Numerical control curved-tooth broaching machine

A technology of arc gear broaching machine and machine tool, which is applied in the direction of gear cutting machine, gear tooth manufacturing device, gear teeth, etc., which can solve the problem of high failure rate, difficulty in effectively guaranteeing the repeatability and rigidity of gear machining, and complicated machining operation and adjustment of machine tools and other problems, to achieve the effect of high machining accuracy and rigidity, simple machining operation and adjustment of machine tools, and enhanced precision and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order for those skilled in the art to further understand the features and technical contents of the present invention, please refer to the following detailed description and accompanying drawings of the present invention.

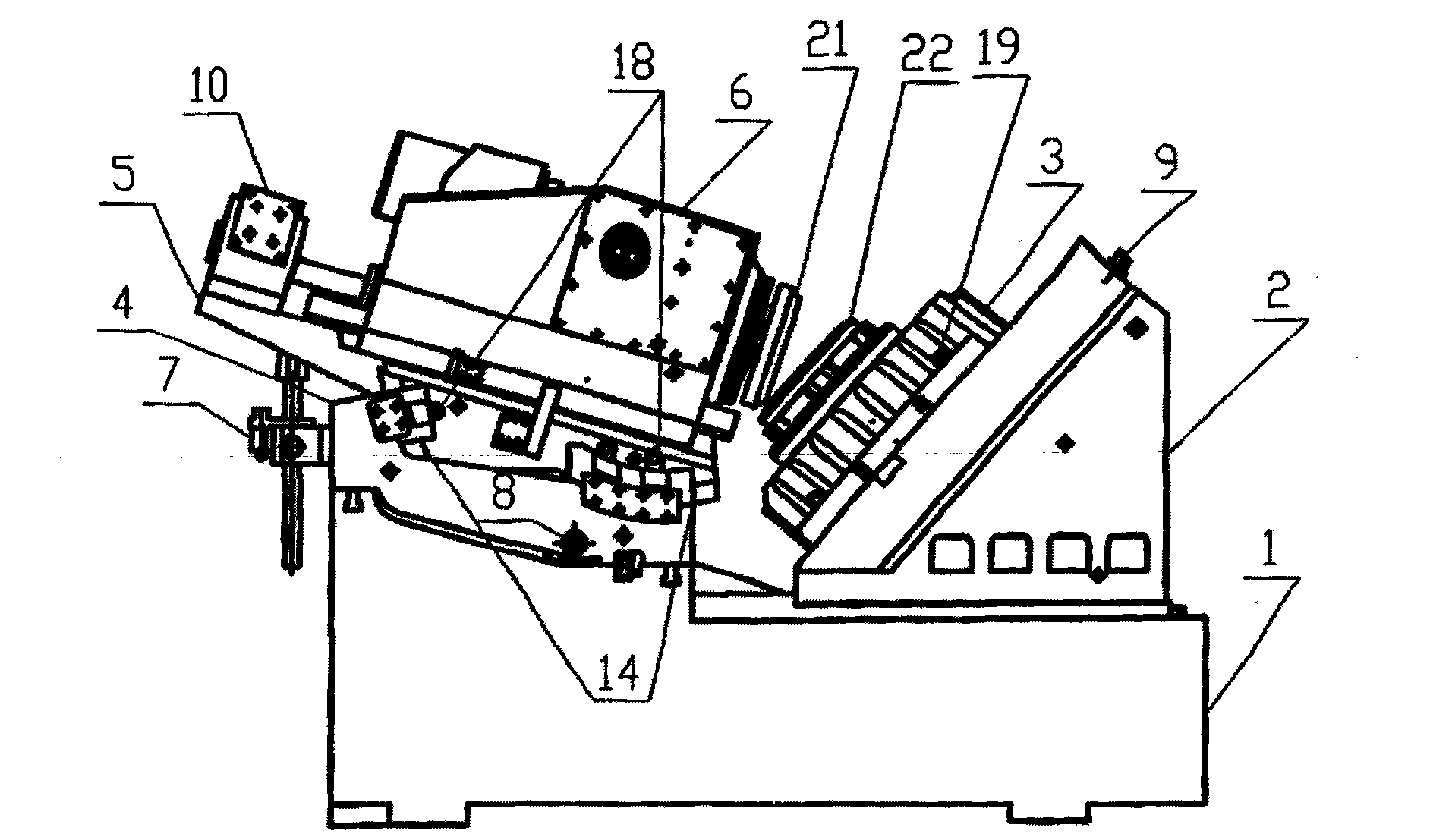

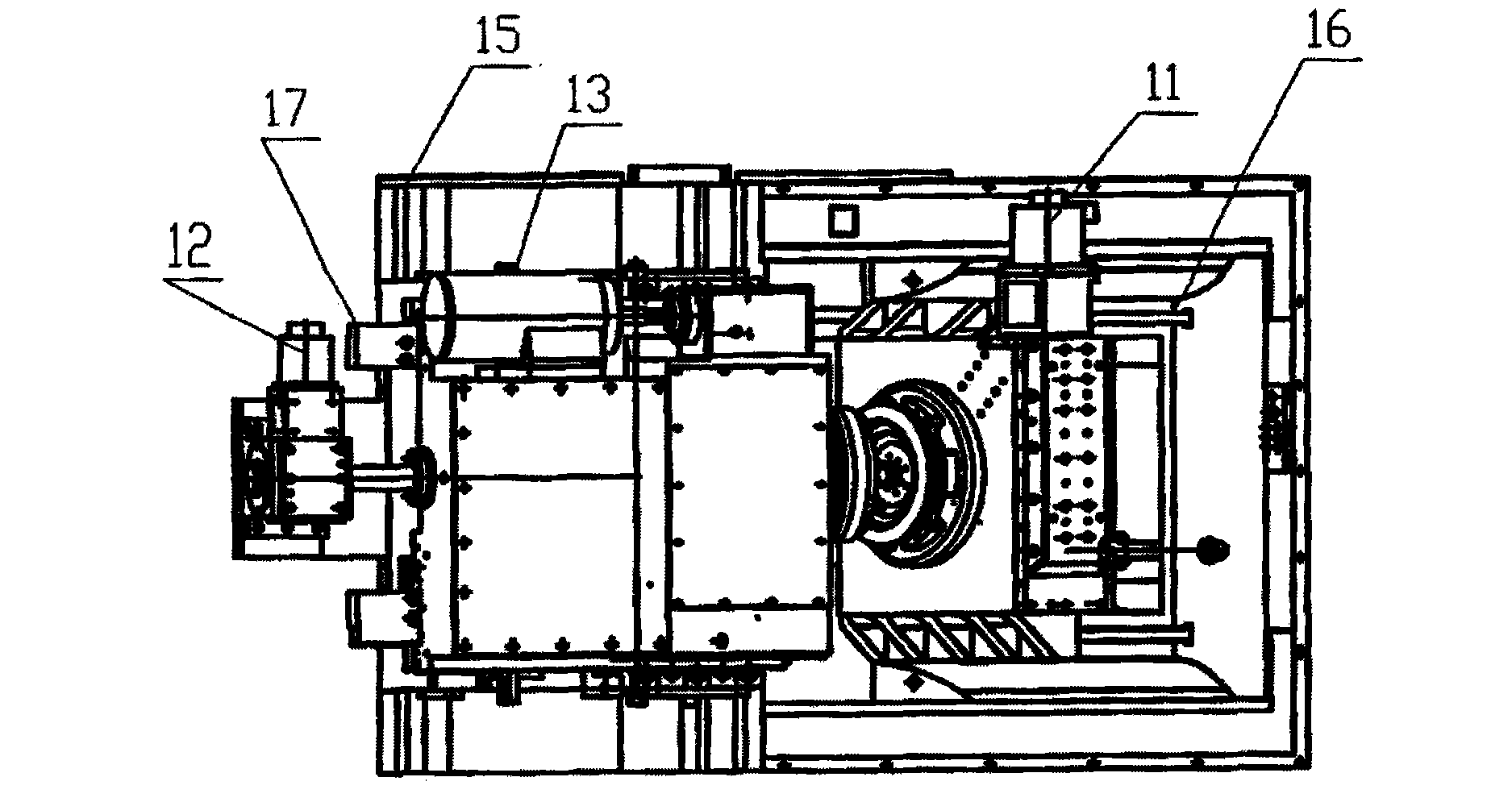

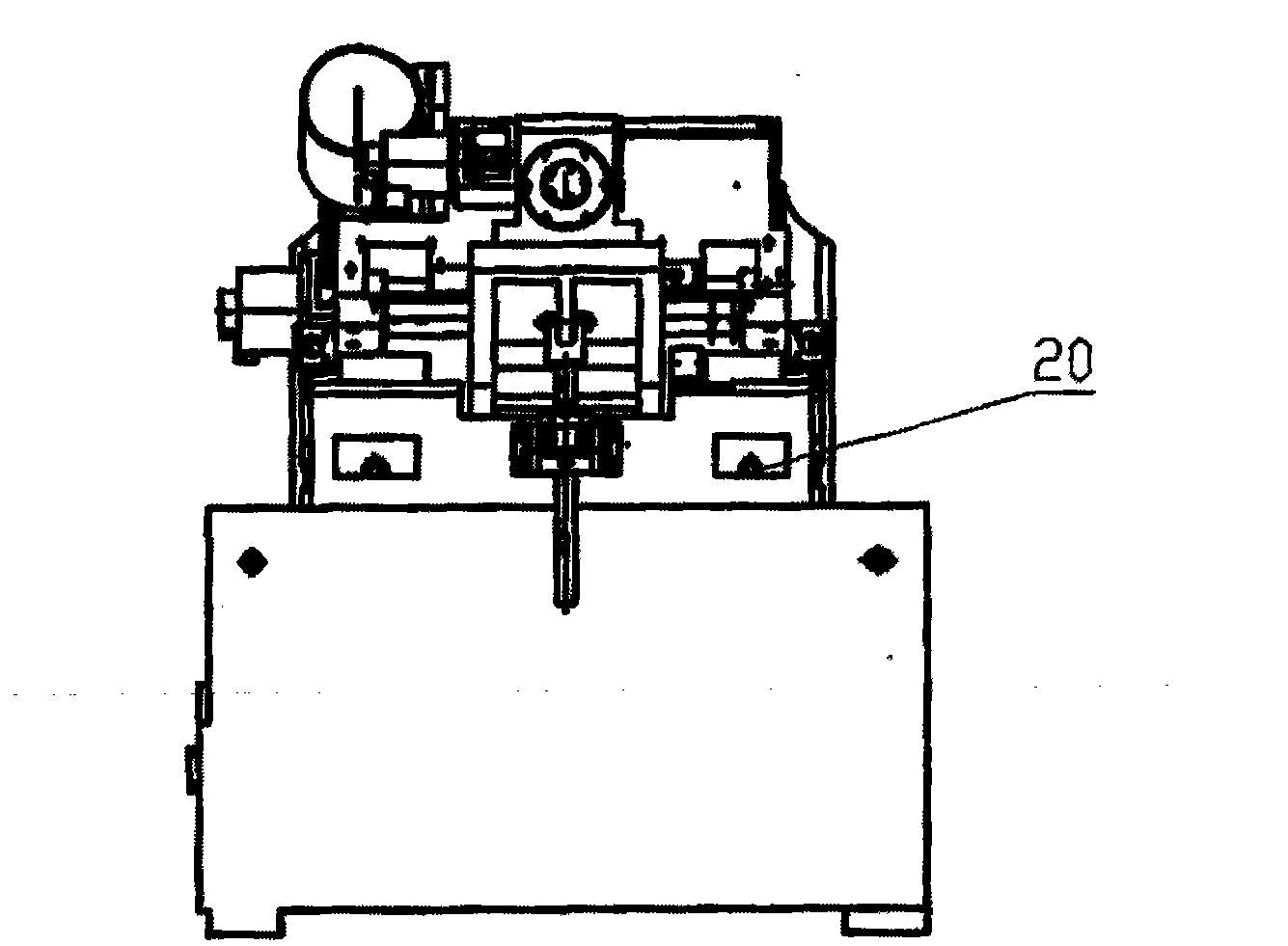

[0024] see Figure 1 to Figure 3 As shown, the present invention provides a numerically controlled arc tooth broaching machine, which includes a gear broaching machine body having a machine tool base 1, a tool box assembly, a workpiece box assembly, a numerical control device, a lubricating cooling device and a chip removal device, The tool box assembly and the workpiece box assembly are located on the machine base, and the tool box assembly has a cutter head head box 6, a cutter head 21, a cutter head spindle motor 13, a Z-axis reducer 10, a Z Axis servo motor 12, Z-axis cutter head advance and retreat guide rail 17, horizontal tool position guide rail 15, horizontal tool position regulator 8, horizontal tool position locking device 20, the workp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com