End face grooving cutter body

A technology of grooving knife and end face, which is applied to the accessories of tool holders, tools for lathes, turning equipment, etc., and can solve the problems of designing relatively large adjustment holes, limited adjustment range, and unstable machining rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

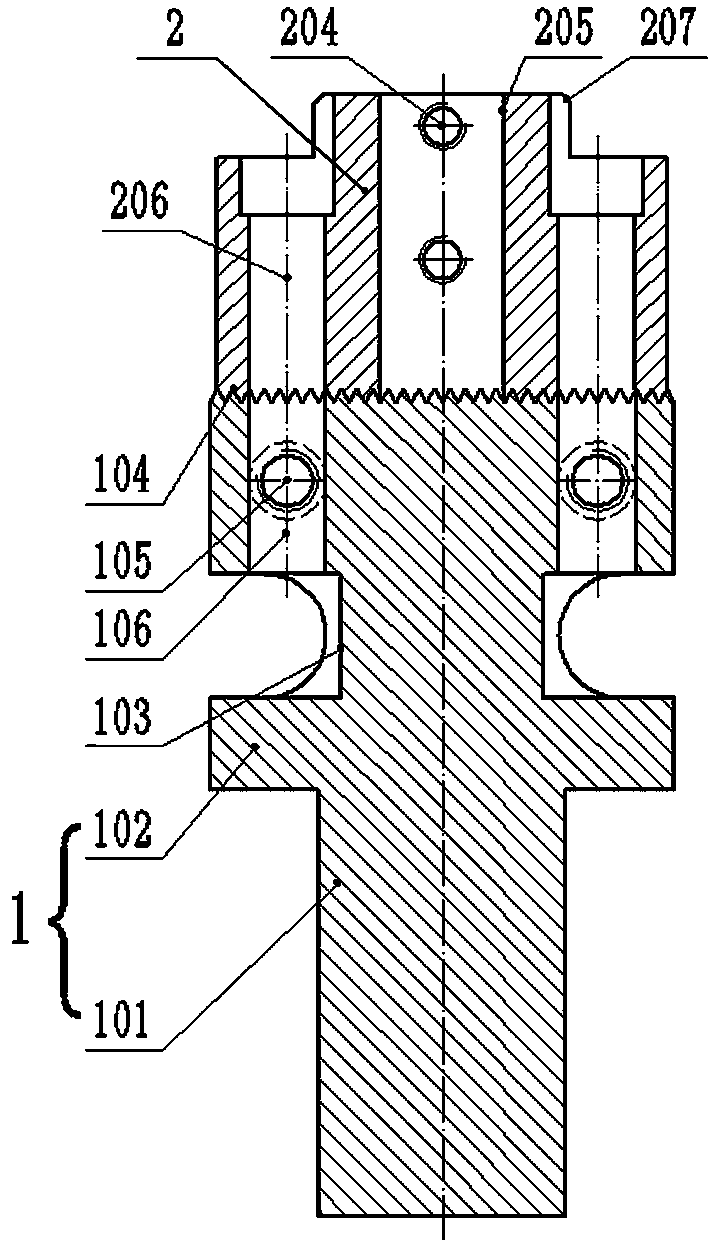

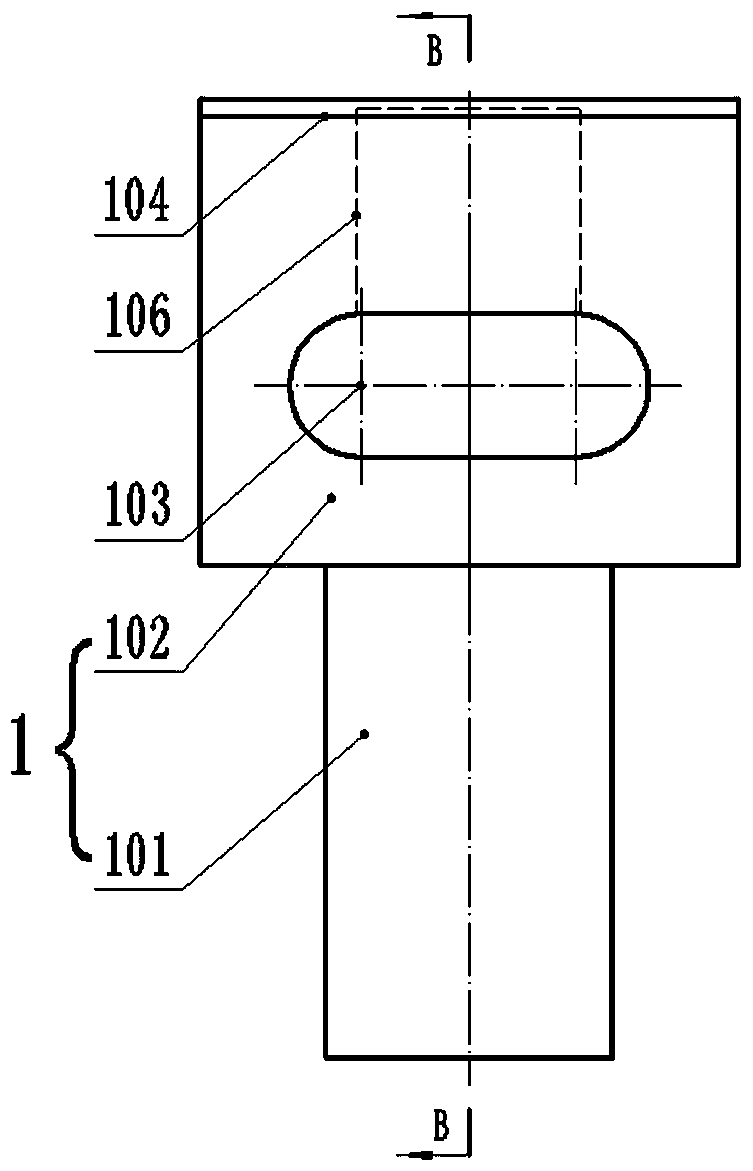

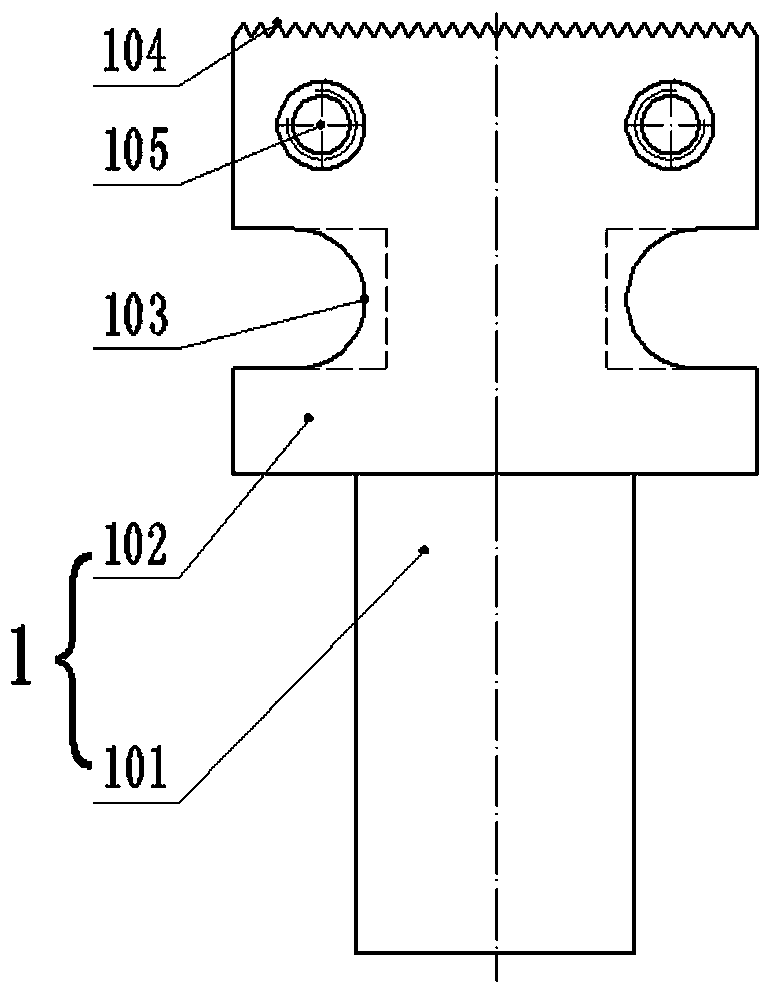

[0026] Specific embodiment 1 of the face grooving cutter body of the present invention, as Figure 1 to Figure 8 As shown, the end grooving cutter body includes a tool seat 1 for connecting with the machine tool spindle and a sliding tool holder 2 connected thereto through locking bolts, and a guide protrusion 104 is passed between the sliding tool holder 2 and the tool seat 1 It is guided and matched with the guide groove 201. The tool holder 1 is a stepped shaft, which includes an equipment connection part 101 for connecting with processing equipment such as machine tools and a tool holder connection part 102 for connecting with the sliding tool holder 2. The equipment connection part 101 is formed by the step shaft. A segment with a smaller shaft diameter is formed, and the toolholder connecting portion 102 is formed by a segment with a larger shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com