CK46 inclined rail numerical control lathe of integral casting lathe bed

An integral casting, CNC lathe technology, applied in the field of CNC lathes, can solve the problems of troublesome force calculation, inability to achieve precision, weak seismic performance, etc., and achieves the effect of compact structure, easy installation of tools, and improved seismic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

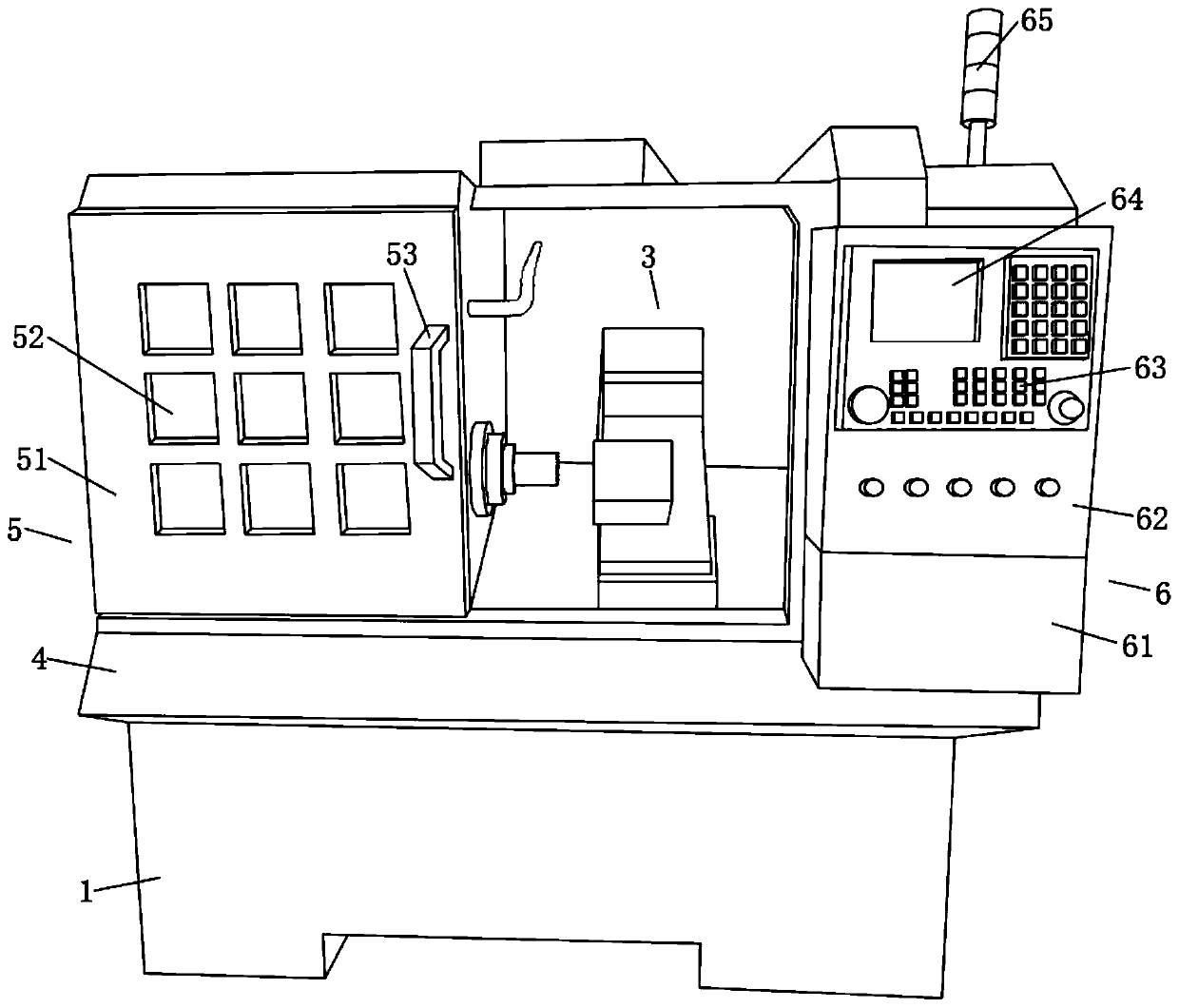

[0023] The CK46 inclined track CNC lathe with integral casting bed includes bed 1, drive shell 2, transmission mechanism 3, machine body shell 4, protection mechanism 5 and control mechanism 6, and the top end of bed 1 is fixed with drive shell 2. A transmission mechanism 3 is fixedly installed on the top of the bed 1 and on one side of the drive housing 2. The top of the bed 1 and on the outside of the drive housing 2 and the transmission mechanism 3 are fixedly connected to the organic housing 4, and one end of the outer side of the machine housing 4 is provided with a protective cover. As for the mechanism 5, a control mechanism 6 is fixedly installed on the outer side of the body shell 4 away from the protection mechanism 5.

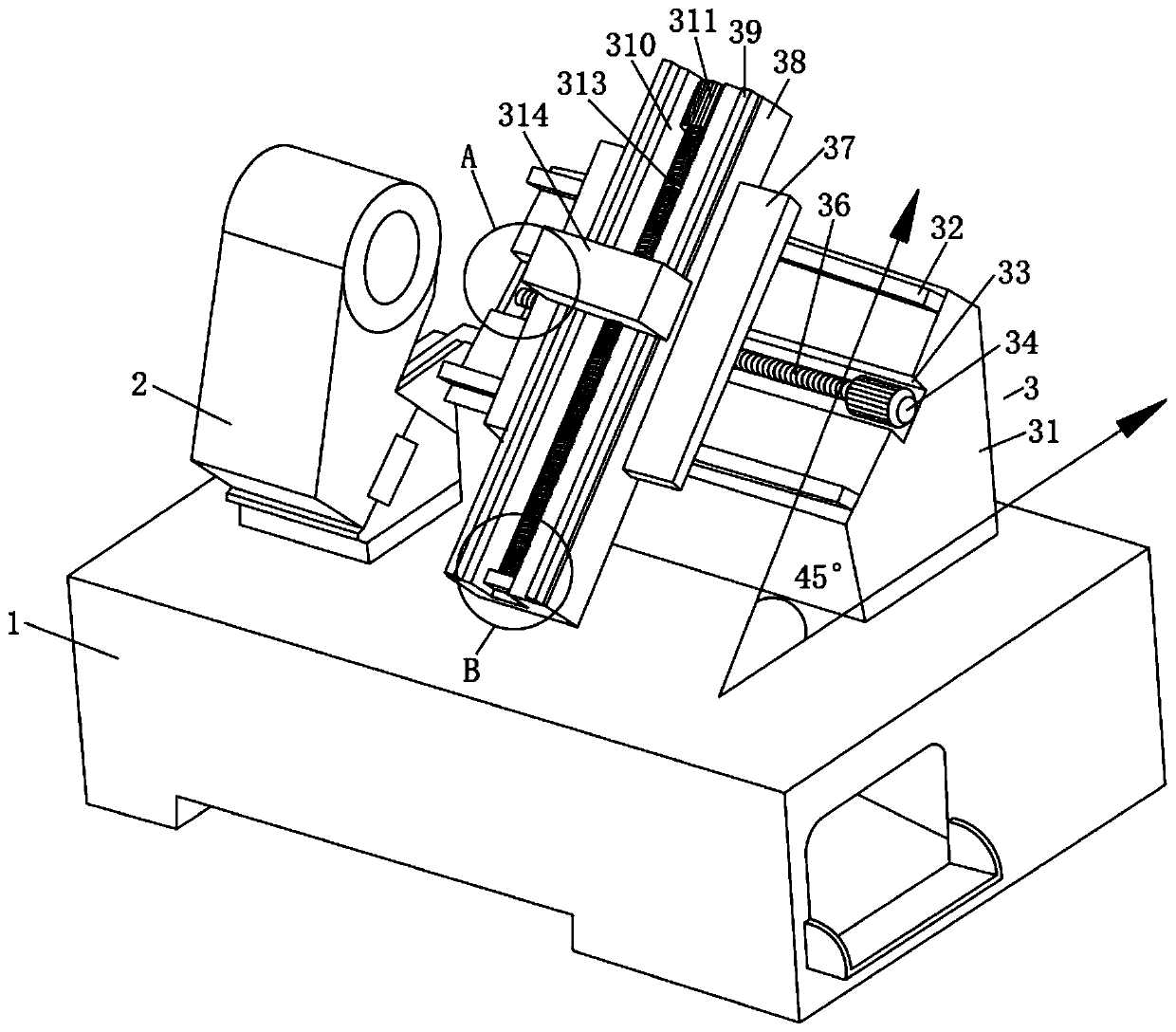

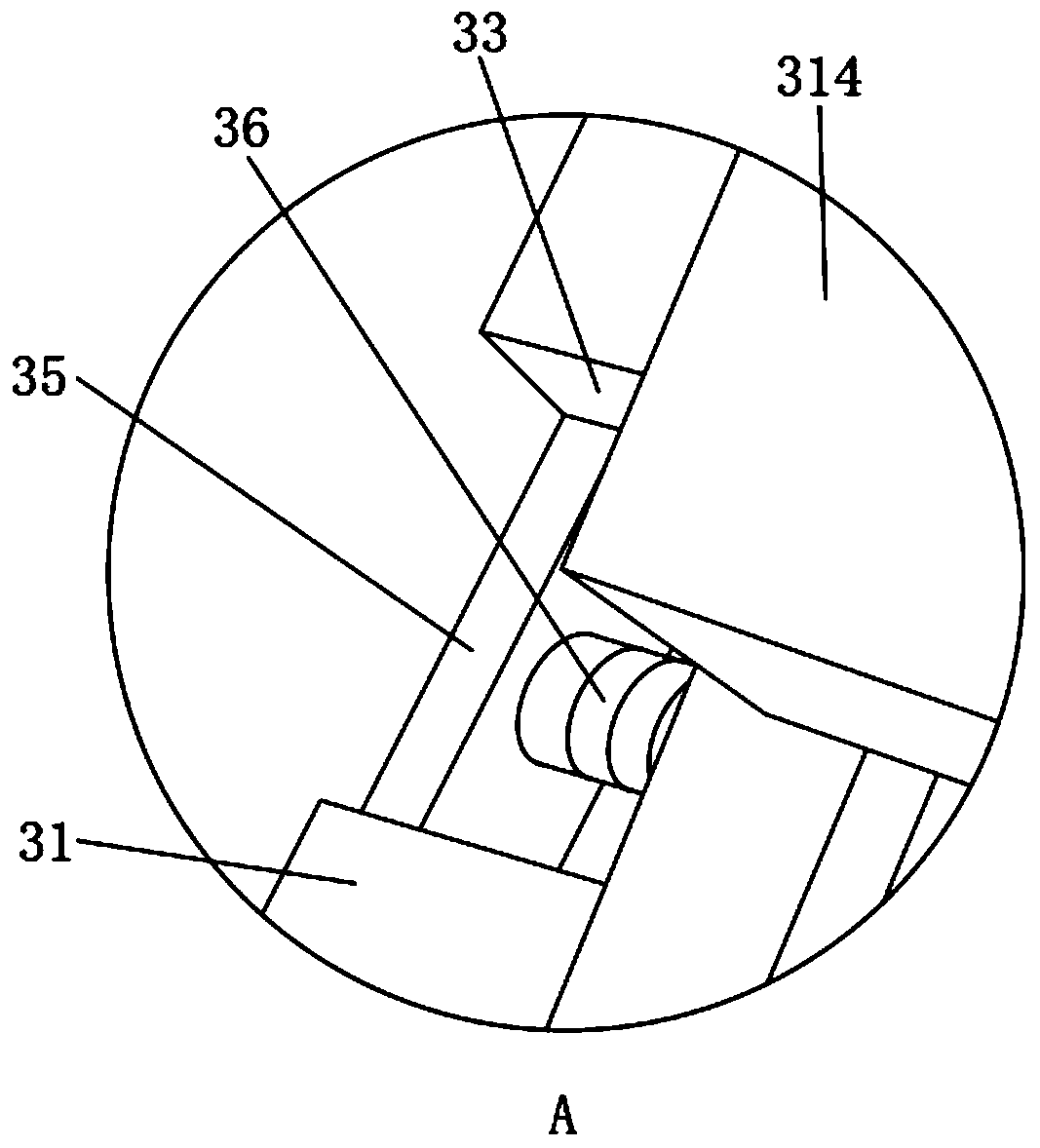

[0024] Wherein, the transmission mechanism 3 includes a transverse base 31, the top of the bed 1 and one side of the drive housing 2 are fixedly connected with a transverse base 31, the two ends of the top of the transverse base 31 are fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com