Rotary milling fixture device for machining guide vane of air compressor

A fixture device and guide vane technology, applied in positioning devices, manufacturing tools, metal processing equipment and other directions, can solve the problems of poor blade processing rigidity, unstable processing dimensions, poor versatility, etc., to increase processing rigidity and ensure processing stability. , the effect of high versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

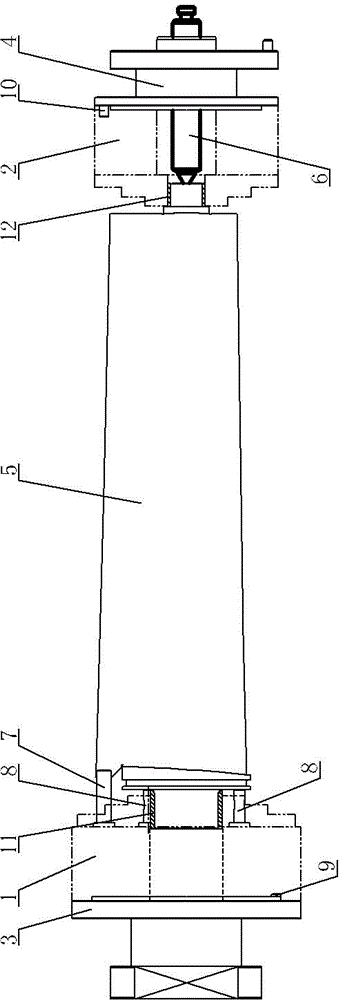

[0016] See figure 1 , the device of the present invention comprises a large-end three-jaw chuck 1 and a small-end three-jaw chuck 2, the large-end three-jaw chuck 1 is connected with the main drive disk of the machine tool through a first transition plate 3, and the small-end three-jaw chuck 2 The second transition plate 4 is connected to the top end of the machine tool 6. The large end and small end of the guide vane 5 to be processed are respectively positioned and clamped by the three-jaw chuck 1 at the large end and the three-jaw chuck 2 at the small end. The small end of the blade 5 is pressed tightly by the top 6 of the machine tool. The blade connection end surface of the three-jaw chuck 1 at the big end is provided with a blade circumferential positioning pin 7 and a blade axial positioning pin 8; the three-jaw chuck connection end surface of the first transition plate 3 is also provided with a first chuck circumferential positioning pin 9. The top end of the machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com