Mining concrete spraying vehicle

A concrete spraying and mining technology, which is applied in mining equipment, earth-moving drilling, shaft equipment and other directions, can solve the problems of difficult concrete spraying construction in mine tunnels, laborious time for pipeline layout and coiling, and inconvenient operation and operation, so as to reduce spraying. Difficulty in construction, improving work efficiency, and the effect of strong passing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

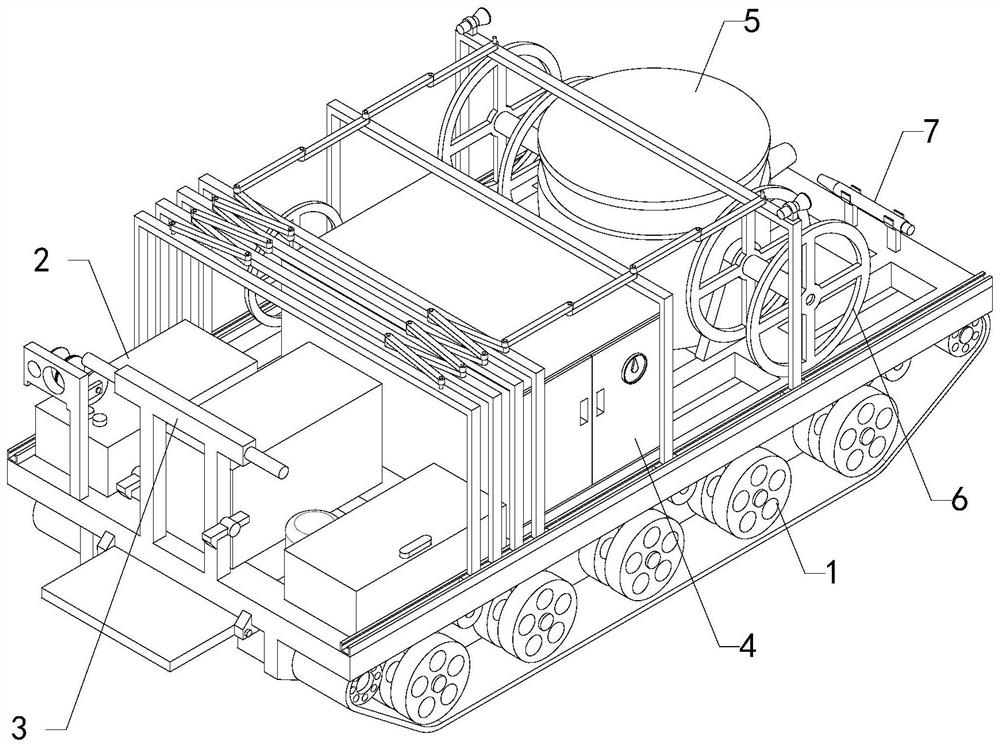

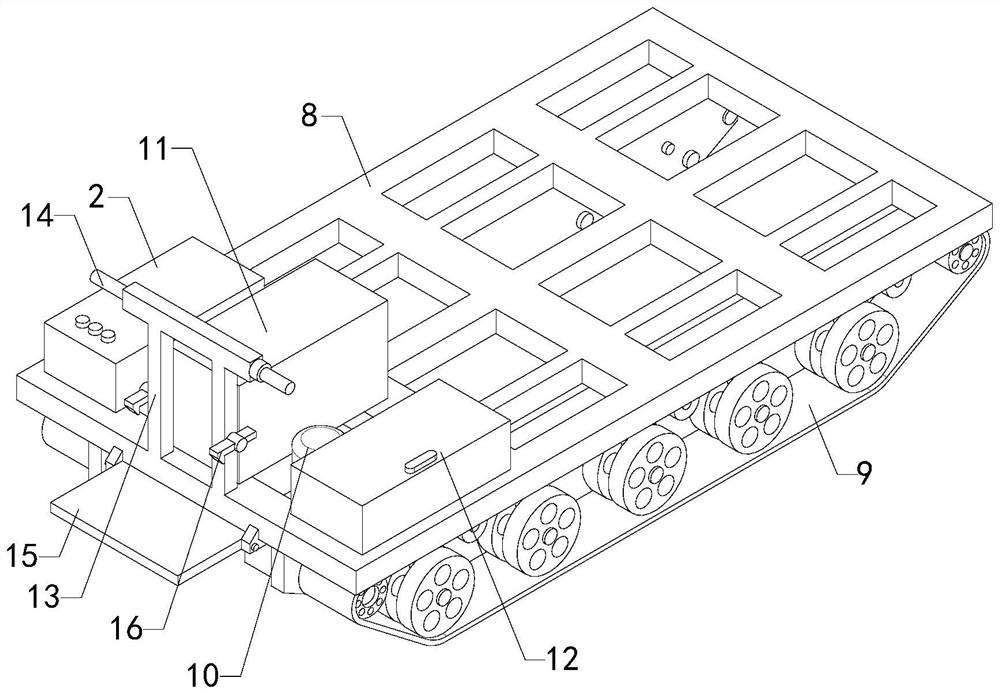

[0021] A mining concrete spraying vehicle, comprising a crawler chassis 1, a control box 2, a driver's platform 3, an air compressor 4, a spraying machine 5, a plurality of retractors 6 and a spray gun 7, the upper end surface of the crawler chassis 1 is installed with a Control box 2, a plurality of control buttons are arranged on the control box 2, the driver's platform 3 is installed in the middle part of the upper end surface rear end of the crawler chassis 1, the operating mechanism of the crawler chassis 1 is arranged on the driver's platform 3, and the air compressor 4 is installed on the track chassis 1. The middle part of the upper end surface of the chassis 1 is to the right, the jet 5 is installed in the middle of the front part of the upper end surface of the crawler chassis 1, and a plurality of retractors 6 are respectively installed on the upper end surface of the crawler chassis 1, and the plurality of retractors 6 are respectively located on the upper end surfac...

Embodiment 2

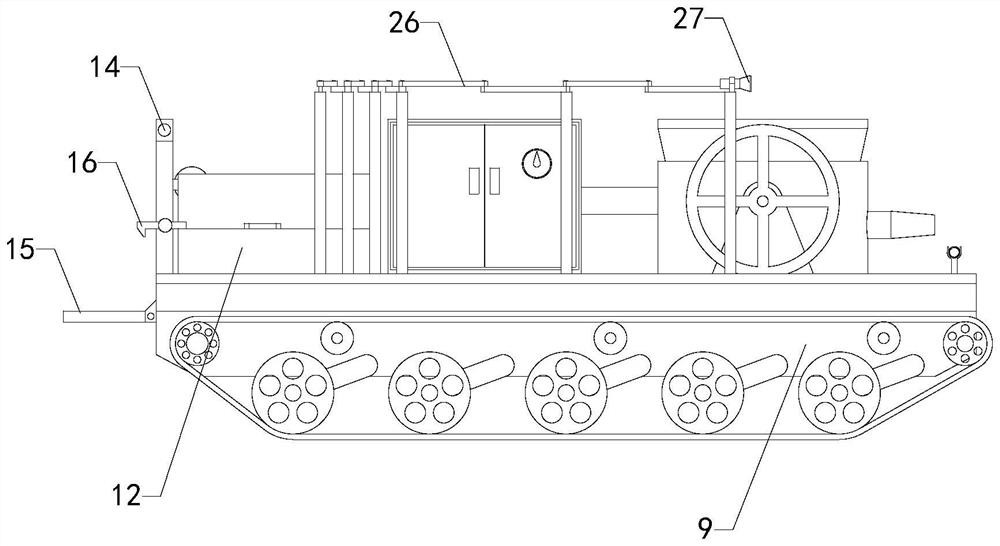

[0023]A mining concrete spraying vehicle, comprising a crawler chassis 1, a control box 2, a driver's platform 3, an air compressor 4, a spraying machine 5, a plurality of retractors 6 and a spray gun 7, the upper end surface of the crawler chassis 1 is installed with a Control box 2, a plurality of control buttons are arranged on the control box 2, the driver's platform 3 is installed in the middle part of the upper end surface rear end of the crawler chassis 1, the operating mechanism of the crawler chassis 1 is arranged on the driver's platform 3, and the air compressor 4 is installed on the track chassis 1. The middle part of the upper end surface of the chassis 1 is to the right, the jet 5 is installed in the middle of the front part of the upper end surface of the crawler chassis 1, and a plurality of retractors 6 are respectively installed on the upper end surface of the crawler chassis 1, and the plurality of retractors 6 are respectively located on the upper end surface...

Embodiment 3

[0025] A mining concrete spraying vehicle, comprising a crawler chassis 1, a control box 2, a driver's platform 3, an air compressor 4, a spraying machine 5, a plurality of retractors 6 and a spray gun 7, the upper end surface of the crawler chassis 1 is installed with a Control box 2, a plurality of control buttons are arranged on the control box 2, the driver's platform 3 is installed in the middle part of the upper end surface rear end of the crawler chassis 1, the operating mechanism of the crawler chassis 1 is arranged on the driver's platform 3, and the air compressor 4 is installed on the track chassis 1. The middle part of the upper end surface of the chassis 1 is to the right, the jet 5 is installed in the middle of the front part of the upper end surface of the crawler chassis 1, and a plurality of retractors 6 are respectively installed on the upper end surface of the crawler chassis 1, and the plurality of retractors 6 are respectively located on the upper end surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com