Multi-main-shaft vertical machining center

A vertical machining center, multi-spindle technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of affecting work efficiency, restricting productivity, and the large area of the machining center, reducing vibration and mutual interference, The effect of improving machining accuracy and reducing tool wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

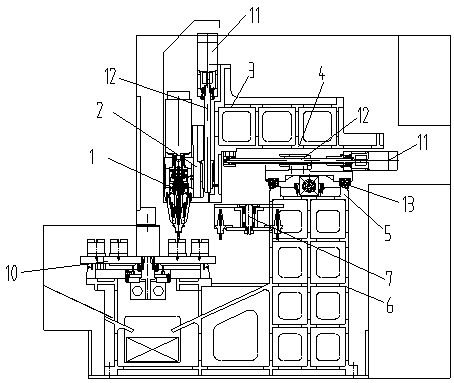

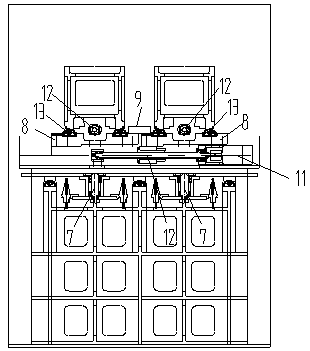

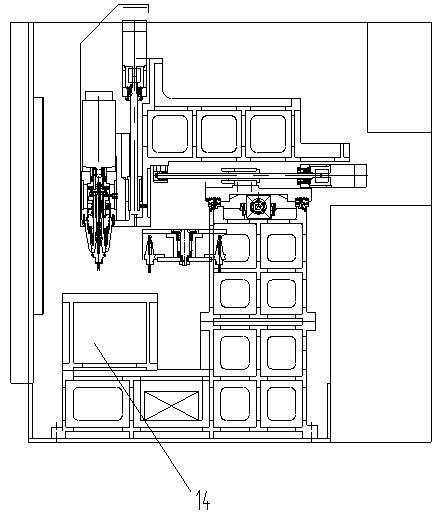

[0018] refer to figure 1 , 2 In the first embodiment shown, in this embodiment, the spindle unit, the X-direction CNC slide table, the Y-direction CNC slide table, the Z-direction CNC slide table, and the rotary tool magazine all adopt two groups; On the slide plate 2 of the Z-direction CNC slide table; the base 3 of the Z-direction CNC slide table and the base 4 of the Y-direction CNC slide table are manufactured as one, and the Z-direction CNC slide table and the Y-direction CNC slide table form a vertical T-shaped structure layout The base 5 and the body 6 of the X-direction CNC slide table are manufactured as one; two sets of direct-connected spindle units 1 are arranged side by side in parallel, and a servo rotary tool magazine 7 is installed on the lower body 6 of each direct-connected spindle unit 1; The slide plates 8 of the two sets of X-direction CNC slide tables are fixedly connected together through the connecting plate 9; the two sets of Y-direction CNC slide tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com