Fast clamping system

A clamping and fast technology, applied in the direction of clamping, positioning devices, supports, etc., can solve the problems of insufficient applicability and inability to guarantee, and achieve the improvement of machine tool utilization, reduction of tool change time, modularization and strong versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

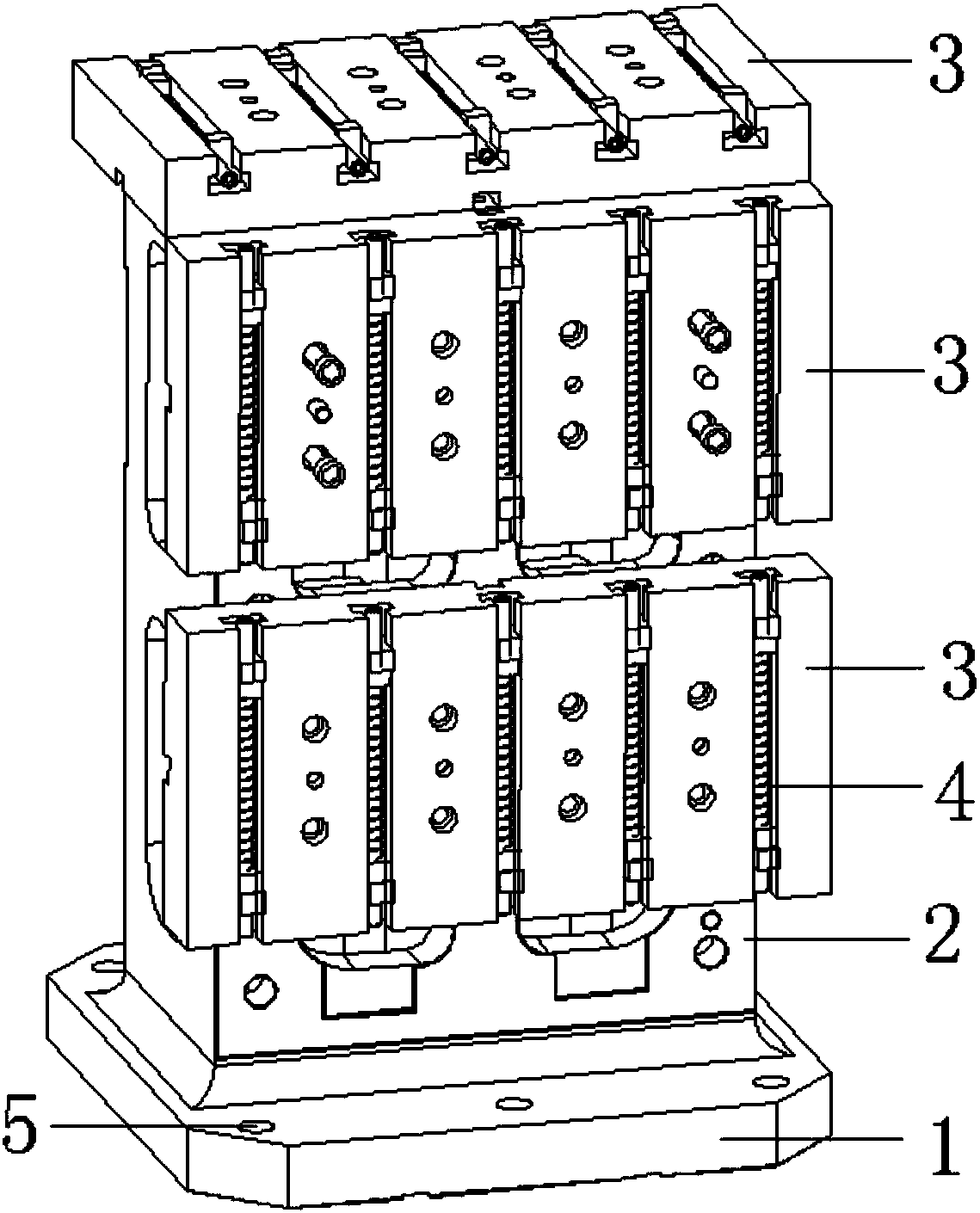

[0028] Such as figure 1 As shown, a quick clamping system includes a base 1, a hanger 2, a fixture holder 3, and a fixture 4; multiple fixture holders 3 are installed at different positions on the hanger 2 of the base 1, and the base 1 Bolt holes 5 are provided, through which the machine tool table is connected.

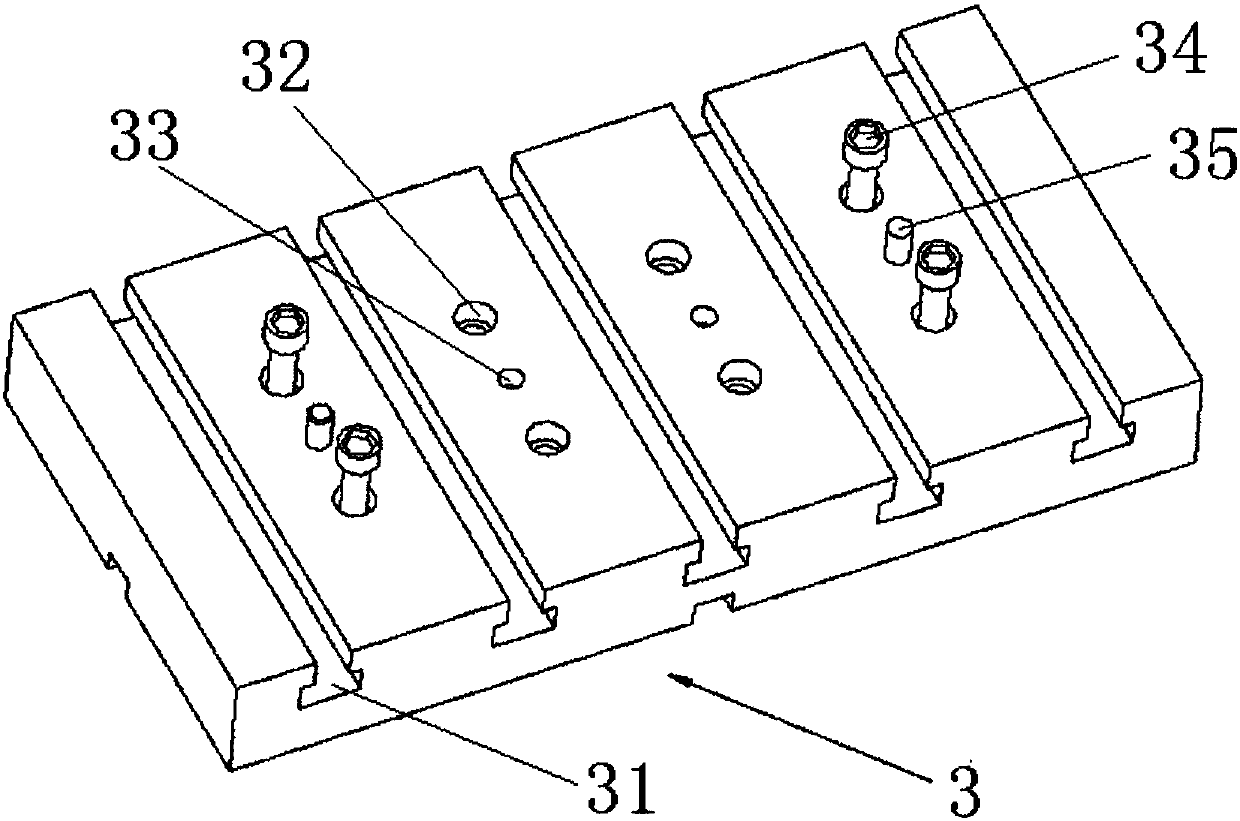

[0029] Such as figure 2 As shown, several mounting grooves 31 are provided on the surface of the fixture holder 3, and the fixture holder 3 is provided with bolt clamping holes 32 and positioning pin holes 33. The fixture holder 3 connects with the hanger 2 on the base 1 through bolts 34. connect.

[0030] The fixture holder 11 is made of cast iron with a surface roughness of Ra1.6.

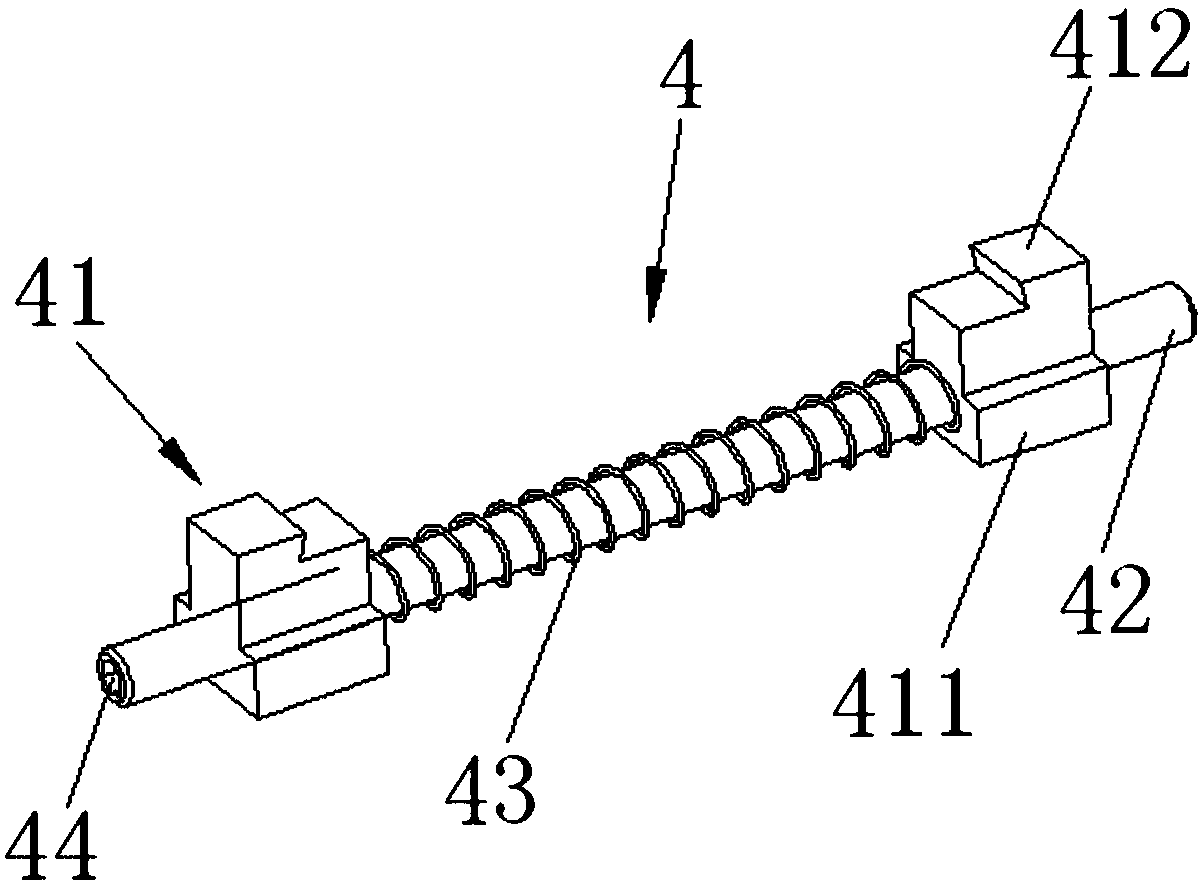

[0031] Such as image 3 As shown, the clamp 4 includes a pair of dovetail clamping blocks 41, a fastening screw 42 and an auxiliary support spring 43; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com