Electrical design method for preventing direct current overhead contact system from being frozen

A design method and catenary technology, applied in the direction of overhead lines, electrical components, overhead installation, etc., can solve the problems of high investment in deicing machinery, uneven secondary icing, large number of catenary wires, etc., and achieve circuit investment Fast and fast operation, easy loop input and exit operation, simple control and logic principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

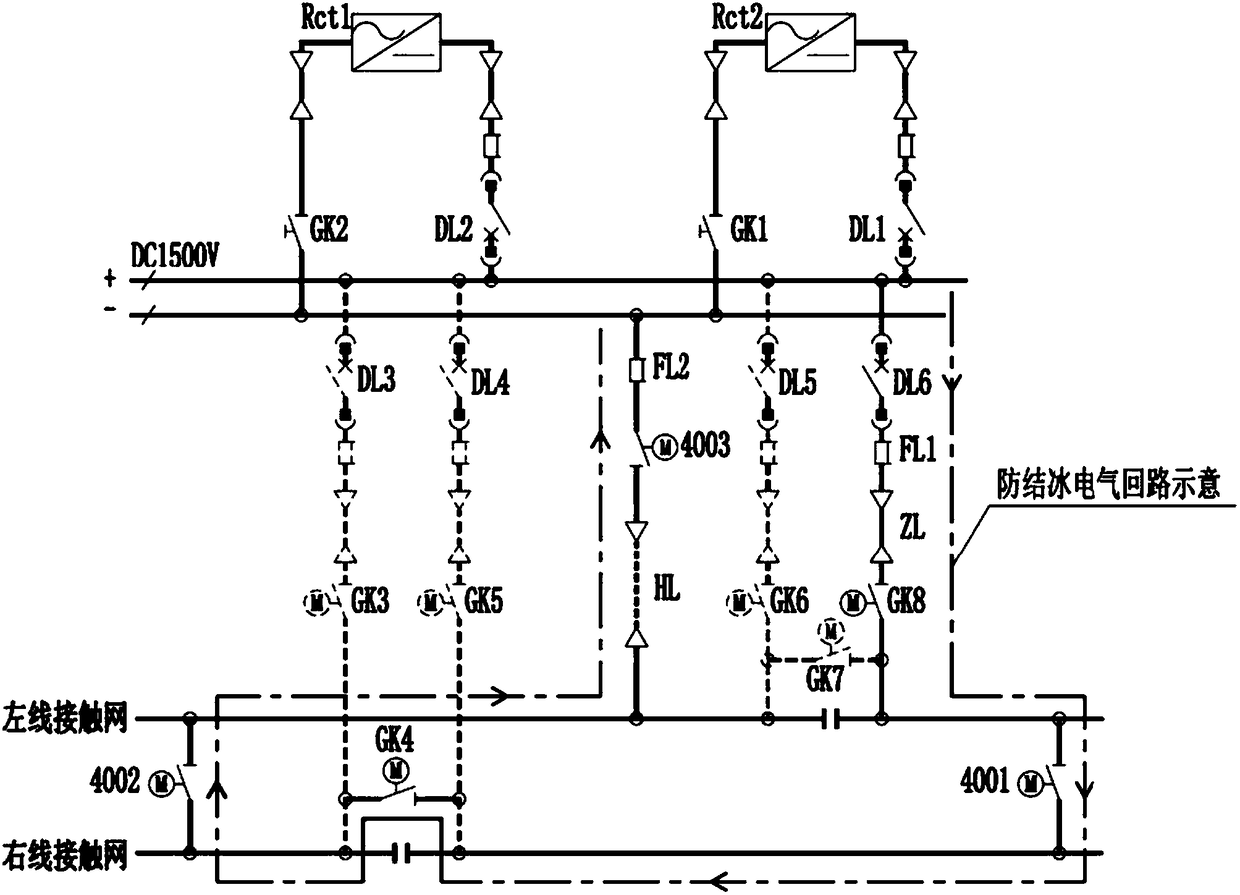

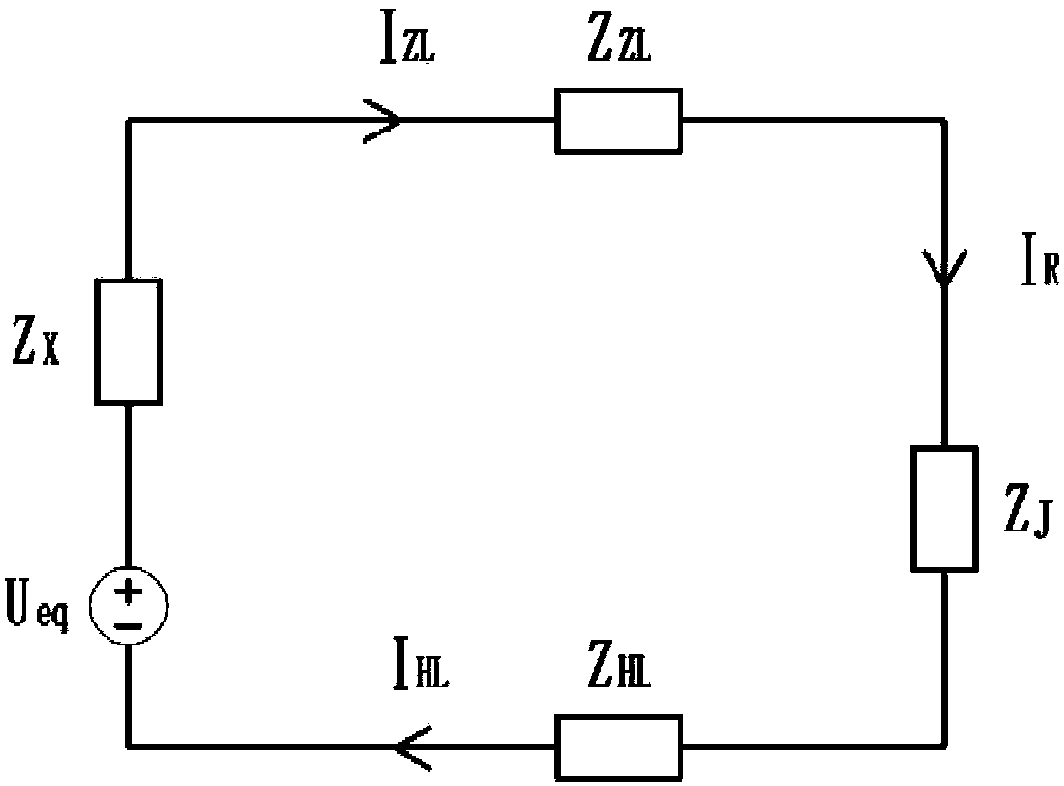

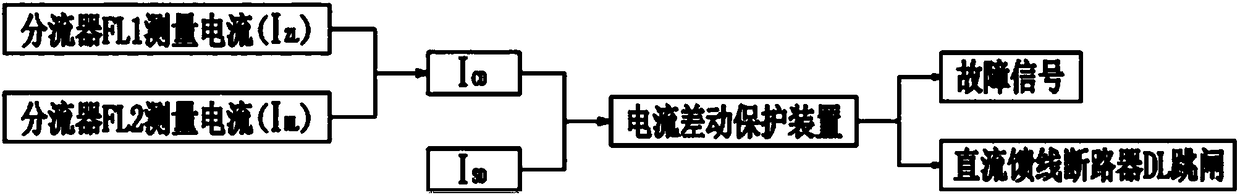

[0036] As shown in the figure, an electrical design method for preventing DC overhead catenary from freezing includes electrical circuit design and electrical control design. The electrical circuit design is to design the anti-icing system circuit on the basis of the basic structure of the DC traction power supply system, The DC busbar of the DC traction substation continuously outputs a certain amount of current to the catenary. The current value is realized by adjusting the input range of the catenary line, and the thermal power of the catenary itself is used to prevent the catenary from freezing; the electrical control design is Set current differential protection between the positive bus outlet and the negative bus inlet of the anti-icing circuit, that is, control protection.

[0037] The DC traction power supply system adopts DC1500 DC traction pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com