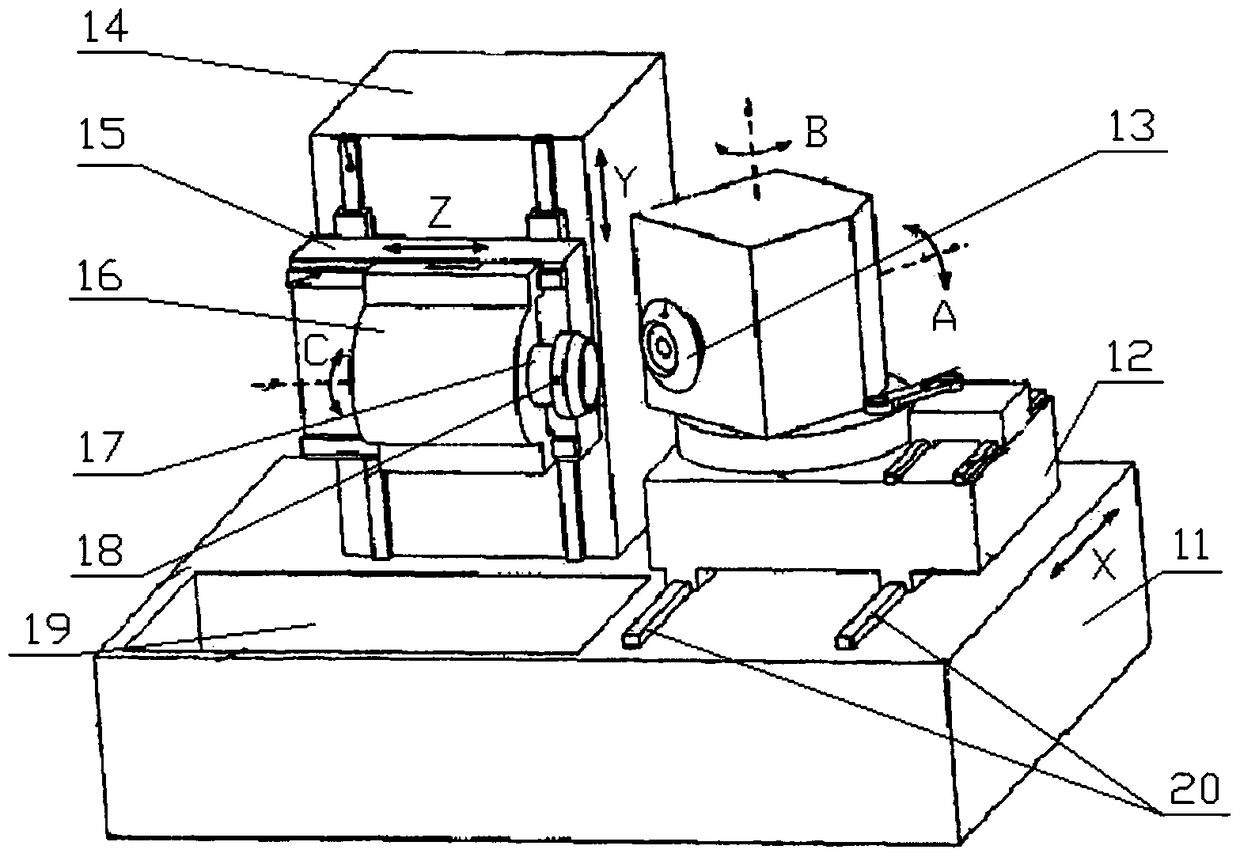

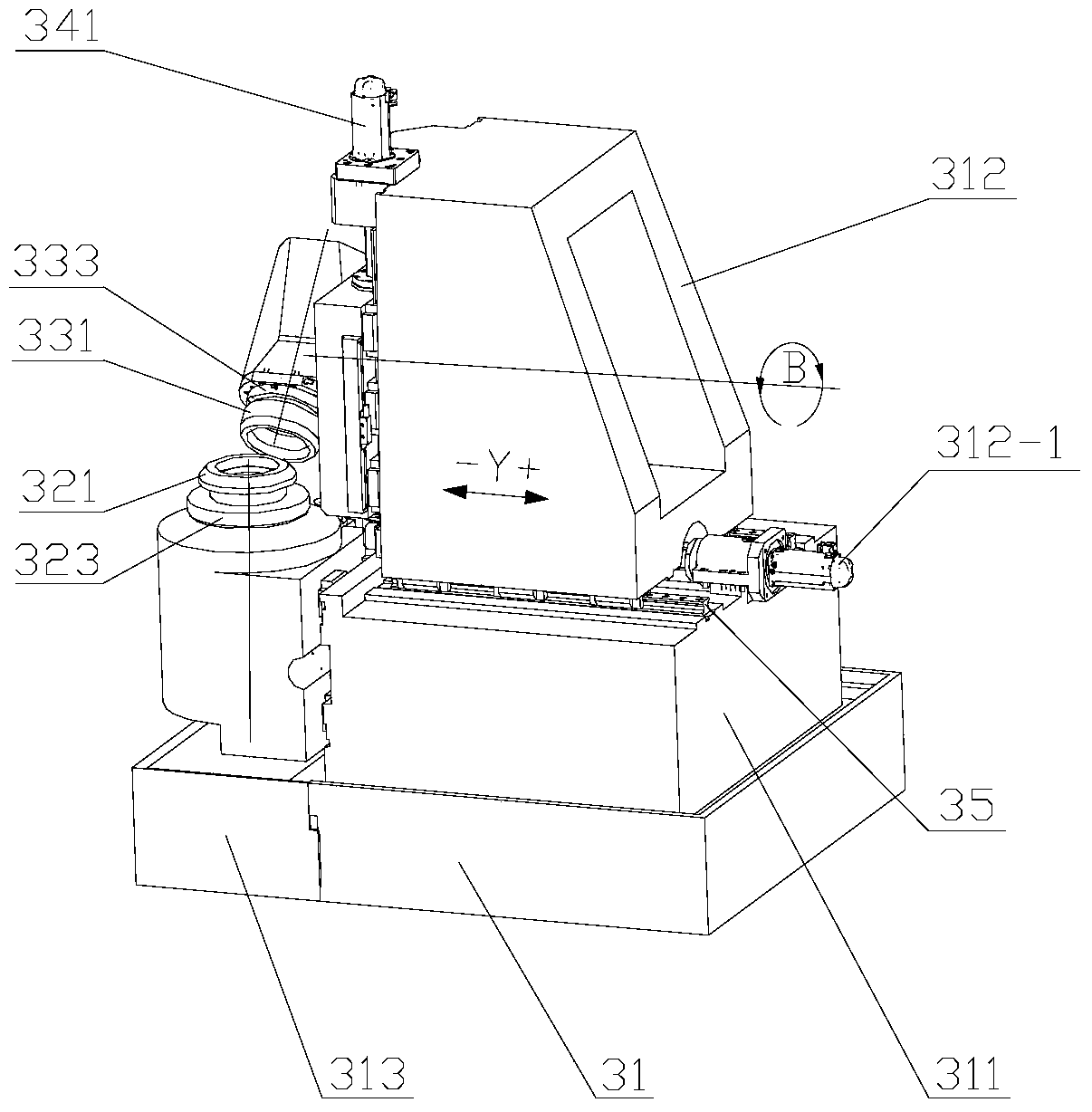

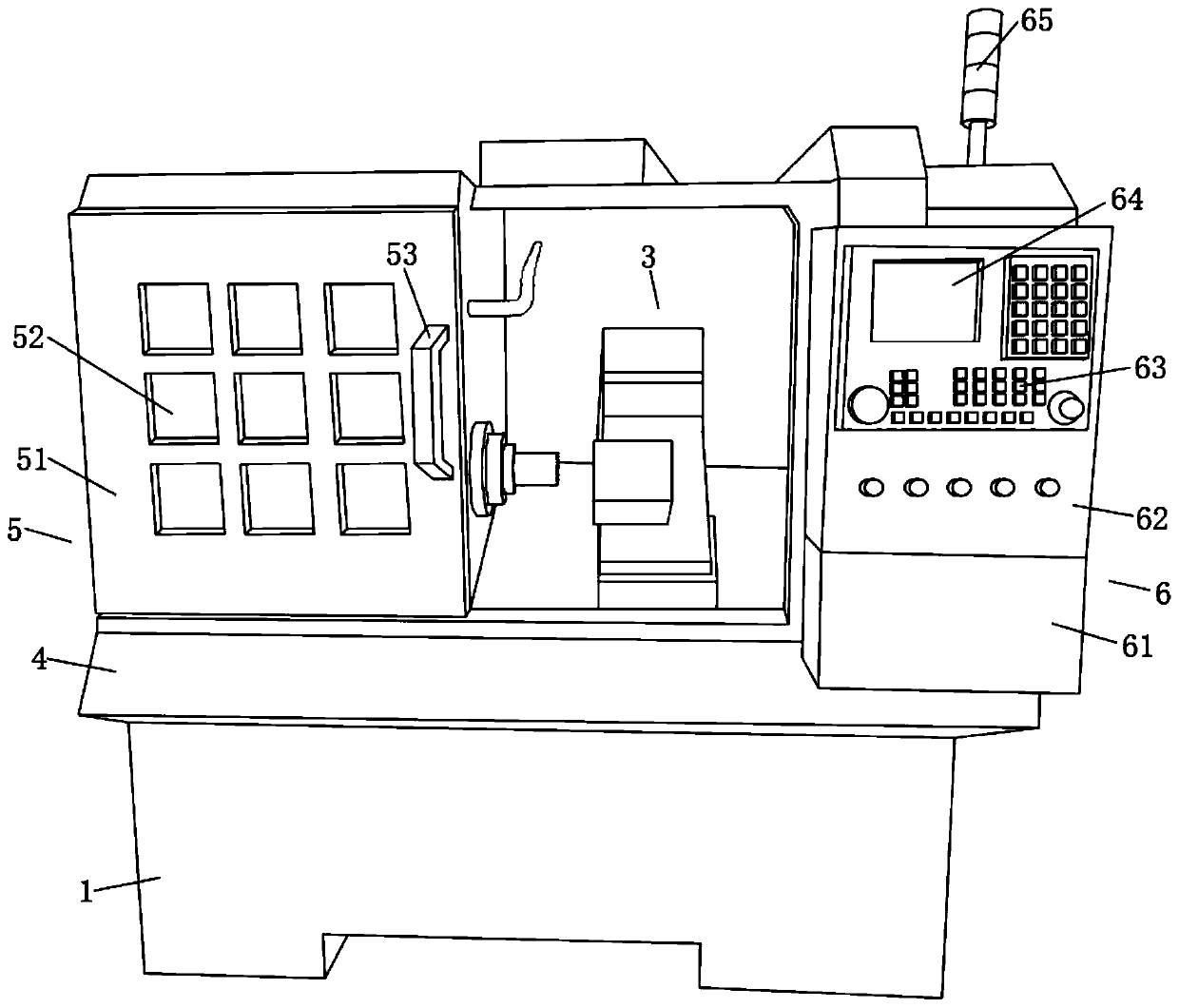

Gear processing lathe

ActiveCN104690369AGuarantee stabilityEnsure reliabilityLarge fixed membersMetal working apparatusGear wheelEngineering

The invention discloses a gear processing lathe. The gear processing lathe comprises a lathe bed, a stand column arranged on the lathe bed, a workpiece box and a B shaft box, wherein the workpiece box is movably mounted on the lathe bed in a first horizontal direction, and the axis of a workpiece revolving shaft is parallel to a vertical direction; the B shaft box is movably mounted on the stand column in the vertical direction, the axis of a B shaft is parallel to a second horizontal direction which is perpendicular to the first horizontal direction, a cutter box is mounted at one end close to the workpiece box, and the axis of a cutter revolving shaft of the cutter box is perpendicular to the second horizontal direction; for the cutter box and the workpiece box, one can approach to or be far away from the other in the second horizontal direction. The gear processing lathe is compact in structure and occupies a small area; the cutter revolving box and the workpiece revolving box can make relative movement, the cutter revolving shaft can process workpieces without extending out of the cutter box too long, so that the rigidity of the cutter revolving shaft is effectively guaranteed; processing points are distributed on the left and the right of a workpiece, so that the processing stability and the processing reliability of the workpiece are guaranteed.

Owner:HUNAN ZDCY (ZHONGDA CHUANG YUAN) CNC EQUIP CO LTD

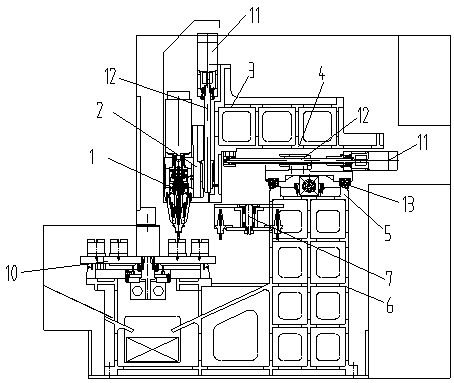

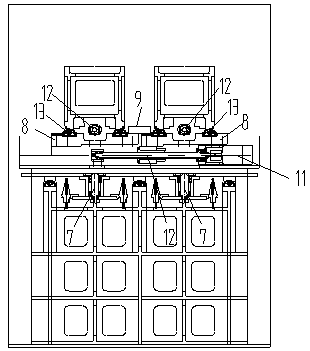

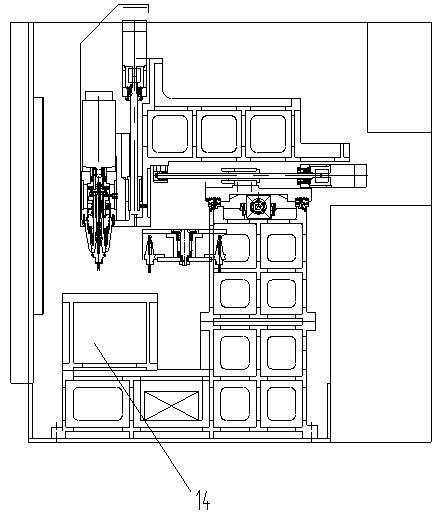

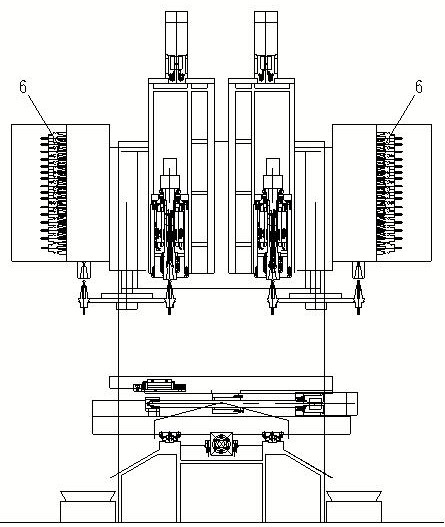

Multi-main-shaft vertical machining center

PendingCN108620958AConducive to the narrowing of the parallel spacingReduce vibration mutual interferenceMetal working apparatusNumerical controlEngineering

The invention discloses a multi-main-shaft vertical machining center. The center is mainly composed of a plurality of sets of main shaft units, X-direction numerical control sliding tables, Y-direction numerical control sliding tables, Z-direction numerical control sliding tables, rotary tool changers and a set of machine body. According to the machining center, multi-main-shaft synchronous tool changing can be carried out at the same time, and independent compensation can be independently carried out on the length of the tool on each main shaft; and the multi-main-shaft vertical machining center is simple in structure and convenient to maintain, and is ideal drilling and milling comprehensive machining equipment.

Owner:林志贺

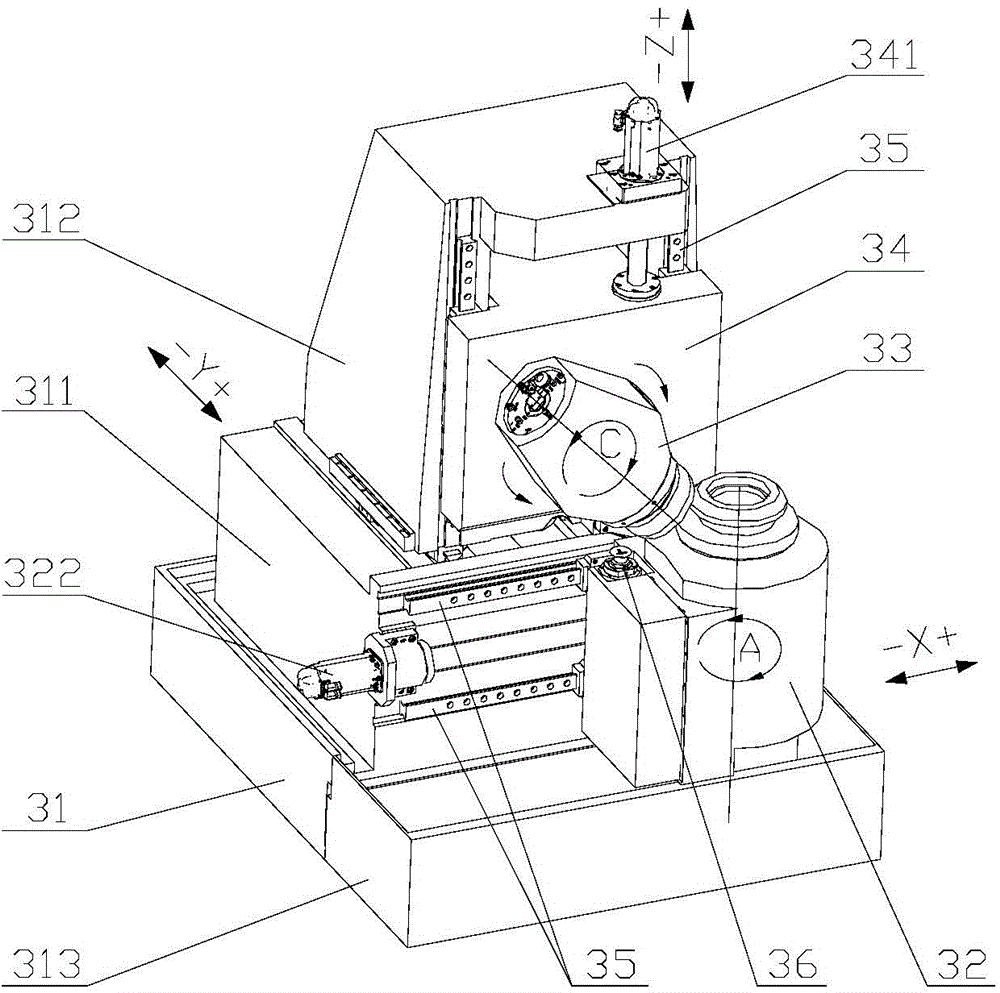

Numerical control curved-tooth broaching machine

InactiveCN103182563AHigh precisionImprove rigidityGear-cutting machinesGear teethNumerical controlReducer

The invention discloses a numerical control curved-tooth broaching machine comprising a broaching machine body, wherein the broaching machine body comprises a machine base, a tool box assembly, a workpiece box assembly, a numerical control device, a lubricating and cooling device and a chip removal device; the tool box assembly and the workpiece box assembly are arranged on the machine base; the tool box assembly is provided with a cutter head headstock, a cutter head, a cutter head main shaft motor, a Z-axis speed reducer, a Z-axis servomotor, Z-axis cutter head feeding and retracting guide rails, horizontal cutter position guide rails, a horizontal cutter position regulator and a horizontal cutter position locking device; the workpiece box assembly is provided with an indexing box seat, an indexing box, an indexing box locking device, vertical cutter position guide rails, a vertical cutter position regulator and an X-axis indexing servomotor and is further provided with a root angle lower seat and a root angle upper seat; the root angle lower seat is provided with vertical double-arc concentric root cone guide rails; the upper seat can slide on the lower seat; the tool box assembly further comprises a root cone regulator and a root cone locking device; and the horizontal cutter position regulator is positioned on the root angle lower seat. Compared with the prior art, the numerical control curved-tooth broaching machine has higher accuracy and rigidity in gear machining.

Owner:王命标

Machining method for automotive downhill reducer control levers

The invention discloses a machining method for automotive downhill reducer control levers. The machining method includes the specific steps of (1) material preparation; (2) heat treatment; (3) auxiliary hole design and turning; (4) heat treatment; (5) milling; (6) bench work; (7) finish turning; (8) heat treatment; (9) turning; (10) grinding; (11) surface treatment; (12) bench work; (13) accurate grinding; (14) bench work, specifically, removing of burrs on sharp edges; and (15) inspection. By means of the machining method, the special vehicle downhill reducer control levers can be conveniently and quickly manufactured, the workpiece production cycle can be effectively shortened, the machined parts are stable in quality, and the machining cost is greatly lowered. The machining method is simple, operation is easy, the special vehicle downhill reducer control levers are good in wear resistance and high in corrosion resistance, and the workpiece machining rigidity can be effectively improved by means of the machining method.

Owner:贵州凯星液力传动机械有限公司

Special lathe for shaft part machining

InactiveCN108044132AImprove coaxialityGood verticality of the step surfaceTurning machinesEngineeringMechanical engineering

The invention relates to a special lathe for shaft part machining. According to the technical scheme, the special lathe for shaft part machining comprises a lathe bed, a guide rail, a first spindle box, a second spindle box, a machine frame, a first spindle, a second spindle and a first center, a second center, a first power motor, a second power motor, a knife rest mechanism and a centerless radial clamp, wherein the first spindle box, the guide rail and the knife rest mechanism are arranged on the lathe bed, a machine frame is arranged on the guide rail, and the second spindle box is arranged on the machine frame; the first power motor is arranged in the first spindle box, the first spindle is arranged at the output end of the first spindle box, and the first center and the centerless radial clamp are arranged on the first spindle; and the second power motor is arranged in the second spindle box, the second spindle is arranged at the output end of the second spindle box, and the second center is arranged on the second spindle. According to the special lathe for shaft part machining, the machined shaft part can be guaranteed to have good coaxiality and step surface perpendicularity.

Owner:凤城市时代龙增压器制造有限公司

End face grooving cutter body

The invention relates to an end face grooving cutter body. The end face grooving cutter body comprises a cutter base used for being connected with a main shaft of a machine tool. A sliding cutter holder is arranged on the cutter base. The sliding cutter holder and the cutter base are in guiding fit through guide protrusions and guide grooves. The sliding cutter holder is fixed to the cutter base through locking bolts. Holes, allowing the locking bolts to penetrate through, in the sliding cutter holder are circular holes. Long holes allowing the locking bolts to penetrate through are formed inthe cutter base. Long axes of the long holes are parallel to the guide movement direction of the sliding cutter holder. Slide grooves extending in the long-axis direction of the long holes are formedin the end, away from the sliding cutter holder, on the cutter base. Each slide groove is internally provided with a nut for connection of the corresponding locking bolt. The long holes for regulationare formed in the cutter base of the end face grooving cutter body, the holes in the sliding cutter holder are the circular holes, and therefore the size of connection holes in the cutter base is notlimited, the regulation range is wide, and the achievement of the grooving operation of large-diameter end face grooves is facilitated.

Owner:HENAN PINGGAO ELECTRIC +2

Positioning device

PendingCN113084559ASimple structureReasonable layoutPositioning apparatusMetal-working holdersEngineeringMachine tool

The invention discloses a positioning device. The positioning device comprises a supporting device used for supporting an instrument grillwork assembly, the supported instrument grillwork assembly comprises an instrument grillwork and an assembly extending downwards from the bottom of the instrument grillwork, and the supporting device is arranged at the bottom of the instrument grillwork and used for supporting the instrument grillwork. The supporting device comprises a supporting body and multiple lifting devices. One end of each lifting device is installed on the supporting body, and the other end of each lifting device is connected to the bottom of the instrument grillwork in a lifting manner so that the levelness of the instrument grillwork can be adjusted. By means of the lifting devices, accurate positioning is provided for installation of the instrument grillwork assembly, the equipment use cost of a machine tool and a cutter is reduced, the machining efficiency is improved, and the manufacturing period is remarkably shortened.

Owner:上海第一机床厂有限公司

A Manufacturing Process of Thin-walled Parts with Large Curvature and Full Surface

ActiveCN103639655BSolve Vibration ProblemsGuaranteed sizeAircraft componentsWorkpiecesMaterial removalEngineering

The invention provides a manufacturing process for a high-curvature full-profile thin-wall part so as to solve the problem of processing deformation and vibration of an ultra-complex spatial thin-wall curved surface. By reasonable process layout, a segmented layer-by-layer processing mode is adopted, an appropriate cutter and a cutter handle are selected, working allowance of every process is set, natural aging time is set, cutting process parameters and feeding strategies are optimized, the uniform material removal amount of the part is guaranteed, an adding cushion block location and gypsum filling method is adopted simultaneously, the problem of clamping difficulty and vibration in part processing is solved, processing rigidity and clamping stability of the part are improved, deformation in the part processing process is controlled, and the part size and precision are guaranteed.

Owner:江西洪都航空工业股份有限公司

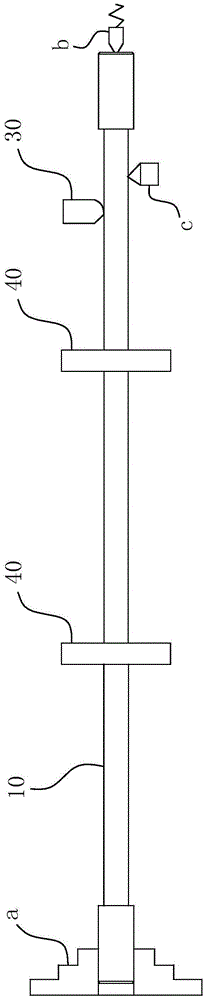

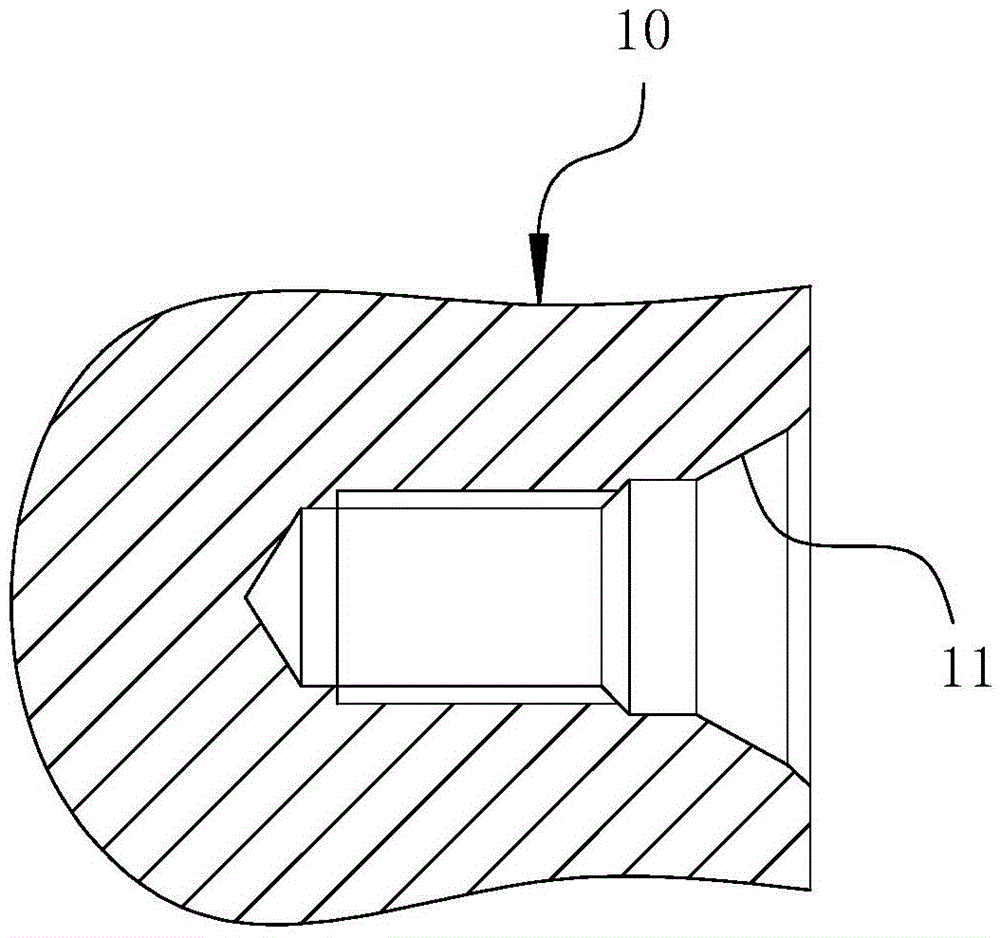

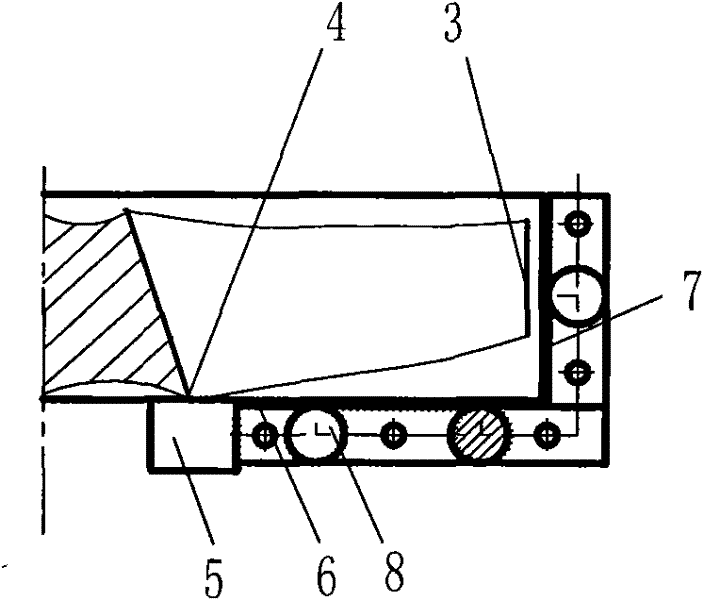

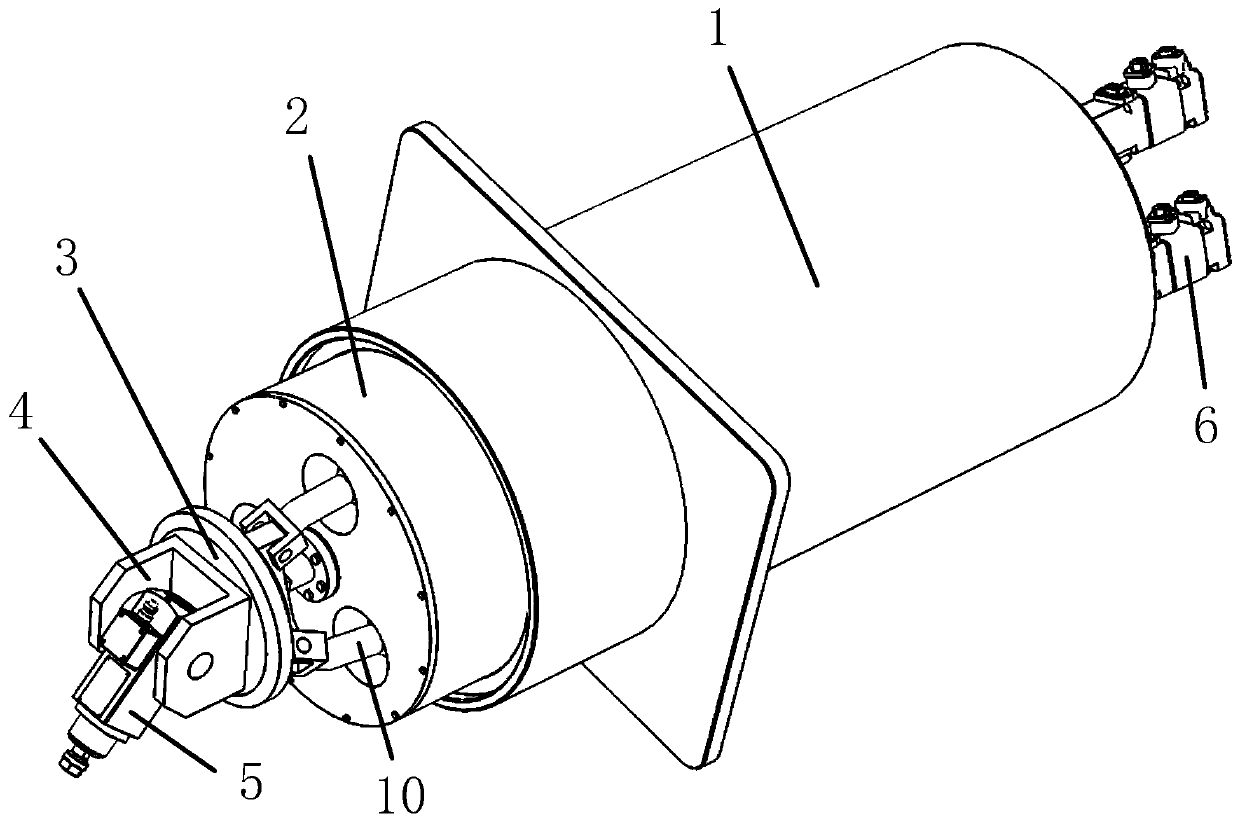

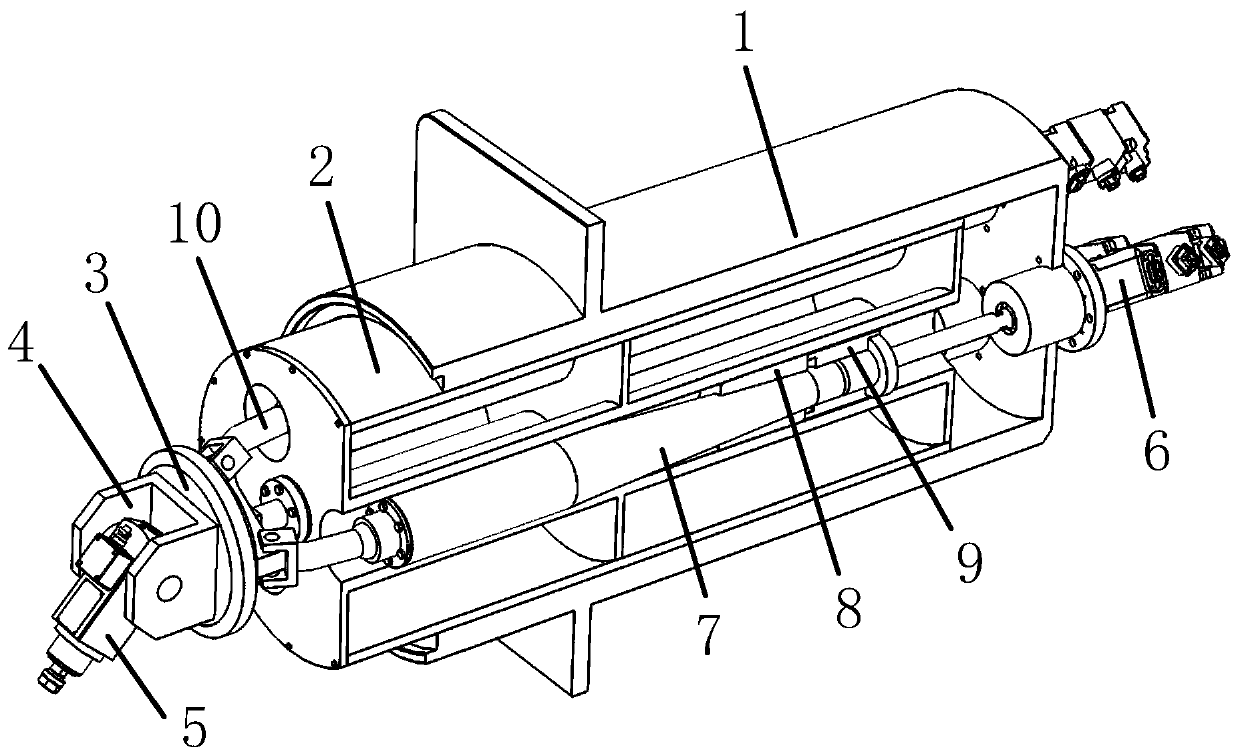

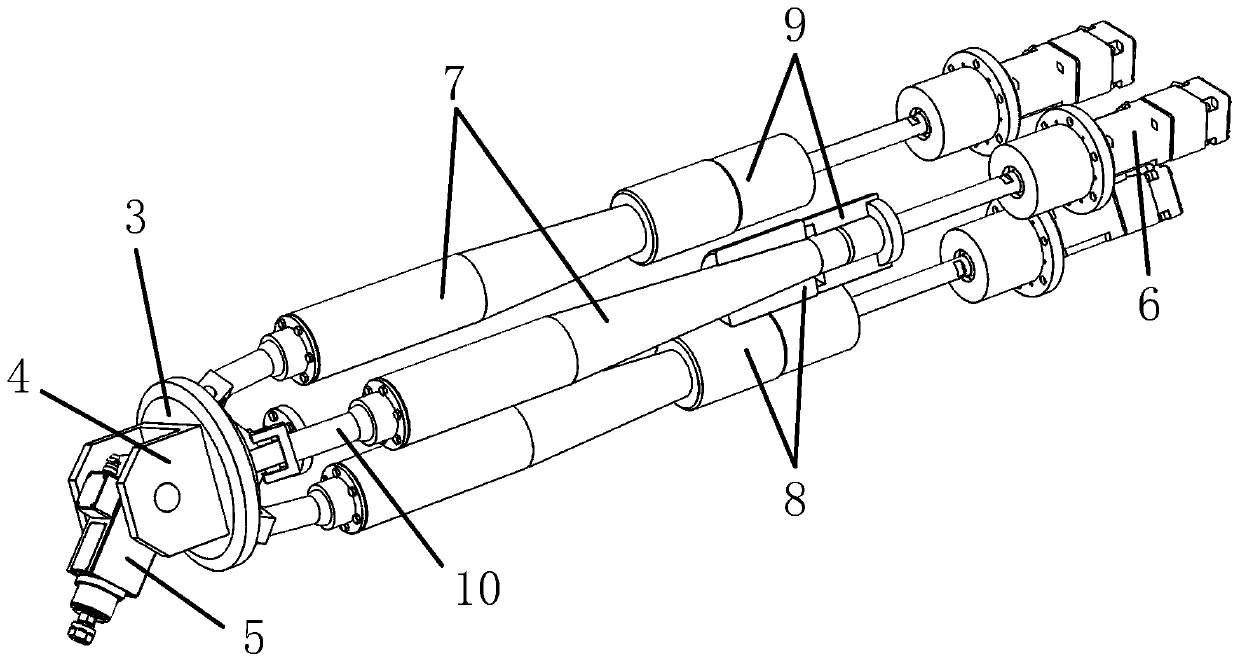

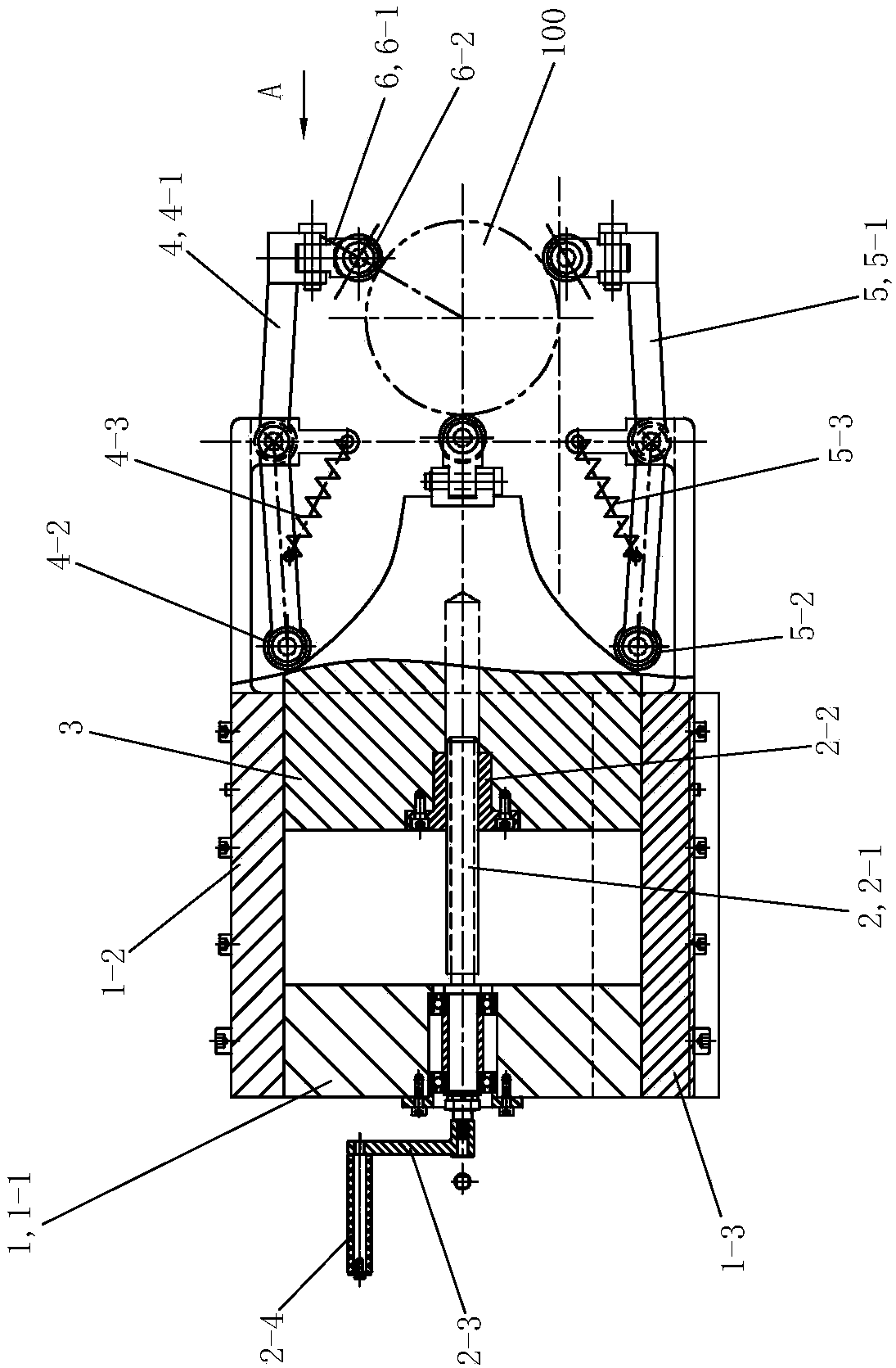

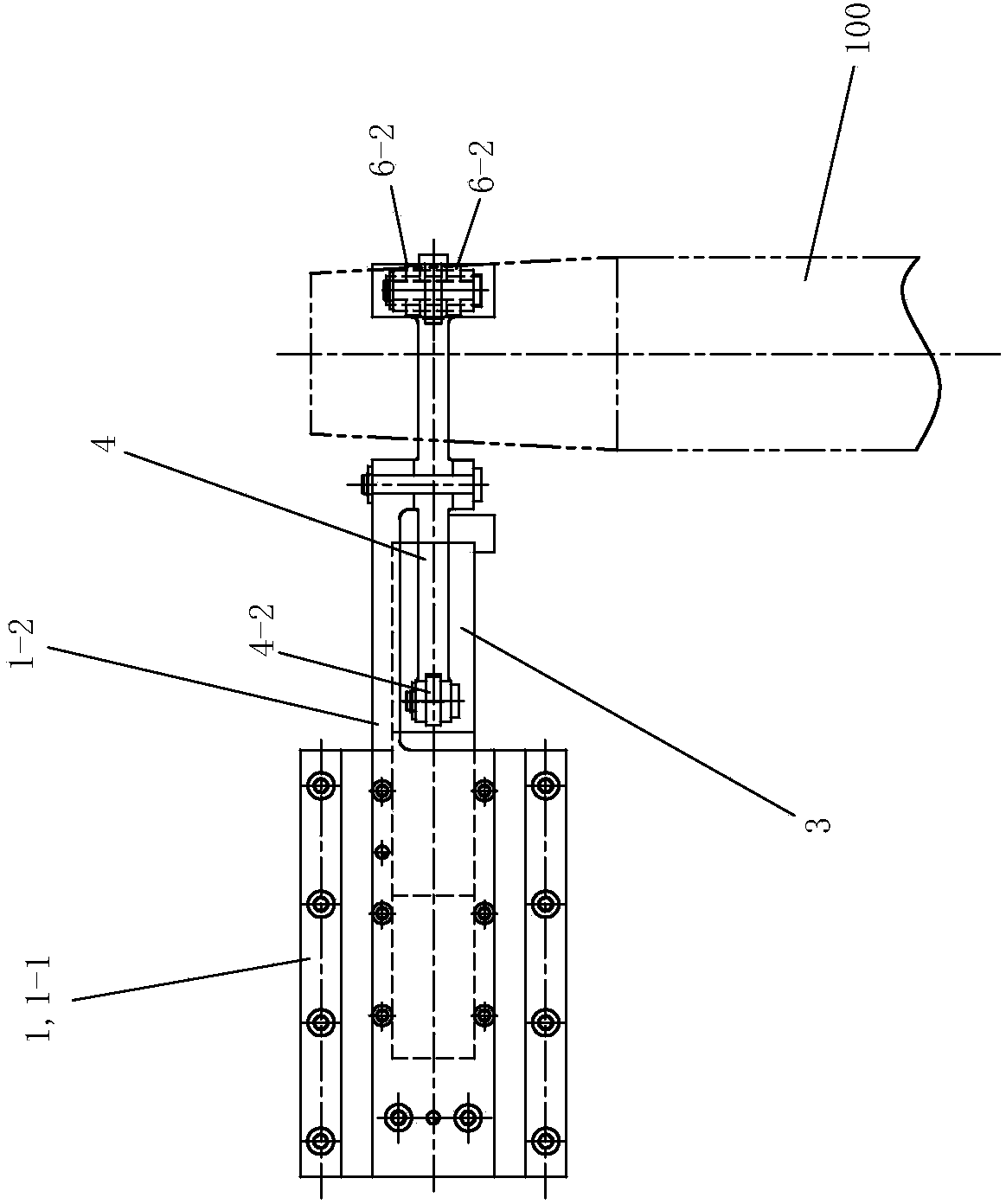

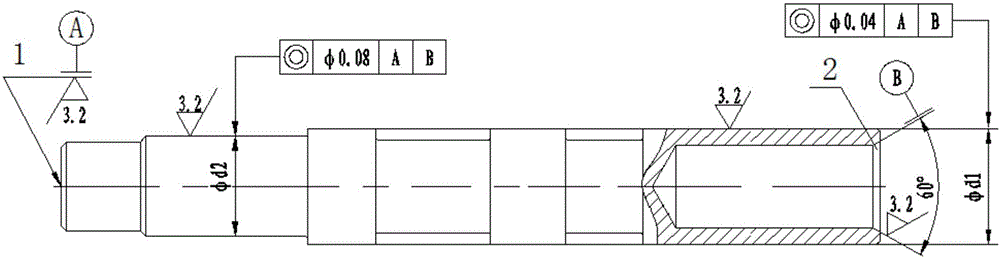

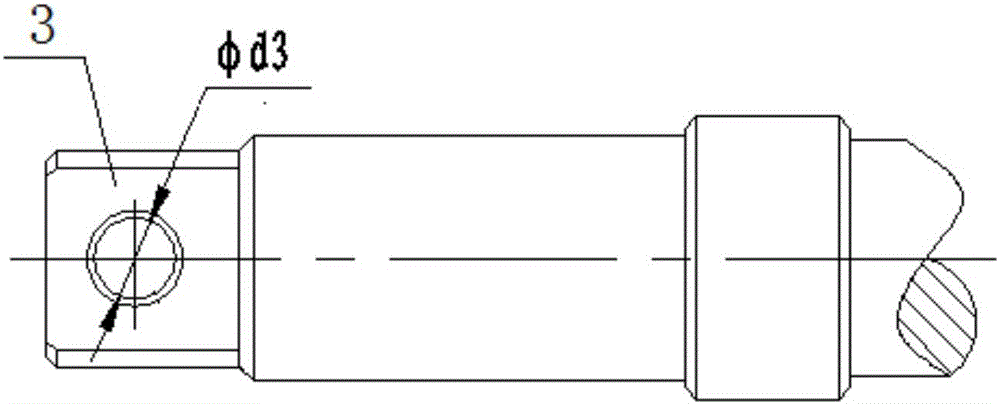

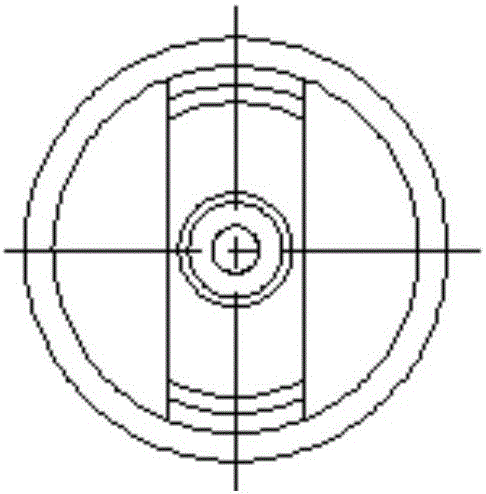

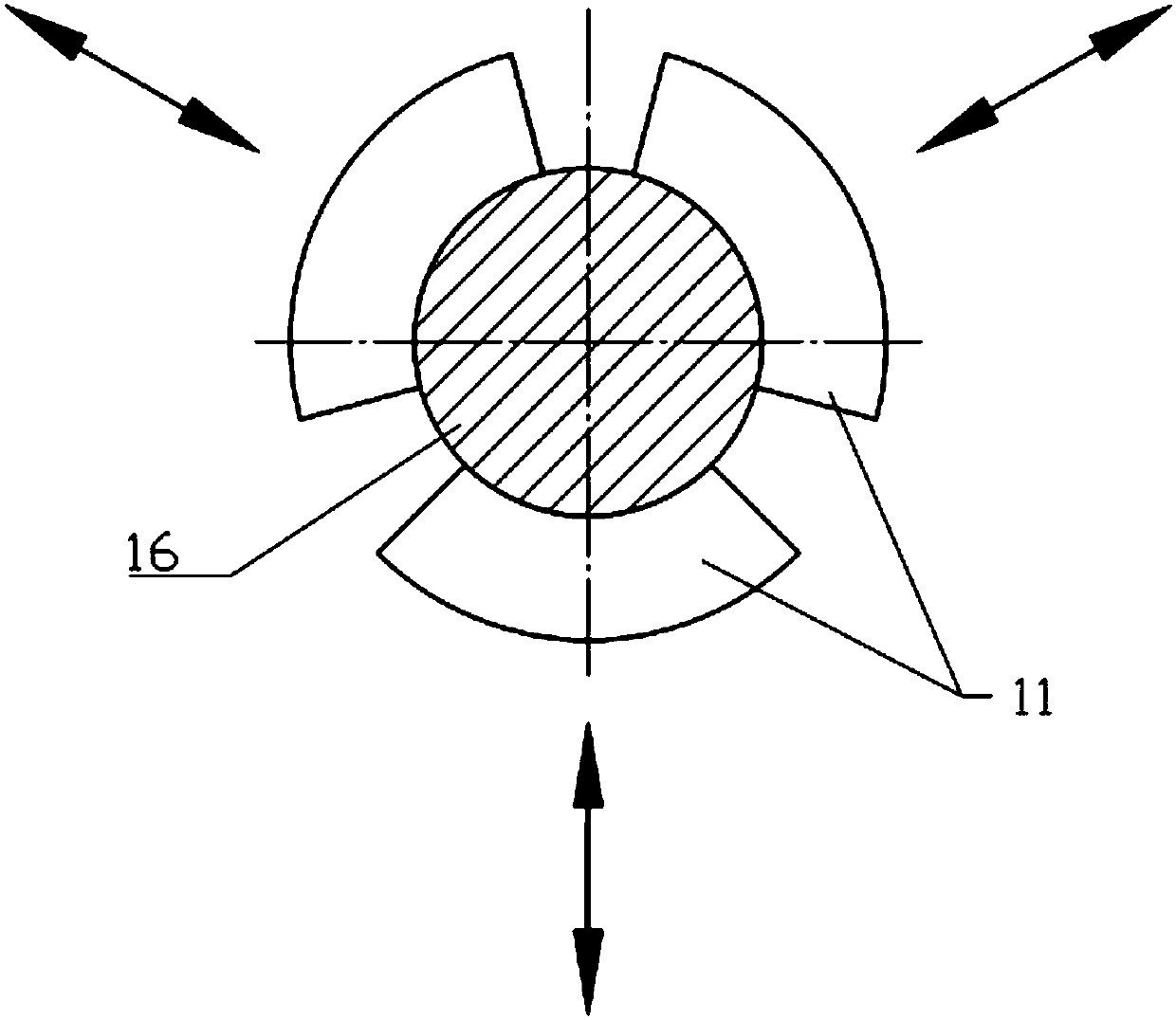

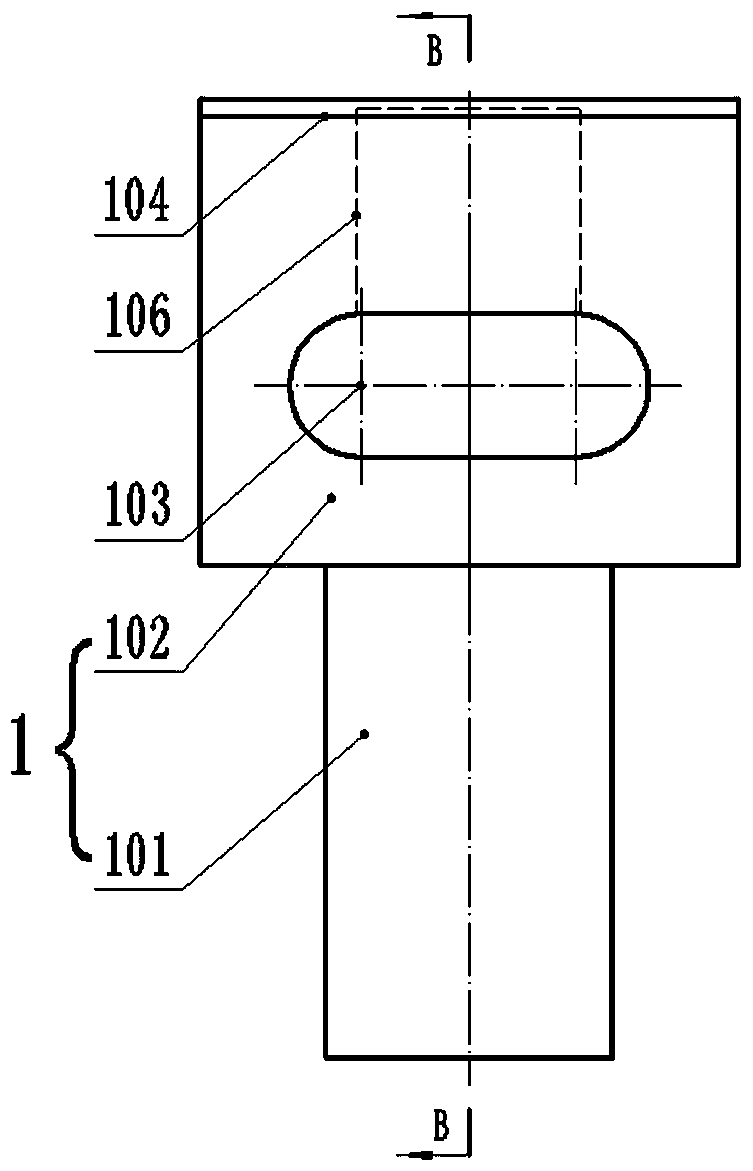

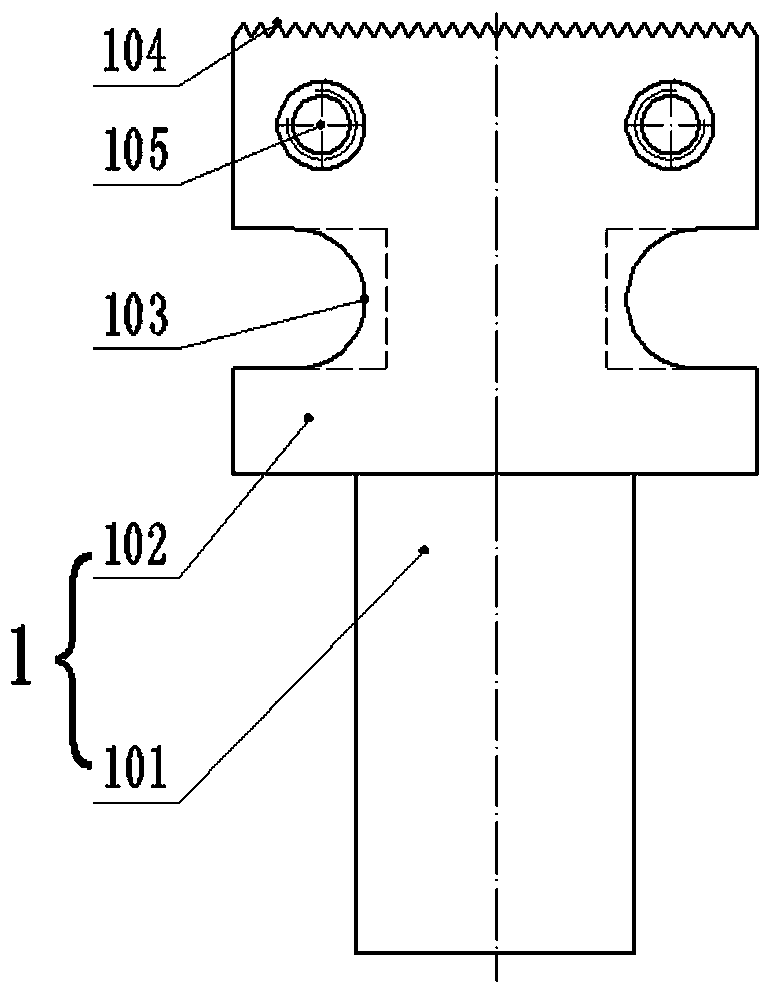

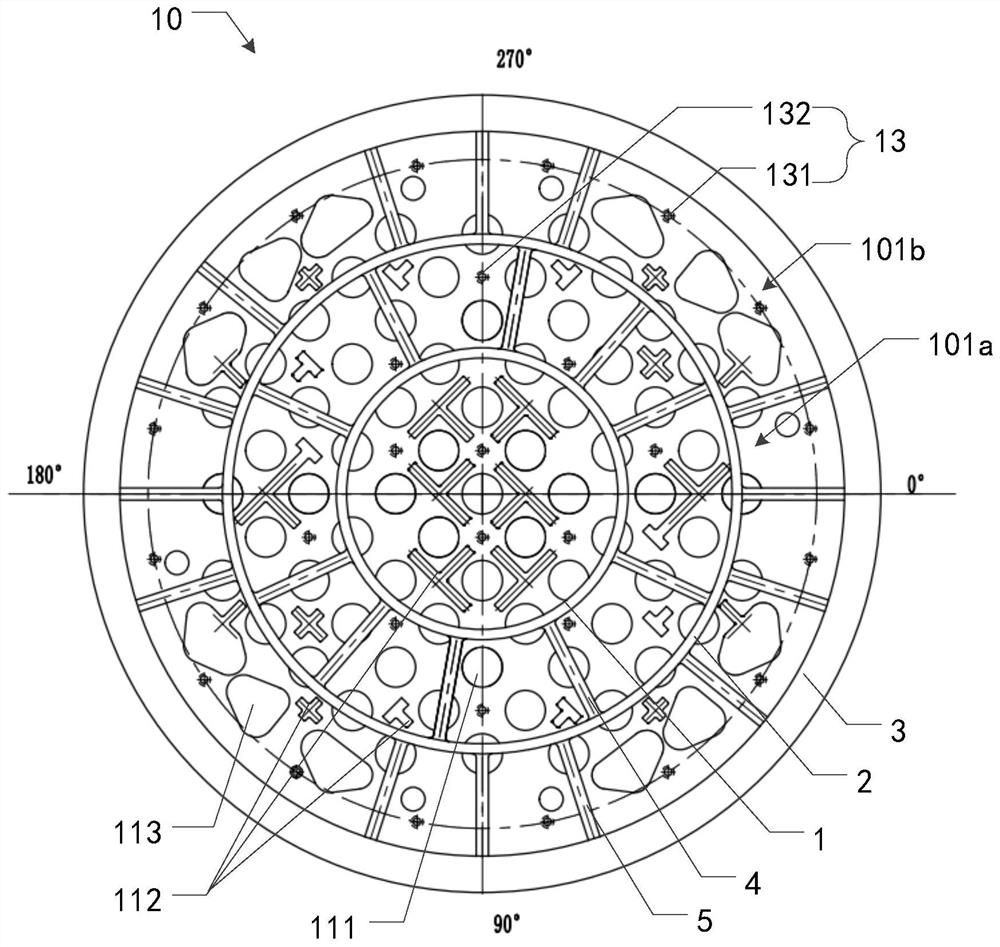

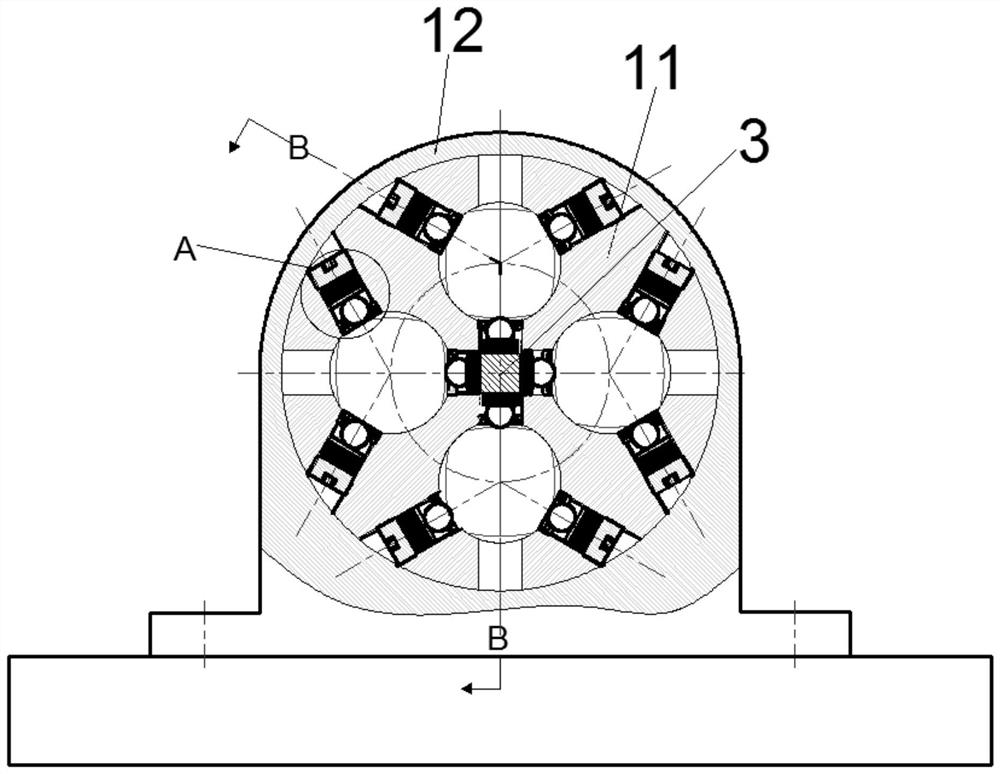

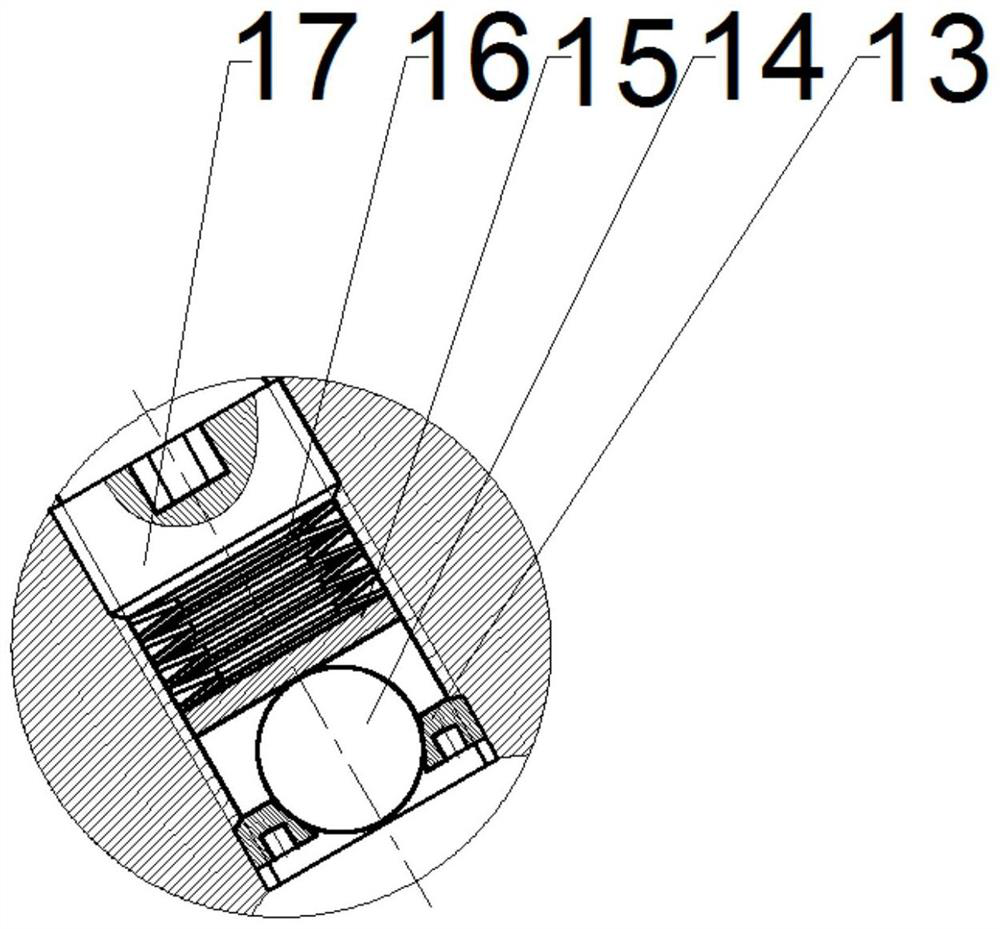

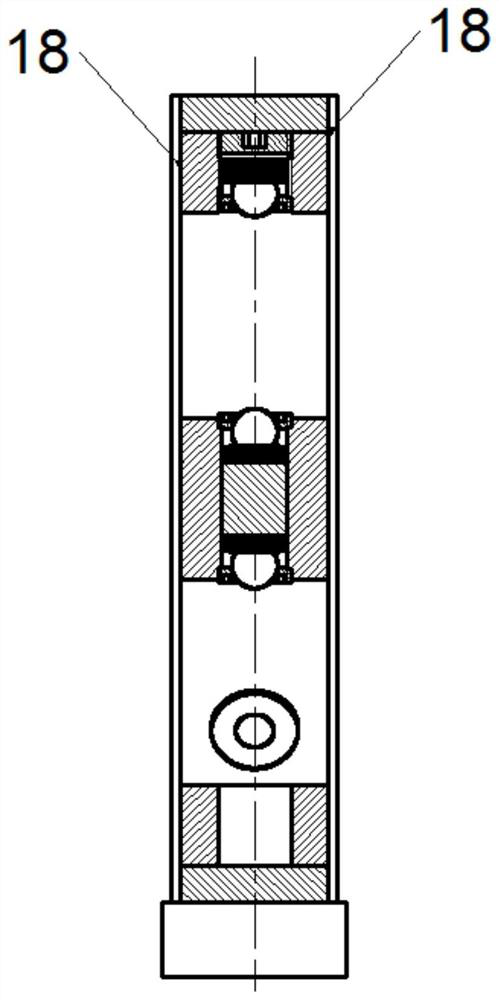

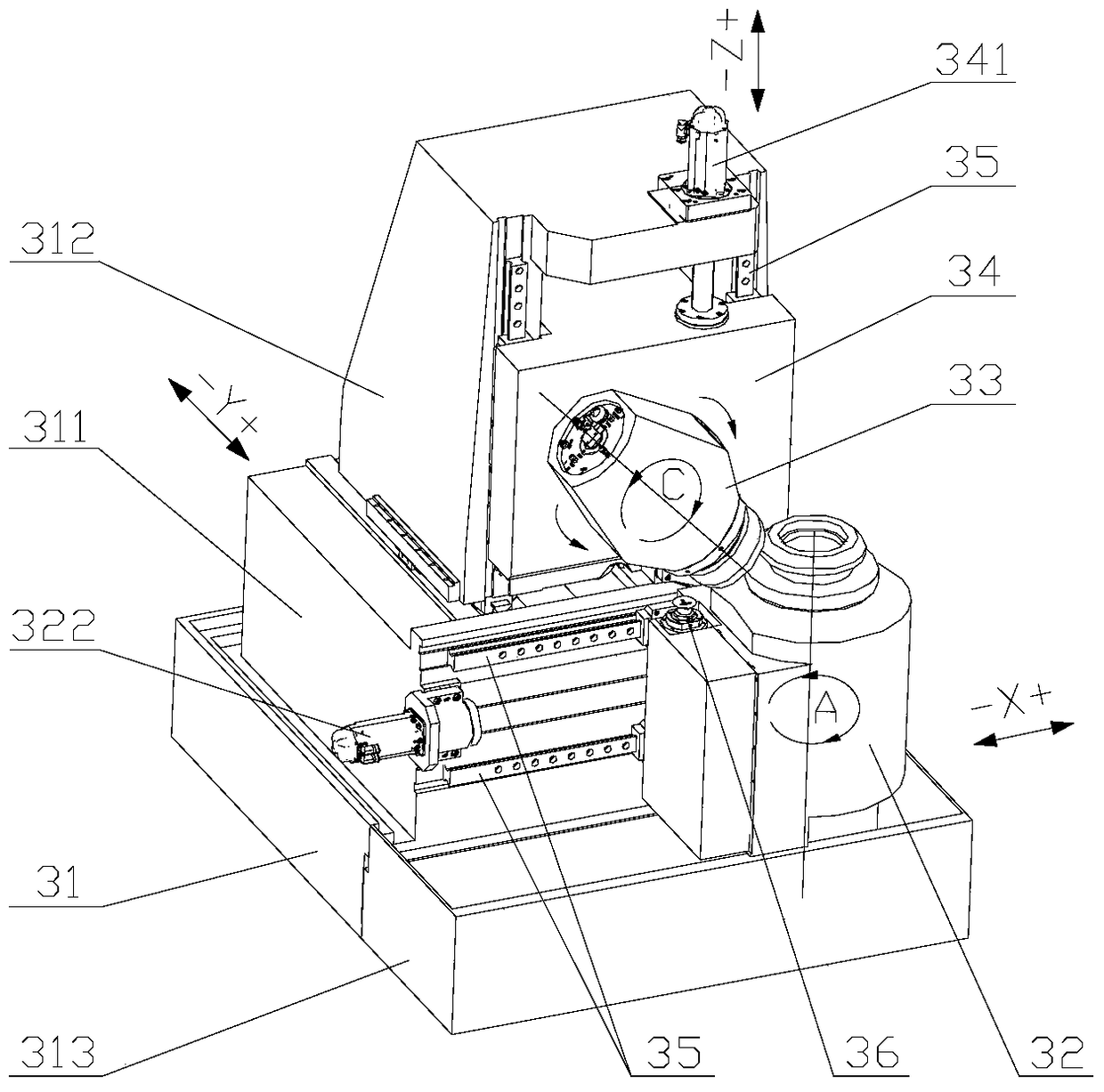

Auxiliary supporting device for improving machining rigidity of equidistant arc surface slender shaft

ActiveCN113560922AImprove processing rigidityAvoid interferencePositioning apparatusMetal-working holdersStructural engineeringMachine tool

The invention discloses an auxiliary supporting device for improving machining rigidity of an equidistant arc surface slender shaft, and belongs to the technical field of machining of equidistant molded surface slender shafts. The auxiliary supporting device for improving the machining rigidity of the equidistant arc surface slender shaft comprises an outer supporting base and an inner supporting plate, the inner supporting plate is arranged inside the outer supporting base, the rotation center of the inner supporting plate is consistent with the rotation center of a machine tool spindle, a plurality of supporting holes are evenly formed in the inner supporting plate in the circumferential direction, each supporting hole is evenly provided with at least three elastic supporting structures in the circumferential direction, and the axes of the elastic supporting structures are arranged in the radial direction of the supporting holes. The auxiliary supporting device for improving the machining rigidity of the equidistant arc surface slender shaft can effectively improve the machining rigidity and machining efficiency of the equidistant arc surface slender shaft, can adapt to simultaneous machining of multiple shafts, and avoids interference of clamps during machining.

Owner:SHENYANG LIGONG UNIV

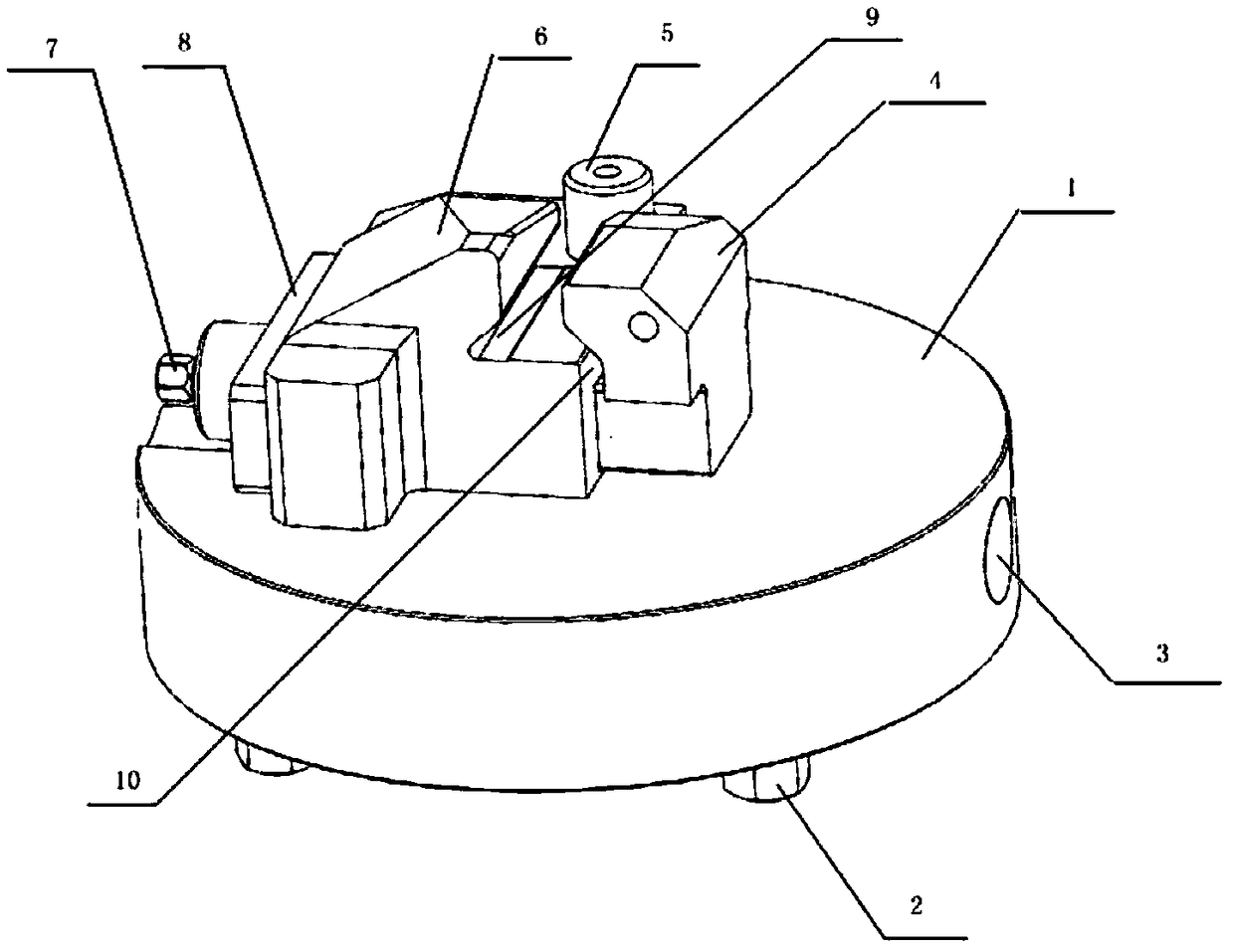

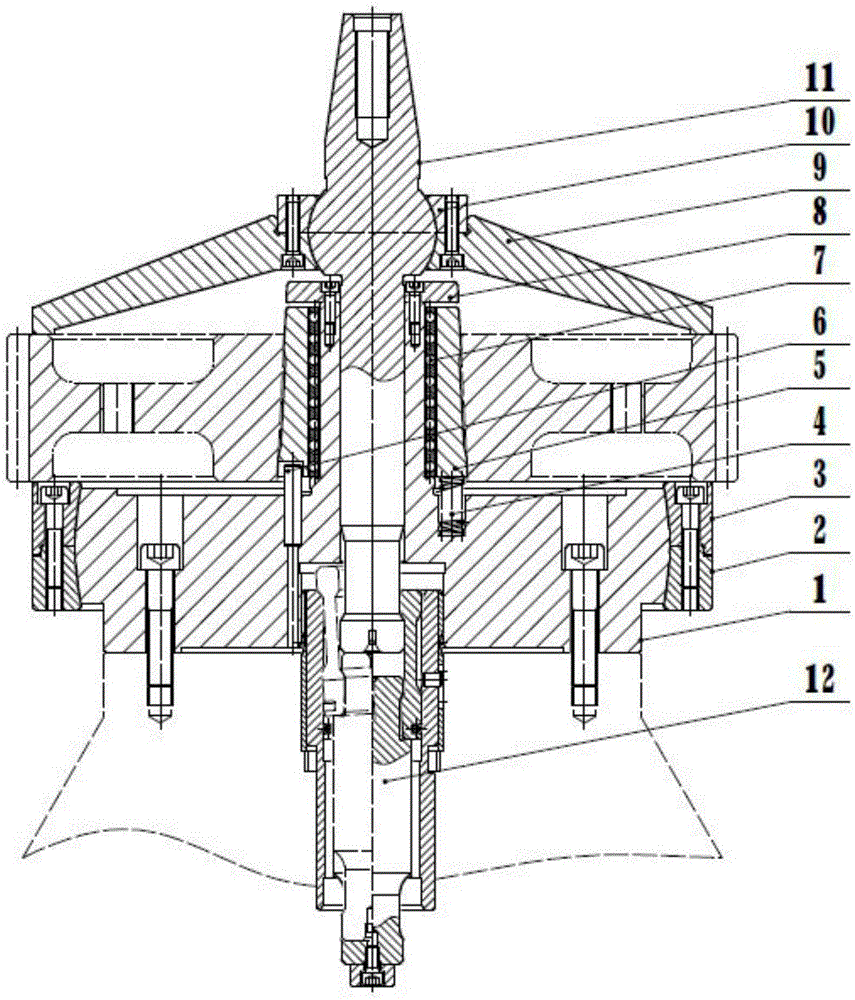

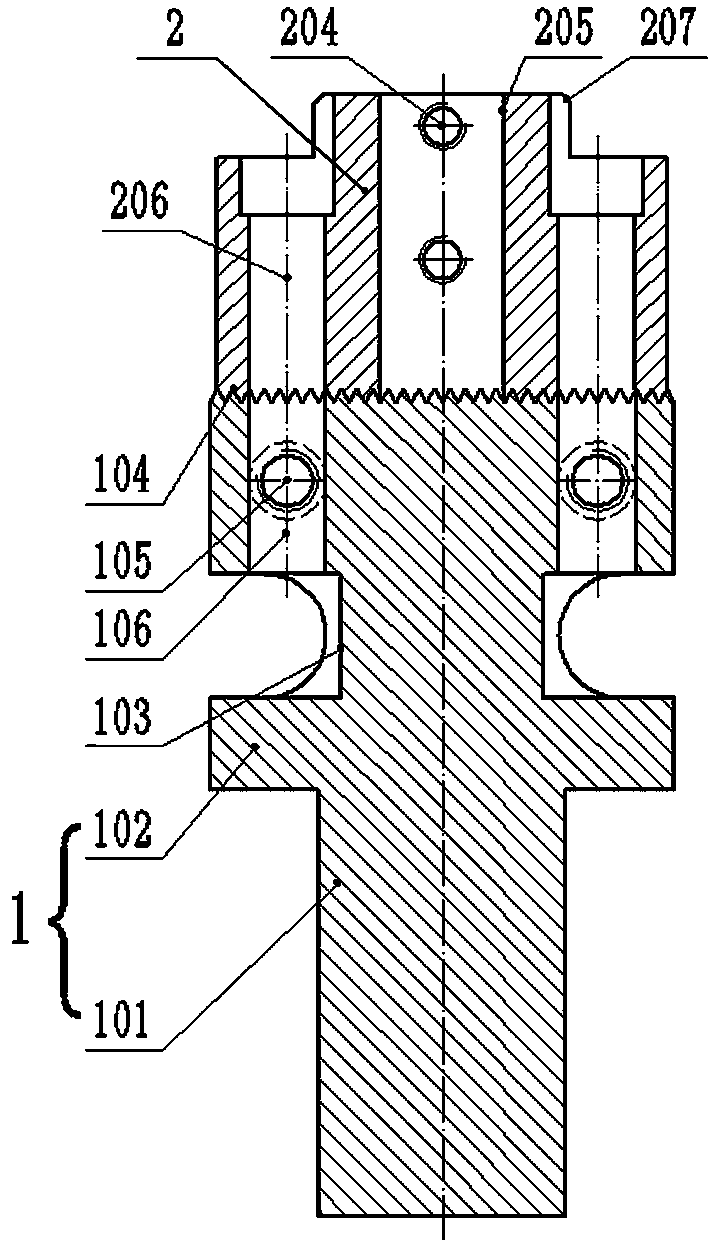

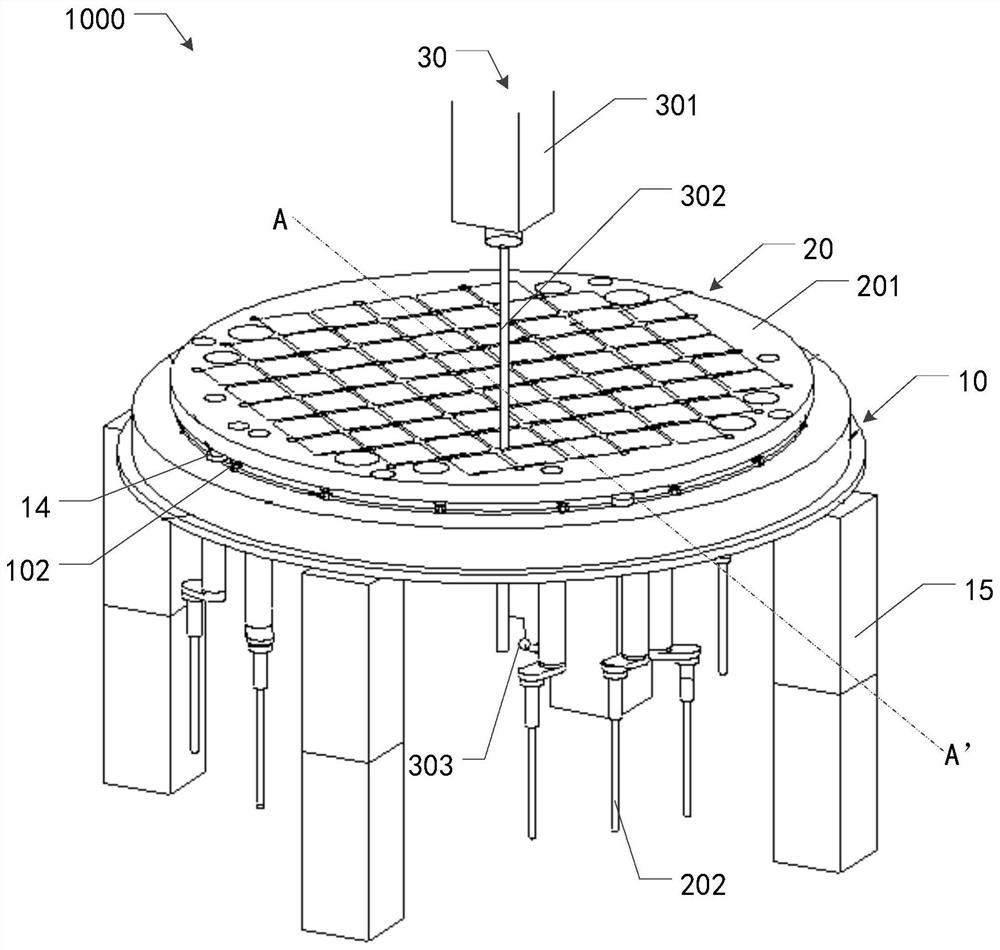

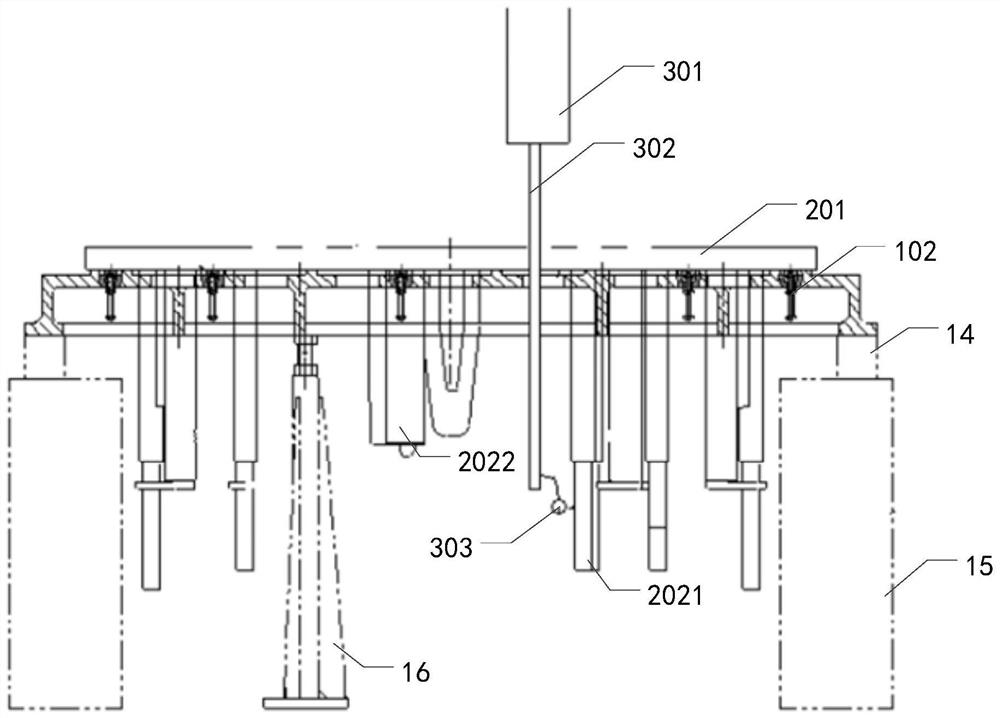

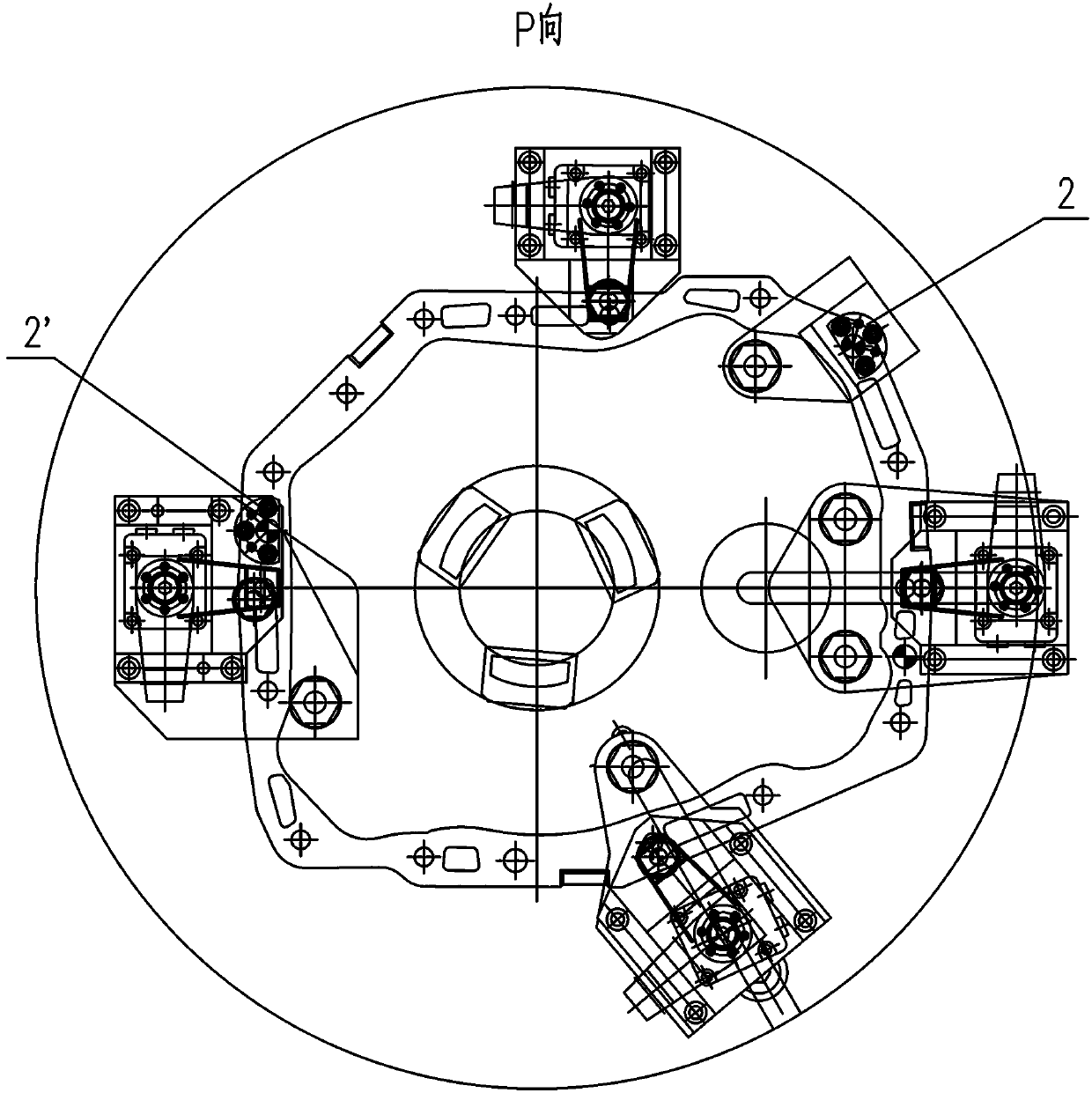

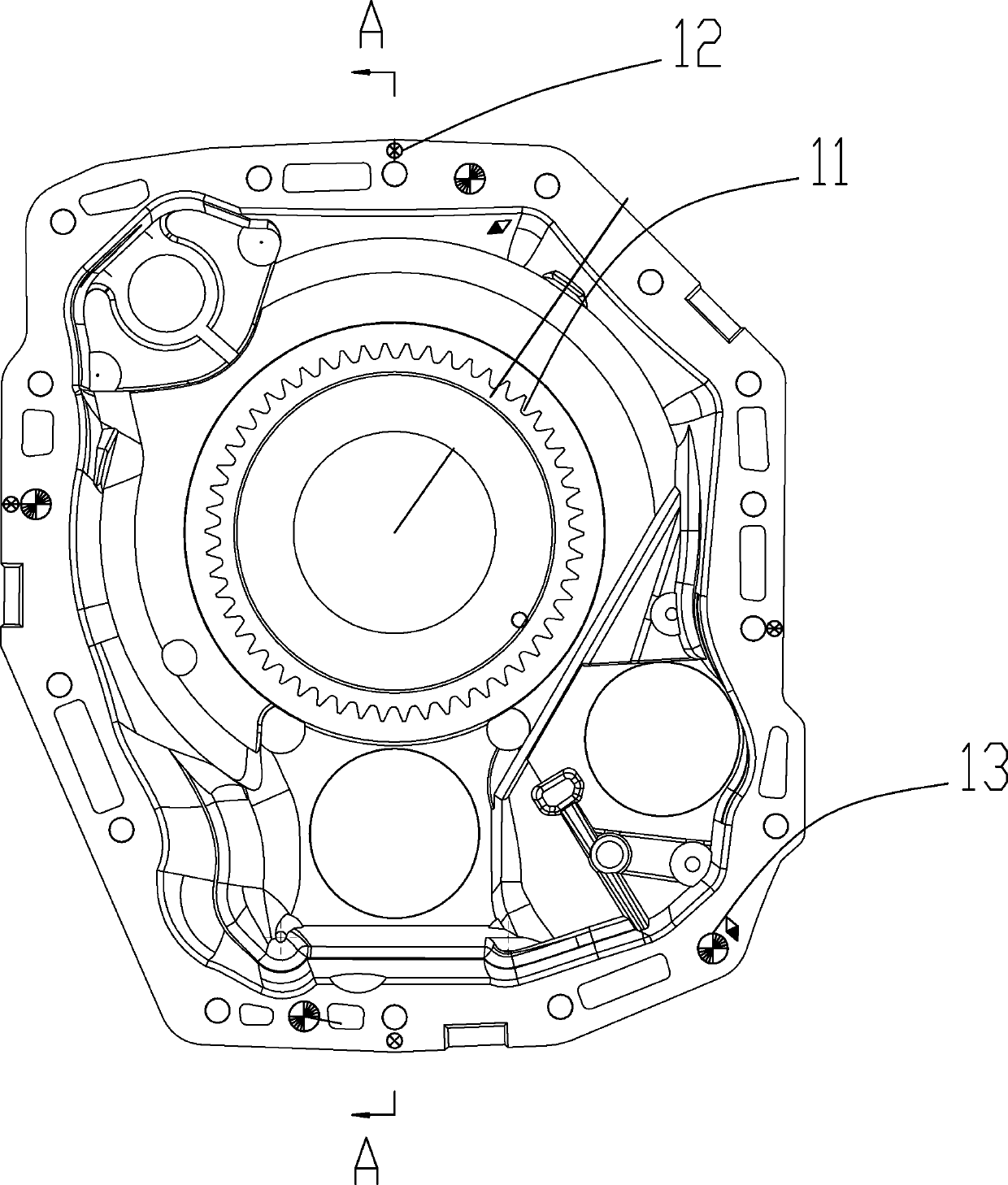

Jig for gear shaping process of engine case

ActiveCN105710685BImprove processing rigidityAvoid deformationPositioning apparatusMetal-working holdersMechanical engineeringGear shaping

The invention provides a jig for the gear-shaping process of an engine casing, which includes a jig body, on which a plurality of support columns for positioning a datum plane and a plurality of positioning pins for locating the center of a circle are arranged; A rotary compression cylinder, and a positioning support cylinder matched with the rotary compression cylinder. The support column locates the datum plane of the component housing through the upper end surface, and the upper end surface of the support column is supported on the inner hole step of the component housing. There are two positioning pins. The positioning of the end face reference plane is realized by using the support column, and the centering of the part shell is realized through the positioning pin, so as to realize the precise clamping and positioning of the part shell with complex structure. Cooperate with the rotary compression cylinder and the positioning support cylinder to compress the part shell, improve the processing rigidity of the part shell, prevent the deformation of the part shell in the gear shaping process, and improve the gear shaping accuracy of the internal gear in the part shell.

Owner:宜昌长机科技有限责任公司

A gear processing machine tool

ActiveCN104690369BGuarantee stabilityEnsure reliabilityLarge fixed membersMetal working apparatusGear wheelSmall footprint

The invention discloses a gear processing lathe. The gear processing lathe comprises a lathe bed, a stand column arranged on the lathe bed, a workpiece box and a B shaft box, wherein the workpiece box is movably mounted on the lathe bed in a first horizontal direction, and the axis of a workpiece revolving shaft is parallel to a vertical direction; the B shaft box is movably mounted on the stand column in the vertical direction, the axis of a B shaft is parallel to a second horizontal direction which is perpendicular to the first horizontal direction, a cutter box is mounted at one end close to the workpiece box, and the axis of a cutter revolving shaft of the cutter box is perpendicular to the second horizontal direction; for the cutter box and the workpiece box, one can approach to or be far away from the other in the second horizontal direction. The gear processing lathe is compact in structure and occupies a small area; the cutter revolving box and the workpiece revolving box can make relative movement, the cutter revolving shaft can process workpieces without extending out of the cutter box too long, so that the rigidity of the cutter revolving shaft is effectively guaranteed; processing points are distributed on the left and the right of a workpiece, so that the processing stability and the processing reliability of the workpiece are guaranteed.

Owner:HUNAN ZDCY (ZHONGDA CHUANG YUAN) CNC EQUIP CO LTD

High-rigidity double-spindle vertical machining center

PendingCN113829128AReduce Z overhangReduce overhangPositioning apparatusMetal working apparatusNumerical controlStructural engineering

The invention relates to a high-rigidity double-spindle vertical machining center. The high-rigidity double-spindle vertical machining center mainly comprises a base, a stand column, a cross numerical control sliding table, Z-direction numerical control sliding tables, main shaft units and tool magazines, wherein an up-and-down adjusting seat is arranged between each Z-direction numerical control sliding table and the stand column; two Z-direction numerical control sliding tables, two main shaft units and two tool magazines are arranged left and right; and the tool magazines are fixedly mounted on the up-down adjusting seats and are arranged on the side surfaces of the main shaft units. The rigidity is high, synchronous tool changing of two main shafts can be carried out simultaneously, and length compensation of tools on the main shafts can be independently carried out; and the high-rigidity double-spindle vertical machining center is simple in structure and convenient to maintain and is ideal drilling and milling comprehensive machining equipment.

Owner:林志贺

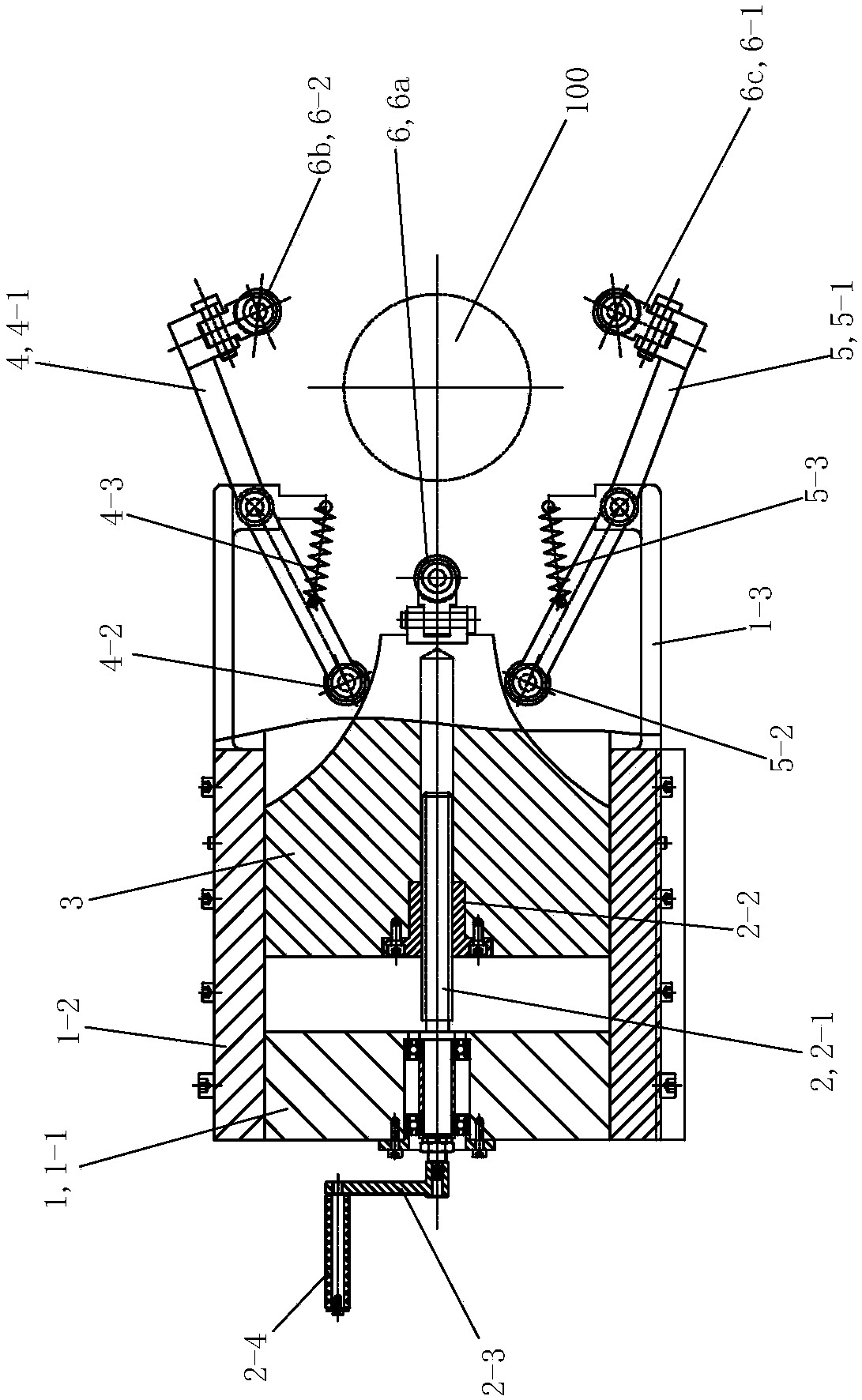

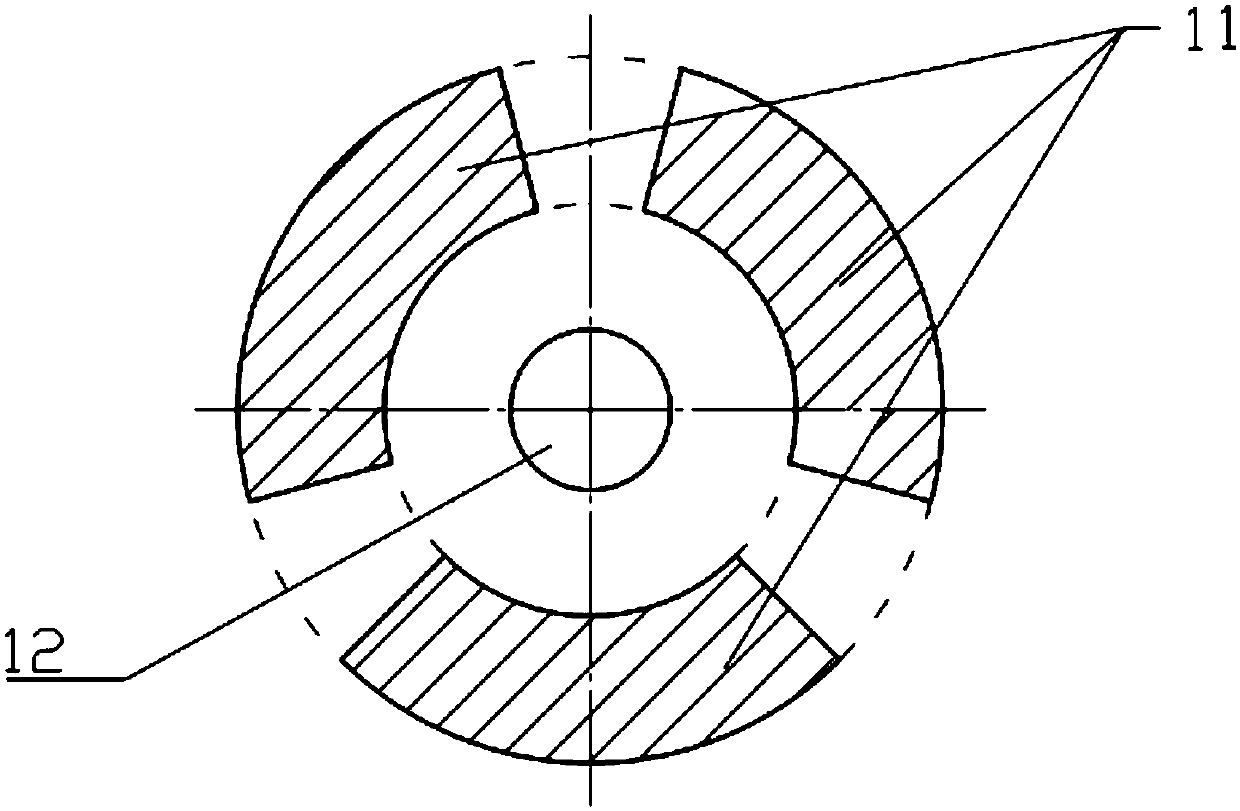

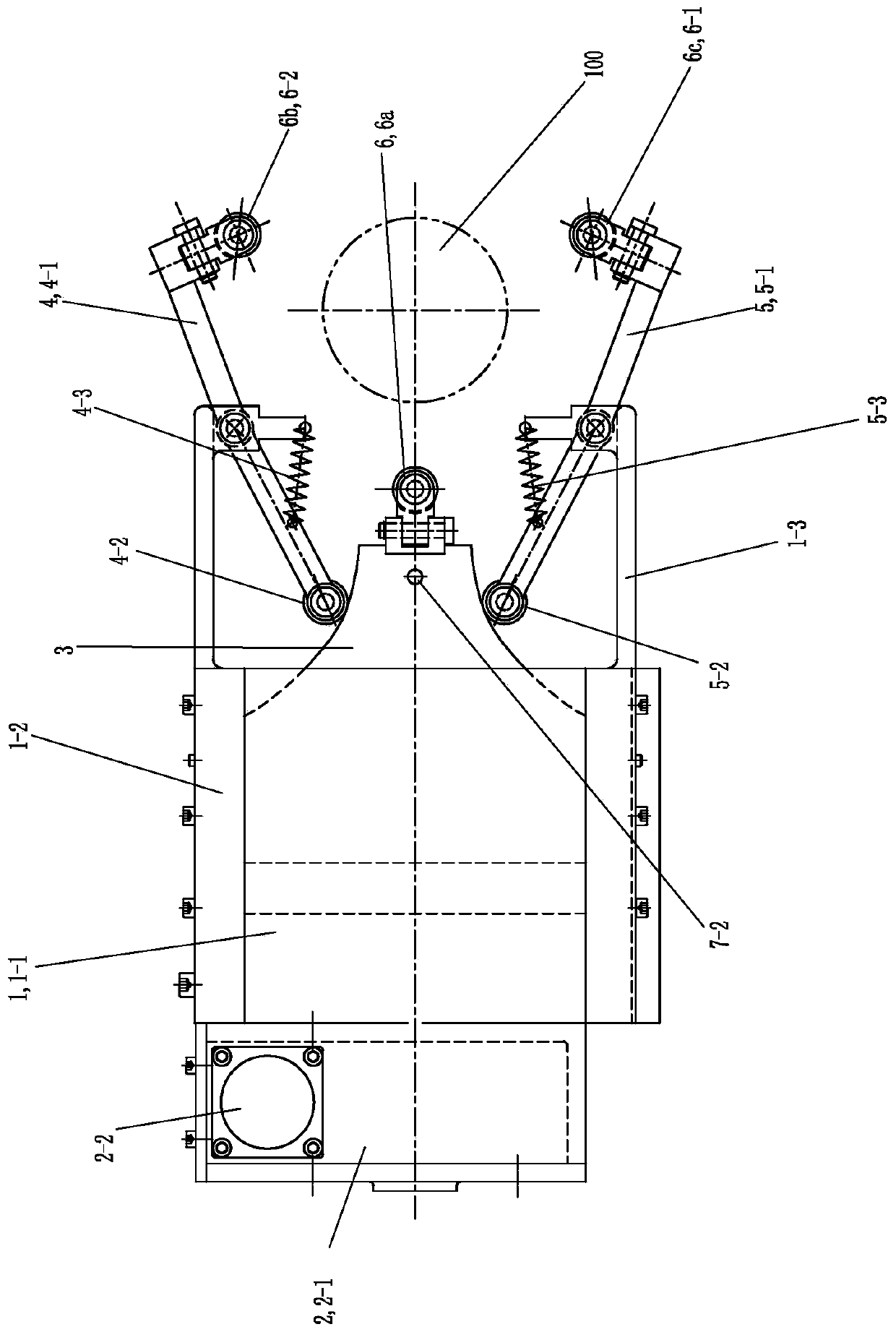

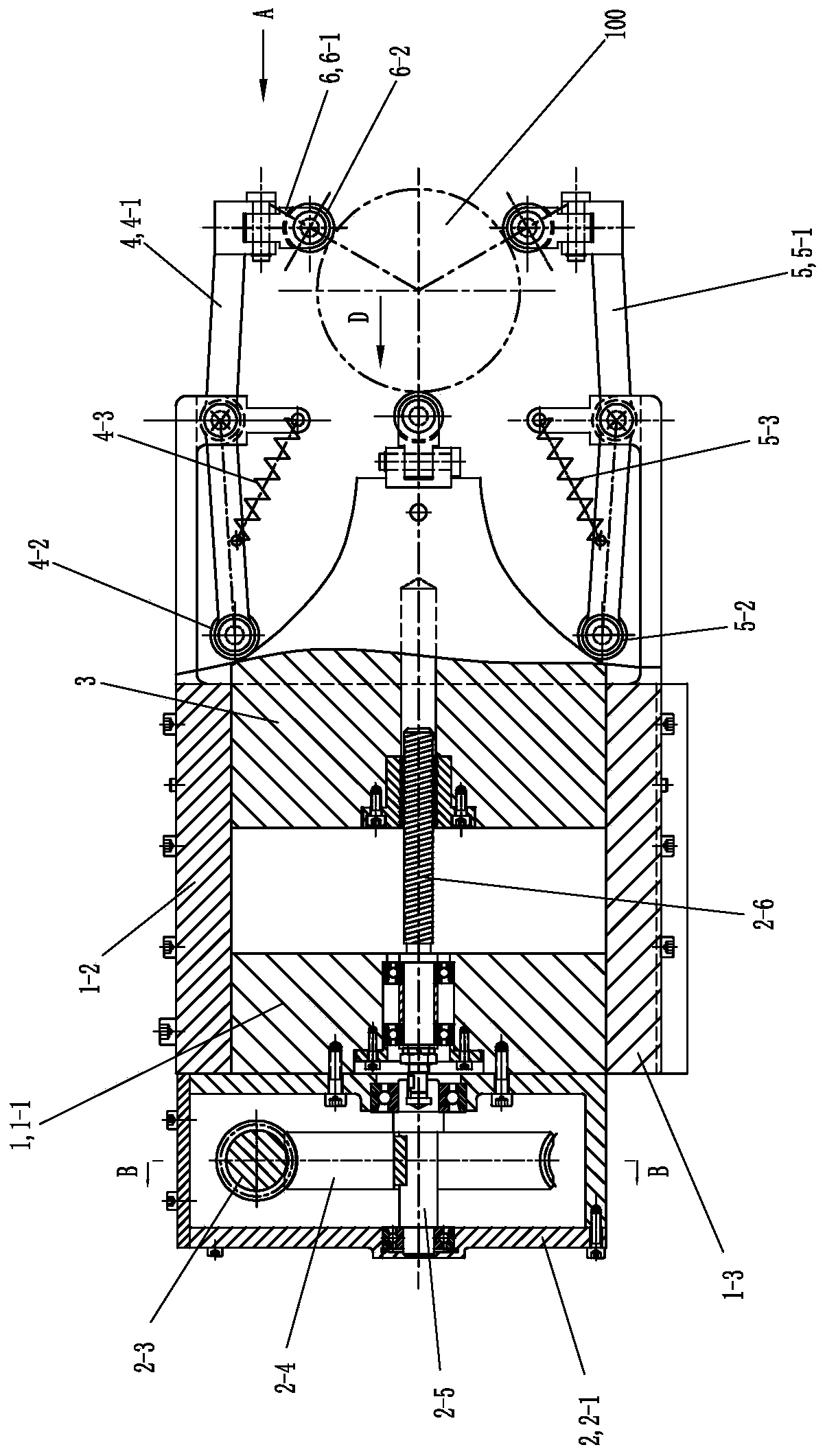

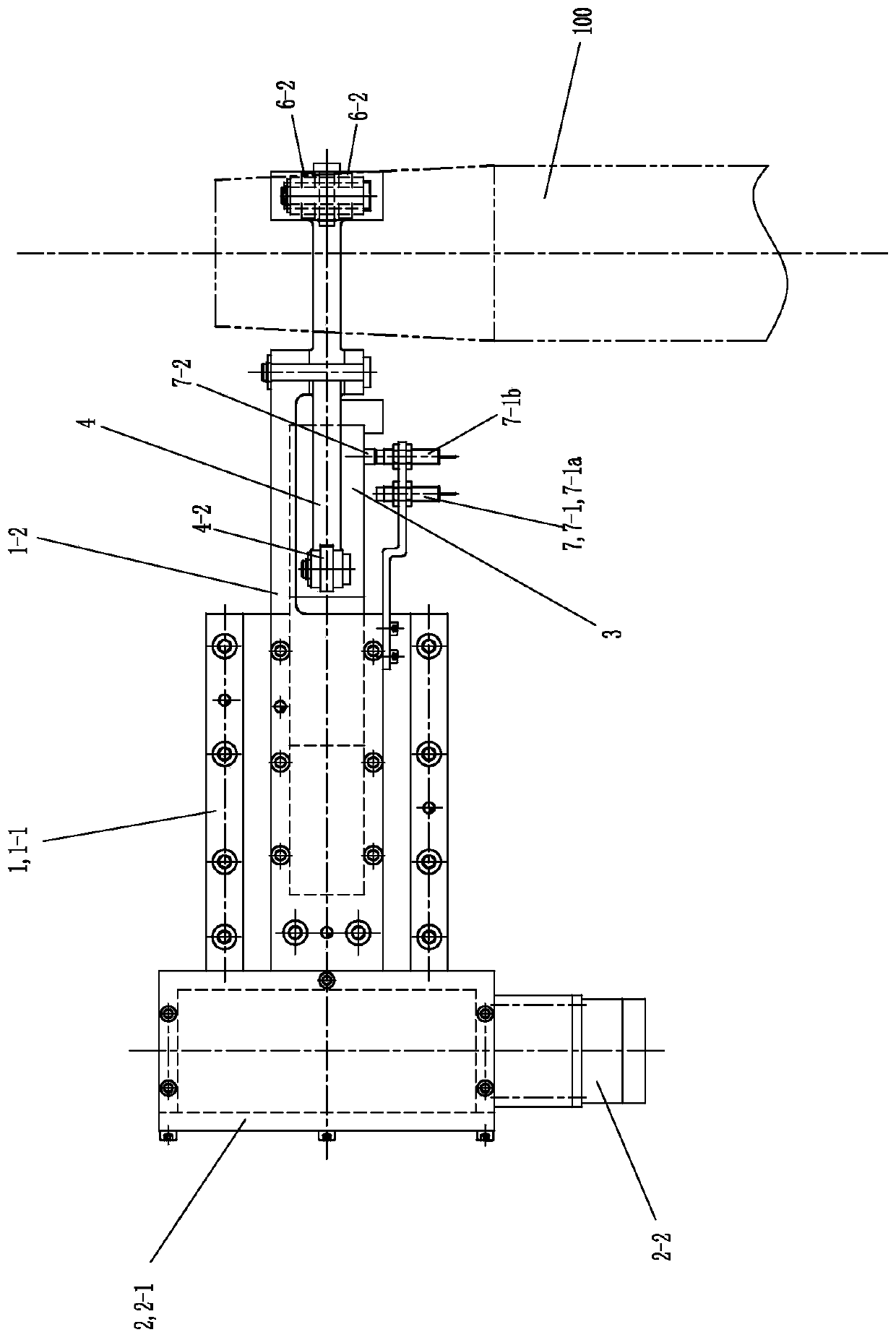

Rotary milling fixture device for machining guide vane of air compressor

ActiveCN102922313BGuaranteed clamping accuracyImprove processing rigidityPositioning apparatusMetal-working holdersGas compressorInstability

The invention provides a rotary milling fixture device for machining a guide vane of an air compressor, which can be used to solve the problems of poor generality, poor vane machining rigidity and machining size instability existing in the traditional guide vane clamping mechanism. The rotary milling fixture device is characterized by comprising a big-head-end three-jaw chuck and a small-head-end three-jaw chuck, wherein the big-head-end three-jaw chuck is connected with a main driving disk of a machine tool by a first transition disk, the small-head-head three-jaw chuck is connected with a tip of the machine tool by a second transition disk, a big head end and a small head end of the guide vane to be machined are respectively positioned and clamped by the big-head-end three-jaw chuck and the-small head-end three-jaw chuck, and a small head end part of the guide vane to be processed is tightly jacked up by the tip of the machine tool.

Owner:WUXI TURBINE BLADE

Automatic centering center frame

InactiveCN108481018BSimple structureEasy to install and disassemble the workpieceLarge fixed membersGrinding work supportsEdge surfaceCam

The invention discloses an automatic alignment center rack. The automatic alignment center rack is characterized by comprising a machine box, a driving device, a translation cam, an upper pressing rodcomponent, a lower pressing rod component and pressing head components, the translation cam is arranged inside the machine box in a left and right sliding manner and is driven by the driving device to move left and right, an upper pressing rod on the upper pressing rod component and a lower pressing rod are made to swing by the translation cam to make the pressing head components located on the upper pressing rod and the lower pressing rod and the pressing head component on the translation cam be simultaneously closed to the axis of a workpiece to be machined, so that the workpiece to be machined is supported, wheel support racks of the pressing head components automatically rotate according to the shape of the outer edge surface of the workpiece to be machined, and two support wheels ofeach wheel support rack are guaranteed to be pressed tightly against the workpiece to be machined simultaneously.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

A Gantry Mobile Machine Tool with Multiple Independent Processing Units

InactiveCN103264288BReduce shockExtended service lifeLarge fixed membersEngineeringDegrees of freedom

Owner:TSINGHUA UNIV

CK46 inclined rail numerical control lathe of integral casting lathe bed

PendingCN111195734ACompact structureSimple force calculationAutomatic/semiautomatic turning machinesNumerical controlStructural engineering

The invention discloses a CK46 inclined rail numerical control lathe of an integral casting lathe bed. The lathe bed, a drive shell, a transmission mechanism, a machine body shell, a protection mechanism and a control mechanism are included. The drive shell is fixedly arranged at one end of the top of the lathe bed. The position, located on one side of the drive shell, of the top of the lathe bedis fixedly provided with the transmission mechanism. The CK46 inclined rail numerical control lathe is compact in structure, simple and convenient to operate and high in practicability. A bridge typemain shaft is arranged, the 45-degree inclined lathe bed is adopted while 45 degrees are the rigidity and stress balance gold degree, so that stress calculation is simple, scrap discharging is convenient, and tool arranging is smooth; meanwhile, the X-axis stroke can reach one meter, the Z-axis stroke can reach 380 mm, a hiwin RGW35 roller guide rail is adopted in a transmission guide rail, a Yaskawa 7-series bus servo motor is matched, and the machining effect can be played perfectly in software and hardware configuration; and in addition, a resin sand integral casting base is adopted, compared with a traditional welding base, the anti-shock performance is improved, the machining rigidity is enhanced, and form and location tolerance is guaranteed to the maximum degree.

Owner:中山市精端数控设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com