Machining method for automotive downhill reducer control levers

A technology of downhill reducer and processing method, which is applied in vehicle parts, transportation and packaging, etc., can solve the problems of poor wear resistance and corrosion resistance, unstable parts quality, high processing cost, etc., and achieve high cost performance and easy Operation, the effect of reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

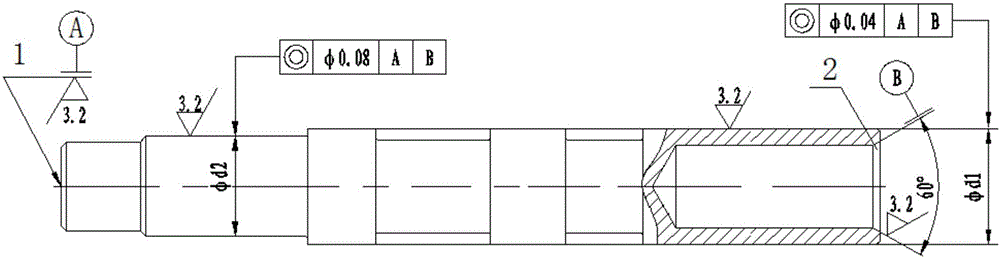

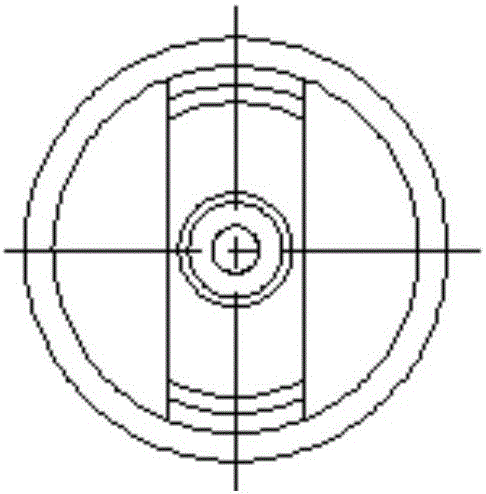

[0061] Such as figure 1 As shown, the process hole of the present invention includes a central hole 1 and an inner hole conical surface 2, the central hole 1 is designed as a B 3.15 / 10 central hole, and the cone angle of the inner hole conical surface 2 is designed as a 60° inner hole cone On the other hand, when the process hole is finishing the outer circle of the part, it needs to use abrasive sand to study the center hole, so as to ensure the shape and position tolerance requirements of the outer circle surface, so as to ensure the assembly requirements of the downhill deceleration control rod and the valve hole.

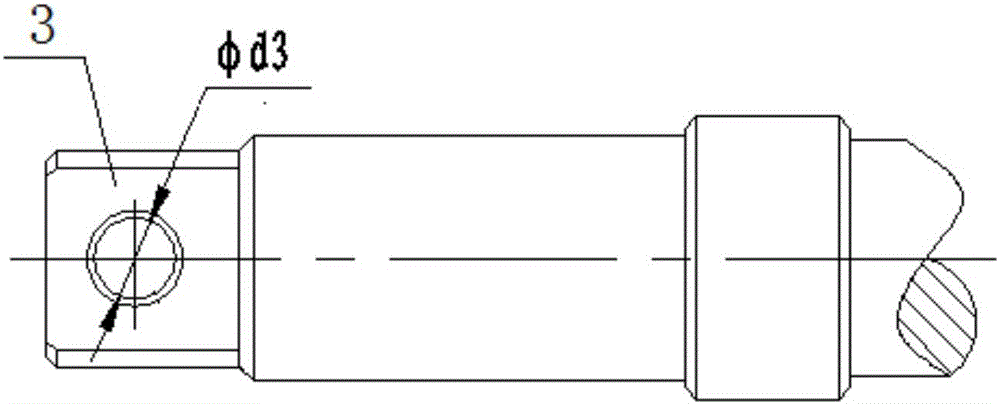

[0062] Using upper process hole B 3.15 / 10 and 60° inner hole conical surface to process as Figure 6 The method for the control rod of the downhill reducer is shown, and its specific processing method steps are as follows:

[0063] (1) Material preparation: choose bar material 20CrMnTi as the blank, and the blanking size is φD×Lmm;

[0064] (2) Heat treatment:...

Embodiment 2

[0080] Such as figure 1 As shown, the process hole of the present invention includes a central hole 1 and an inner hole conical surface 2, the central hole 1 is designed as a B 3.15 / 10 central hole, and the cone angle of the inner hole conical surface 2 is designed as a 60° inner hole cone On the surface, the process hole needs to use abrasive sand to study the center hole when finishing the outer circle of the part, so as to ensure the shape and position tolerance requirements of the outer circle, so as to ensure the assembly requirements of the downhill deceleration control rod and the valve hole; the downhill The assembly gap between the reducer control rod and the valve hole is 0.045mm.

[0081] Using upper process hole B 3.15 / 10 and 60° inner hole conical surface to process as Figure 6 The method for controlling the valve stem of the downhill reducer shown, the specific processing steps are as follows:

[0082] (1) Material preparation: choose bar material 20CrMnTi as ...

Embodiment 3

[0099] Such as figure 1 As shown, the process hole of the present invention includes a central hole 1 and an inner hole conical surface 2, the central hole 1 is designed as a B 3.15 / 10 central hole, and the cone angle of the inner hole conical surface 2 is designed as a 60° inner hole cone On the surface, the process hole needs to use abrasive sand to study the center hole when finishing the outer circle of the part, so as to ensure the shape and position tolerance requirements of the outer circle, so as to ensure the assembly requirements of the downhill deceleration control rod and the valve hole; the downhill The assembly gap between the reducer control rod and the valve hole is 0.06mm.

[0100] Using upper process hole B 3.15 / 10 and 60° inner hole conical surface to process as Figure 6 The method for the control rod of the downhill reducer is shown, and its specific processing method steps are as follows:

[0101] (1) Material preparation: choose bar material 20CrMnTi a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circularity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com