Manufacturing process for high-curvature full-profile thin-wall part

A manufacturing process and large curvature technology, which is applied in the manufacturing process of large-curvature full-shaped thin-walled parts, can solve problems such as processing deformation and vibration of thin-walled curved surfaces in ultra-complex spaces, and achieve enhanced clamping stability and processing rigidity. Controlling the effect of NC program quality, verifying correctness and rationality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

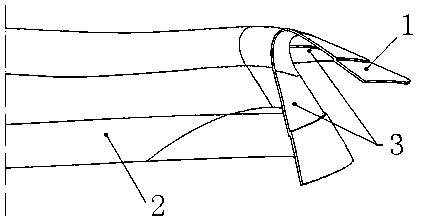

[0029] Attached below figure 1 The present invention is described further, as attached figure 1 As shown, the large-curvature full-surface thin-walled structural member involved in the present invention is composed of an outer cavity profile 1, an inner cavity profile 2, and an inner cavity V-shaped groove 3. Rib support surface area up to 0.397m 2 , The effective depth of the profile is 196mm, the groove of the profile is deep and narrow, in a V-shaped layout, the opening angle of the groove is about 30°, and the depth is 100mm.

[0030] The invention discloses a manufacturing process of large-curvature full-surface thin-walled structural parts, which uses five-coordinate high-speed milling to perform rough machining of the outer cavity profile, rough machining of the inner cavity profile, semi-finishing and finishing of the inner cavity profile, and outer cavity profile machining. Surface semi-finishing and finishing machining, fitter polishing, clamping and positioning b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com