Double-bearing positioning fixture

A technology of positioning fixtures and double bearings, which is applied in the direction of manufacturing tools, grinding workpiece supports, grinding machines, etc., can solve the problems of low alignment efficiency, high failure rate, and complex hydraulic structure, and achieve a high degree of automation and simplify the structure of the fixture , The effect of high processing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

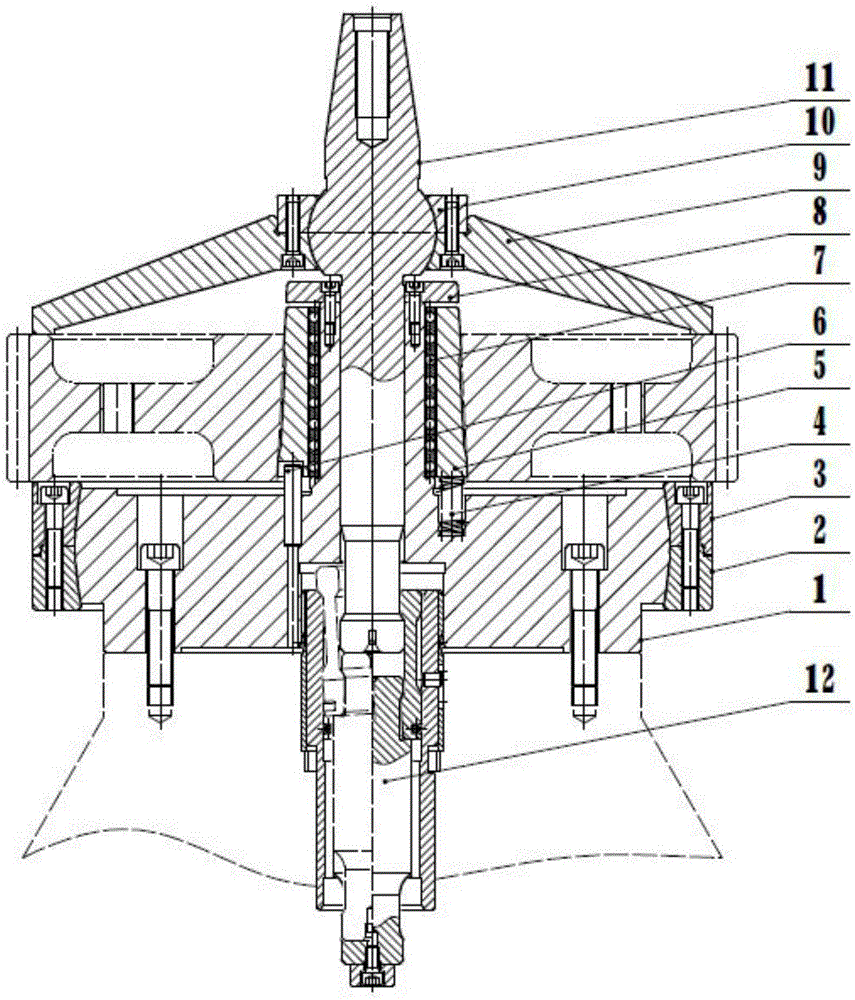

[0014] A double-bearing positioning fixture, including a clamp body 1, a first supporting joint bearing 2, a second supporting joint bearing 3, a taper sleeve 5, a ball bearing 7, a gland 9, a compression joint bearing 10, a mandrel 11, and a taper sleeve 5. The ball bearing 7 is arranged on the clamp body 1. The first support joint bearing 2 and the second support joint bearing 3 are arranged up and down opposite to each other to form the outer ring of the support joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com