Tractor chassis self-weight load type running-in purification test stand and running-in purification process thereof

A tractor and test bench technology, applied in the electromechanical field, can solve the problems of high cost of returning to the factory for repair, reducing the quality and service life of the tractor, affecting product quality, etc., to improve the running-in quality and production efficiency, protect the bearings and moving parts, The effect of eliminating hidden dangers of safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

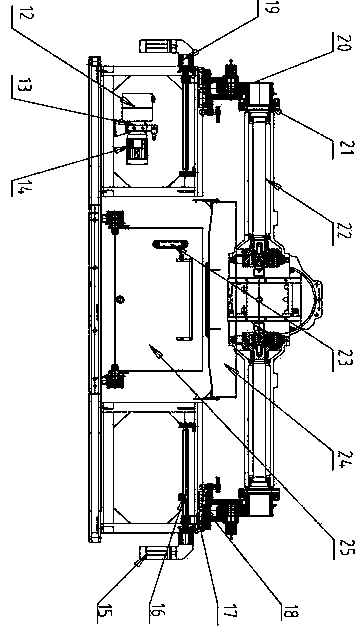

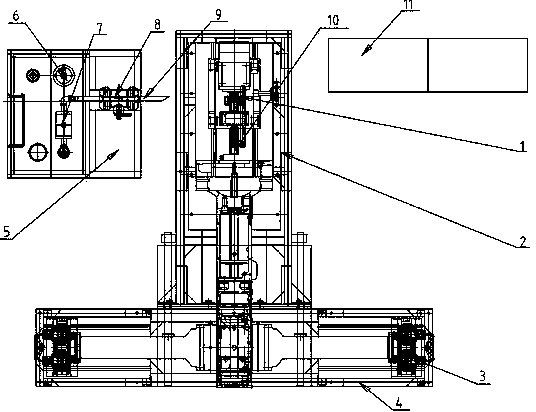

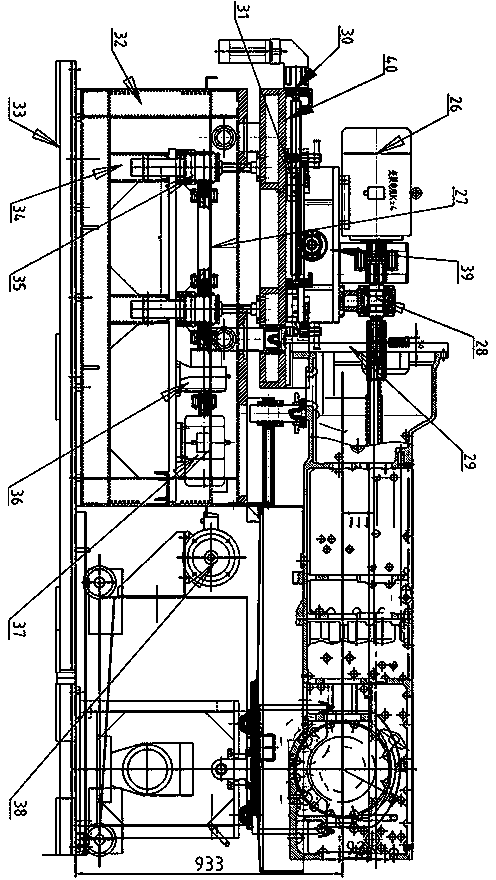

[0050] Such as figure 1 , 2 , shown in 3, tractor chassis self-weight load type running-in test bench of the present invention, by input mechanism 1, elevating mechanism 27, rear axle installation and positioning mechanism 3, front end installation and positioning mechanism 29, input machine base 2, rear axle support 4, The base 33, the hydraulic system 12, the hydraulic purification system 5 and the automatic control system 11 are composed.

[0051] The input base 2 is installed on the front end of the base 33, the input mechanism 1 is installed above the input base 2, and a lifting mechanism 27 is arranged between the input mechanism 1 and the input base 2; the input mechanism 1 includes: a traction motor 26, the motor installation base plate 39, the propulsion mechanism 30, and the input connection mechanism 28. One end of the propulsion mechanism 30 is connected to the input coupling of the tractor test piece chassis through a coupling, and the other end is connected to ...

Embodiment 2

[0063] Such as figure 1 and figure 2 As shown, the running-in process of the tractor chassis self-weight load-type running-in test bench of the present invention is: the tractor chassis test piece 22 is installed on the tractor chassis running-in test bench, start the tractor chassis self-weight load type running-in test bench, and the automatic control system 11 automatically Carry out loading and running-in on the chassis, and start the hydraulic purification system 5 at the same time, use the purified oil to carry out running-in purification on the tractor and the automobile chassis test piece 22 with a large flow pressure, and test the tractor chassis through the automatic control system 11 during the running-in process After testing, the purified oil is recycled through the mesh filter and magnetic filter system, and the purified oil is composed of diesel oil, lubricating oil, and oily detergent in a ratio of 2:1:1.

[0064] The chassis of the tractor that has been run-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com