Vacuum chuck for KDP crystalline material

A vacuum suction cup, crystal material technology, applied in suction cups, connecting components, mechanical equipment, etc., can solve the problems of low precision, high cost, low efficiency, etc., to ensure the accuracy of clamping and reduce the effect of processing residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

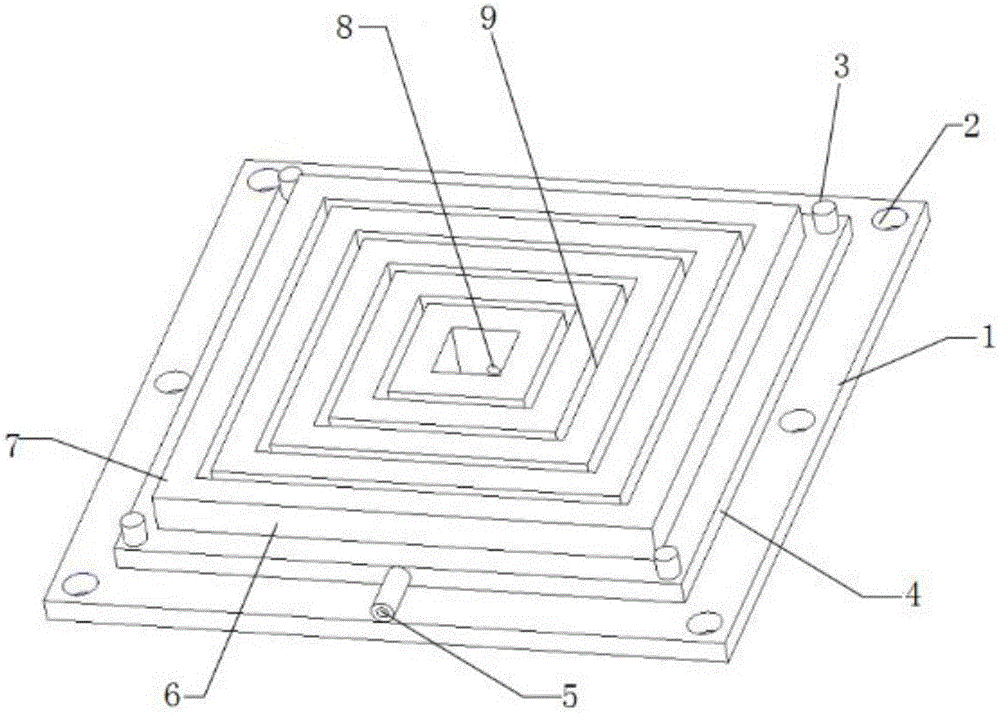

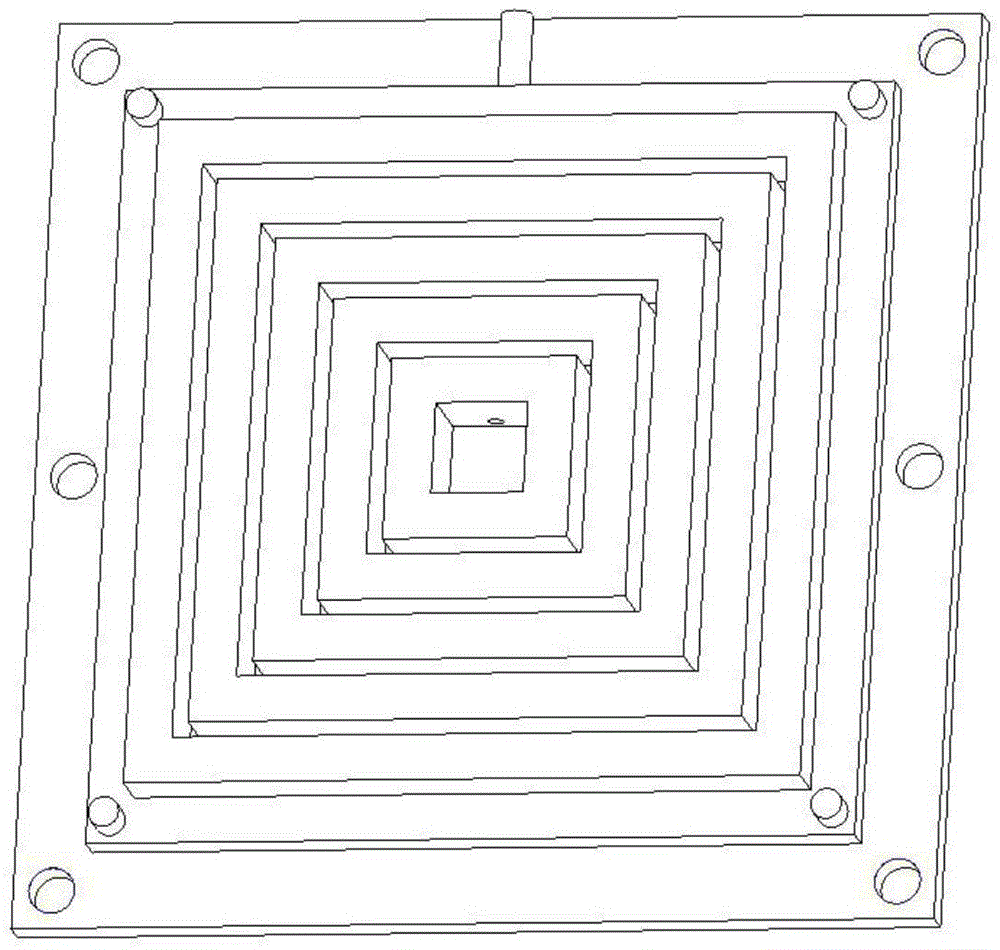

[0022] Such as Figure 1-2 As shown, when starting processing, first start the computer and electronic control system components, air pump and vacuum generator components, the vacuum chuck starts to have a certain suction force, and then fix it on the special vacuum chuck according to the size of the KDP crystal part to be cut. After adjusting the special arc-edge diamond tool and the initial processing distance with the KDP crystal part, the spindle motor starts to rotate, and the arc-edge diamond tool is driven by the special cutterhead connecting shaft, the special cutterhead and the special arc-edge diamond tool angle adjuster. The set working radius follows the high-speed rotation of the spindle motor. At the same time, the hydrostatic guide rail linear drive motor starts to work. The high flatness worktable and the hydrostatic guide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com