A Gantry Mobile Machine Tool with Multiple Independent Processing Units

A mobile, machine tool technology, used in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of no independent full degree of freedom, serious energy consumption, insufficient stiffness, etc., to improve flexibility and processing efficiency. , The effect of ensuring machining accuracy and improving machining rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

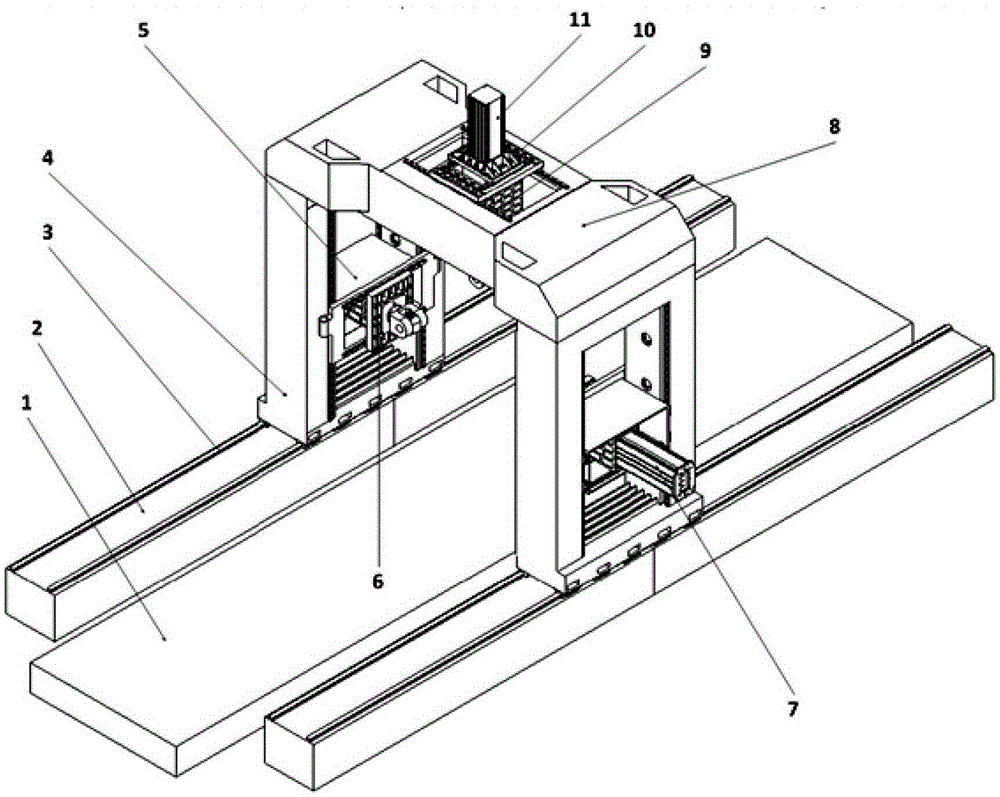

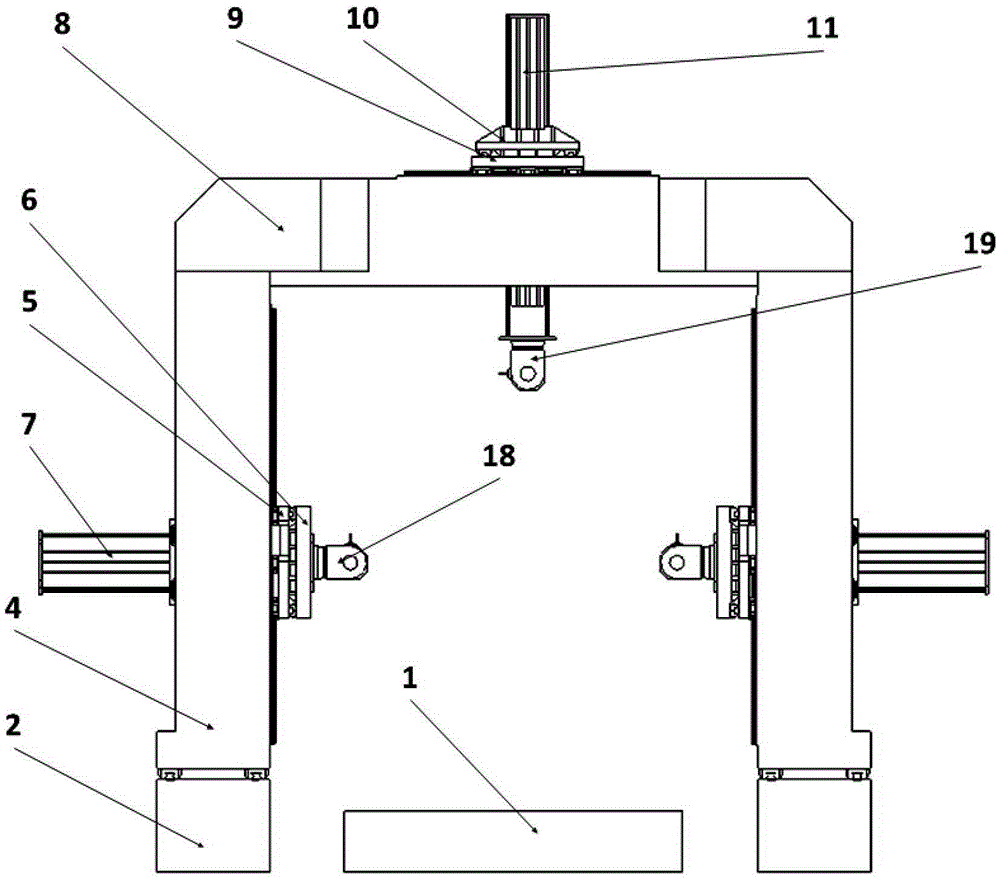

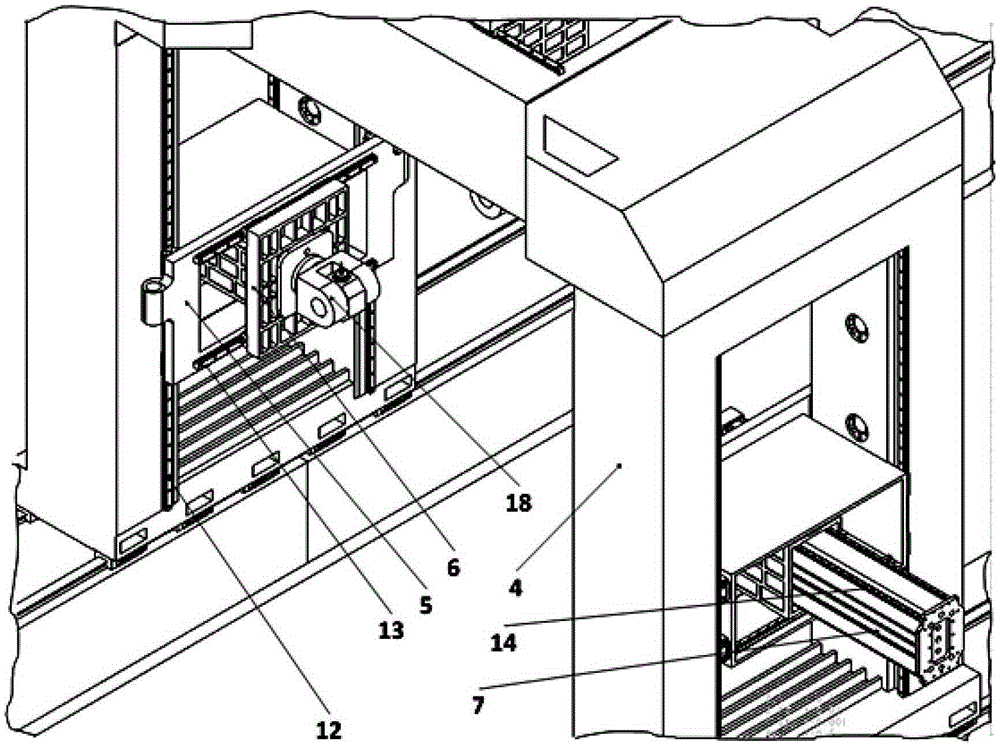

[0011] A kind of gantry mobile machine tool with multiple independent processing units proposed by the present invention, its structure is as follows figure 1 , 2 , 3 and 4, including workbench 1, machine bed 2, column 4, beam 8, column processing head 18 and beam processing head 19. The workbench 1 is placed in the middle of the machine bed 2, the columns 4 are installed on the column guide rails 3 on both sides of the bed, and the beams 8 are installed on the columns 4 on both sides of the machine bed 1. The middle of the column 4 on both sides of the machine tool bed 2 is respectively provided with a through frame. The outer sliding seat 5 of each column is nested in the through frame, the inner sliding seat 6 of each column is nested in the inner cavity of the outer sliding seat 5 of each column, and the column rams 7 on both sides of the machine bed 2 are respectively nested in the column In the inner cavity of the sliding seat 6 , the column processing heads 18 on both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com