High-rigidity double-spindle vertical machining center

A vertical machining center and dual-spindle technology, which is applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of increasing labor intensity of workers, weak rigidity, and large footprint of machining centers, and achieve reduction Spindle overhang, reduce Z-direction overhang, reduce the effect of Z-direction travel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

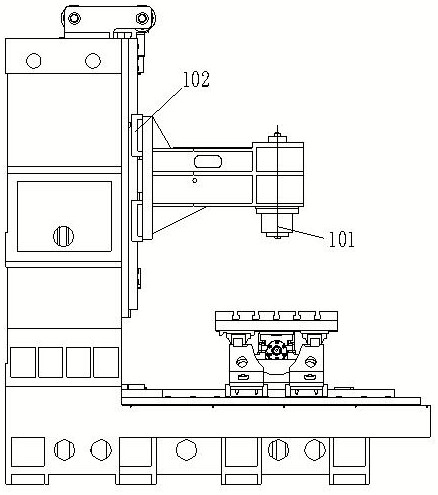

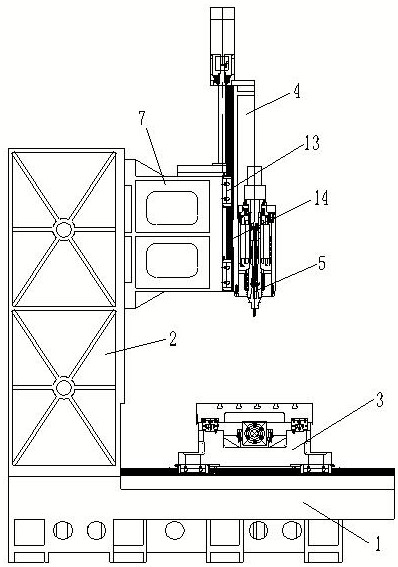

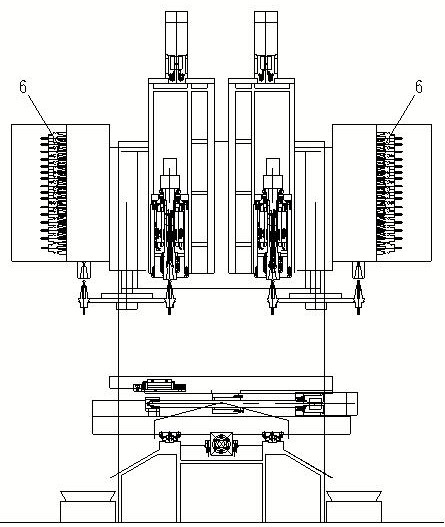

[0017] refer to figure 2 , 3 In the first embodiment shown, in this embodiment, the spindle unit adopts a short-nose electric spindle unit (5), and the tool magazine adopts a rotating arm manipulator type disc tool magazine (6). refer to Figure 4 There are two T-shaped slots (11) parallel to the axis of the main shaft and a set of matrix positioning pin holes (8) on the mounting surface of the column (2) and the upper and lower adjustment seats (7); the upper and lower adjustment seats (7) The matrix positioning pin holes (8) on the column (2) corresponding to the mounting surface of the column (2) are also processed with a set of matrix positioning pin holes 2 (9); the installation of the upper and lower adjustment seats (7) and the column (2) The surface corresponds to the T-shaped groove (11) on the column (2) and is also correspondingly processed with screw mounting holes (12).

[0018] refer to figure 2 , 3 . In the first embodiment shown in 4, the column (2) is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com