Jig for gear shaping process of engine case

An engine casing and process technology, which is applied in the field of fixtures in the gear shaping process of the engine casing, can solve the problems of the engine casing being unable to be clamped and the rigidity is poor, and achieve the effects of improving processing rigidity, preventing deformation and improving clamping accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

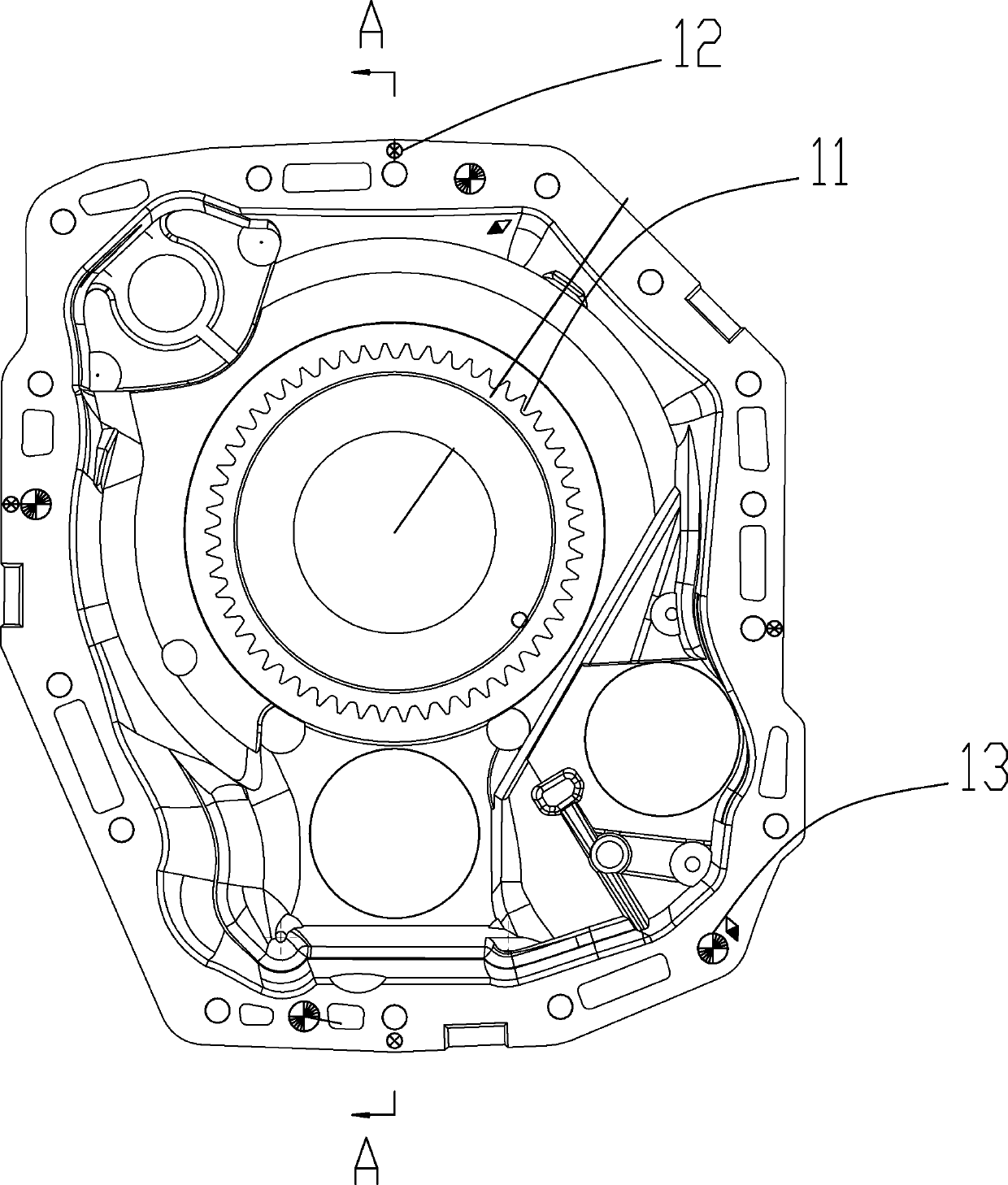

[0025] like Figure 3~6 Among them, the component housing 7 in the present invention is a thin-walled component with an irregularly shaped inner cavity 16 in the middle. An internal gear 11 is provided in the middle of the inner cavity 16, and stepped holes and reinforcing ribs are provided at the bottom of the part housing 7. The outer contour is irregular, it is difficult to locate and clamp, and the rigidity is poor, and it is easy to deform during processing. . A flange edge 14 is arranged on the top of the part housing 7, and a plurality of flange holes are arranged on the flange edge 14.

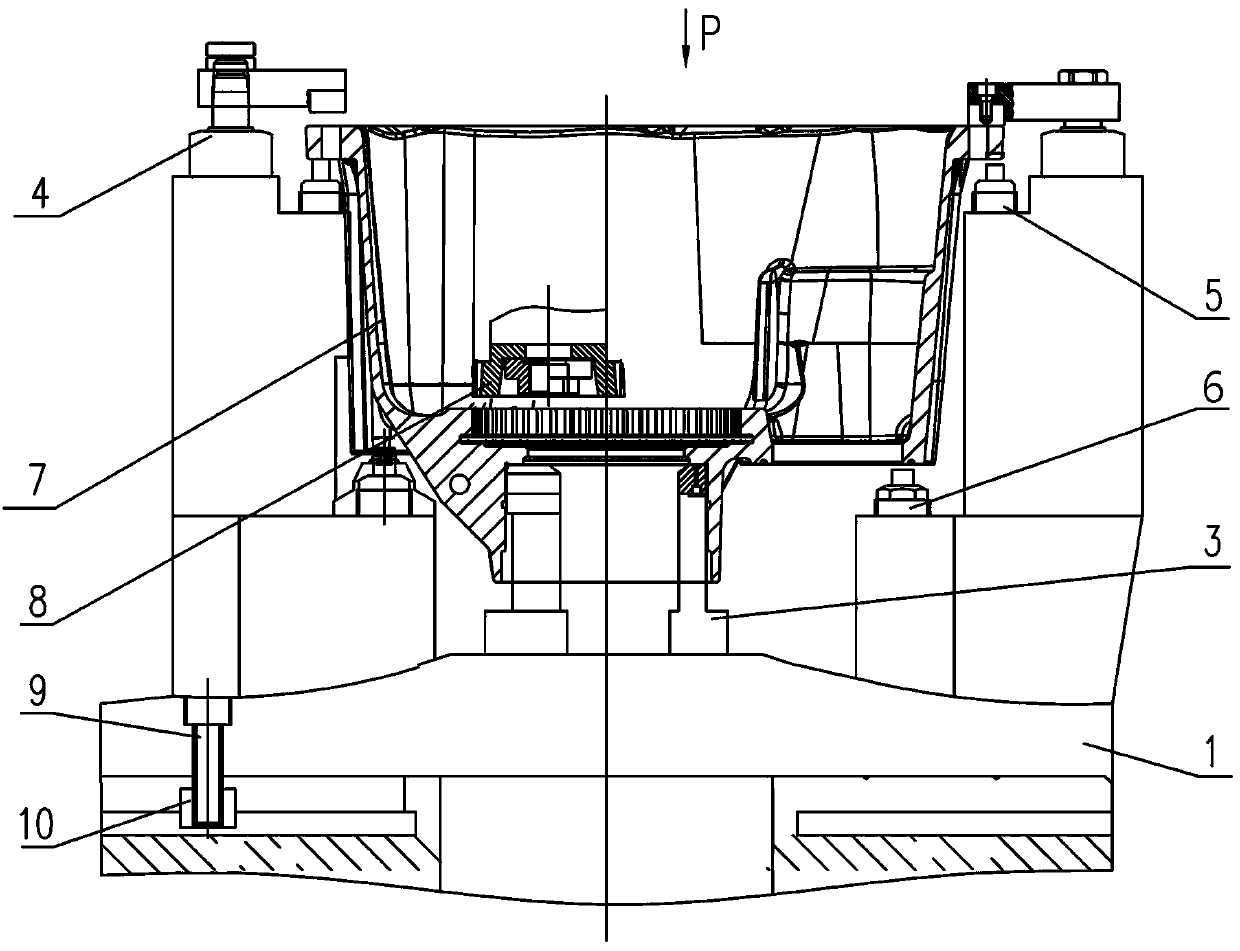

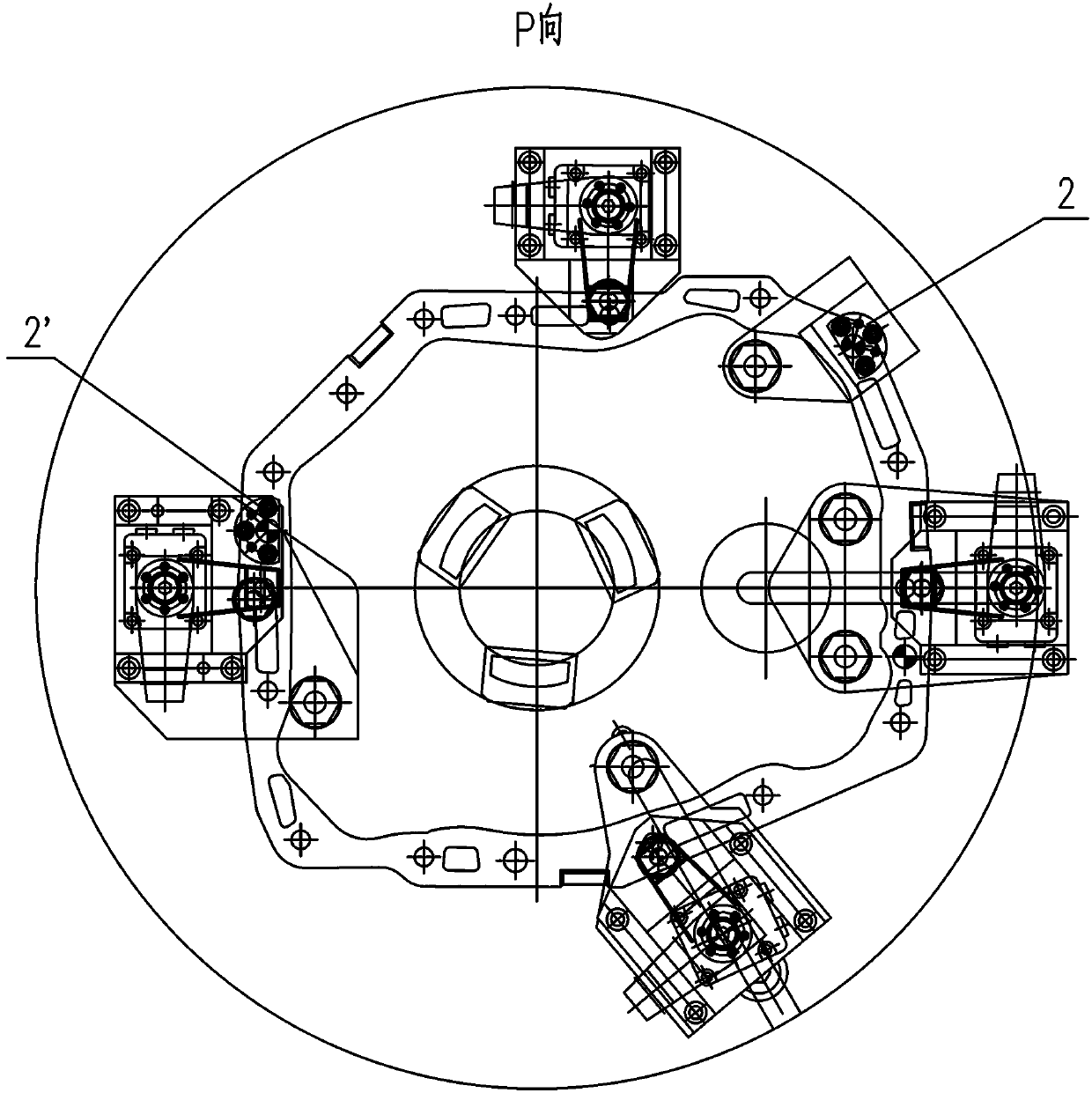

[0026] like figure 1 , 2 Among them, a jig for the gear-shaping process of an engine casing includes a jig body 1, and a plurality of support columns 3 for positioning a datum plane are provided on the jig body 1, preferably as figure 1 As shown in , the support column 3 locates the datum plane of the component housing 7 through the upper end surface, and the upper end surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com