Sliding bearing element

A technology for sliding bearings and supporting components, which is applied in the direction of bearing components, sliding contact bearings, engine components, etc., and can solve the problems of damage, adaptation (slow running-in wear, fatigue, etc.)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

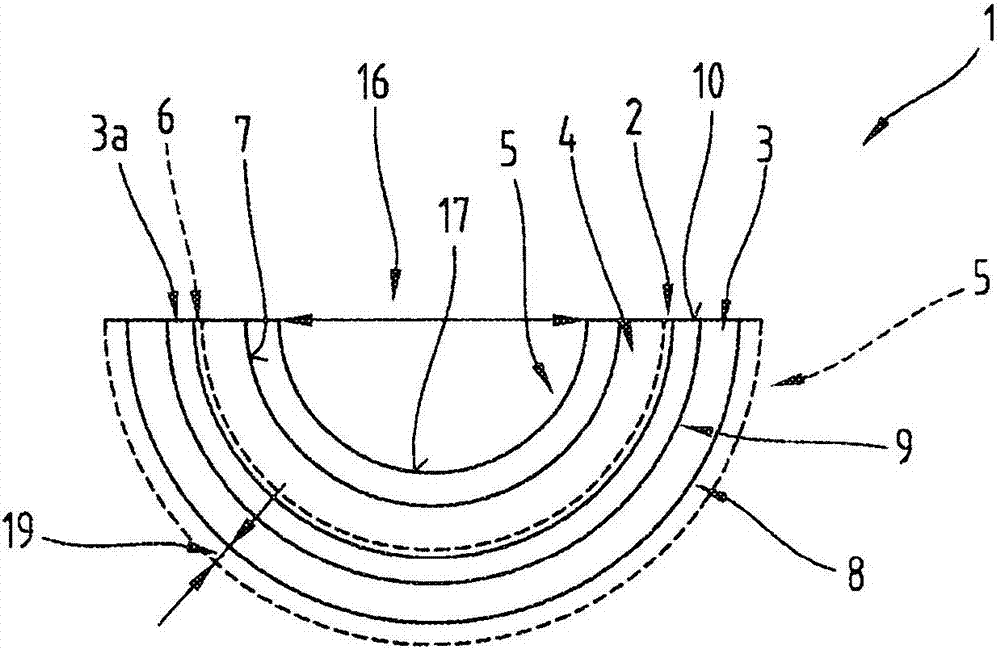

[0140] structure

[0141]

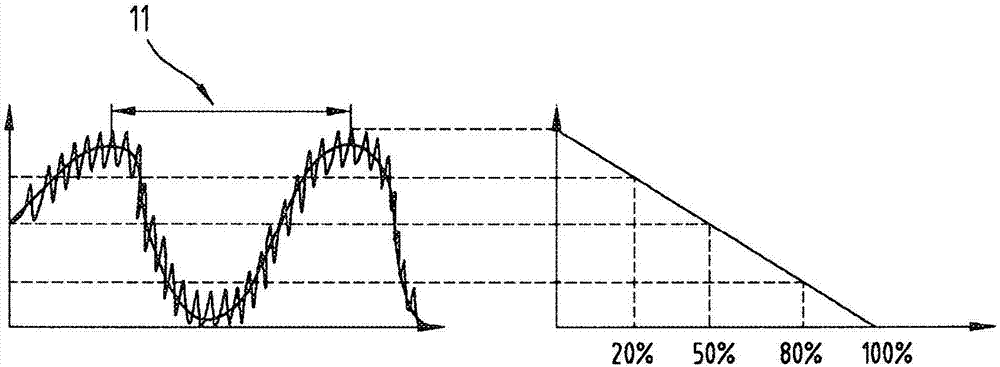

[0142] result

[0143]

[0144] Compared to comparative example 2, an improvement in the load carrying capacity of the plain bearing element 1 is achieved.

example 2

[0146] structure

[0147]

[0148] result

[0149]

[0150]

[0151] It is also shown in this example that, compared to comparative example 3, an improvement in the load-carrying capacity of the plain bearing element 1 is achieved.

example 3

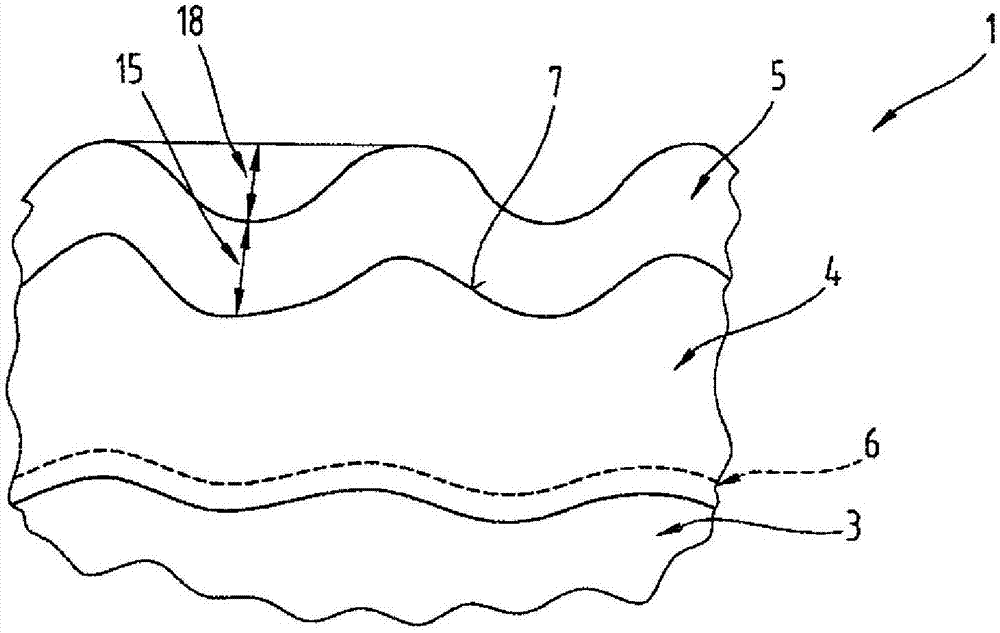

[0153] structure

[0154]

[0155] result

[0156]

[0157] It is shown here that compared to Comparative Example 4, improvements are achieved in both tests.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com