Patents

Literature

50results about How to "Shorten break-in time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

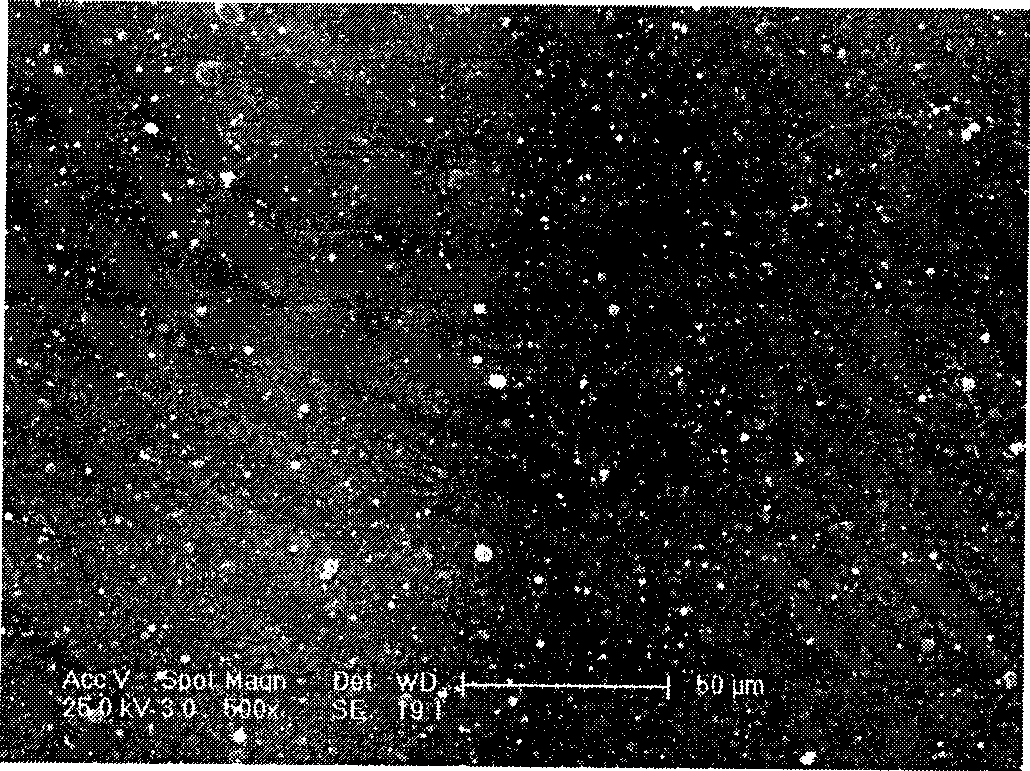

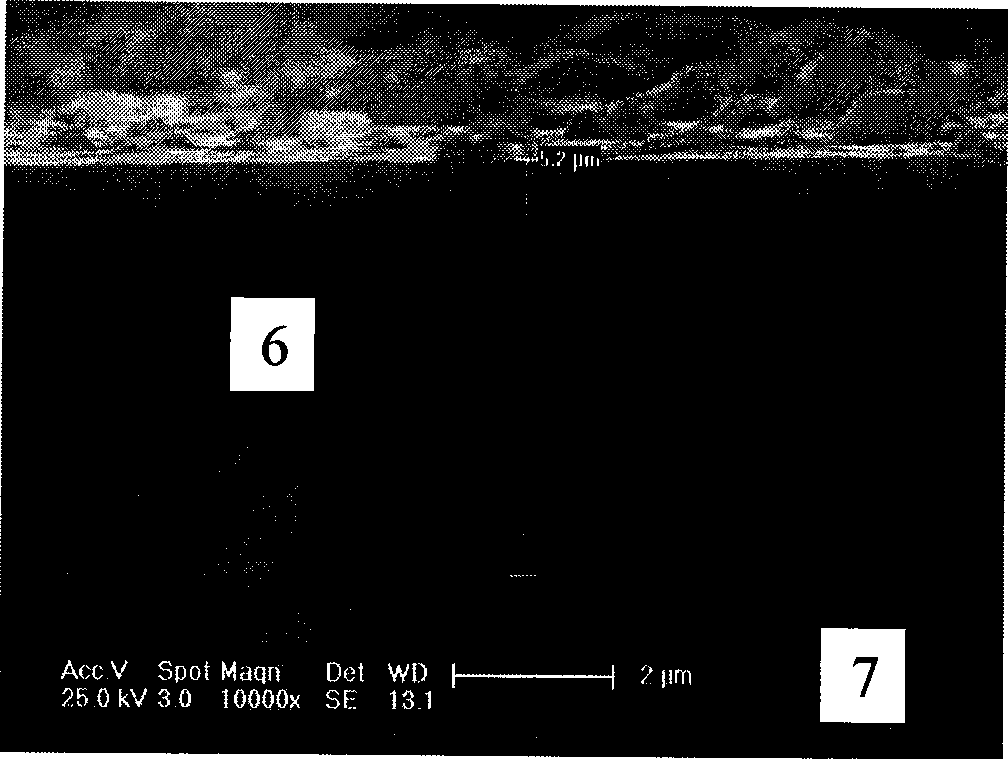

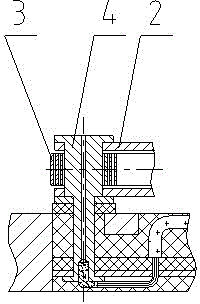

PVD nano composite ceramic coating screw and method for manufacturing same

InactiveCN101518935ASolve pollutionIncreased microhardnessLayered productsVacuum evaporation coatingCarbon filmDiamond-like carbon

The invention provides a PVD nano composite ceramic coating screw. A screw substrate (7) is coated with a coating (6) consisting of a bonding layer, a primary wear-resistance layer and a lubricating layer sequentially. The method for manufacturing the screw comprises the following steps: firstly, depositing a 50 to 100 nanometer thick transitional metal bonding layer at an air pressure of 0.1 Pa; secondly, depositing a 2 to 5 micrometer thick composite ceramic layer as the primary wear-resistance layer at a temperature of between 350 and 400 DEG C, a voltage of between -50 and -200 volts and an air pressure of 0.2 to 1Pa; and finally, depositing a 1 to 3 micrometer transitional metal doped diamond carbon film layer as the lubricating layer at a temperature of between 100 and 150 DEG C, a voltage of between -50 and -150 volts and an air pressure of 0.1 to 0.5Pa. Compared with the prior art, the screw has the advantages of having lubricating performance, along with high hardness (more than 40GPa Hv hardness) and excellent wear resistance (friction coefficient about 0.1). The method is free from pollution and the coating has strong adhesive force.

Owner:舟山市汉邦机械科技有限公司

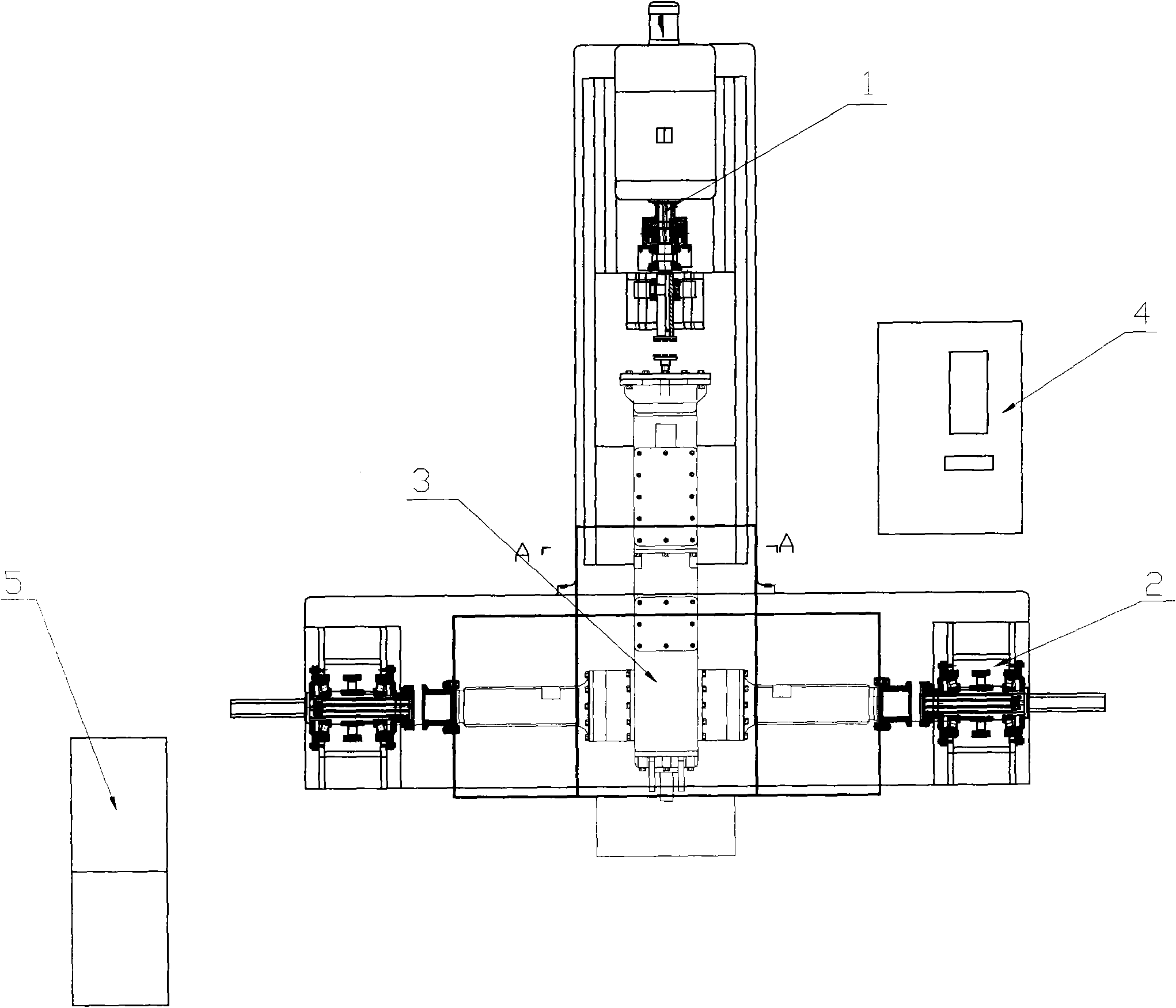

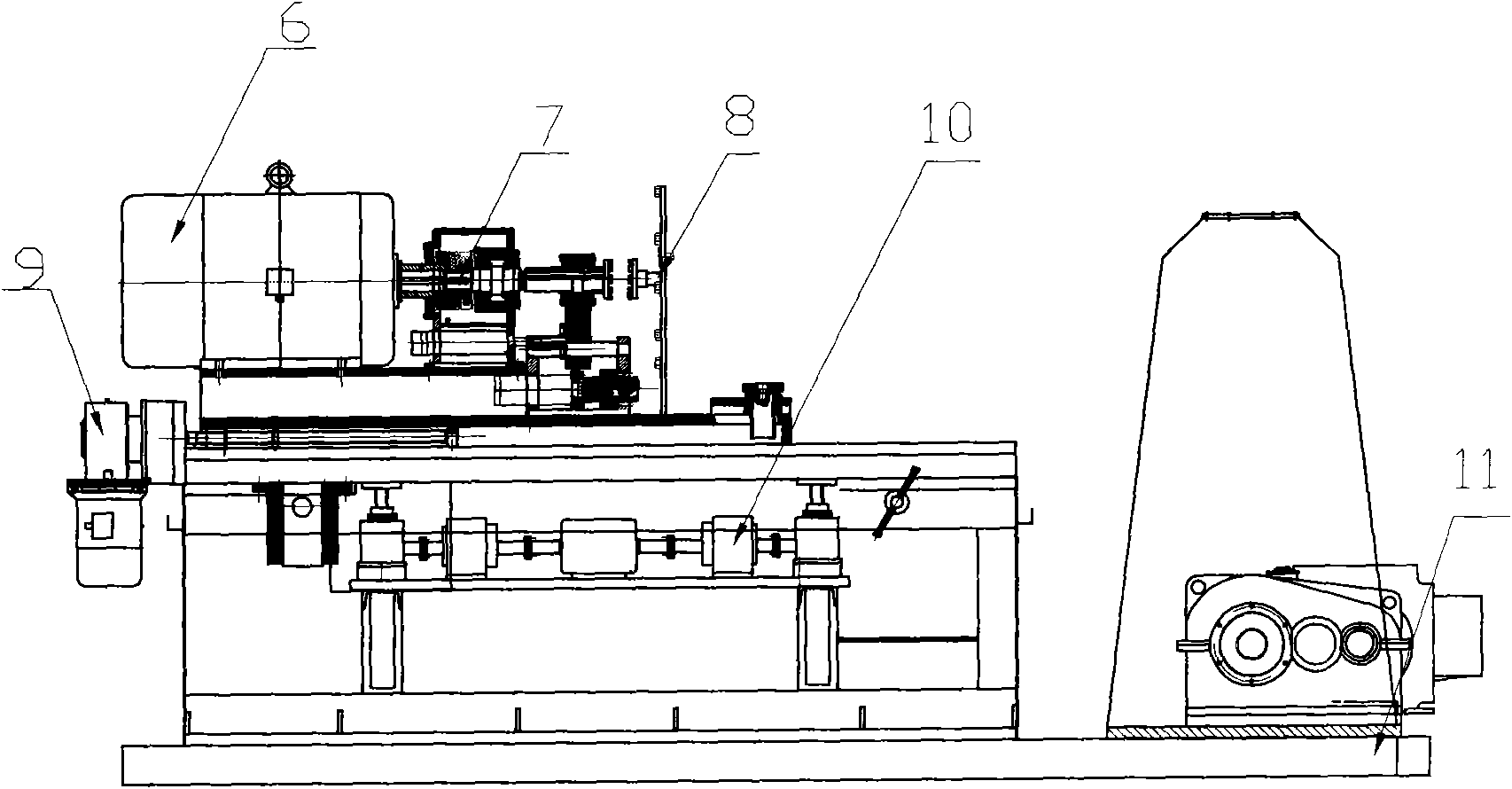

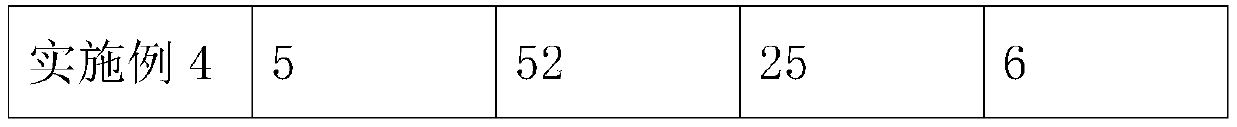

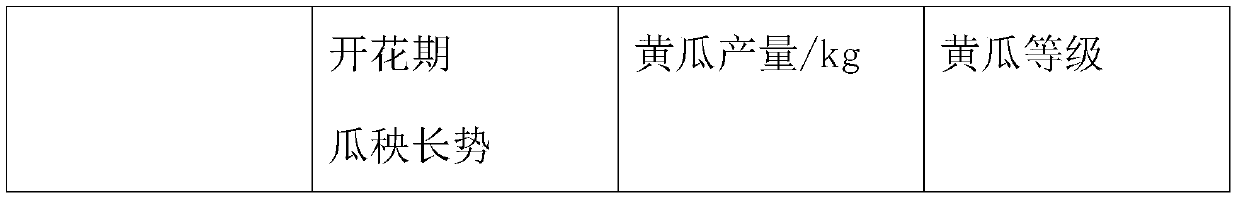

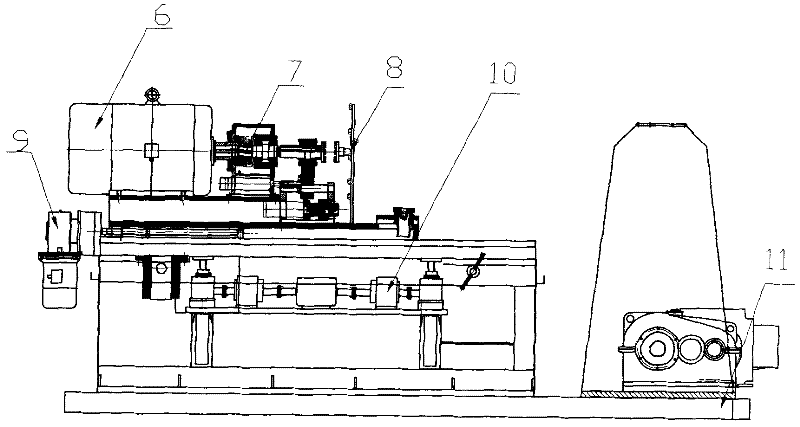

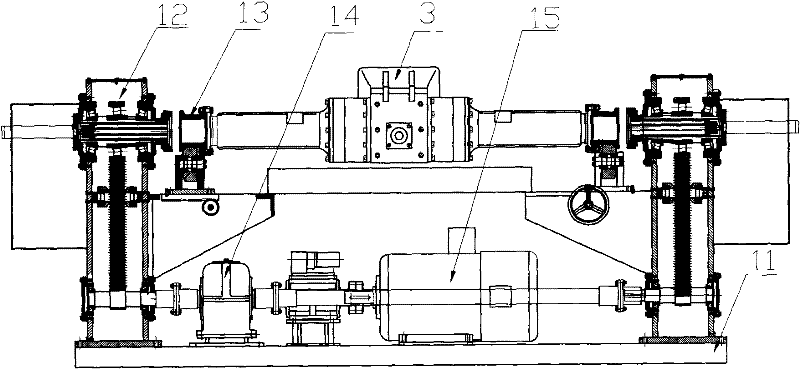

Load running-in test bench for tractor and auto chassis and running-in technology thereof

The invention relates to the electrical and mechanical field and discloses a load running-in test bench for tractor and auto chassis and a running-in technology thereof, wherein, the running-in test bench comprises an input mechanism, a lifting mechanism, an output mechanism, a loading mechanism, a base, a hydraulic purification system and an automatic control system; the input mechanism is positioned at one end of the base, and the lifting mechanism is arranged between the input mechanism and the base; the output mechanism and the loading mechanism are positioned at the other end of the base,and the loading mechanism is positioned below the output mechanism and connected with the output mechanism through a coupling; and the automatic control system is electrically connected with the input mechanism and the loading mechanism. When a running-in test is carried out, the input mechanism, the output mechanism and the hydraulic purification system are respectively connected with a test piece of the tractor chassis or the auto chassis. The running-in technology mainly adopts the loading running-in purification technology. The running-in test bench has the beneficial effects of improvingthe quality of a whole vehicle, saving energy, time and occupied space, improving the production efficiency, reducing the ex-factory back repair rate of products and realizing the automatic control.

Owner:湘潭科达电工专用成套设备有限责任公司

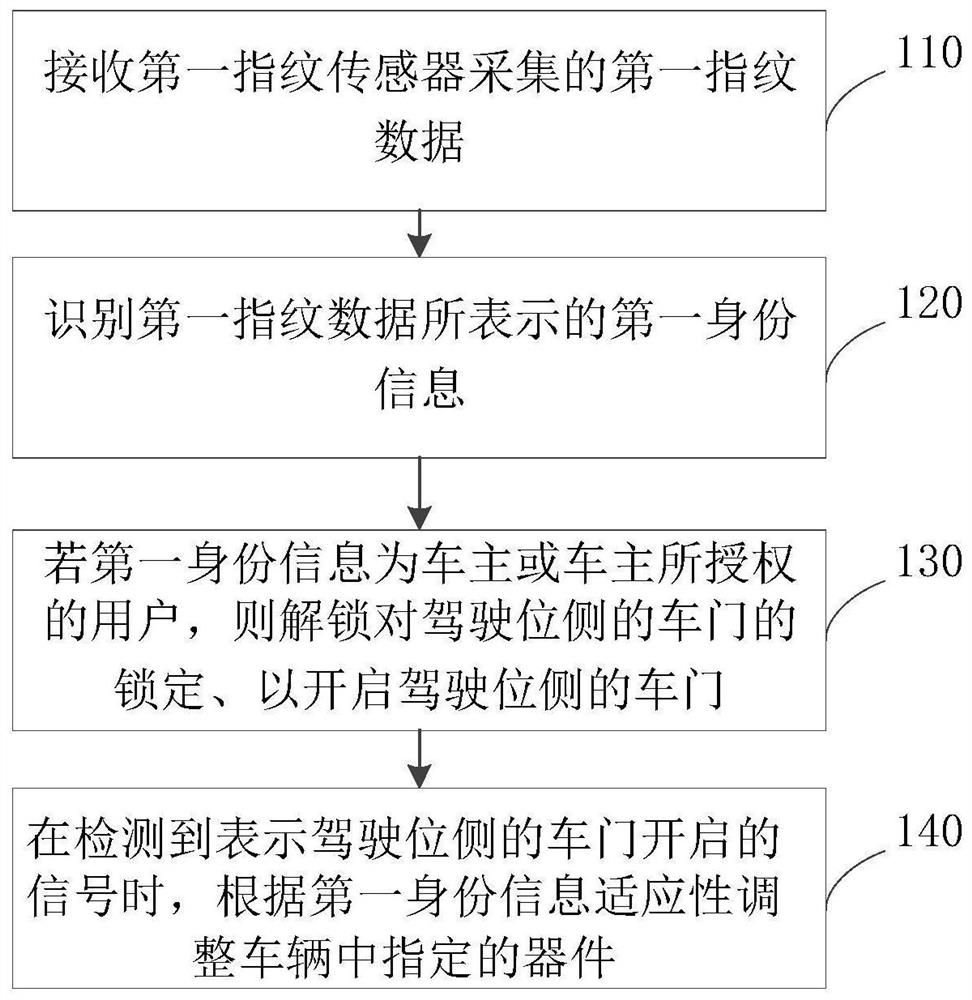

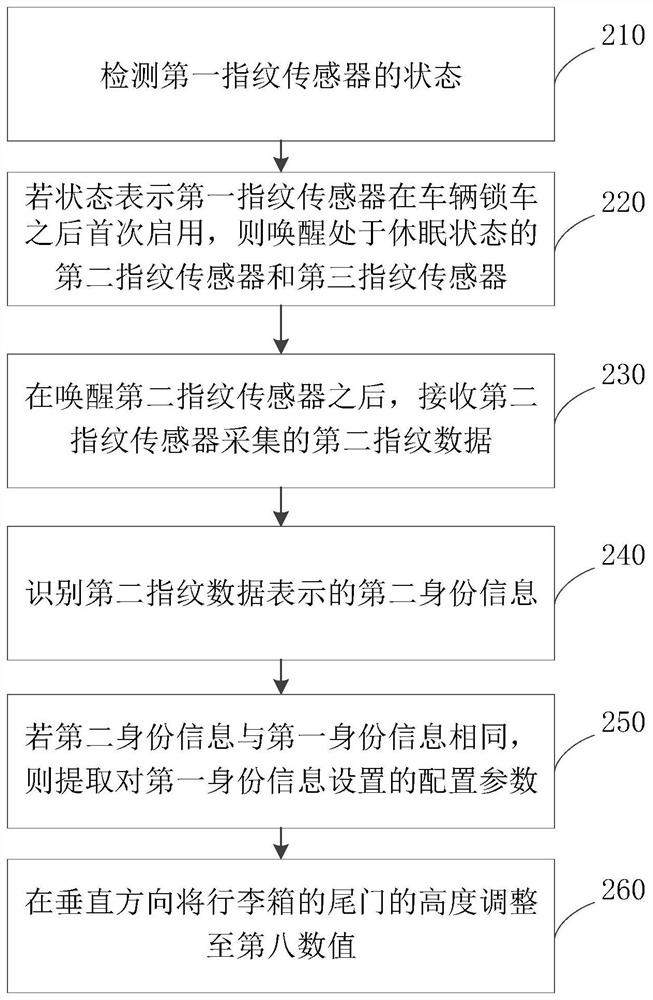

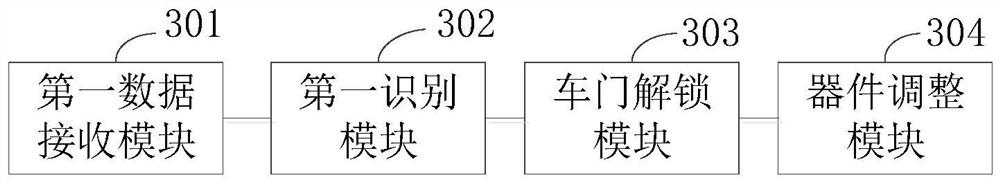

Vehicle starting method, device and equipment and storage medium

The embodiment of the invention discloses a vehicle starting method, device and equipment and a storage medium, and the method comprises the steps: receiving first fingerprint data collected by a first fingerprint sensor, and enabling the first fingerprint sensor to be located on a handle of a vehicle door at the side of a driving seat in a vehicle; identifying first identity information represented by the first fingerprint data; if the first identity information is a vehicle owner or a user authorized by the vehicle owner, unlocking the vehicle door on the driving seat side so as to open thevehicle door on the driving seat side; and adaptively adjusting a specified device in the vehicle according to the first identity information when a signal indicating that the vehicle door on the driving seat side is opened is detected. According to the embodiment of the invention, the identity information is recognized by collecting the fingerprint data, and the automatic adjustment of the devicein the vehicle is realized according to the identity information so that the operation steps of starting the vehicle are reduced, the vehicle starting time is saved, and the user experience is improved.

Owner:CHINA FIRST AUTOMOBILE

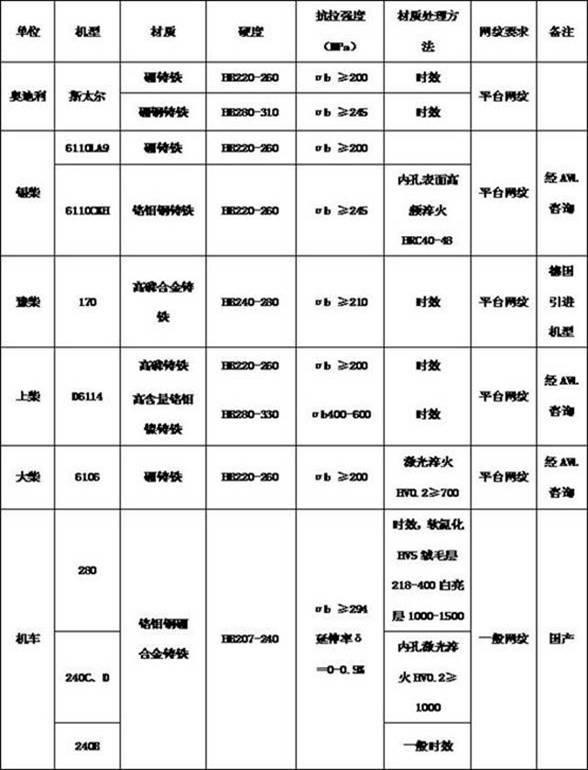

Method for producing austempered ductile iron (ADI) cylinder sleeve

The invention discloses a method for producing an austempered ductile iron (ADI) cylinder sleeve, belongs to metal materials, and in particular relates to the technical field of production processes for ADI supercharged engine cylinder sleeves. The method comprises the steps of casting an ADI cylinder sleeve casting blank, finely machining the cylinder sleeve casting blank, performing isothermal quenching treatment and shot blasting treatment and machining platform reticulate patterns. The method solves the problem that the fatigue property and the abrasion resistance of the conventional service materials such as boron cast iron, boron-copper cast iron, chromium-molybdenum-copper cast iron, high-phosphorus alloy cast iron, high-phosphorus cast iron, high-content chromium-molybdenum-nickel cast iron and chromium-molybdenum-copper-boron alloy cast iron cannot meet the service requirements of high strength engines.

Owner:扬州华铁机电集团有限公司

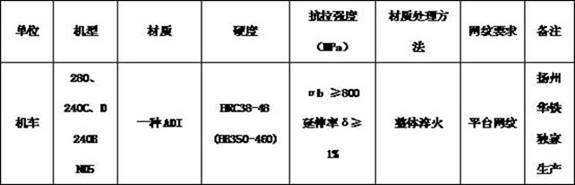

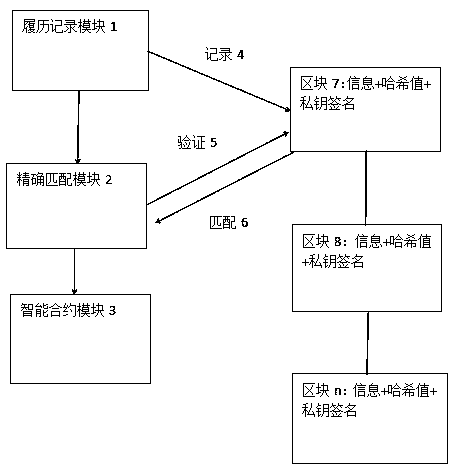

A contract transaction management method and system based on a block chain

InactiveCN109684876AReduce the cost of trustReduce the likelihood of disputesFinanceDigital data protectionSmart contractCapital cost

The invention relates to a contract transaction management method and system based on a block chain. The contract transaction management system comprises a qualification and project experience recording module, an accurate matching module and an intelligent contract module. Wherein the qualification and project experience recording module is used for recording qualification and project experienceof a user; The accurate matching module is used for matching the qualification and the project experience of the user with specific requirements listed by the party A and searching an appropriate transaction object for the party A; And the intelligent contract module is used for operating the contents of the contract and the execution routing algorithm through the intelligent contract, so that thetrust benefits of the two parties of the contract are ensured. Due to the application of the new technology, the contract transaction efficiency is improved, and the time and capital cost are saved.

Owner:河南中欧企业咨询有限公司

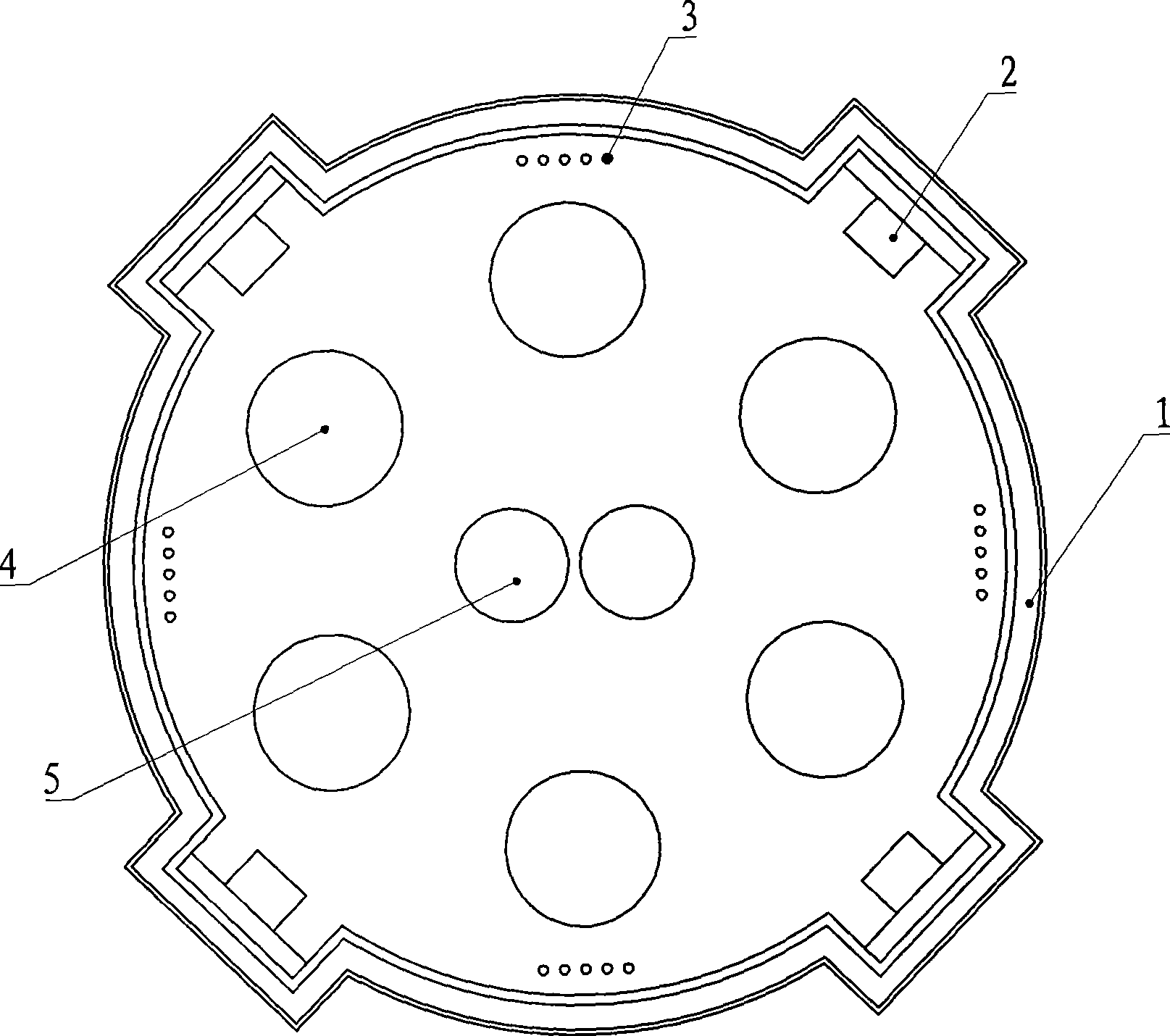

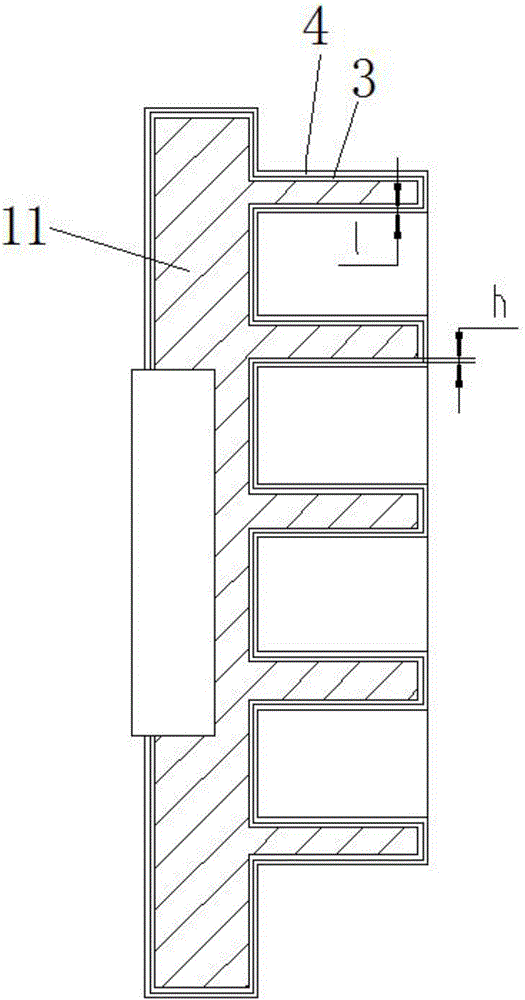

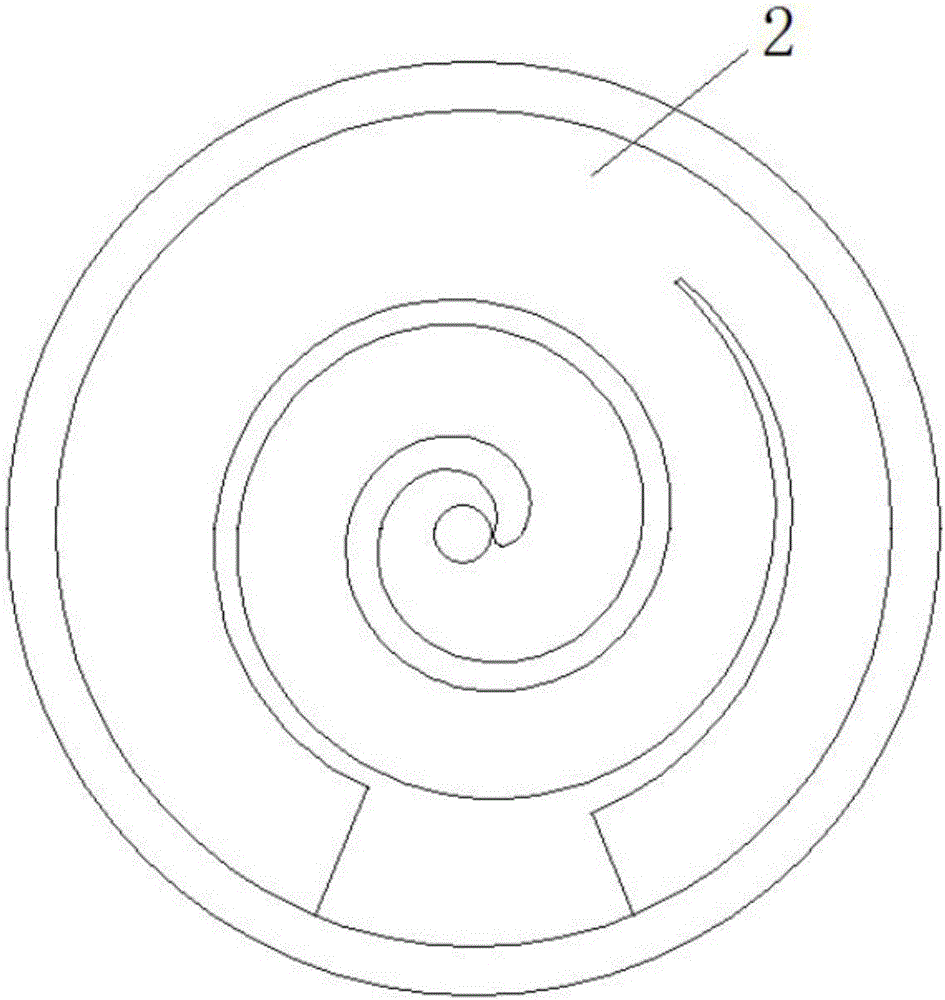

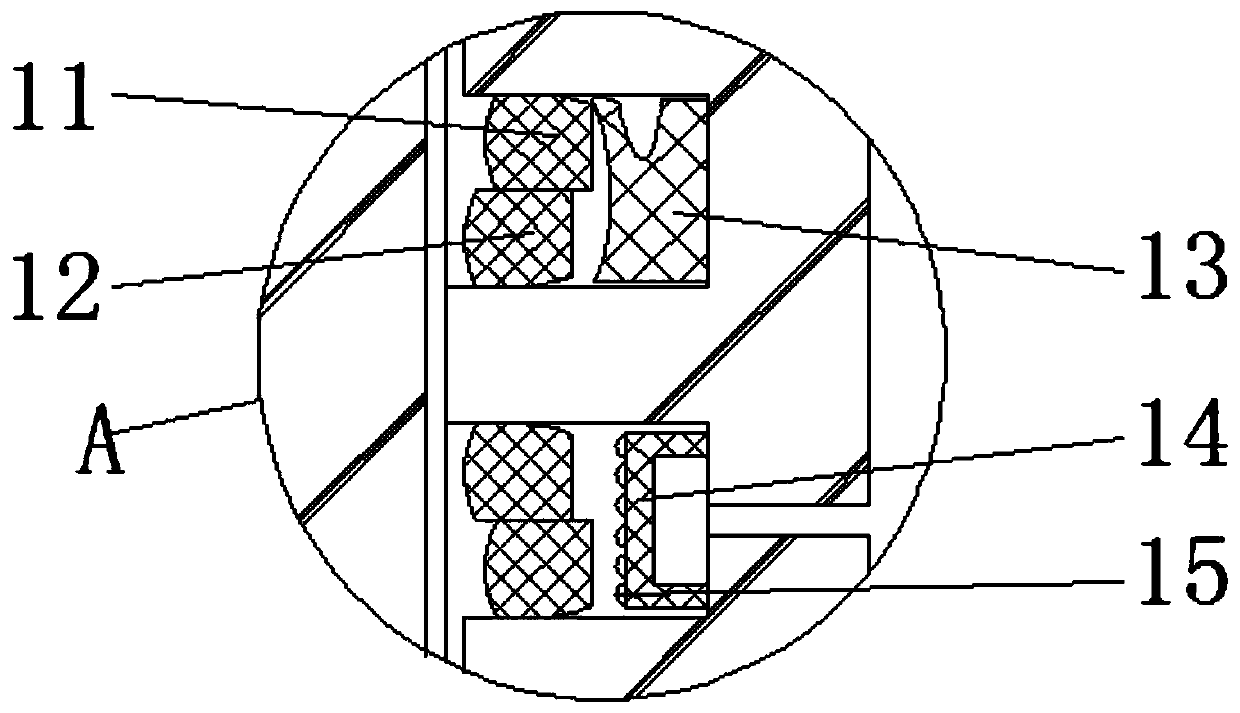

Scroll compressor assembly, manufacturing method thereof and scroll compressor

ActiveCN106762631ACompact structureHigh hardnessAnodisationRotary piston pumpsMicro arc oxidationSurface roughness

The invention relates to a scroll compressor assembly. The scroll compressor assembly comprises a movable scroll part and a static scroll part, wherein the movable scroll part comprises a first main body; the static scroll part comprises a second main body; the surface, opposite to the second main body, on the first main body is defined as a first surface; the surface, opposite to the first main body, on the second main body is defined as a second surface; ceramic layers are formed on the first surface and / or the second surface through micro-arc oxidation treatment, so that service wear of the movable scroll part and the static scroll part is reduced; and the ceramic layers are good in abrasion resistance, high in hardness and low in surface roughness, so that the scroll compressor assembly can maintain high matching precision and stable working performances during the long-term utilization process. The invention further relates to a scroll compressor with the scroll compressor assembly and a manufacturing method of the scroll compressor assembly. The scroll compressor is high in reliability and long in service life. The manufacturing method is simple, efficient and energy-saving, and pollution is reduced.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

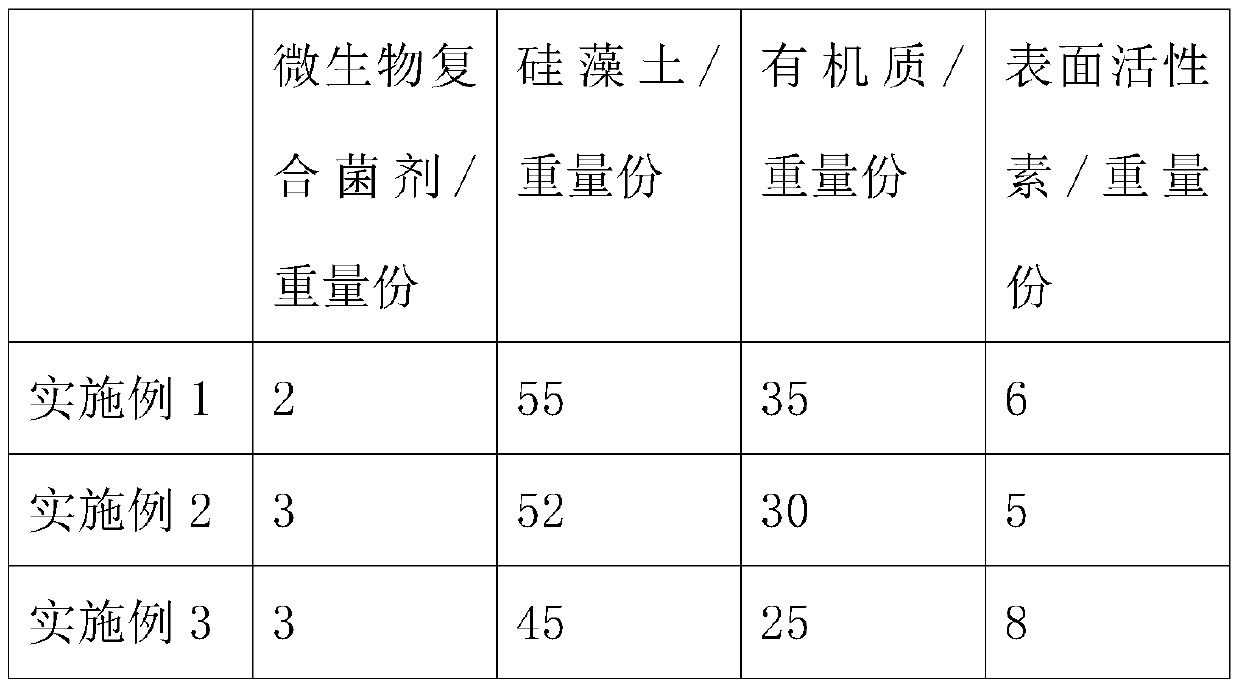

Microorganism compound fungicide, soil repairing agent and preparing method and application of fungicide

InactiveCN110004091ASynergistic effectImprove soil structureBiocideFungiContinuous croppingBacillus licheniformis

The invention provides a microorganism compound fungicide, a soil repairing agent and a preparing method and application of the fungicide. The microorganism compound fungicide comprises bacillus licheniformis, bacillus mucilaginosus, yeast, nitrogen-fixing bacteria and microorganism growth aids. After the compound fungicide is reasonably combined with organic matter, a porous carrier and surfactin, the soil repairing agent for preventing and treating soil continuous cropping diseases is formed; the lost nutrients of a continuous cropping land can be compensated for, bacteria restraining and resisting substances can be generated through the metabolism effect of the microorganisms, and the soil physiochemical performance and soil structure of the continuous cropping land are comprehensivelyimproved from different aspects. The soil repairing is conducted on the soil continuous cropping land through various approaches, and the repairing effect is improved.

Owner:微生物肥料技术研究推广中心

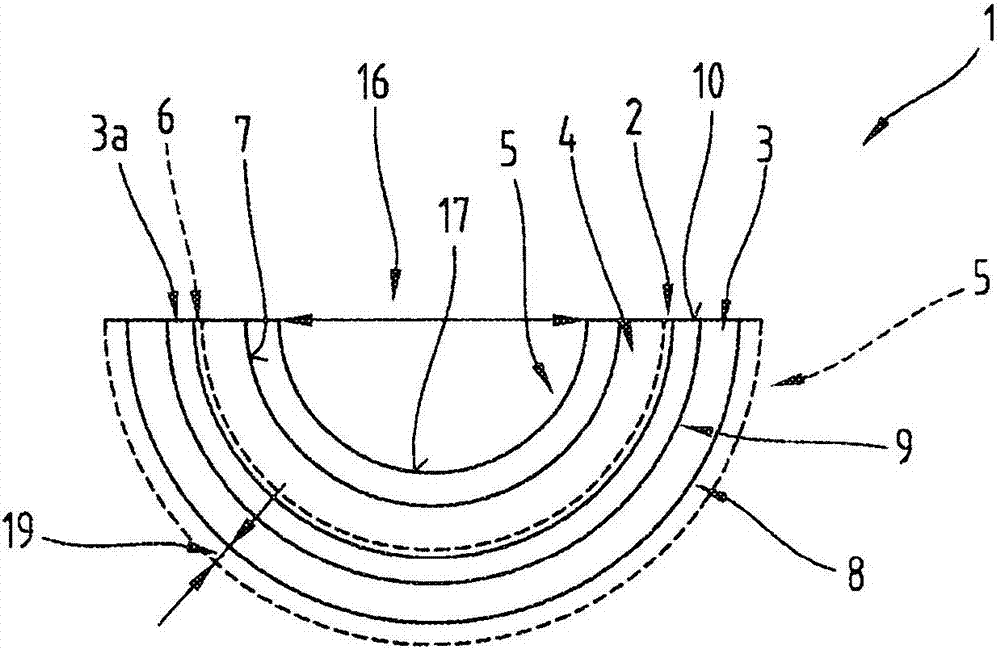

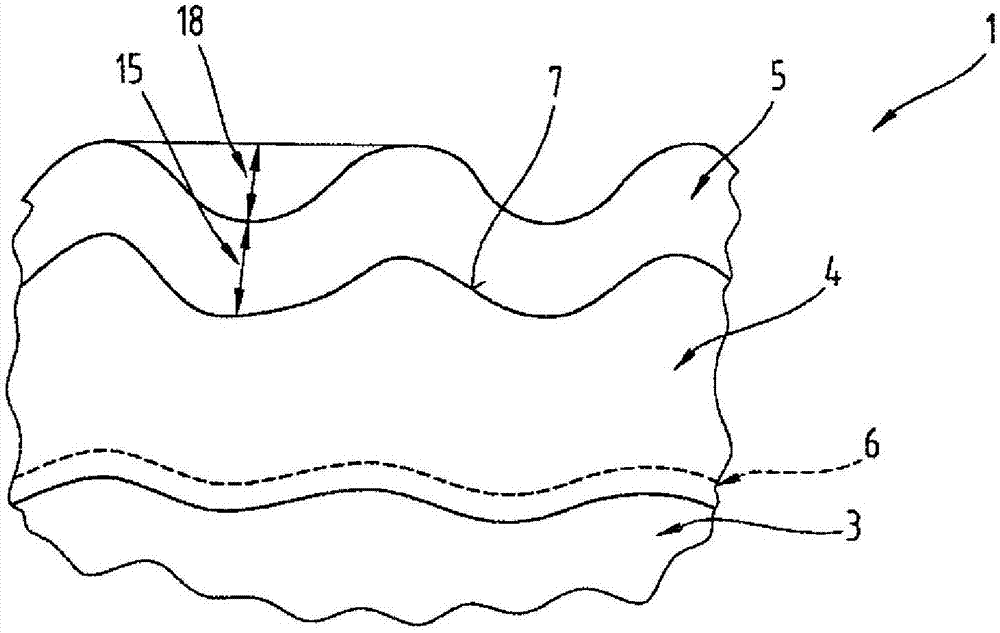

Sliding element, in particular a piston ring, having a coating

ActiveUS9488275B2Maintain good propertiesFavorable run-in behaviorPiston ringsSuperimposed coating processHydrogenPiston ring

The invention relates to a sliding element, in particular a piston ring, having at least one running surface. The running surface comprises a coating, which from the inside to the outside has at least one first adhesive layer, a hard hydrogen-free DLC layer, a second adhesive layer, a soft hydrogen-containing, metal and / or metal carbide-containing DLC layer, which is softer than the hard hydrogen-free DLC layer, and a hard hydrogen-containing DLC layer, which is harder than the soft hydrogen-containing, metal and / or metal carbide containing DLC layer.

Owner:FEDERAL MOGUL BURSCHEID

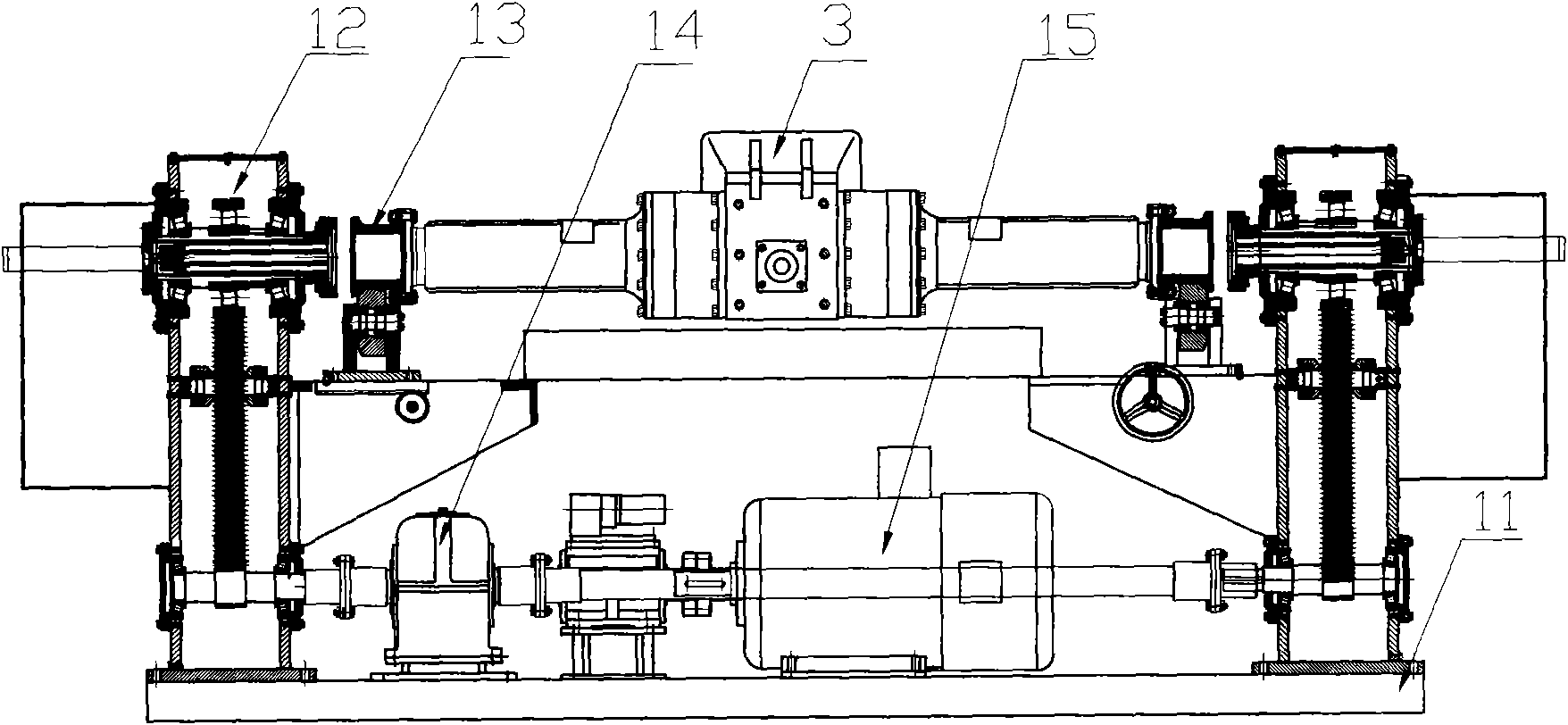

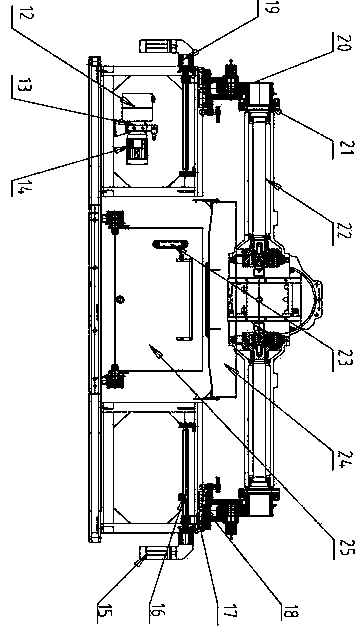

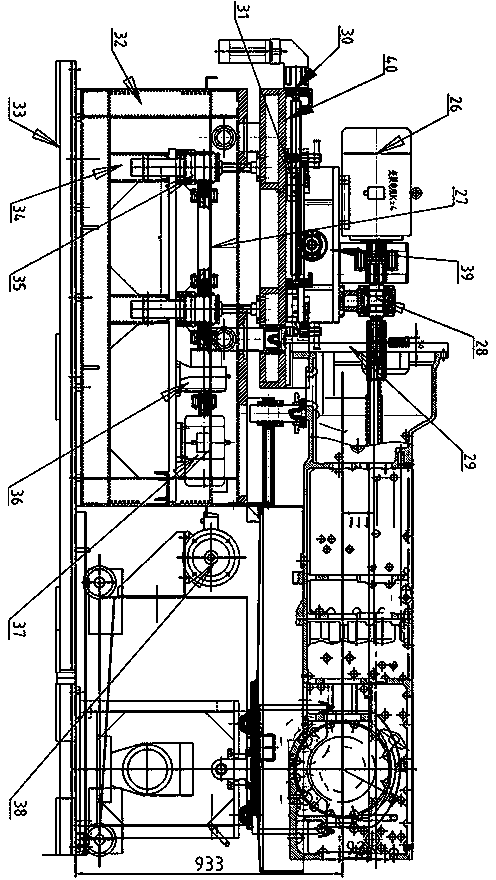

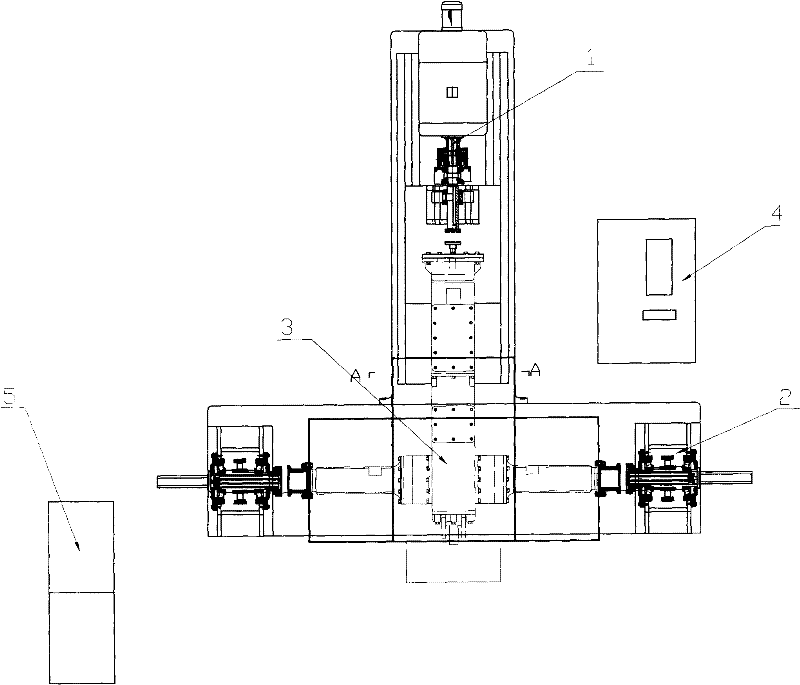

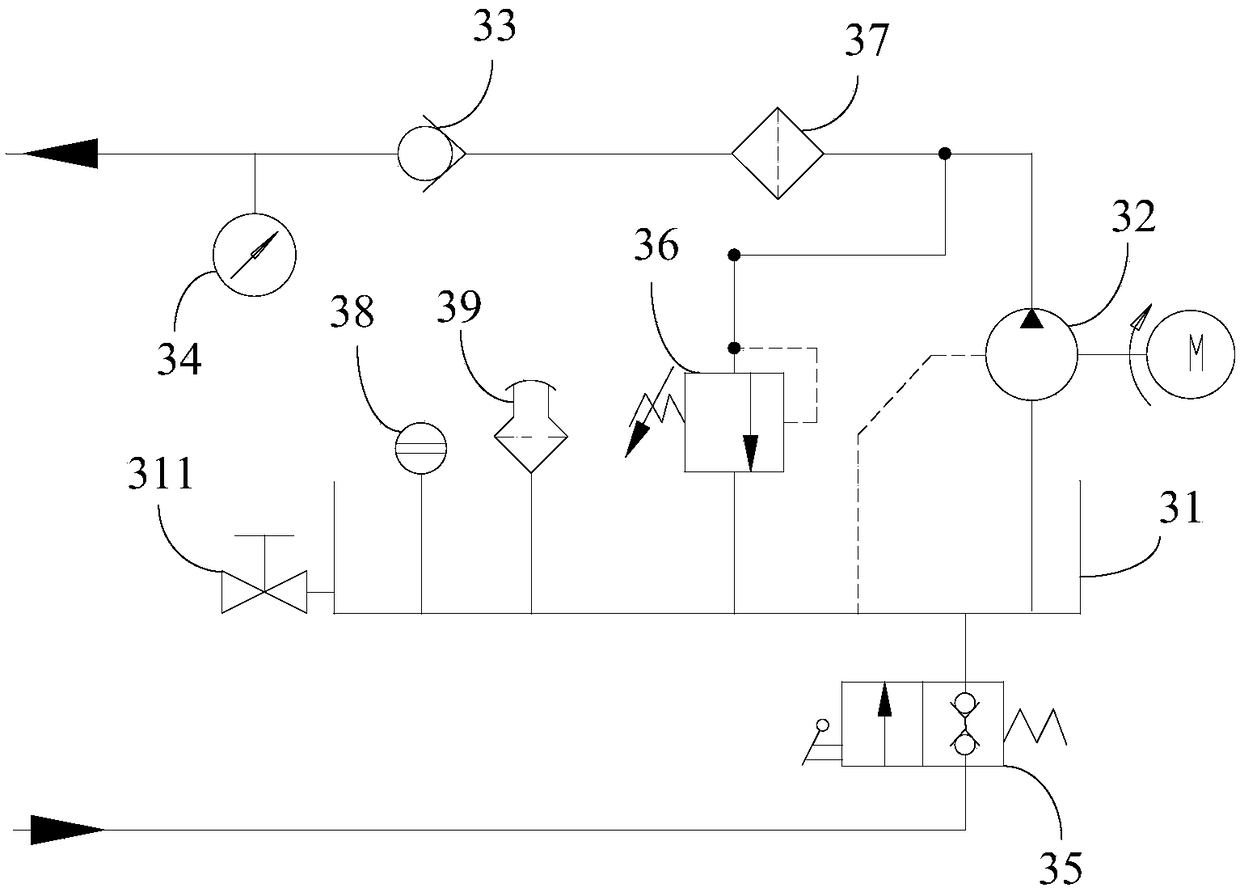

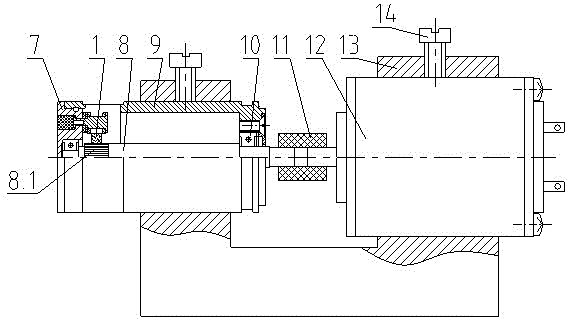

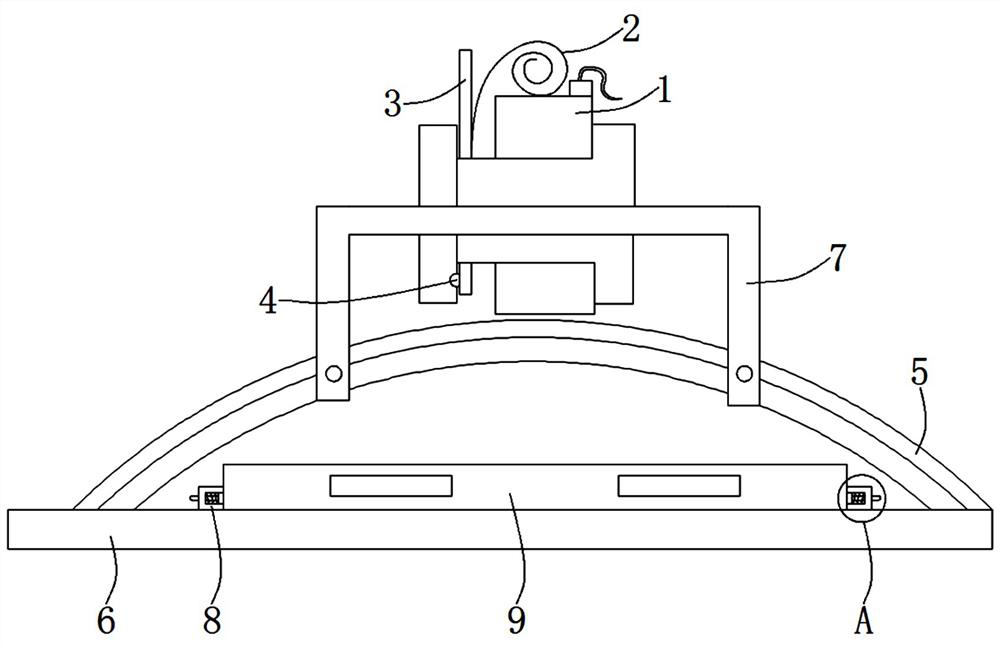

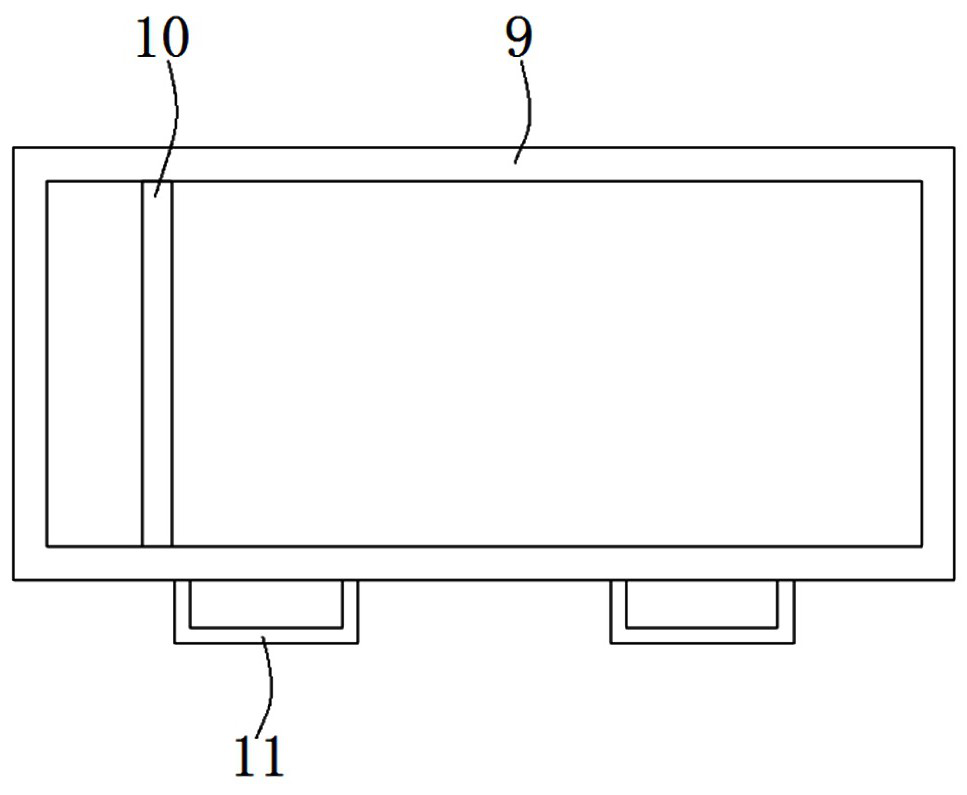

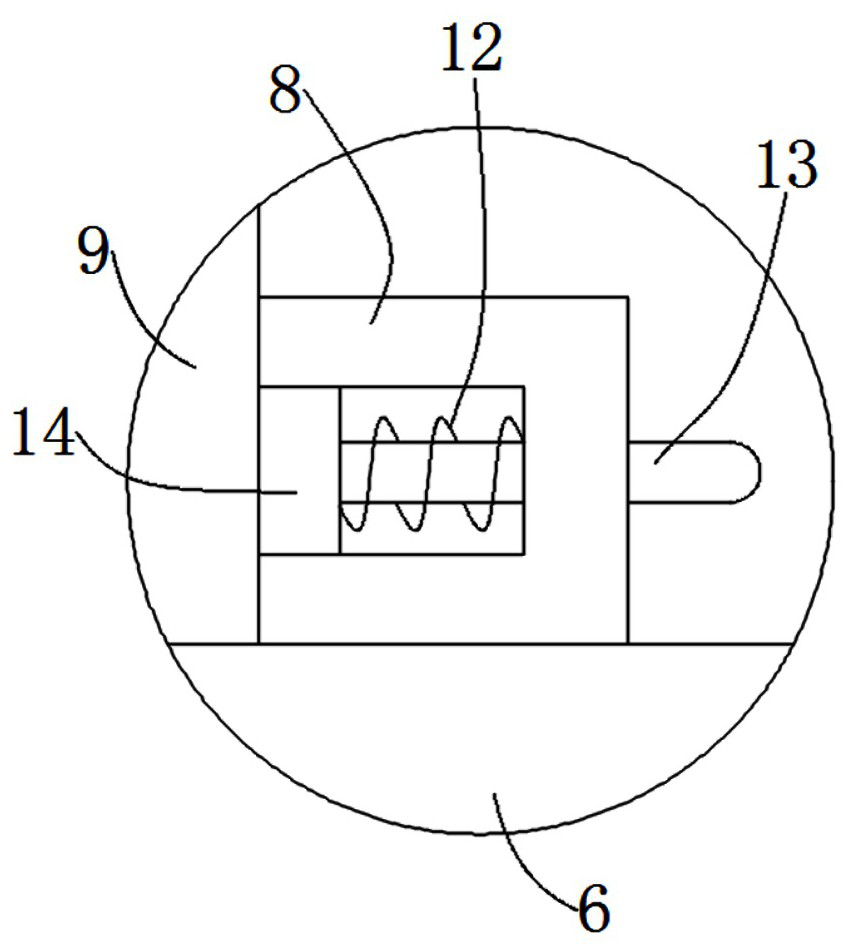

Tractor chassis self-weight load type running-in purification test stand and running-in purification process thereof

ActiveCN103454094AShorten the timeReduce job preparation timeVehicle testingAutomatic controlEngineering

The invention discloses a tractor chassis self-weight load type running-in purification test stand and process. The tractor chassis self-weight load type running-in purification test stand comprises an input mechanism, a lifting mechanism, a rear axle installation locating mechanism, a front end installation locating mechanism, an input machine base, a rear axle machine base, a base, a hydraulic system, a hydraulic purification system and an automatic control system. The running-in purification process of the test stand is further disclosed. According to the tractor chassis self-weight load type running-in purification test stand and the running-in purification process, running-in purification can be conducted by utilizing the self-weight load of a tractor chassis transmission system under the condition that an external loading mechanism is not added, potential safety hazards inside the transmission system are removed, energy and time are saved, and production efficiency and quality of the whole vehicle are improved.

Owner:湘潭科达电工专用成套设备有限责任公司

Intelligent recruitment system based on block chain

InactiveCN109636327AReduce the cost of trustShorten break-in timeDatabase distribution/replicationOffice automationSmart contractRouting algorithm

The invention relates to an intelligent recruitment system based on a block chain. The intelligent recruitment system comprises a history recording module, an accurate matching module and an intelligent contract module. The resume recording module is used for recording the working resume of a user with high reliability through a block chain technology. The accurate matching module is used for matching the history of the user with the recruitment requirements of the employer and searching the most suitable talents for the specific positions; and the intelligent contract module is used for operating the contents of the contract and the execution routing algorithm through the intelligent contract, so that the trust benefits of the two parties of the contract are ensured. Due to the application of the new technology, the efficiency of the talent market is improved, and the time and capital cost are saved.

Owner:河南中欧企业咨询有限公司

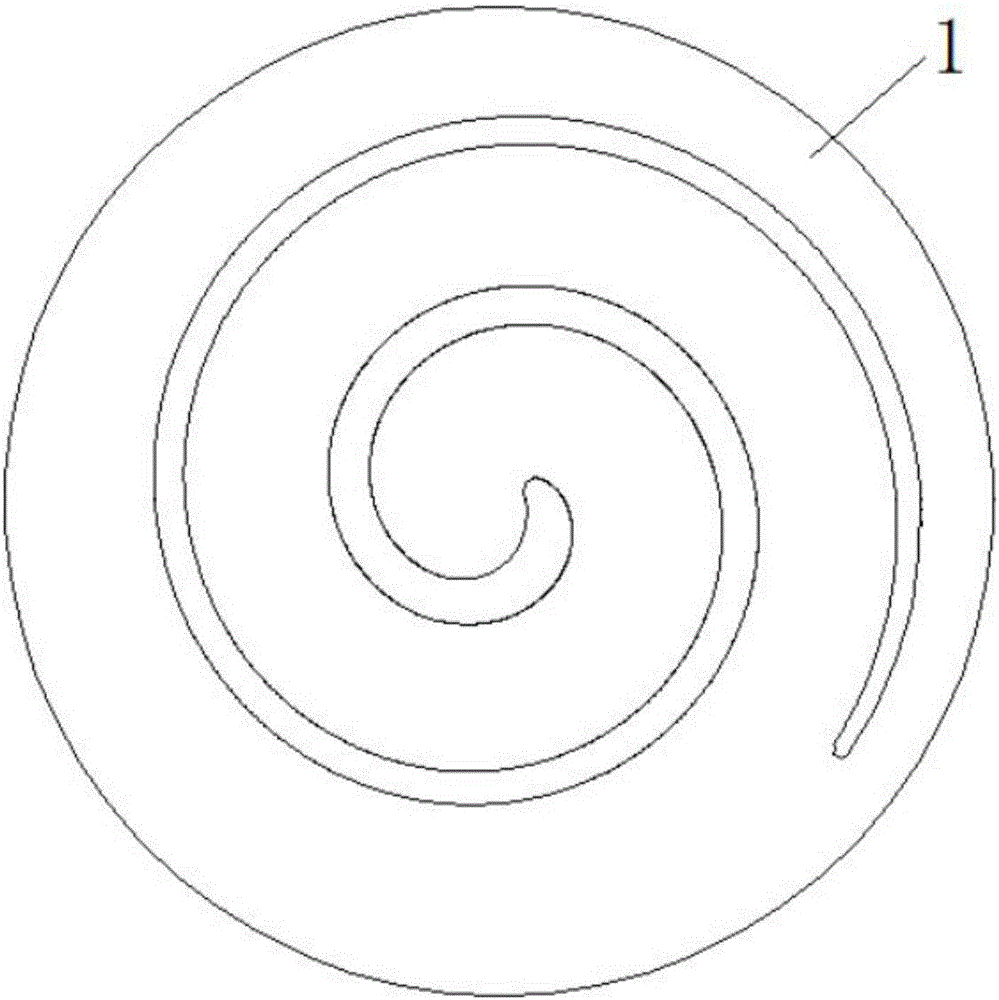

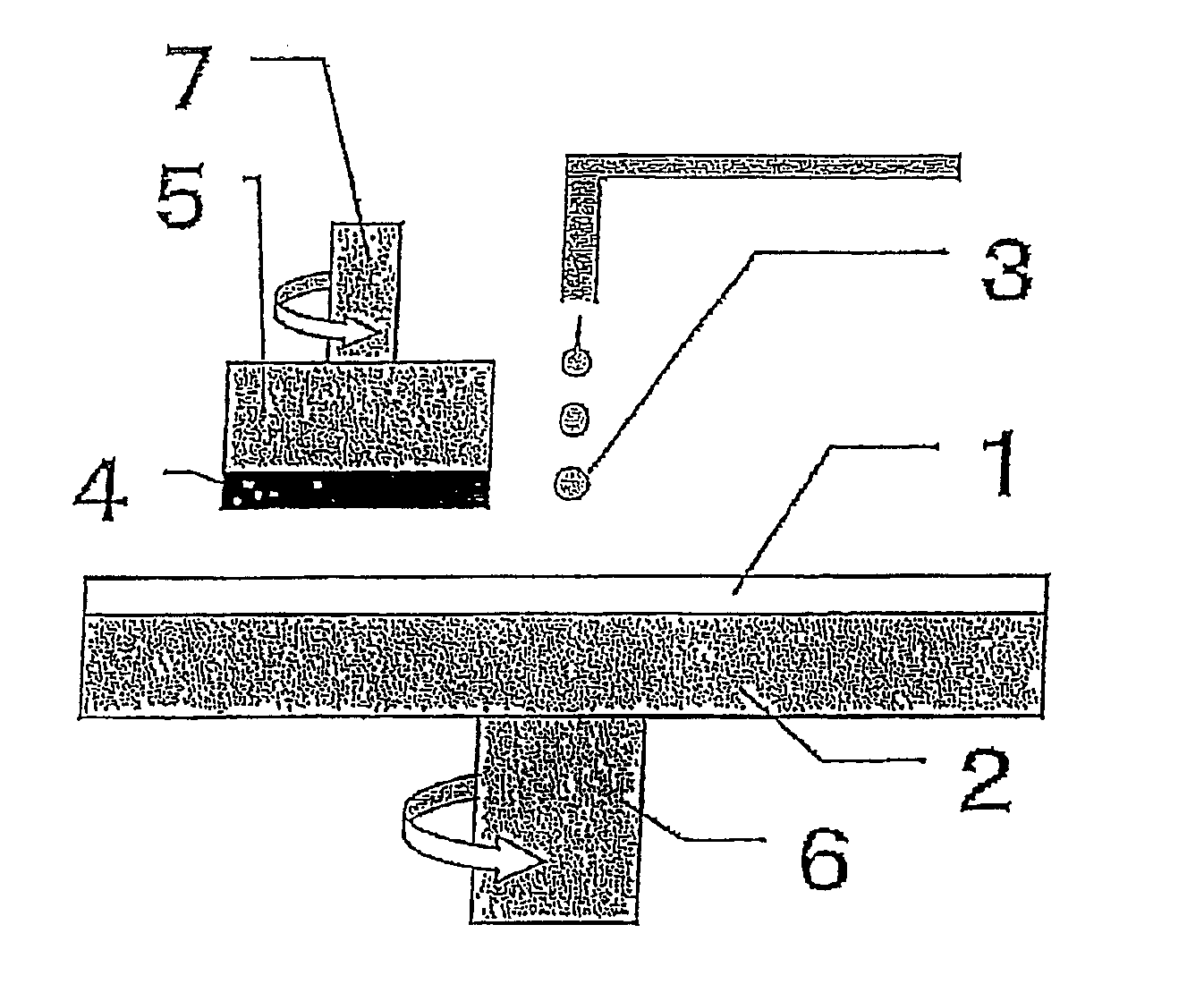

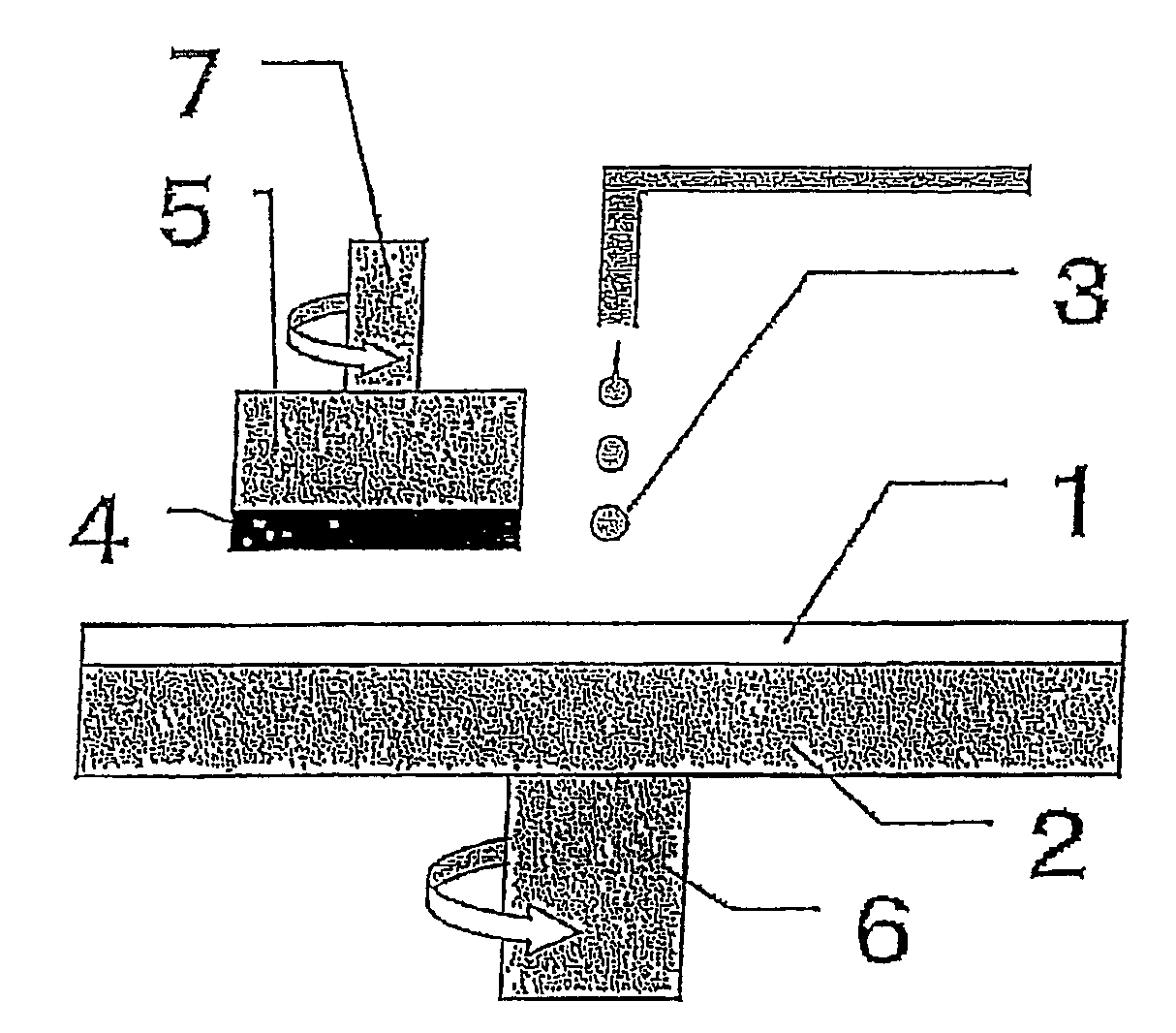

Polishing pad and method for producing same

ActiveUS9156127B2High thickness accuracyShorten break-in timeLayered productsAbrasion apparatusMetallurgyMaterials science

An object of the invention is to provide a polishing pad that achieves a high polishing rate and has high thickness precision so that the break-in time (dummy polishing time) can be shortened, and to provide a method for producing same. The invention is directed to a polishing pad including a base material layer and a polishing layer provided on the base material layer, wherein the polishing layer includes a thermoset polyurethane foam having roughly spherical interconnected cells with an average cell diameter of 35 to 200 μm, and the polishing layer has a storage modulus E′ (40° C.) of 130 to 400 MPa at 40° C., a ratio of storage modulus E′ (30° C.) at 30° C. to storage modulus E′ (60° C.) at 60° C. [E′(30° C.) / E′(60° C.)] of 1 to less than 2.5, and a ratio of storage modulus E′ (30° C.) at 30° C. to storage modulus E′ (90° C.) at 90° C. [E′(30° C.) / E′(90° C.)] of 15 to 130.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

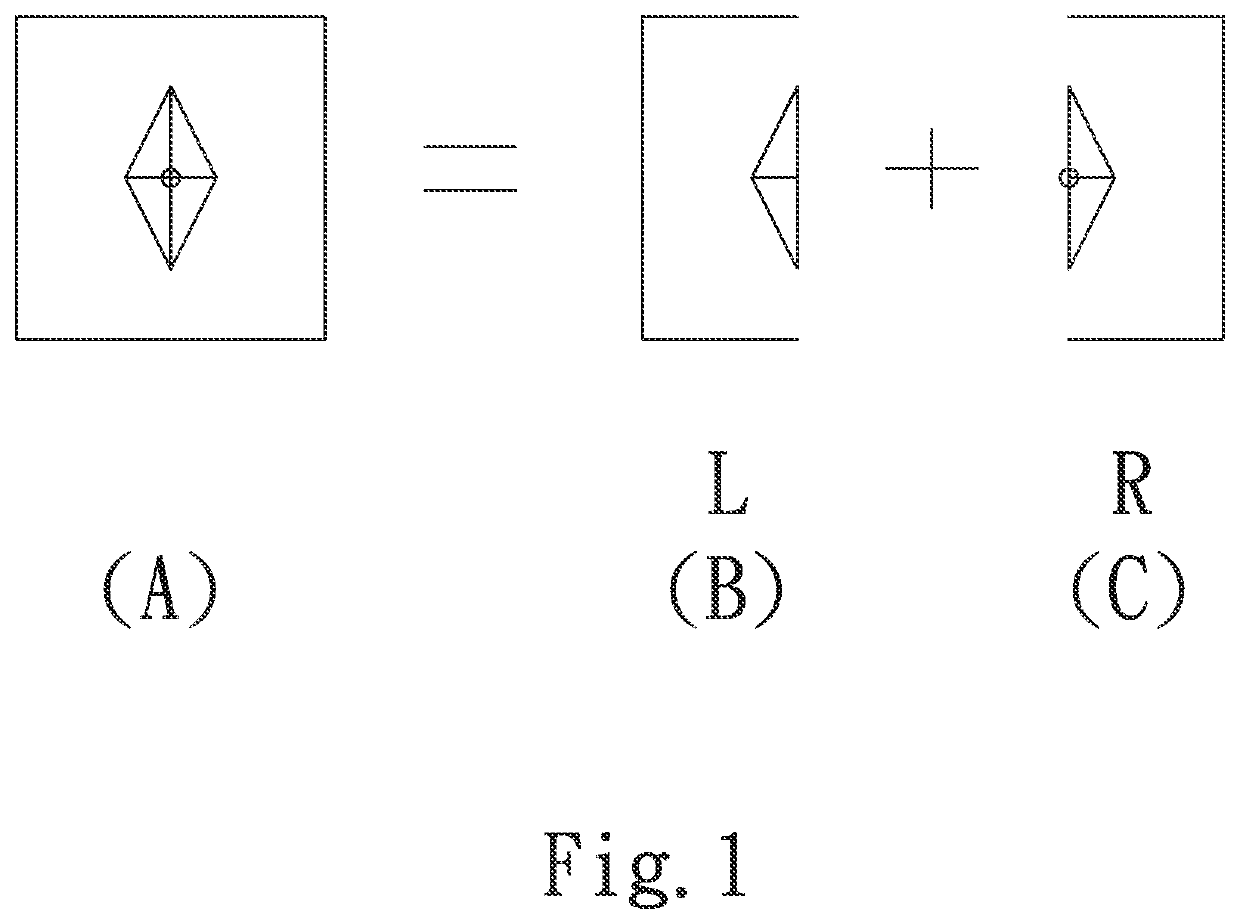

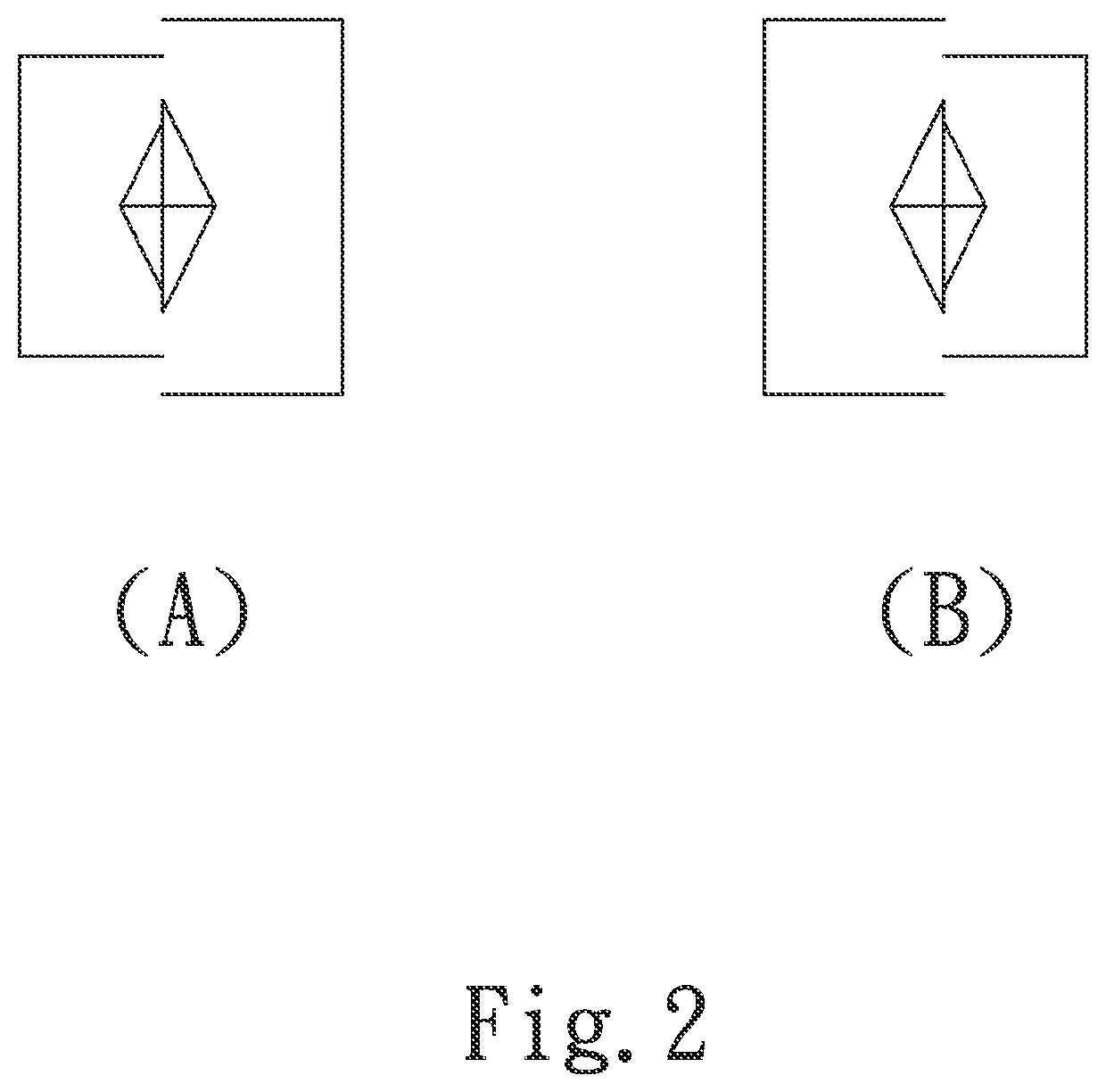

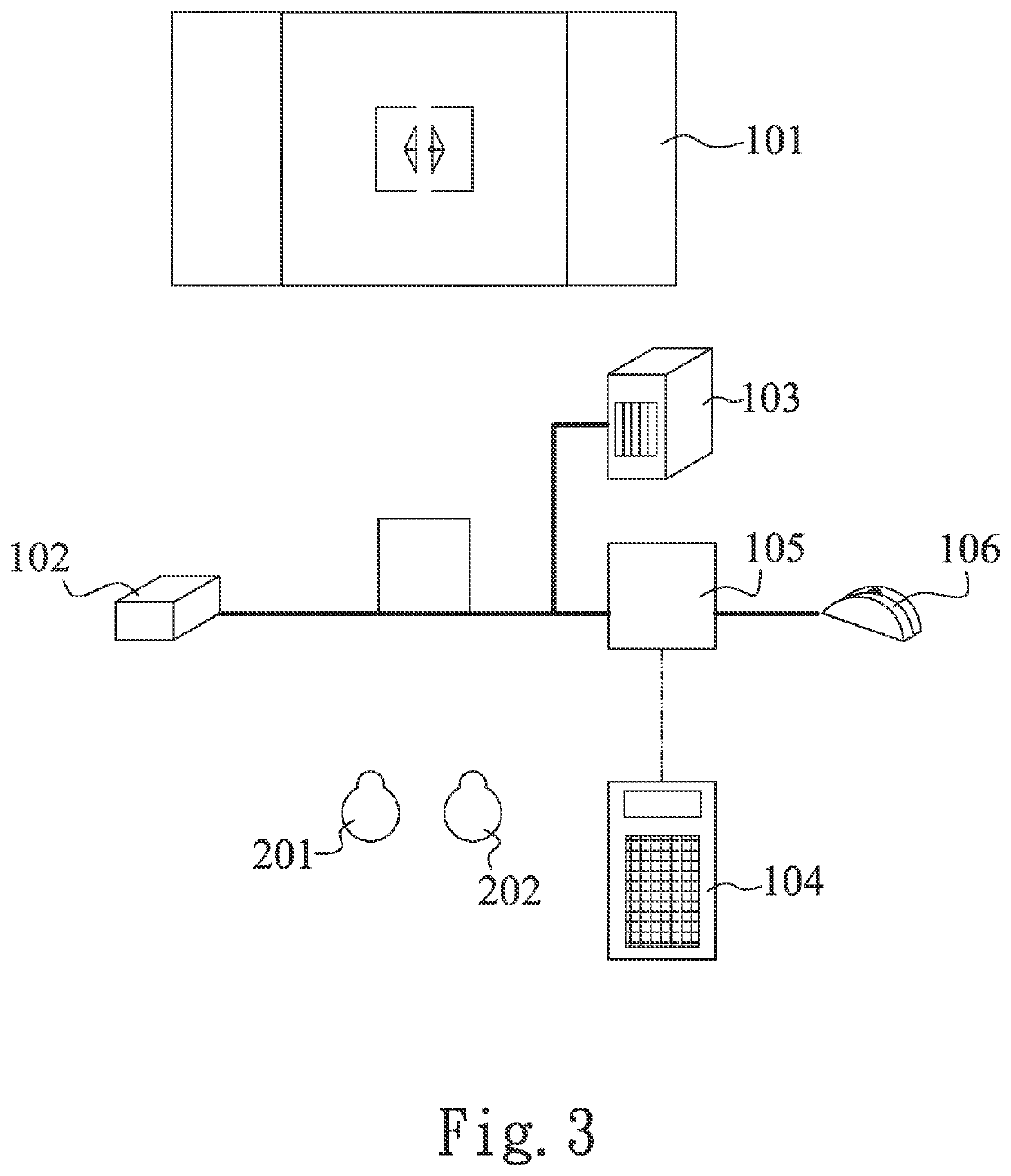

Vision inspection and correction method, together with the system apparatus thereof

PendingUS20220206291A1Shorten break-in timeAdapt quicklySpectales/gogglesPhotometryVisual markingVision inspection

A vision inspection and correction method, which mainly uses an image adjustment software / device to separate the eyes of the inspected person on an independent display screen, and the visual mark seen by the same vision is designed to be misaligned; through the guidance and interaction of the inspector and the inspected person, the inspector can adjust the image operation to zoom in / out / shift / focus / diverge / rotate, etc., so that the inspected person's binocular images can be clearly distinguished and adjusted. Then, the binocular images are aligned, and the inspector will implant the correction parameters during the image adjustment process into 3D projectors, VR (virtual reality), AR (augmented reality device), MR hybrid reality device and other equipment to adjust the binocular digital image parameters, thus the users can enjoy personalized adjustment and comfortable images of both eyes, or provide them to lens makers, based on this, create lenses that can make the inspected person's eyes see clearly aligned images.

Owner:PASSION LIGHT INC

Half-thread half-burr type cylinder sleeve and production method thereof

InactiveCN107654309AShorten break-in timeExtended service lifeCylinder headsCylindersSurface roughnessPulp and paper industry

The invention discloses a half-thread half-burr type cylinder sleeve. The half-thread half-burr type cylinder sleeve comprises an air cylinder sleeve base body; an inner coating is formed on the innersurface of the air cylinder sleeve base body; the inner coating ranges from 80 [mu]m to 120 [mu]m in surface roughness and ranges from 0.2mm to 0.4 mm in thickness; a burr portion and a thread portion are formed on the outer surface of the air cylinder sleeve base body and are independent of each other; the burr portion is provided with a plurality of protrusions which range from 0.1 mm to 0.5 mmin height; and the thread portion comprises a plurality of thread grooves which range from 0.2mm to 0.4 mm in groove depth. By means of the half-thread half-burr type cylinder sleeve disclosed by theinvention, the bonding strength to the air cylinder sleeve base body can be improved, the abrasion resistance is sufficient, and the effective heat conductivity is advantageously obtained.

Owner:ZYNP GRP ANHUI CO LTD

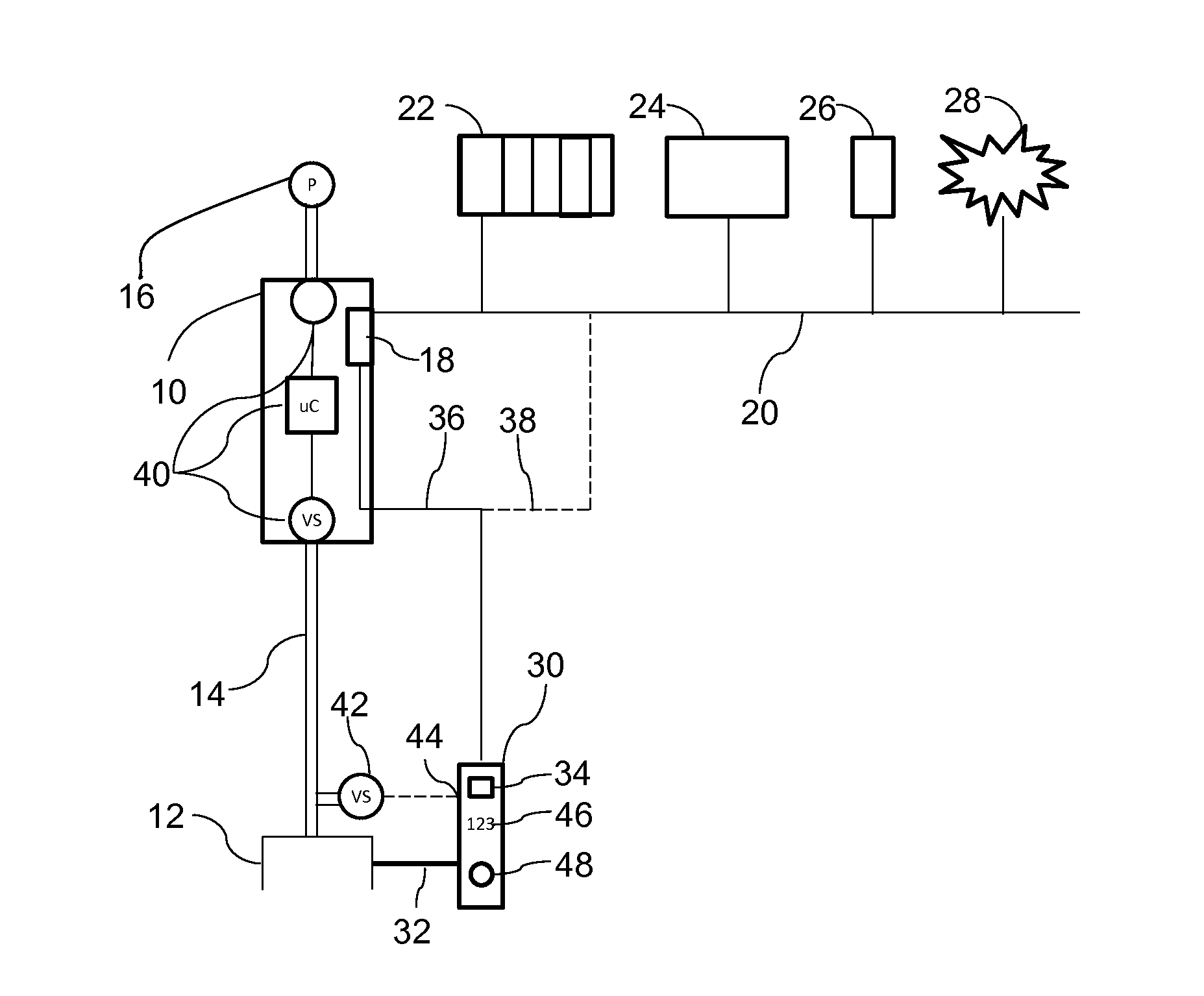

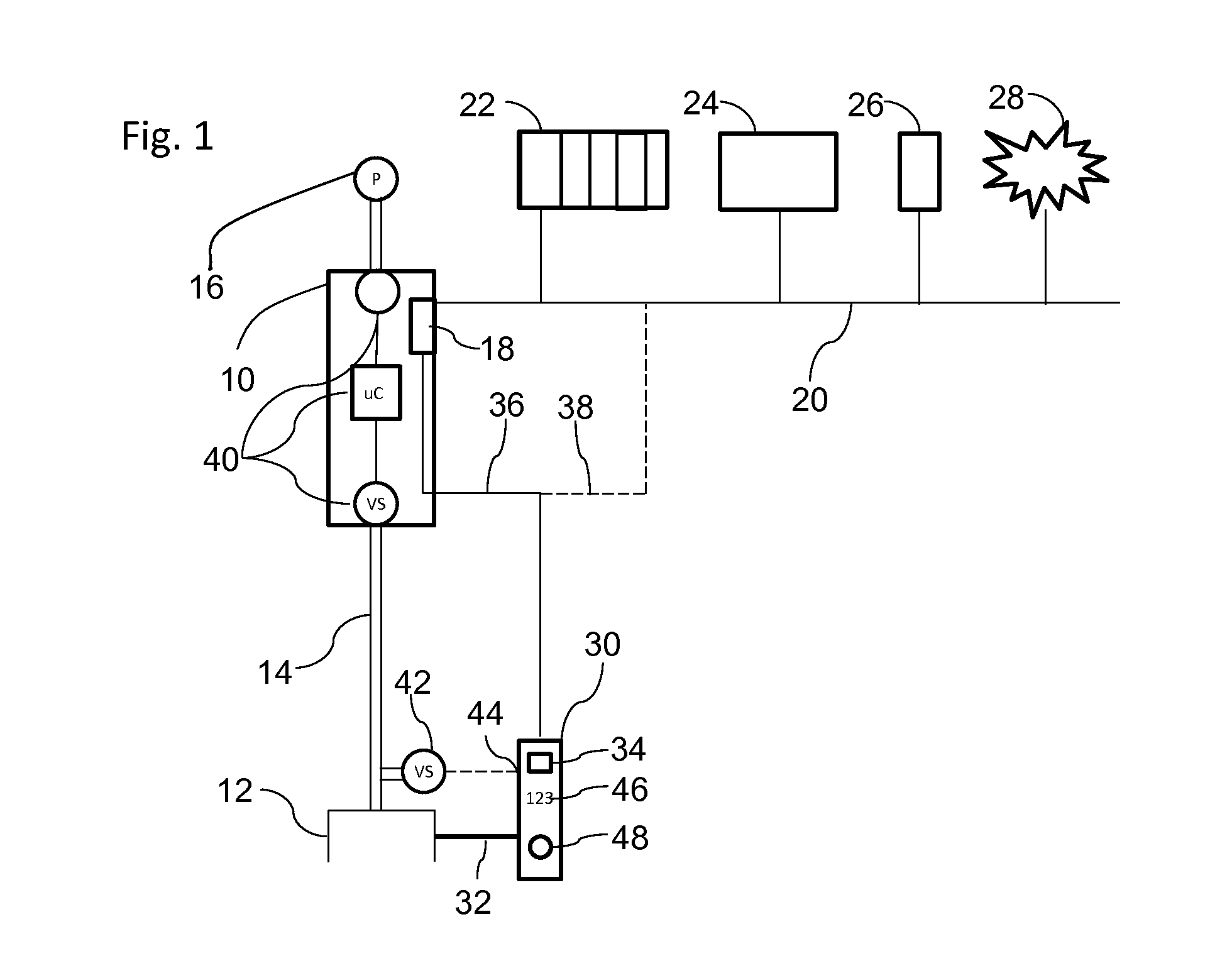

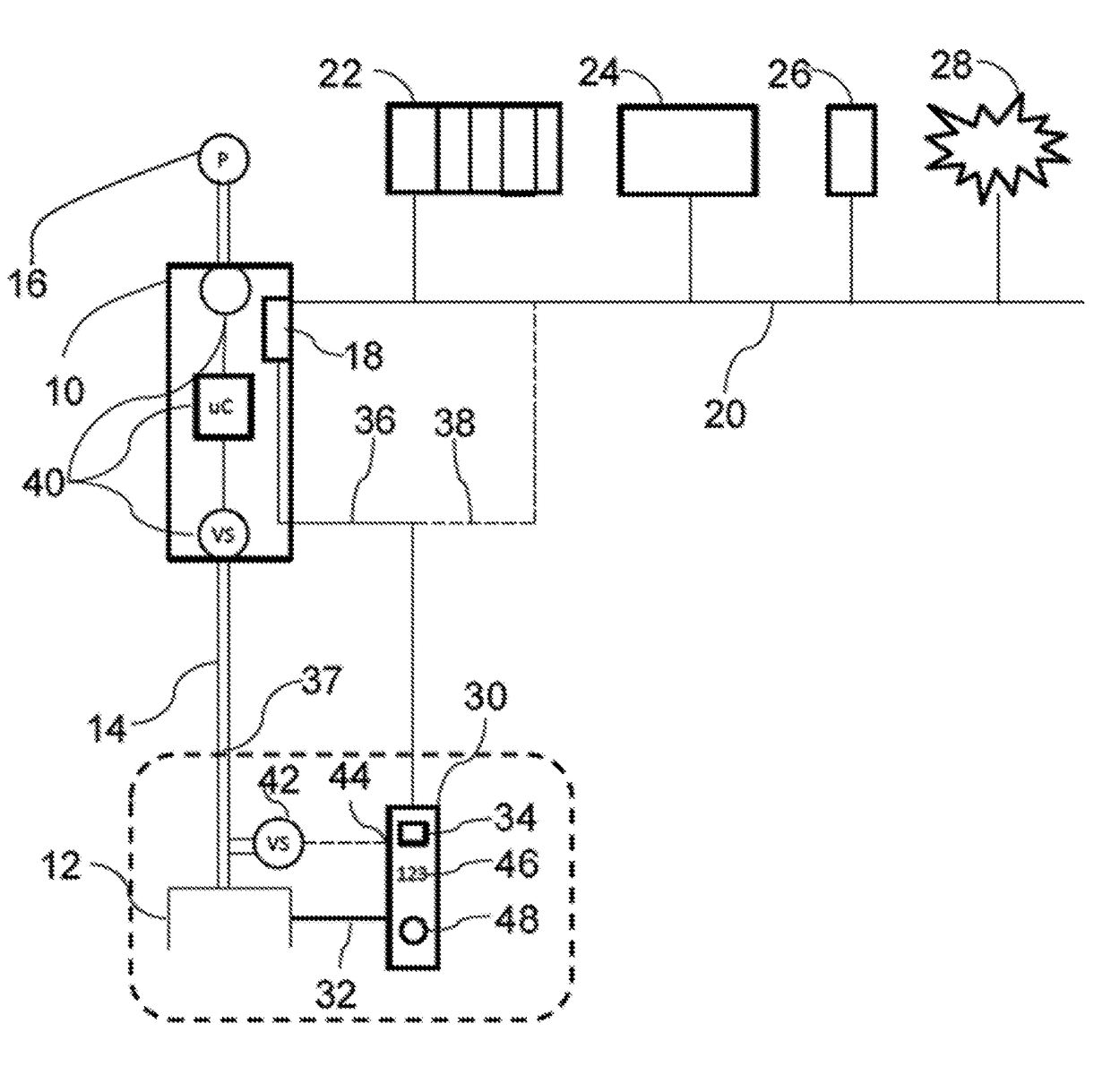

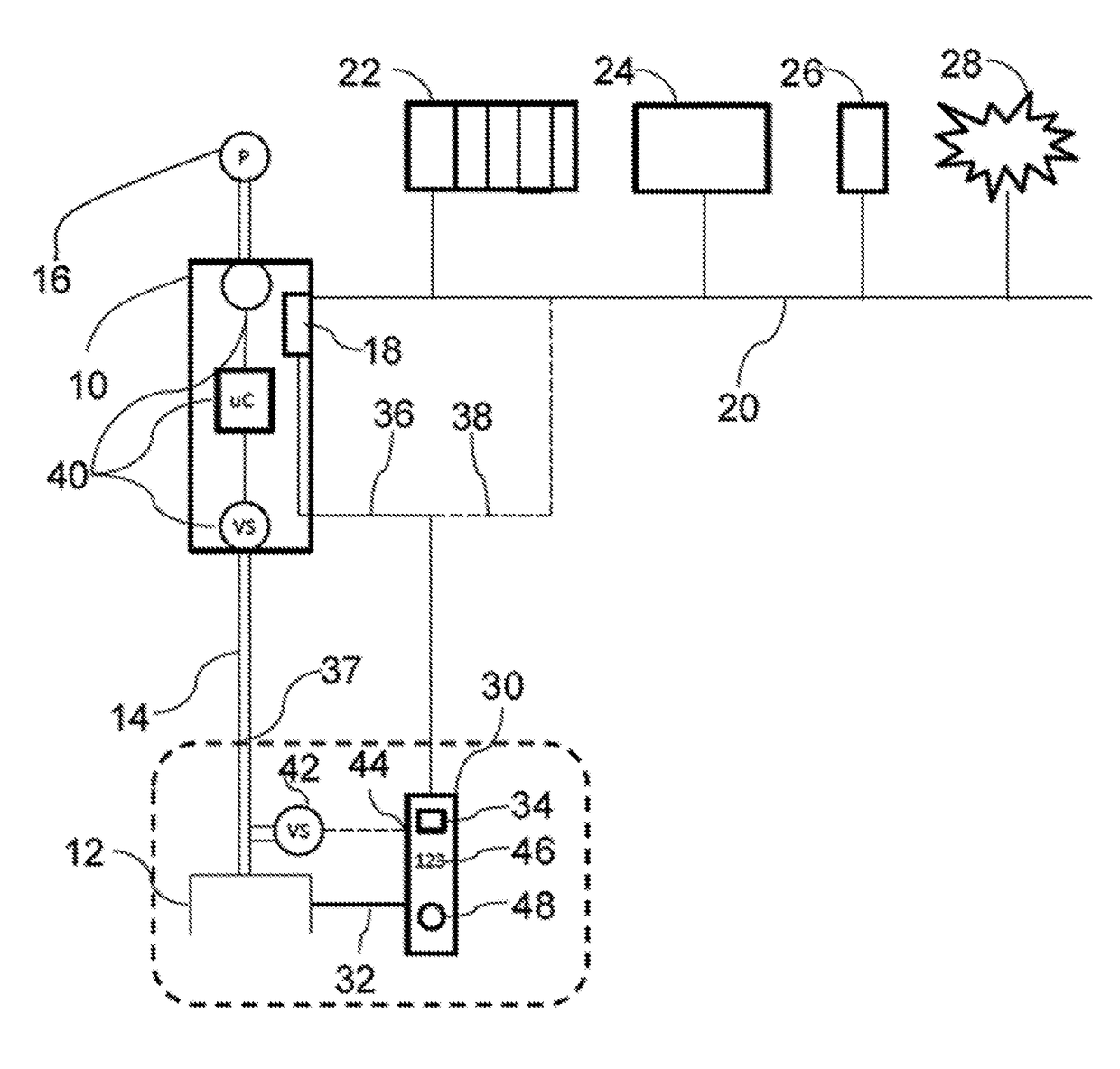

Handling system and method of operating a handling system

ActiveUS20150283707A1Improve scalabilityShorten break-in timeGripping headsKitchen equipmentEmbedded systemHandling system

A handling system having at least one vacuum generator and an associated vacuum handling device connected to and operable via the vacuum generator. The vacuum handling device is provided with an individually assigned recognition unit including a memory device in which operating data for the vacuum handling device is storable and can be read out. Each vacuum generator has a respective sub-control unit adapted to control the vacuum generator depending on data transmitted from the recognition unit. The memory device of the recognition unit can be read out directly from the sub-control unit.

Owner:J SCHMALZ GMBH

Sliding bearing element

The invention relates to a sliding bearing element (1) with a running layer (4) made of a first tin-based alloy and an additional layer (5) made of an additional tin-based alloy, said alloys containing at least one element of a group comprising Cu, Ni, Ag, Sb, As, Pb, Bi, Te, Tl and / or non-metal particles. The first tin-based alloy has a strength index FI of at least 5 and maximally 25 and the additional tin-based alloy has a strength index (FI) of at least 0.3 and maximally 3. The strength index of the running layer (4) is at least five times the strength index of the additional layer (5), and the strength index FI is defined by the equation, in which C represents at least one of the elements Cu, Ni, Ag; S represents Sb and / or non-metal particles; B represents at least one of the elements Pb, Bi, Te, Tl; and omega represents the total content of each of the tin-based alloy components assigned to the letters C, S, and B.

Owner:MIBA SINTER AUSTRIA

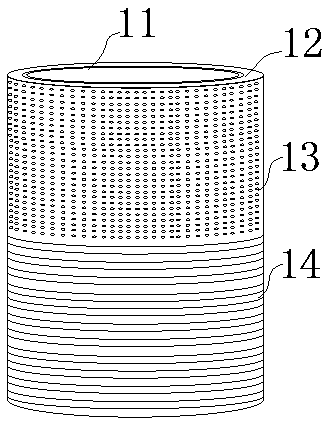

Aluminum alloy cylinder sleeve and preparation method thereof

InactiveCN107460377AHigh hardnessShorten break-in timeMolten spray coatingCylinder headsAluminium alloyCoating

An aluminum alloy cylinder liner disclosed by the present invention comprises a cylinder liner base, the inner surface of the cylinder liner base is coated with a ceramic material to form an inner coating, and the chemical composition of the cylinder liner base includes C: 0.1% by weight ~0.4%, Si:15%~20%, Cr:0.2%~0.4%, Ni:0.1%~0.2%, Mo:0.2%~0.3%, Cu:2%~5%, Zn:≤0.4%, Mn: 0.2%~0.3%, Ti: ≤0.4%, and the balance is Al. The aluminum alloy cylinder liner disclosed by the invention has excellent high-temperature stability and wear resistance, high mechanical strength, light weight, excellent thermal conductivity, and is beneficial to heat dissipation of the engine.

Owner:ZYNP GRP ANHUI CO LTD

Tractor and automobile chassis load running-in test bench and its running-in process

The invention relates to the electromechanical field, and discloses a tractor and automobile chassis load running-in test bench and a running-in process thereof, wherein the running-in test bench includes an input mechanism, a lifting mechanism, an output mechanism, a loading mechanism, a base, a hydraulic purification system and an automatic control system; The input mechanism is located at one end of the base, and a lifting mechanism is arranged between the input mechanism and the base; the output mechanism and the loading mechanism are located at the other end of the base, and the loading mechanism is located below the output mechanism and passes through the coupling and the output mechanism connection; the automatic control system is electrically connected with the input mechanism and the loading mechanism; during the running-in test, the input mechanism, the output mechanism and the hydraulic purification system are respectively connected with the tractor or the automobile chassis test piece. The running-in process mainly adopts the loading and running-in purification process. The invention has the beneficial effects of improving the quality of the whole vehicle, saving energy, time, occupying space, improving production efficiency, reducing the repair rate of products leaving the factory, and being capable of automatic control.

Owner:湘潭科达电工专用成套设备有限责任公司

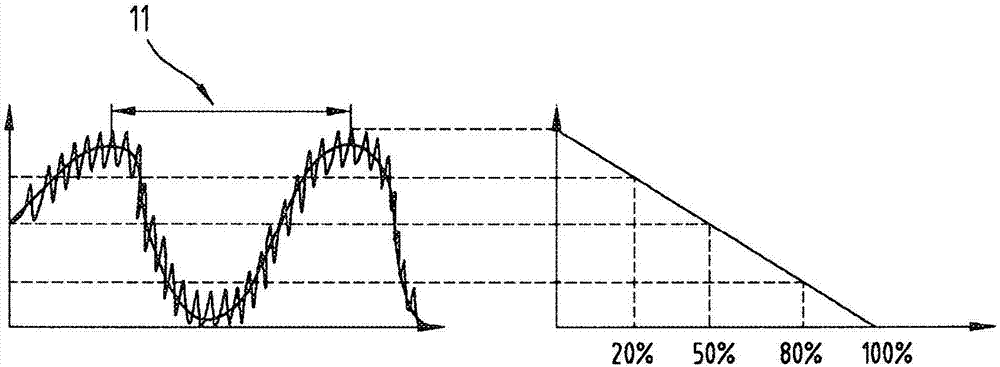

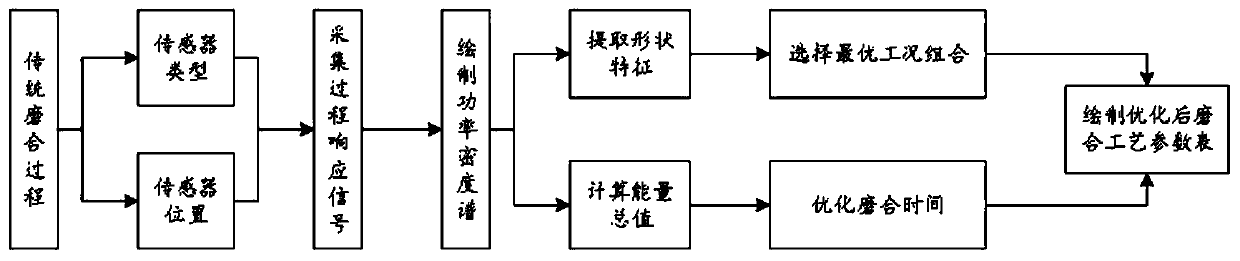

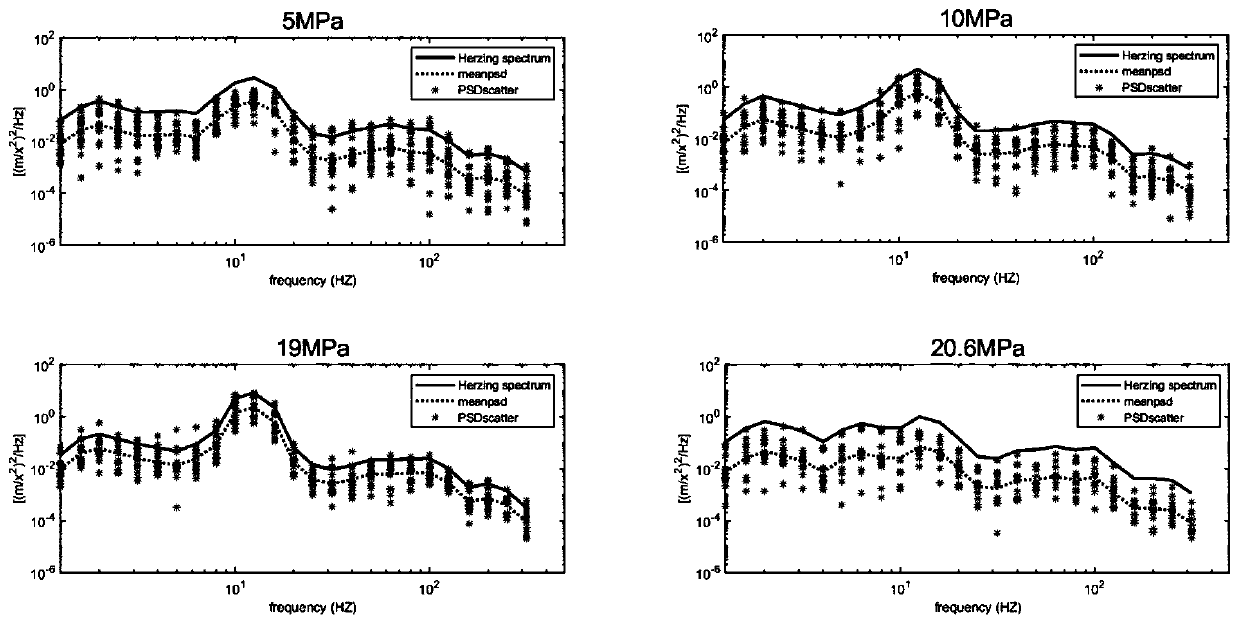

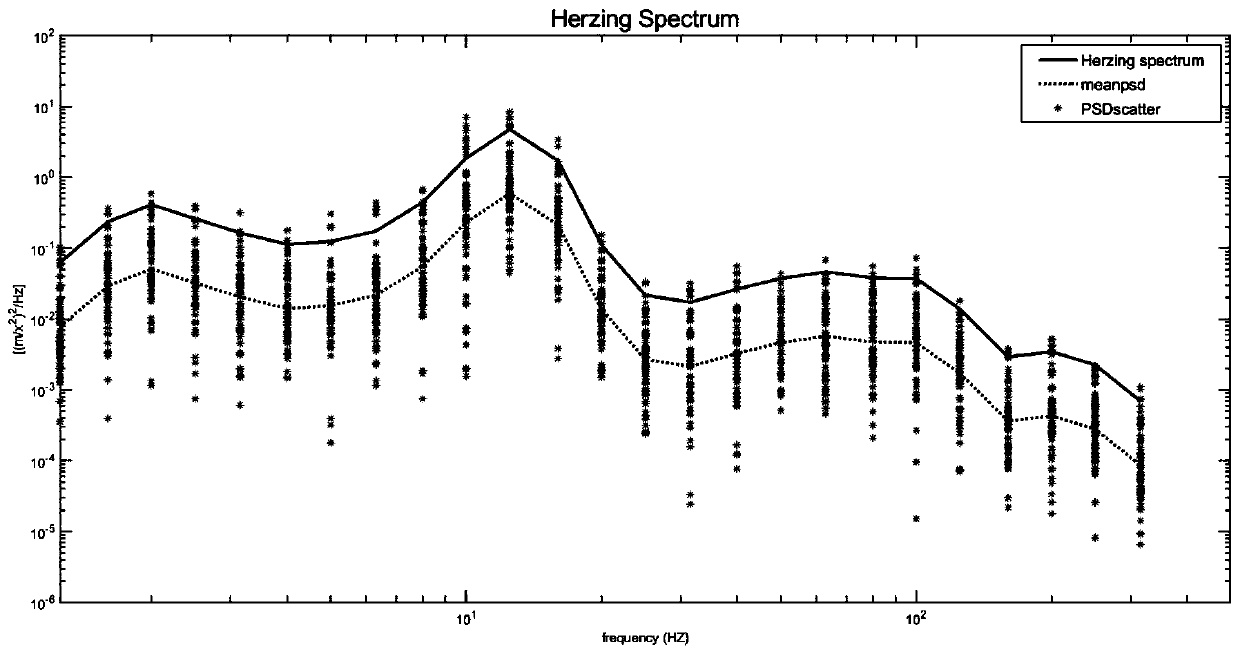

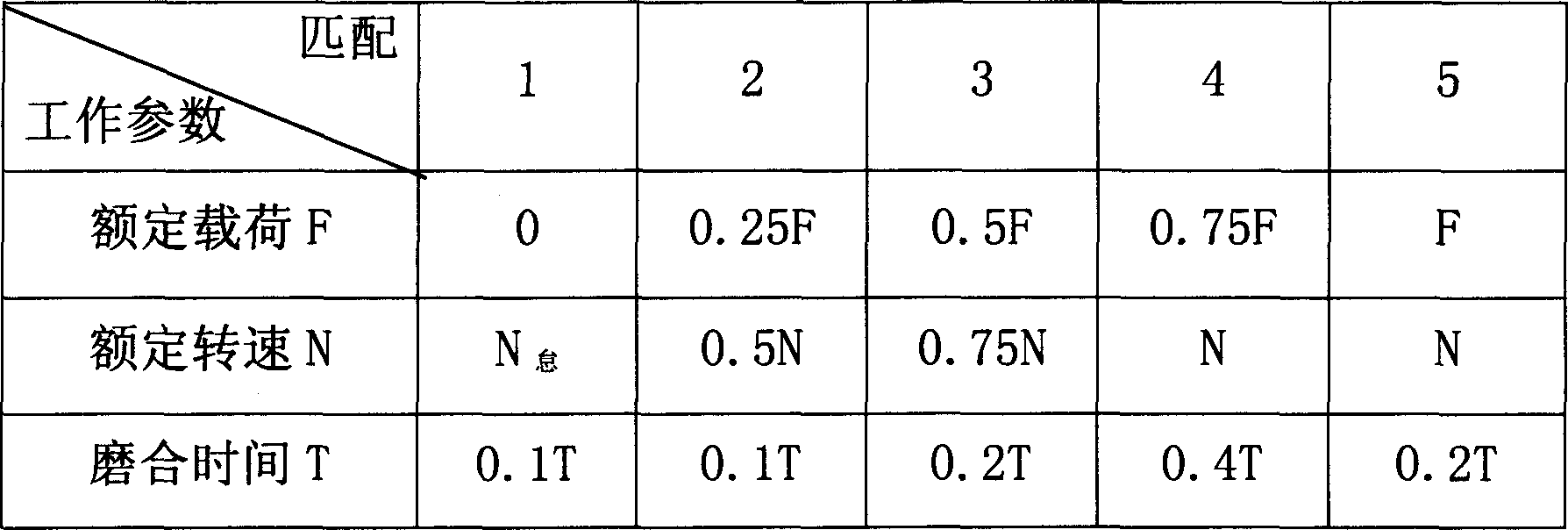

Method for optimizing running-in process of mechanical product by utilizing power spectral density curve

ActiveCN110866339ASame sizeConsistent total energyDesign optimisation/simulationCAD numerical modellingProcess engineeringMechanical products

The invention discloses an optimization method of a mechanical product running-in process. The method comprises the following steps: step 1, collecting a traditional running-in process signal; step 2,drawing a random signal power density spectrum; step 3 , calculating the total energy value in one running-in cycle of the traditional method; step 4, selecting an optimal working condition combination; step 5, optimizing the running-in time; and step 6, drawing an optimized running-in process parameter table.

Owner:BEIHANG UNIV

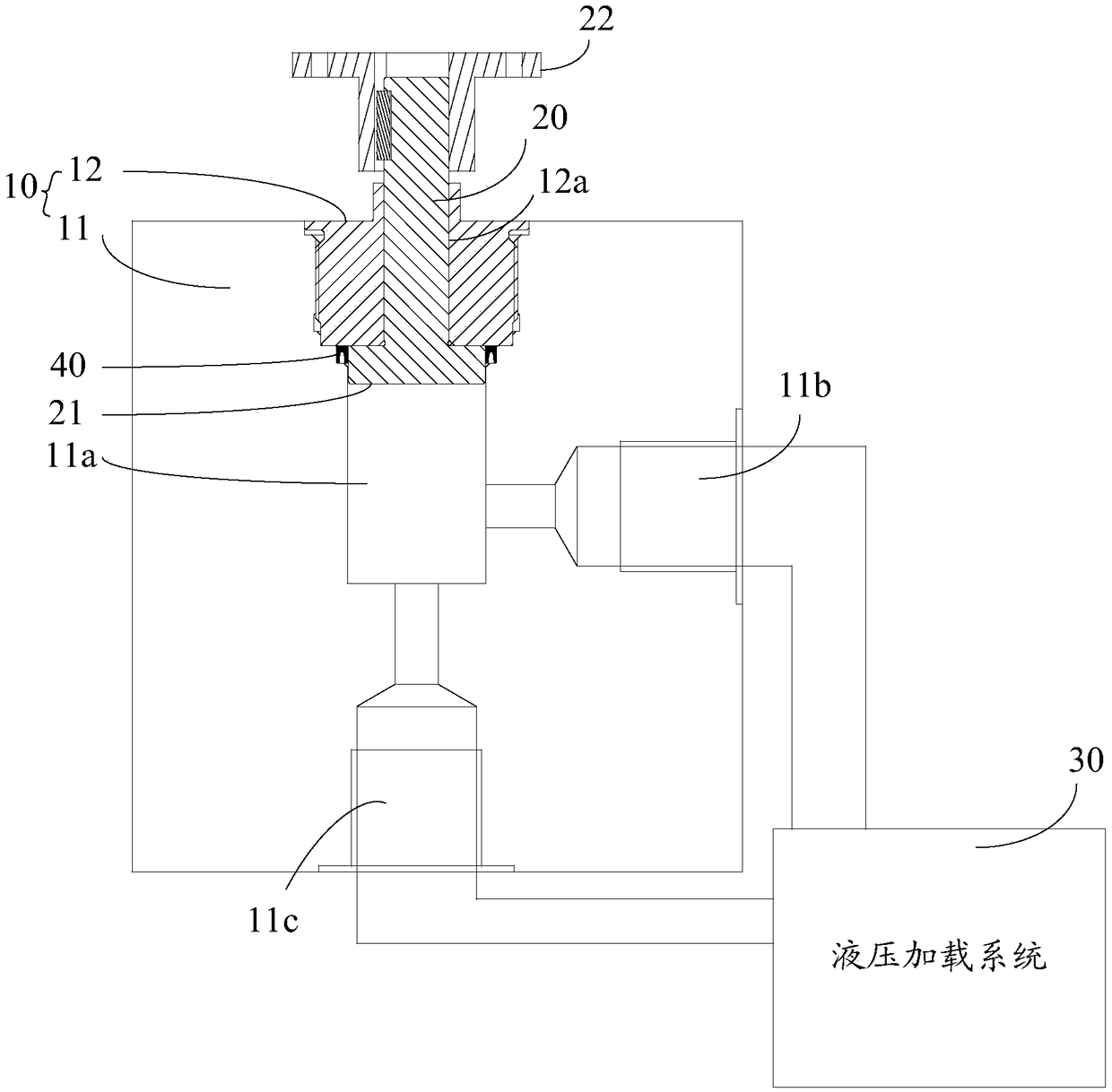

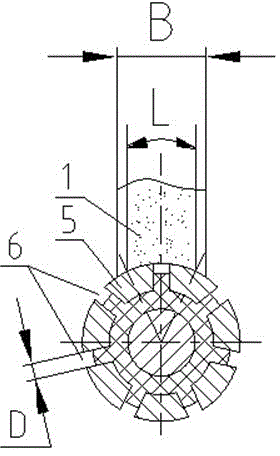

Variable-load tool

ActiveCN109114051AGood running-in effectShorten break-in timeServomotor componentsServomotorsCouplingEngineering

The invention discloses a variable-load tool, and belongs to the field of test devices. The variable-load tool comprises a pressure bearing block, a pressure shaft and a hydraulic loading system, wherein a cylindrical pressure cavity is arranged in the pressure bearing block; an axle hole, an oil inlet hole and an oil outlet hole are further formed in the pressure bearing block; the axle hole is positioned in one end of the pressure cavity; the pressure shaft is inserted into the axle hole; the first end of the pressure shaft is equipped with a shaft coupler; the second end of the pressure shaft is equipped with an outer flange; the oil inlet and the axle hole are separately formed in reverse two sides of the outer flange; the oil inlet and the oil outlet are positioned at the same side ofthe outer flange; and after the pressure cavity is pressurized, the outer flange can press onto the inner wall of the pressure cavity. During running-in, the pressure shaft can be connected with theoutput shaft of to-be-run equipment through the shaft coupler, and friction force between the outer flange and the inner wall of the pressure cavity is equal to load which acts on the output shaft ofthe to-be-run equipment, so that a working condition during running-in is the same with the working condition in practical use, and therefore, the running-in effect is improved, and running-in time isshortened.

Owner:WUHAN MARINE MACHINERY PLANT

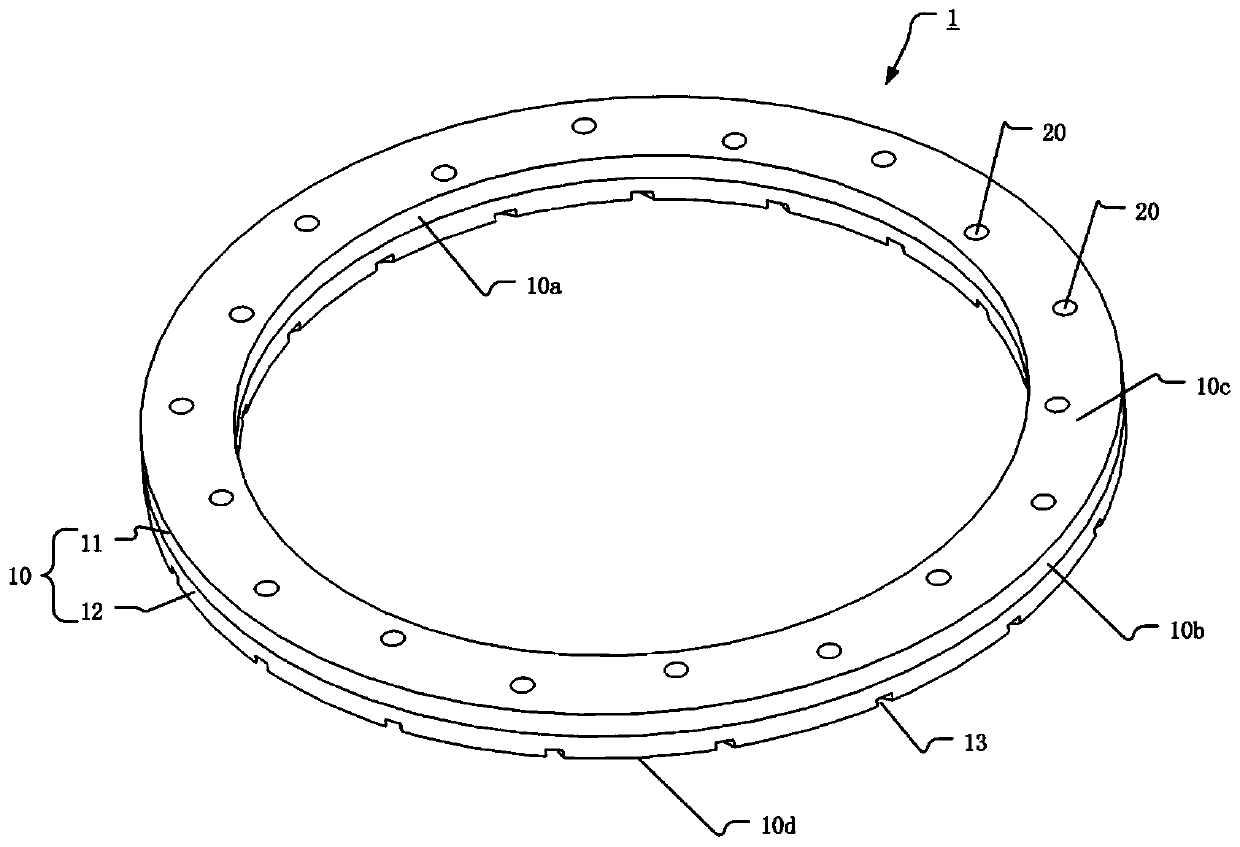

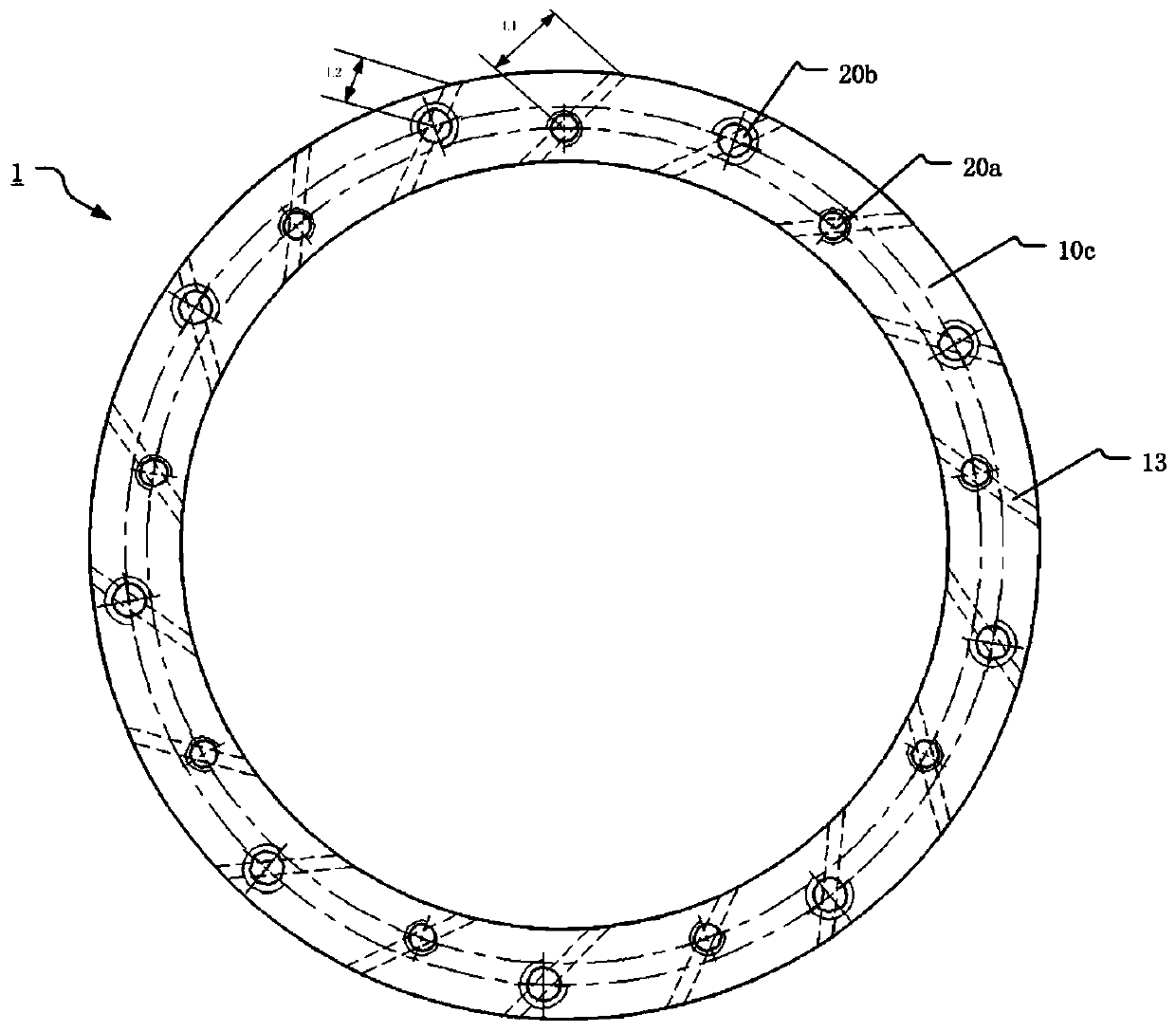

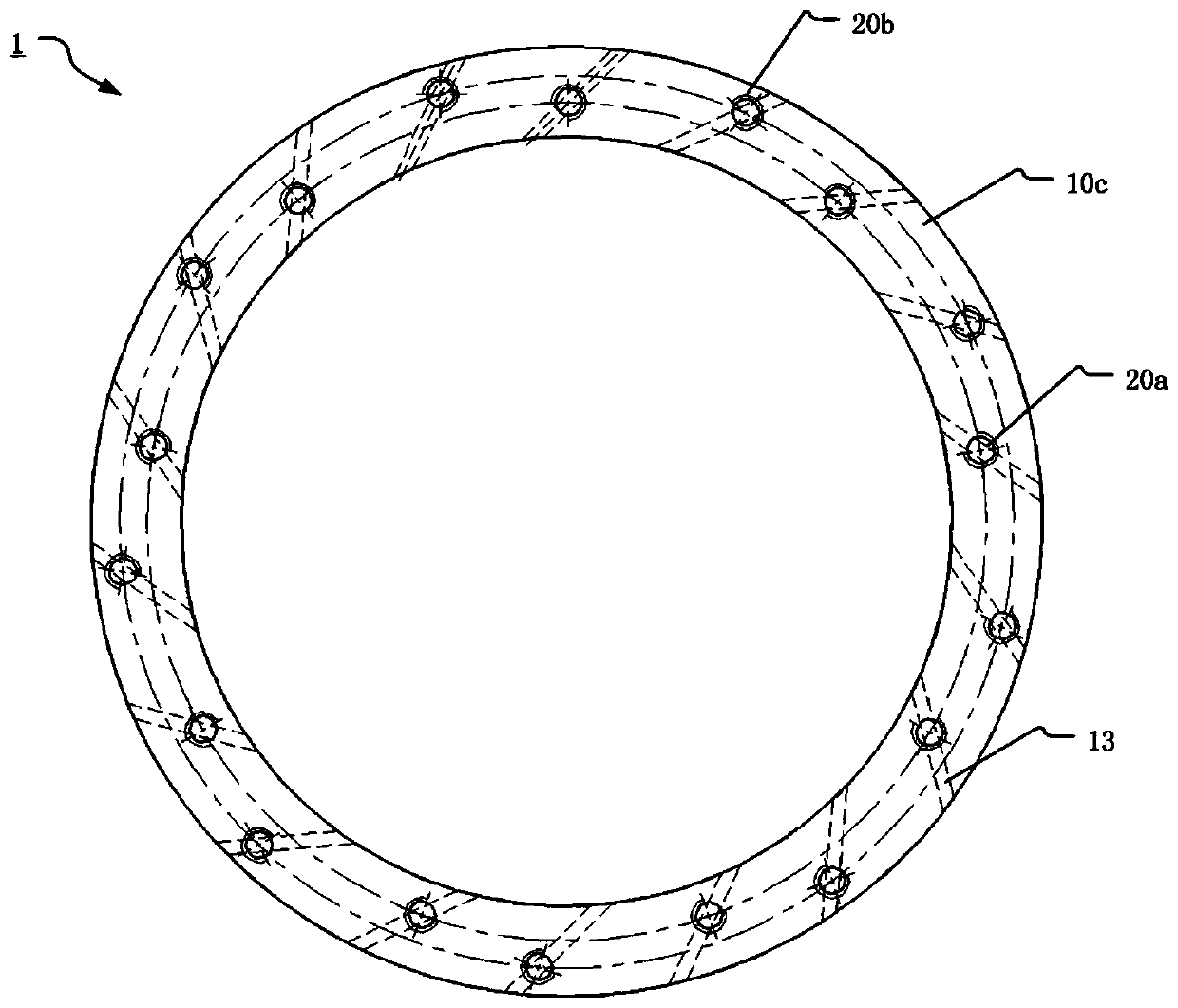

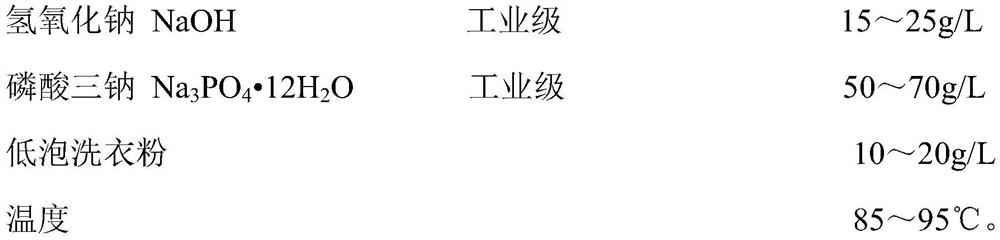

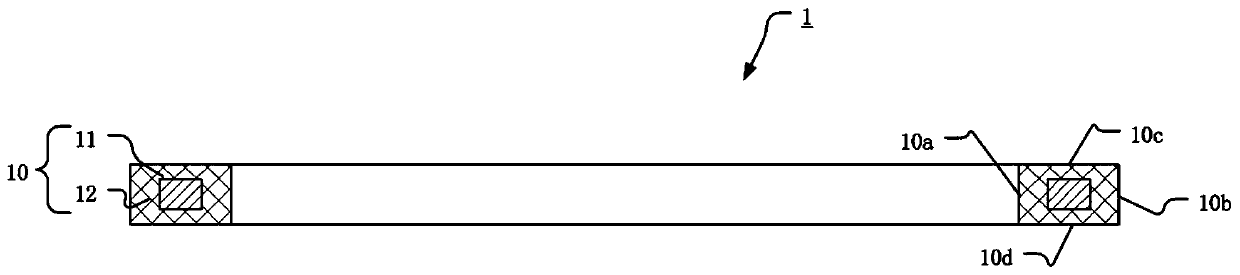

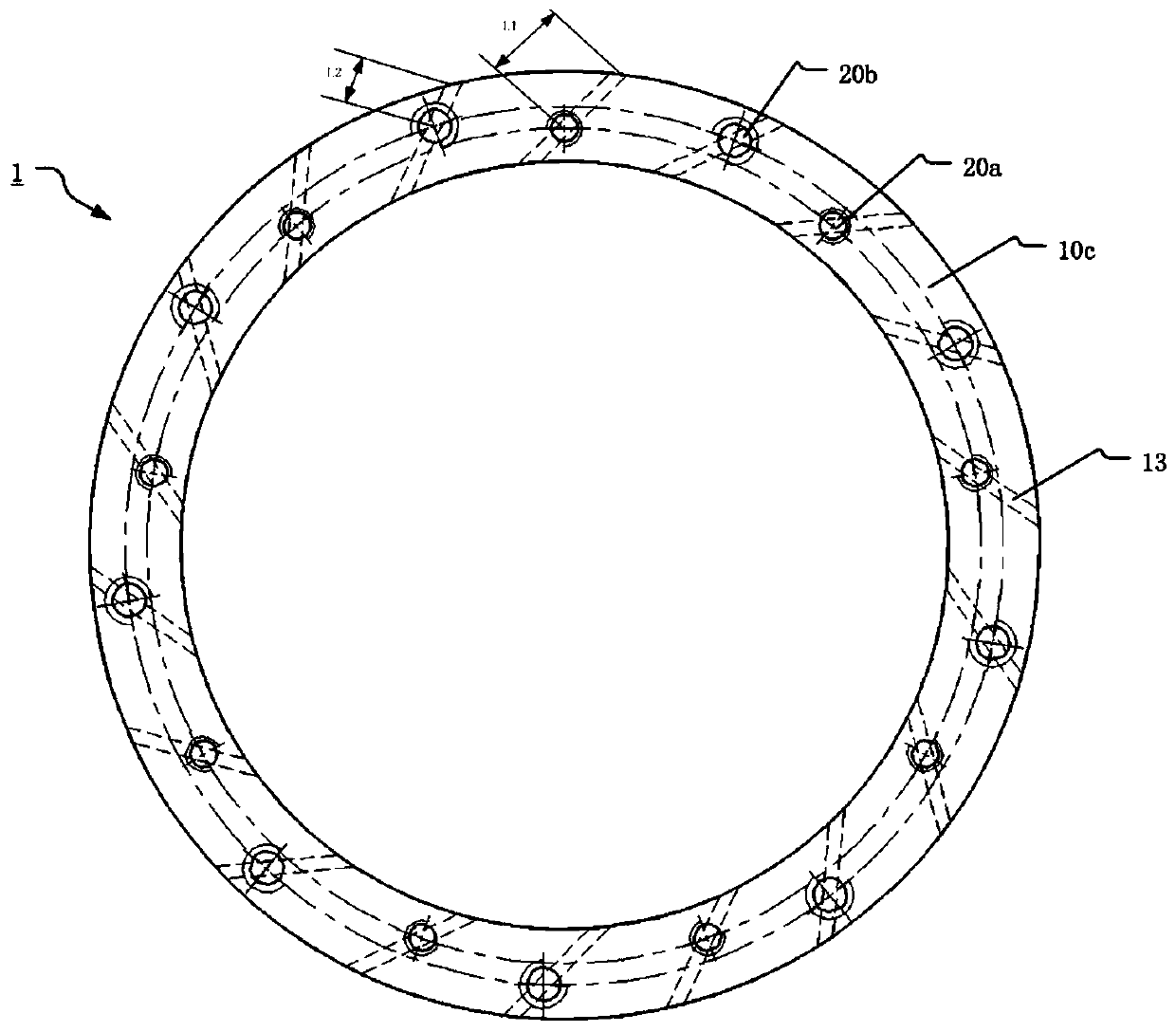

Retaining ring with wave structure on bottom surface and bearing head

ActiveCN111318960AShorten break-in timeCost controlWork carriersGrinding/polishing apparatusWave structureScrew thread

The invention discloses a retaining ring with a wave structure on the bottom surface and a bearing head. The retaining ring is composed of an annular part, and the annular part is formed by laminatingand gluing a metal part and a nonmetal part; the annular part comprises a top surface, a bottom surface, an outer side surface and an inner side surface, the top surface is fixedly connected with thebearing head, the bottom surface abuts against a polishing surface, the outer side surface is arranged on the outer side of the annular part and is connected with the top surface and the bottom surface, the inner side surface is arranged on the inner side of the annular part and is connected with the top surface and the bottom surface, and the bottom surface is provided with a liquid supply groove communicating with the inner side surface and the outer side surface; and the top surface is provided with a threaded hole, and the threaded hole is located at the corresponding position of the liquid supply groove.

Owner:HWATSING TECH

Formula of breaking-in lubricating oil and breaking agent and its production

InactiveCN1854271AImprove running-in qualityImprove fatigue resistanceAdditivesZinc phosphateOil additive

This invention discloses a kind of lubricating oil additive and the preparation method of it. The following are the components of the additive (calculated by the weight): The proportion of phosphonitrile is 9-10%, that of C12-C18 organic amine salt is 7-11%,that of the derivant of thiadiazole is 5-7%,that of tertiary alkylthioalkyl zinc phosphate is 9-13%, that of alkyl calcium salicylate is 6-7%,that of the succimide dispersant agent and di-esters oil is 55-65%,The derivant of thiadiazole, preparation method is as following: The phosphonitrile, C12-C18 organic amine salt, tertiary alkylthioalkyl zinc phosphate, alkyl calcium salicylate, succimide dispersant agent and di-esters oil are combined and resolved, and then agitate it for 1.5-2.0h.The obvious excellence showed after using the method is the running-in period is short, the running-in Quality and the fatigue resistance will be improved obviously, hard running-in can be leaved out, the overhaul ratio of the whole machine can be decrease 60%, the benefit of economy and society is outstanding.

Owner:上海润祥化工有限公司 +1

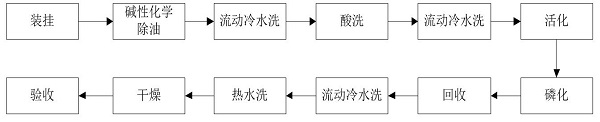

High-power diesel engine cylinder sleeve surface functional phosphating technology

The invention discloses a high-power diesel engine cylinder sleeve surface functional phosphating technology. The technology is carried out according to the following processes: hanging, alkaline chemical oil removal, flowing cold water washing, acid washing, flowing cold water washing, activation, phosphating, recycling, flowing cold water washing, hot water washing, drying and acceptance inspection, so that a phosphating film is generated on the surface of a cylinder sleeve. According to the invention, besides the corrosion resistance of the phosphating film, the non-metal phosphating film layer is generated between a cylinder sleeve and a piston ring, the attraction between molecules is reduced, the friction coefficient is reduced, and the purposes of shortening the running-in time and reducing cylinder scoring accidents are achieved. Meanwhile, after the phosphating film is abraded, the thickness of a lubricating oil film is ensured by utilizing the small corrosion holes regularly distributed on the working surface of the inner wall of the cylinder sleeve, the anti-friction performance is continuously exerted, and the effect of prolonging the service life of the cylinder sleeve is achieved.

Owner:HEBEI HUABEI DIESEL ENGINE

Diesel engine running-in oil reinforcing agent

The invention discloses a diesel engine running-in oil reinforcing agent, wherein antimony dialkyl-dithiocarbamate and zinc dialkyldithiophosphate are compounded in a compounding ratio of 0.2-0.8 and then added to base oil for use. The diesel engine running-in oil reinforcing agent provided in the invention is capable of effectively improving the performance of the diesel engine running-in oil. After the reinforcing agent is added to the diesel engine running-in oil, the running-in time of the diesel engine can be shortened. Besides, the diesel engine running-in oil reinforcing agent is rational in raw material mixing, simple in production process, and thereby can be widely applied to the existing diesel engine running-in oil.

Owner:LUBRICANT RES DEV BEIJING OF CHINA GASOLINEEUM & CHEM CORP

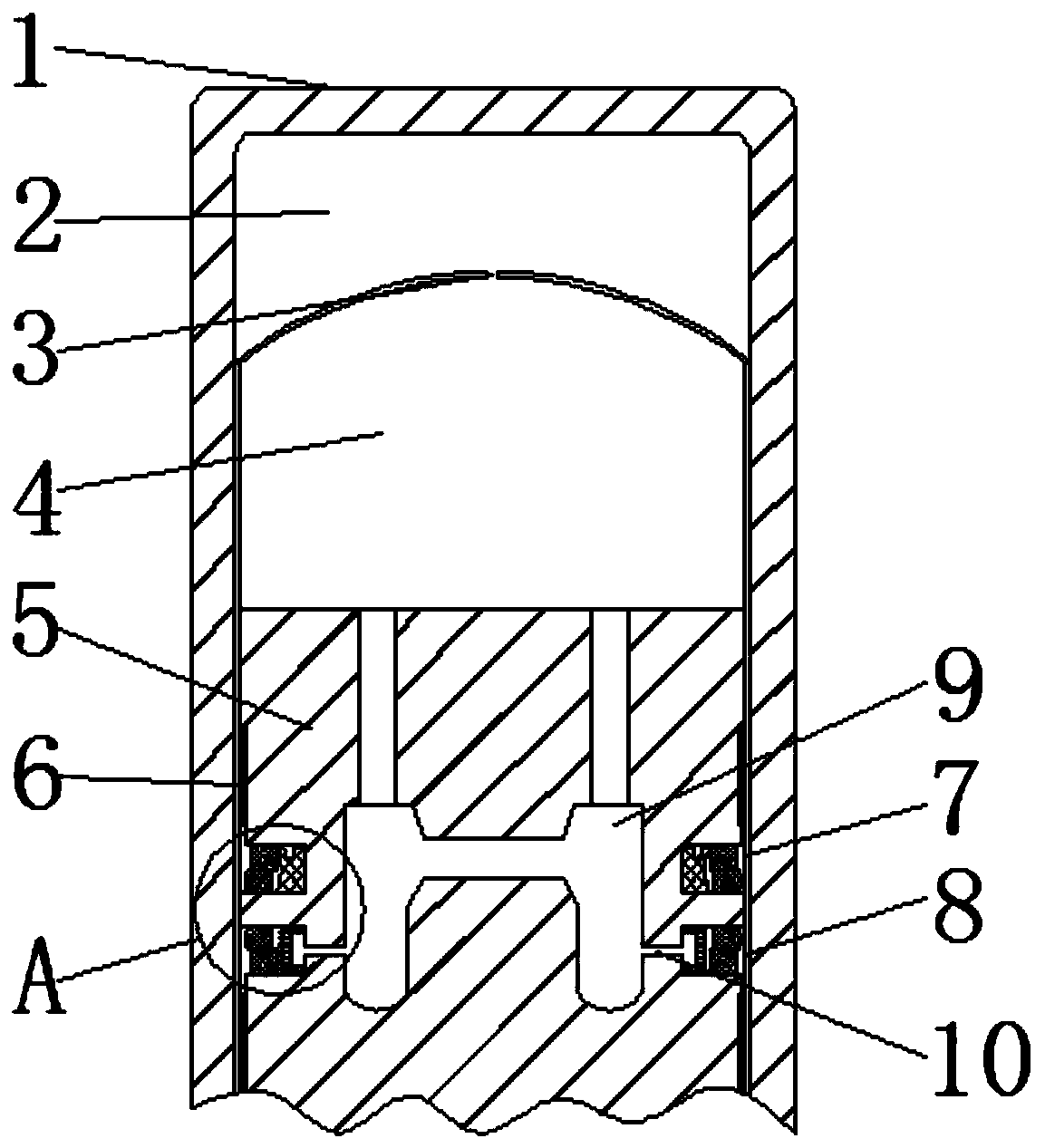

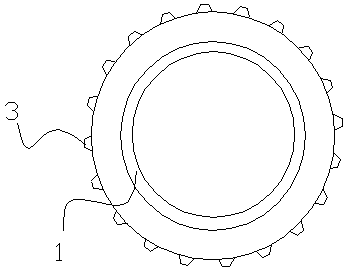

Retaining ring and carrier head for chemical mechanical polishing

The invention discloses a retaining ring and a bearing head for chemical mechanical polishing. The retaining ring is composed of an annular part, the annular part is composed of a metal part and a non-metal part, and the non-metal part is formed on the peripheral side of the metal part in a molding mode; the annular part comprises a top face, a bottom face, an outer side face and an inner side face, the top face is fixedly connected with the bearing head, the bottom face abuts against the polishing surface, the outer side face is arranged on the outer side of the annular part and connected with the top face and the bottom face, and the inner side face is arranged on the inner side of the annular part and connected with the top face and the bottom face; the bottom face is provided with a liquid supply groove communicating with the inner side face and the outer side face; and a threaded hole is formed in the top face and located vertically above the liquid supply groove.

Owner:HWATSING TECH

Combined piston sealing element

InactiveCN109737204AReach position compensationGuaranteed tightnessEngine sealsSurface typeEngineering

The invention discloses a combined piston sealing element, which relates to the technical field of sealing rings, specifically a cylinder, a hot cavity and a through hole, wherein a convex top cavityis arranged in the cylinder, a piston is connected in the convex top cavity, a micro small hole is formed in the top end of the convex top cavity, the hot cavity is arranged above the convex top cavity, a guide ring is arranged on the outer wall surface of the piston; an upper combined seal element is arranged below the guide ring; a lower combined seal element is arranged below the upper combinedseal element, the upper combined seal element and the lower combined seal element are respectively arranged in the outer wall surface of the piston, and the through hole is formed in the top end of the piston. According to the combined piston seal element, the cross section of a floating ring is a semi-rectangular barrel surface type under a working state, the lower edge of the working surface ofthe outer circle of the floating ring is in contact with the cylinder wall, and the lower edge of the inner circle of the ring is in contact with a C-shaped compensation bulge, so that the sealing performance is good, and the semi-rectangular angle is 7 degrees according to the standard.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +1

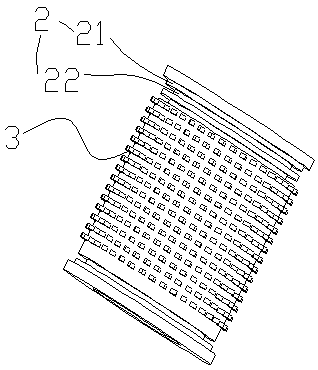

Method, structure and device for improving contact reliability of electric brush and reverser of direct current speed measuring power generator

InactiveCN104682632AReduce shakingContinuous and stable forceSupports/enclosures/casingsWork performanceDynamo

The invention discloses a method, a structure and a device for improving contact reliability of an electric brush and a reverser of a direct current speed measuring power generator. The method comprises the steps of arranging the direct current speed measuring power generator for applying voltage to the electric brush by a volute spring, mounting the volute spring on a brush box, mounting and fixing the brush box on a brush frame ring of an end cover of a direct current motor by using a binding post, controlling a matching gap between a mounting hole in the brush box and the binding post within 0.015 to 0.08mm, meanwhile, manufacturing the width of the electric brush to be equal to or larger than a reversing segment pitch of the direct current speed measuring power generator, wherein a reversing segment of the direct current speed measuring power generator is made of silver, copper and nickel alloy, and the electric brush adopts a silver graphite electric brush with the brand number being J385. The method, the structure and the device have the advantages of simple structure, easiness in manufacturing, high work efficiency, good quality, stable and reliable product work performance and stable output voltage, and large-scale burr are not easily generated for output voltage waveforms.

Owner:GUIZHOU AEROSPACE LINQUAN MOTOR CO LTD

Generator motor collector ring carbon brush polishing device

PendingCN114147580AEasy to fixEasy to adjustGrinding carriagesGrinding drivesBrushConstant-force spring

The invention discloses a generator motor collector ring carbon brush polishing device which comprises a carbon brush polishing device base and a carbon brush polishing device rail fixed to the top end of the carbon brush polishing device base, a sliding frame is arranged on the carbon brush polishing device rail, and a spring support is fixed to the sliding frame; a through groove used for containing a carbon brush is formed in the sliding frame, a constant-force spring used for fixing the carbon brush is arranged in the spring support, a limiting buckle is arranged on one side of the carbon brush, a collecting box is arranged at the top end of the carbon brush polishing device base, two handles are fixed to the outer wall of the collecting box, a partition plate is arranged in the collecting box, and the carbon brush polishing device is arranged in the partition plate. Protruding blocks are fixed to the two sides of the partition plate correspondingly, and sliding grooves matched with the protruding blocks are formed in the two symmetrically-arranged vertical inner walls of the collecting box correspondingly. According to the generator motor collector ring carbon brush polishing device, the carbon brush can be fixed conveniently, and scraps can be collected conveniently.

Owner:STATE GRID CORP OF CHINA +2

High occlusion cylinder liner and preparation method thereof

InactiveCN107654306AShorten break-in timeExtended service lifeLiquid surface applicatorsCylinder headsSurface roughnessMaterials science

The invention discloses a high occlusion cylinder liner. The high occlusion cylinder liner comprises a cylinder liner body, wherein the inner surface of the cylinder liner body is coated with an innercoating; the inner coating is 80-120 [mu]m in surface roughness and 0.2-0.4 mm in thickness; an annular groove body is formed in each of the two ends of the outer surface of the cylinder liner body;the annular groove bodies are 0.1-0.4 mm in depth; and burrs, which are 0.1-0.5 mm in height, are arranged in the middle area on the outer surface of the cylinder liner body. The invention further discloses a preparation method of the high occlusion cylinder liner. The high occlusion cylinder liner and the preparation method thereof have the technical effects that the occlusion force is great, andthe service life is long.

Owner:ZYNP GRP ANHUI CO LTD

Handling system and method of operating a handling system

ActiveUS9616582B2Shorten break-in timeImprove distributionGripping headsHandling systemEmbedded system

A handling system having at least one vacuum generator and an associated vacuum handling device connected to and operable via the vacuum generator. The vacuum handling device is provided with an individually assigned recognition unit including a memory device in which operating data for the vacuum handling device is storable and can be read out. Each vacuum generator has a respective sub-control unit adapted to control the vacuum generator depending on data transmitted from the recognition unit. The memory device of the recognition unit can be read out directly from the sub-control unit.

Owner:J SCHMALZ GMBH

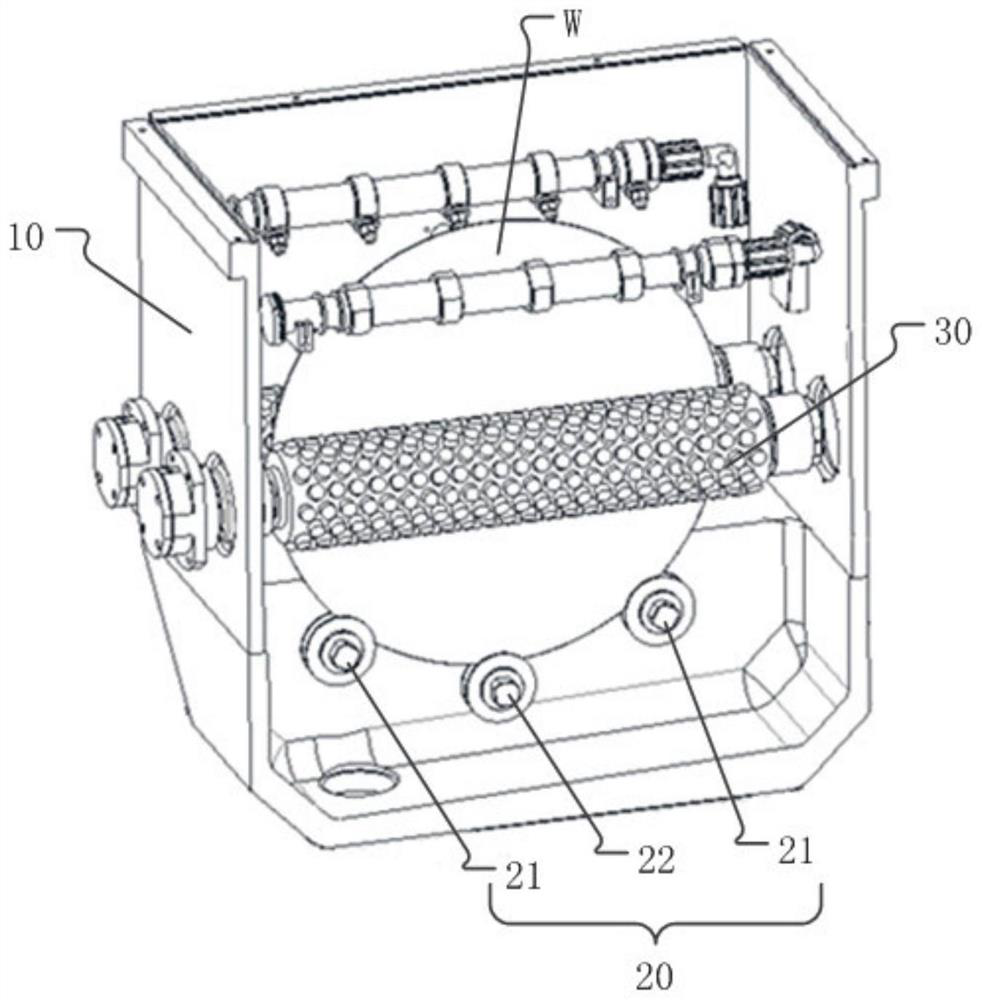

Wafer cleaning method and wafer cleaning device

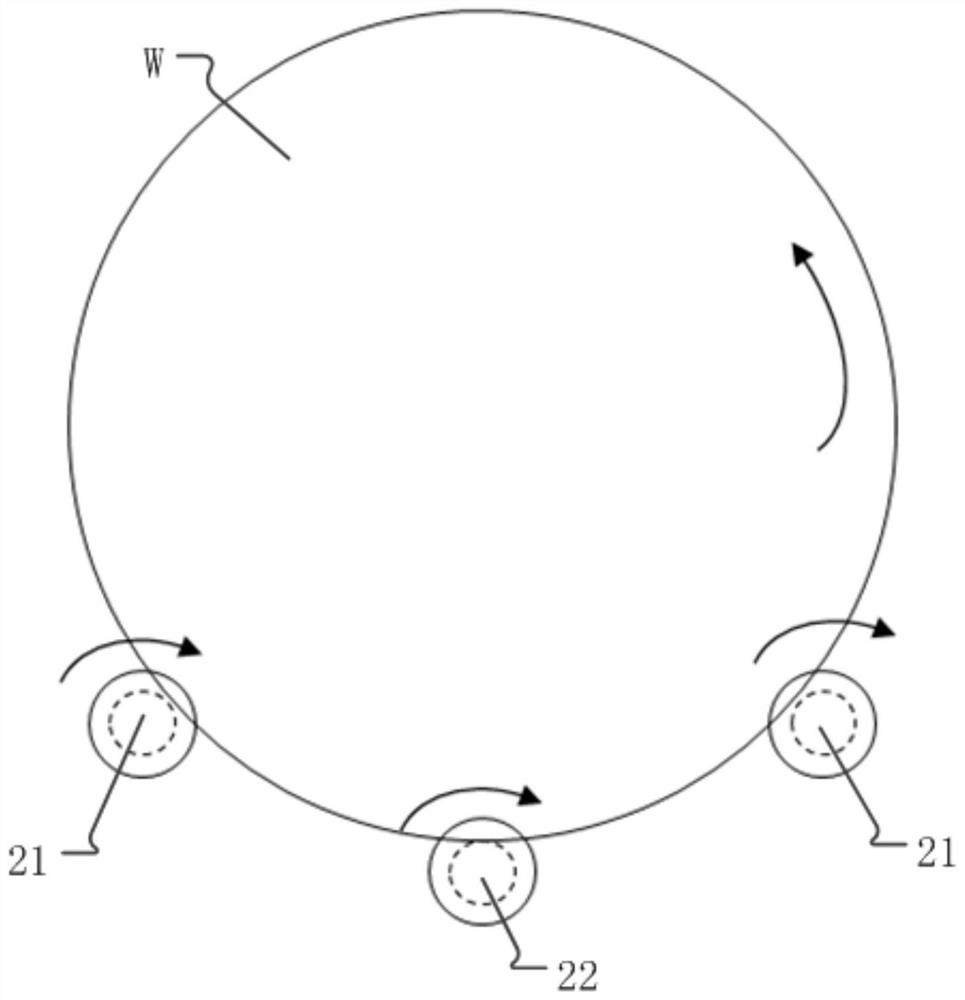

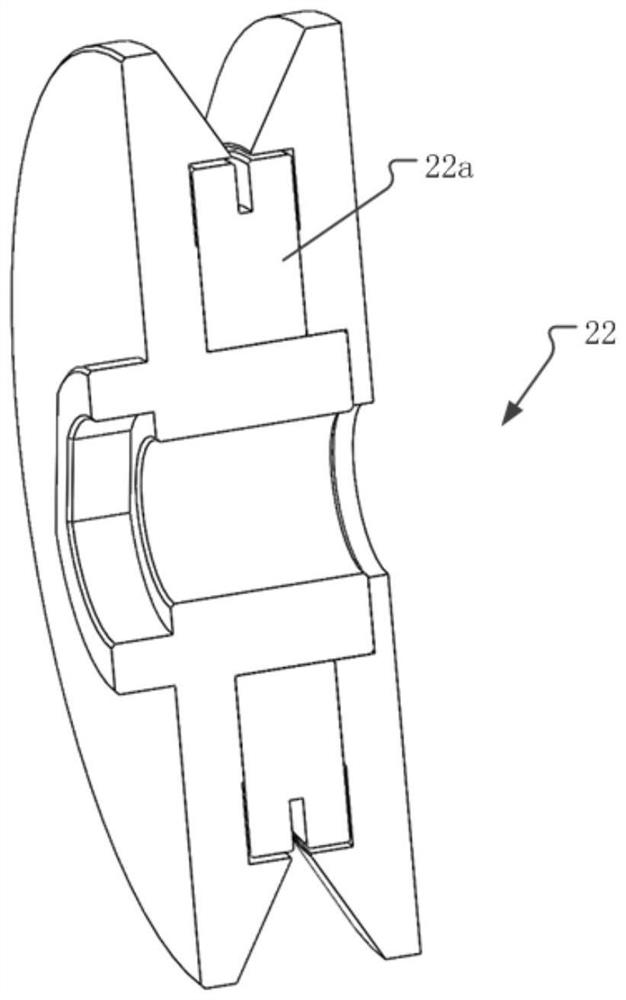

ActiveCN113976498BGuaranteed cleaning effectOvercoming wear and tearSemiconductor/solid-state device manufacturingCleaning using toolsDrive wheelWafer

The invention discloses a wafer rolling brush cleaning method and a wafer cleaning device. The wafer rolling brush cleaning method comprises: placing a wafer on a wafer support device formed by a driven wheel and a driving wheel; The driving wheel performs the adjustment operation, and the reference position of the driven wheel is determined according to the set rotational speed of the wafer and the rotational speed of the driven wheel; the installation position of the driven wheel is set by the roller adjusting device according to the reference position of the driven wheel; the cleaning brushes located on both sides of the wafer Move to the cleaning position to perform roller brush cleaning on both the front and back of the wafer.

Owner:HWATSING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com