Method for connecting slotted sections in underground construction of diaphragm wall

An underground diaphragm wall, a technology in construction, applied to sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as complex construction, water seepage in concrete joints, difficult safety, etc., to ensure construction quality, prevent soil collapse, Solve the effect of anti-circumvention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

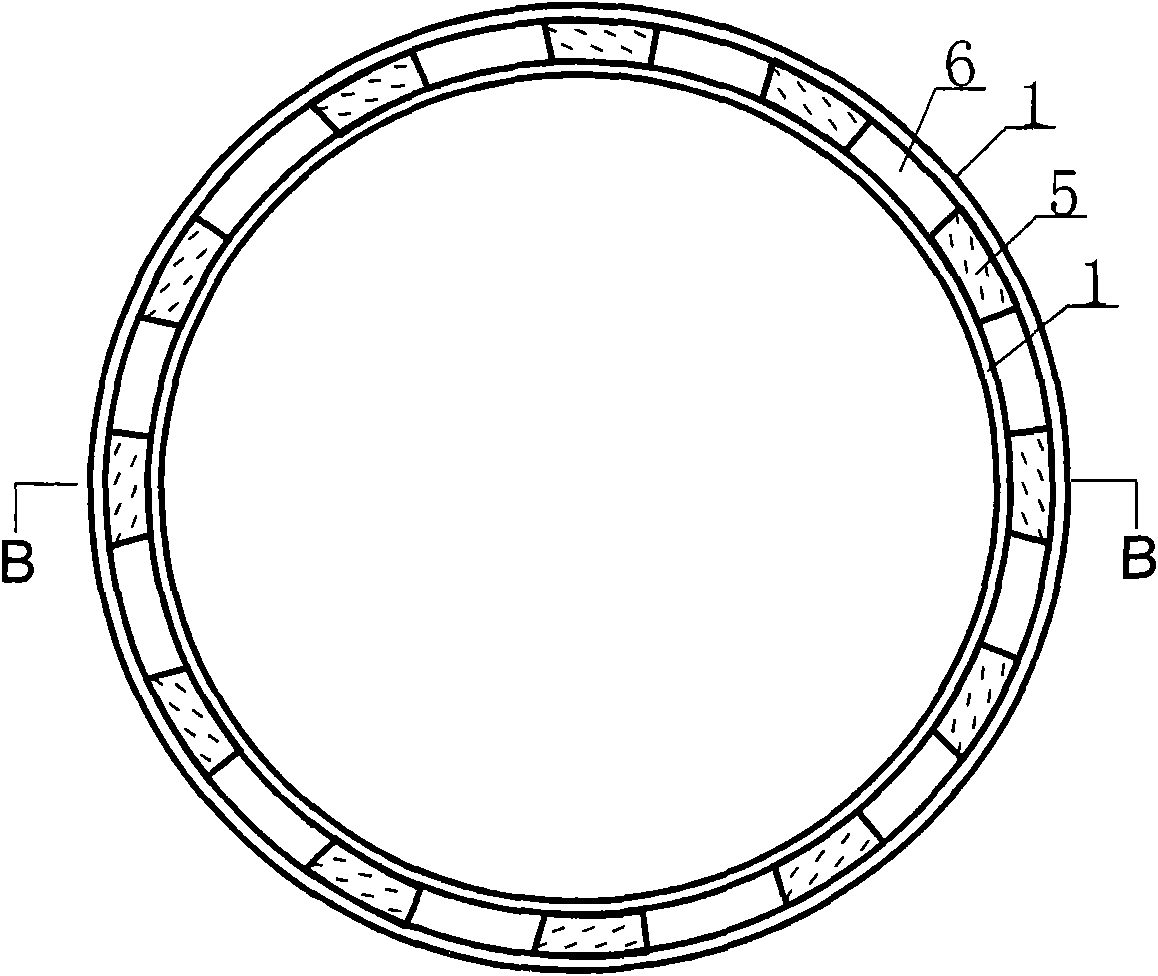

[0017] The south anchor of the south branch of the Huangpu Bridge on the Pearl River is located on the south bank. It is a gravity anchor. The ground connection wall adopts a circular structure with an outer diameter of 73m, an inner diameter of 70.6m, and a wall thickness of 1.2m. The underground diaphragm wall is divided into 50 groove sections with two groove shapes in total, and the overlapping length of the groove sections between Phase II and Phase I is 0.25m. The method for connecting groove sections in the construction of the underground diaphragm wall of the south anchorage of the Huangpu Bridge on the Pearl River includes the following steps:

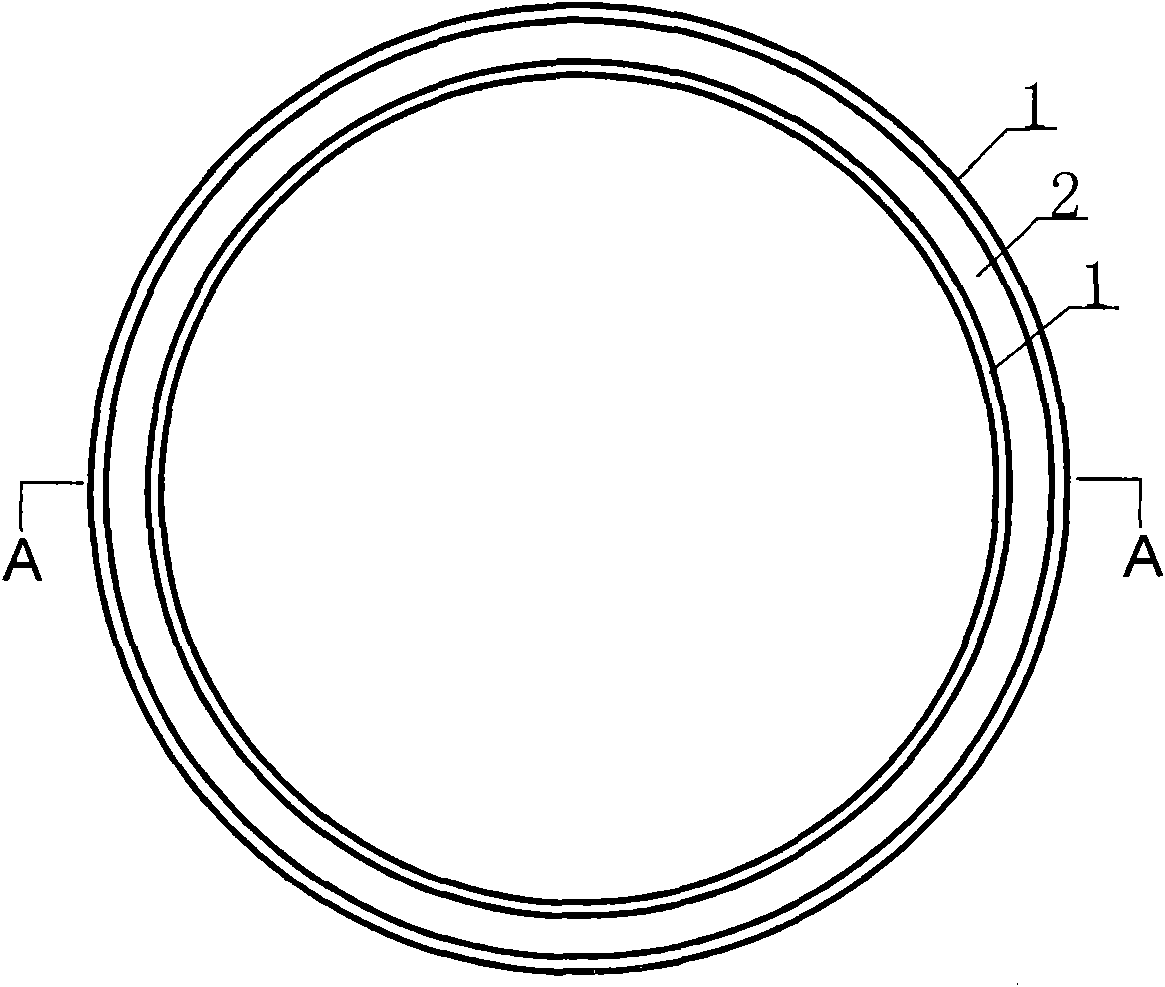

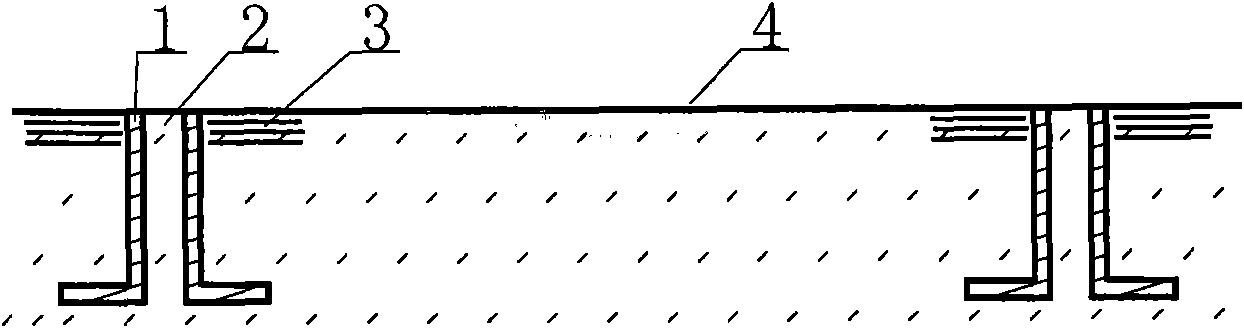

[0018] ① if figure 1 , figure 2 As shown, build the guide wall and construction platform: build an "L" shaped reinforced concrete structure guide wall 1 on the inner and outer sides of the location 2 of the underground diaphragm wall on the ground 4, and set a reinforced concrete construction platform 3 with a certain thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com