Forming and transmitting device of semi-steel radial tires

A radial tire and transfer device technology, applied in the field of semi-steel radial tire forming transfer device, can solve the problems of poor synchronization of the clamping device, low roundness, and many supporting clamping block toolings, etc., to ensure movement and ensure concentricity. , Increase the effect of adjustable opening and closing gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

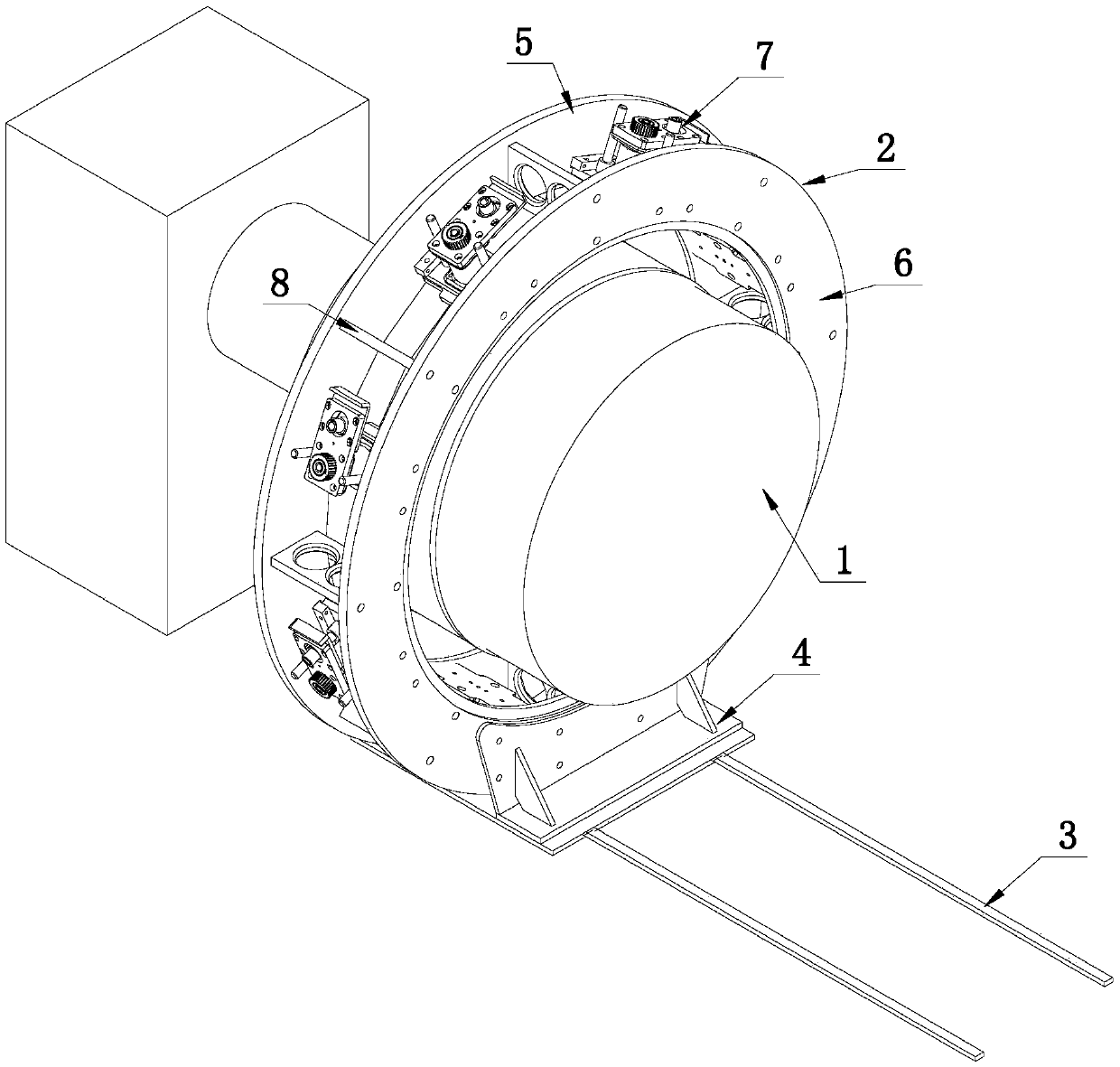

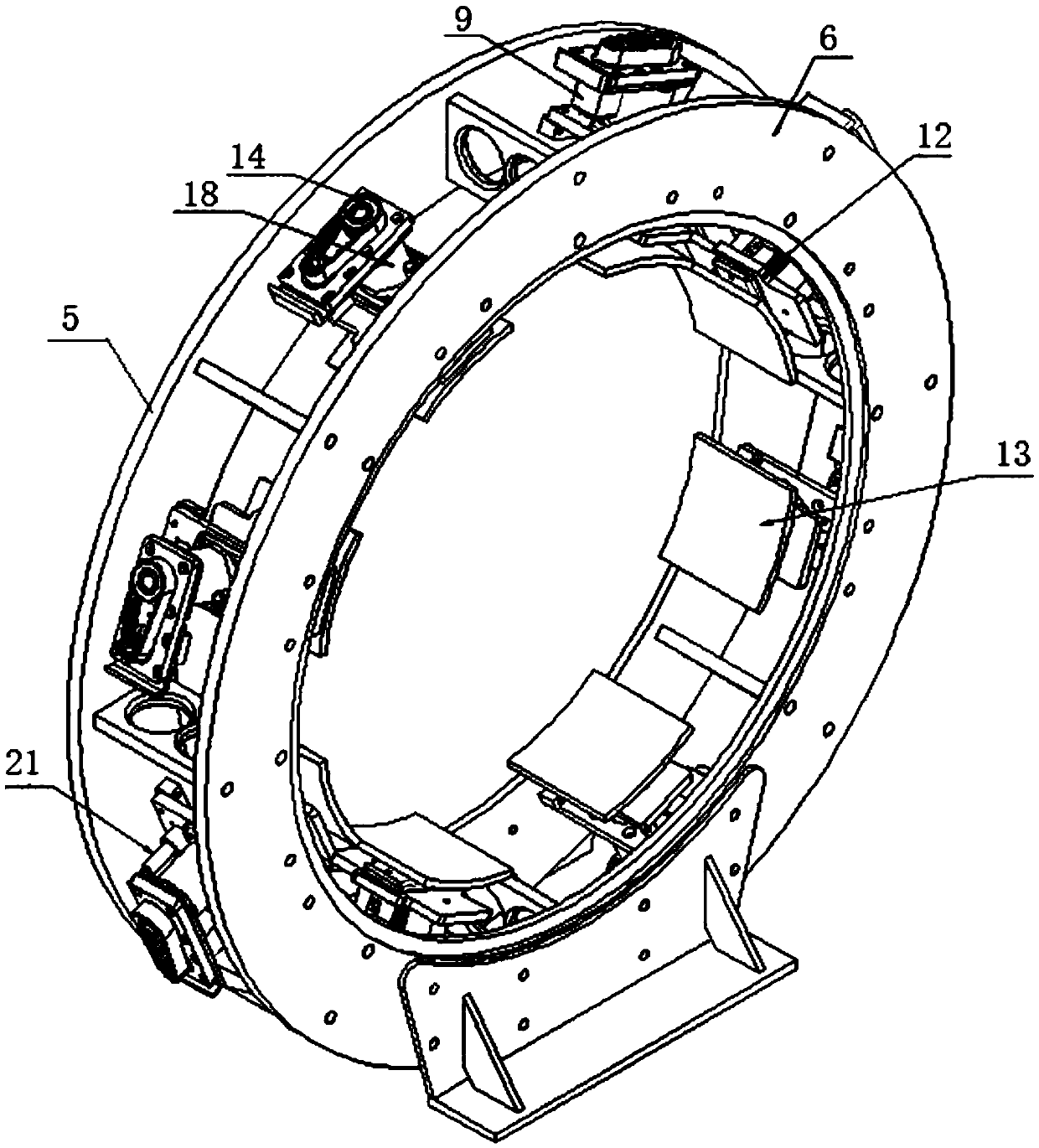

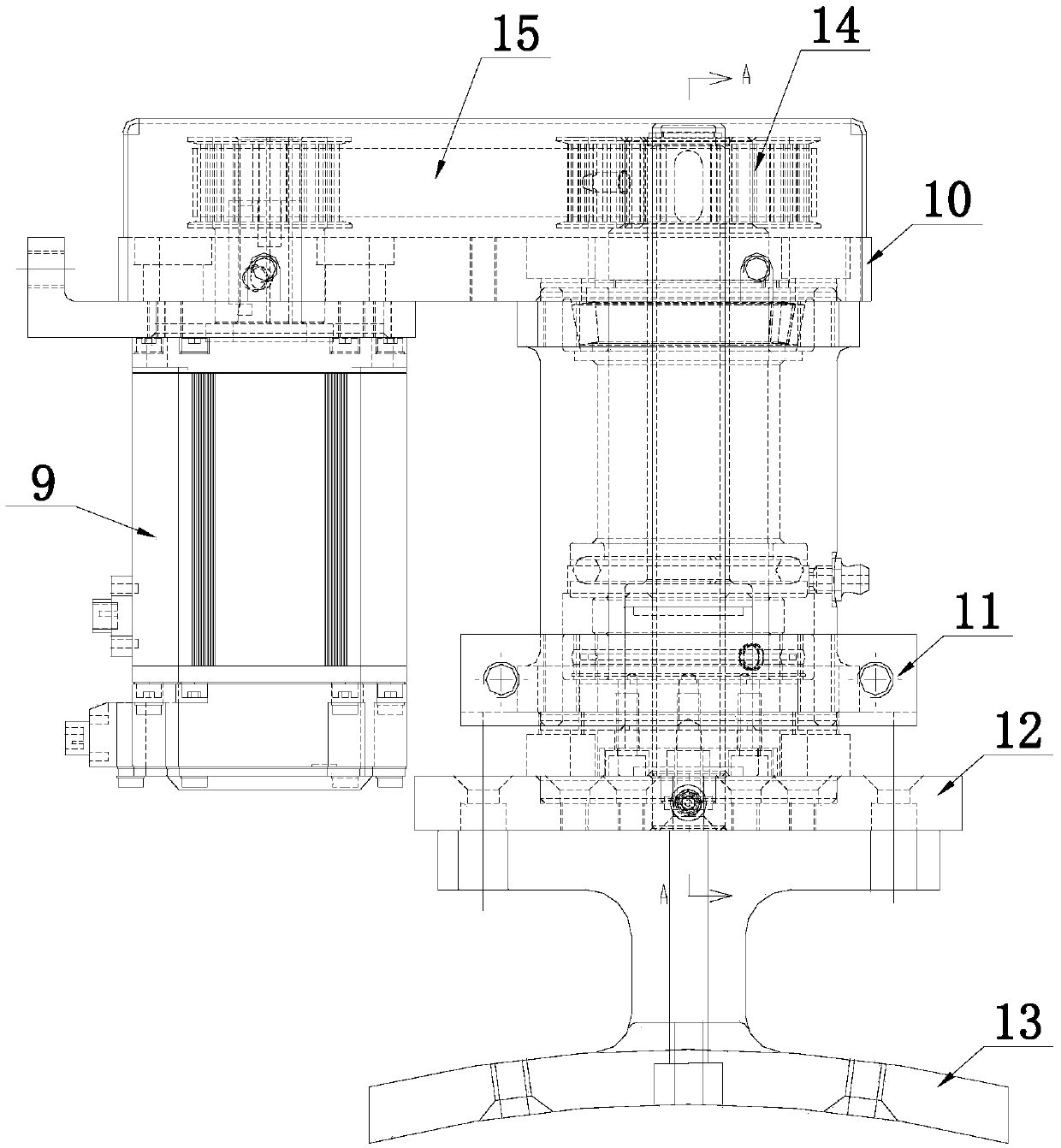

[0026] Such as figure 1 Shown is a semi-steel radial tire building transfer device, which includes a building drum device 1, a transfer ring device 2 and a track 3, the transfer ring device 2 is arranged on the outer ring of the building drum device 1, and the track 3 is laid on the ground. Such as figure 2 As shown, the transfer ring device 2 includes a base 4, a left wall panel 5, a right wall panel 6 and 8 sets of clamping devices 7, the base 4 is installed on the track 3 by setting guide rails, the left wall panel 5 and the right wall panel The bottom of the board 6 is fixedly arranged on the base 4, and an annular installation space is provided between the left wall board 5 and the right wall board 6, and a plurality of supporting boards 8 are arranged to connect with each other, and the supporting boards 8 are provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com