Hydraulic swabbing machine

A hydraulic and hydraulic cylinder technology, which is applied in the field of underground oil and gas extraction equipment, can solve the problems of high consumption of fuel and wire rope, high moving and maintenance costs, and poor safety, so as to improve safety and reliability, save moving costs, and facilitate transition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

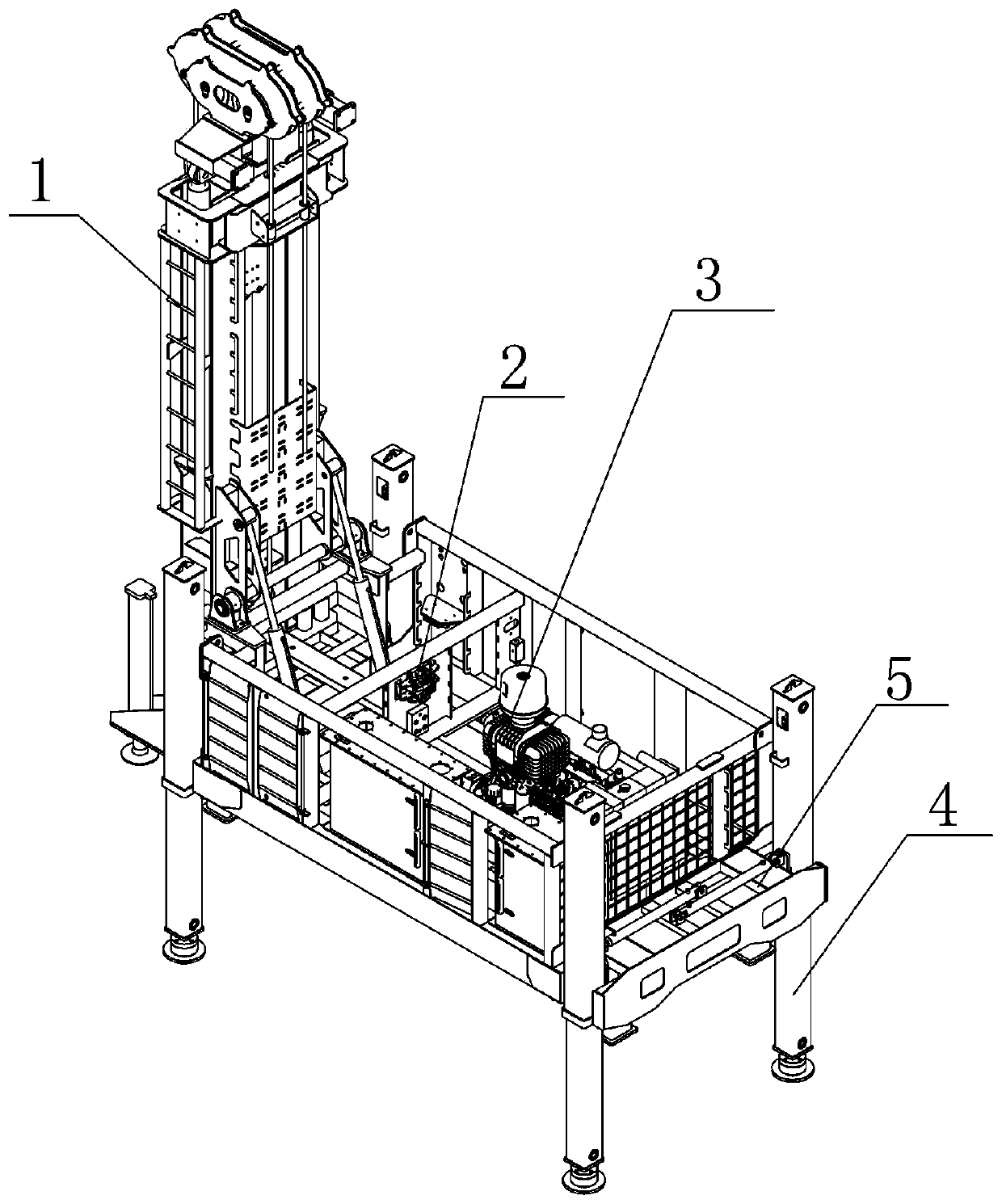

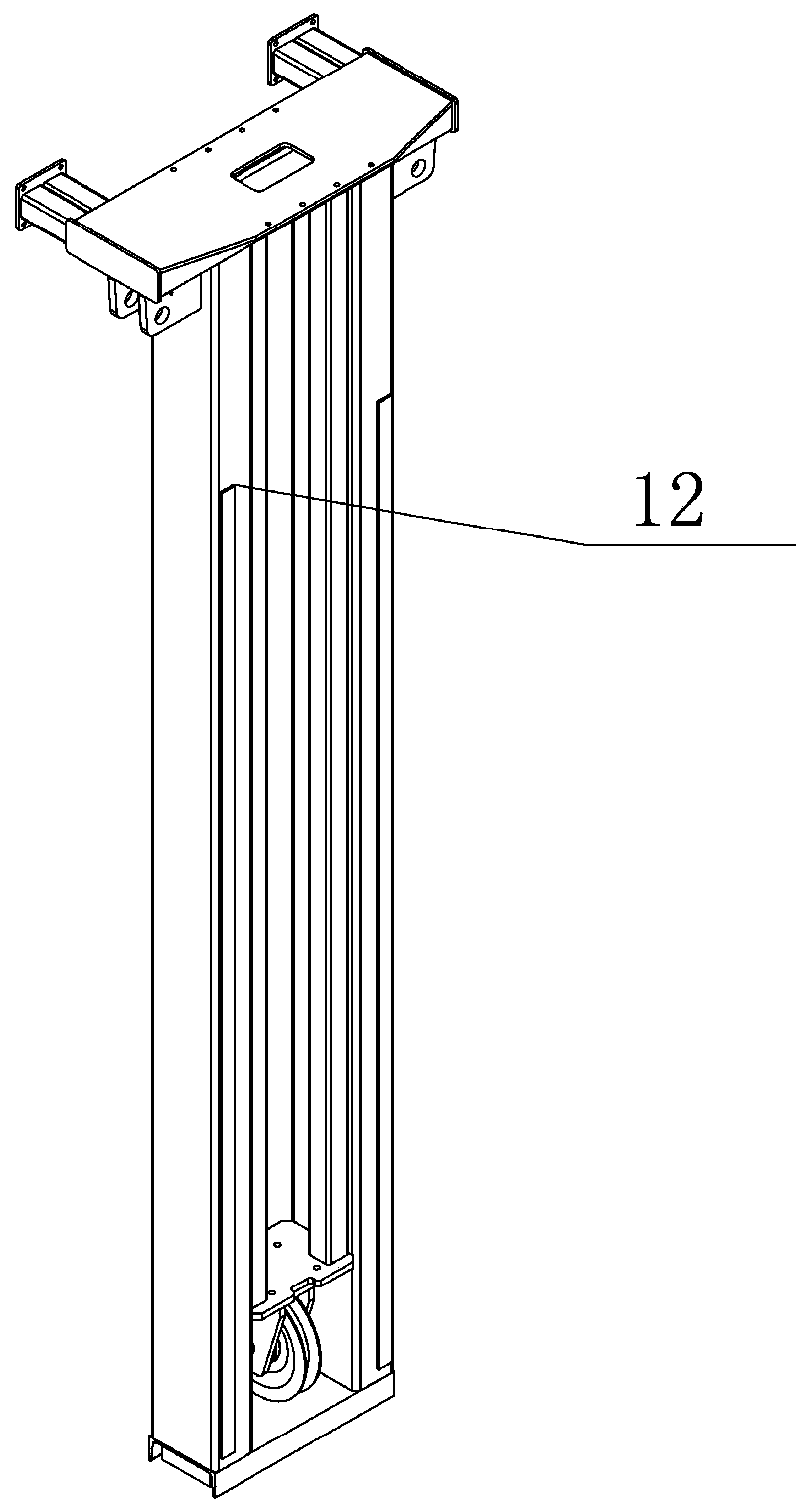

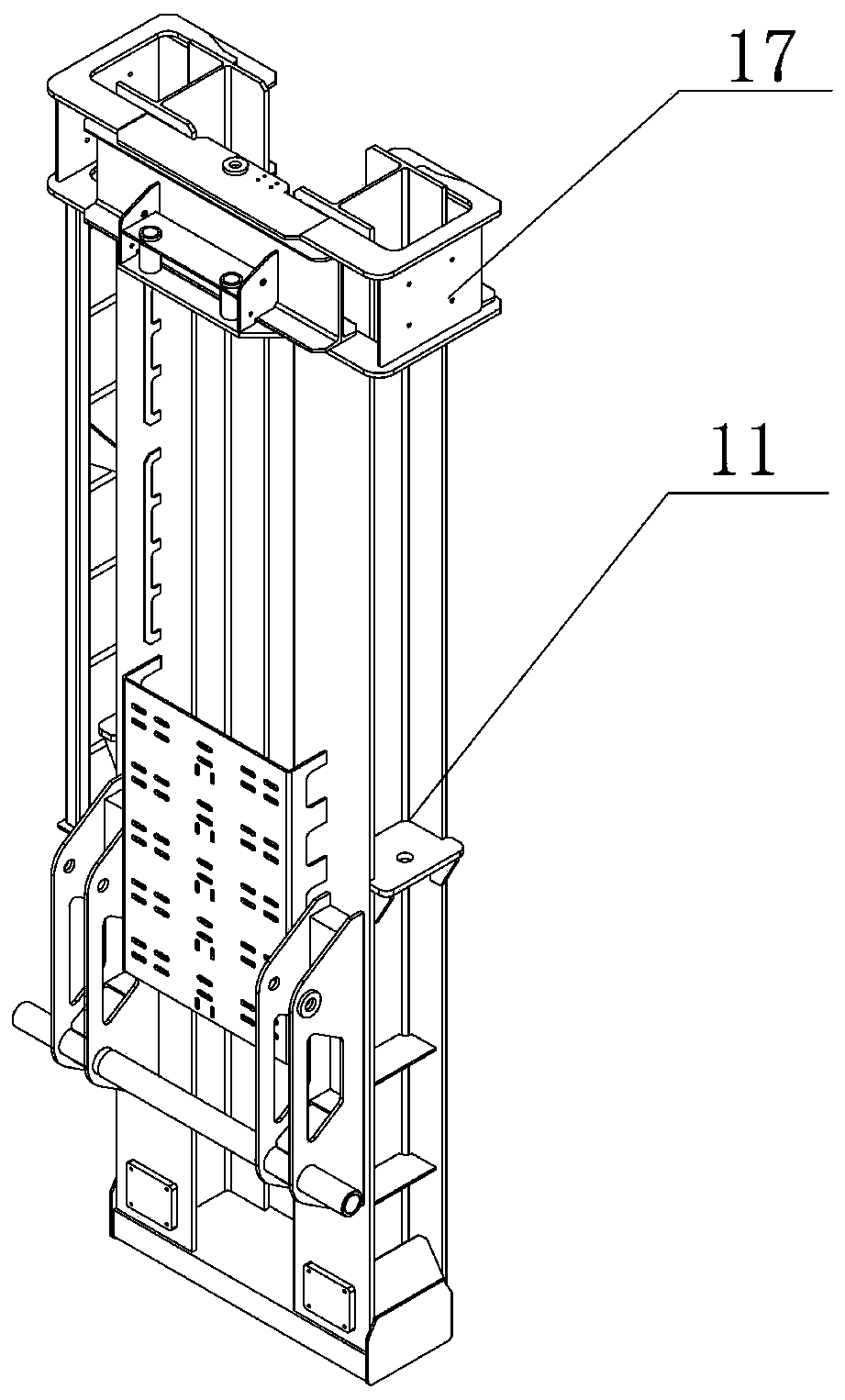

[0034] Such as Figure 1-6 As shown, a hydraulic pumping machine provided in this embodiment includes a pumping module 1, a power module 2 for providing power for the pumping module, a control module for controlling the actions of the pumping module and the power module 2, and The leg module 4 and the unit structure module 5 are used to support the pumping module 1, the power module 2 and the control module. The hydraulic pumping machine provided by the present invention realizes the automatic pumping operation through the lifting and lowering movement of the hydraulic oil cylinder, which replaces the traditional working mode in which the pumping machine equipment is separated from the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com