Formula of breaking-in lubricating oil and breaking agent and its production

A technology of lubricating oil and mixture, which is applied in the field of lubricating oil, can solve the problems of increased anti-fatigue wear characteristics and low anti-oxidative decay performance of the engine, and achieves shortened running-in time, obvious economic and social benefits, and increased anti-fatigue wear characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The formula of running-in agent is: (by weight %)

[0022] Phosphazene 9

[0023] C 12 -C 18 Organic amine salt 7

[0024] Thiadiazole Derivatives 5

[0025] Zinc tertiary alkylthiophosphate 9

[0026] Calcium Alkyl Salicylate 6

[0027] Succinimide dispersant and diester oil 64

[0028] Phosphazene, C 12 -C 18 Organic amine salt, thiadiazole derivatives, tertiary alkyl zinc thiophosphate, calcium alkyl salicylate, succinimide dispersant and diester oil are mixed and dissolved at 56°C to make a running-in agent.

[0029] At normal temperature, the prepared running-in agent is added into the base lubricating oil at a ratio of about 4% by weight, mixed and stirred for 1.8 hours, and filtered to become the running-in lubricating oil.

Embodiment 2

[0031] The formula of running-in agent is: (by weight %)

[0032] Phosphazene 9.5

[0033] C 12 -C 18 Organic amine salt 9

[0034] Thiadiazole Derivatives 6

[0035] Zinc tertiary alkylthiophosphate 11

[0036] Calcium Alkyl Salicylate 6.5

[0037] Succinimide dispersant and diester oil 58

[0038] Phosphazene, C 12 -C 18 Organic amine salt, thiadiazole derivatives, tertiary alkyl zinc thiophosphate, calcium alkyl salicylate, succinimide dispersant and diester oil are mixed and dissolved at 60°C to make a running-in agent.

[0039] At normal temperature, the prepared running-in agent is added into the base lubricating oil at a ratio of about 5% by weight, mixed and stirred for 1.5 hours, and filtered to become the running-in lubricating oil.

Embodiment 3

[0041] The formula of running-in agent is: (by weight %)

[0042] Phosphazene 10

[0043] C 12 -C 18 Organic amine salt 10

[0044] Thiadiazole Derivatives 7

[0045] Zinc tertiary alkylthiophosphate 11

[0046] Calcium Alkyl Salicylate 7

[0047] Succinimide dispersant and diester oil 55

[0048] Phosphazene, C 12 -C 18 Organic amine salt, thiadiazole derivative tertiary alkyl zinc thiophosphate, calcium alkyl salicylate, succinimide dispersant and diester oil are mixed and dissolved at 65°C to make a running-in agent.

[0049] At normal temperature, the prepared running-in agent is added to the base lubricating oil at a ratio of about 6% by weight, mixed and stirred for 2 hours, and filtered to become the running-in lubricating oil.

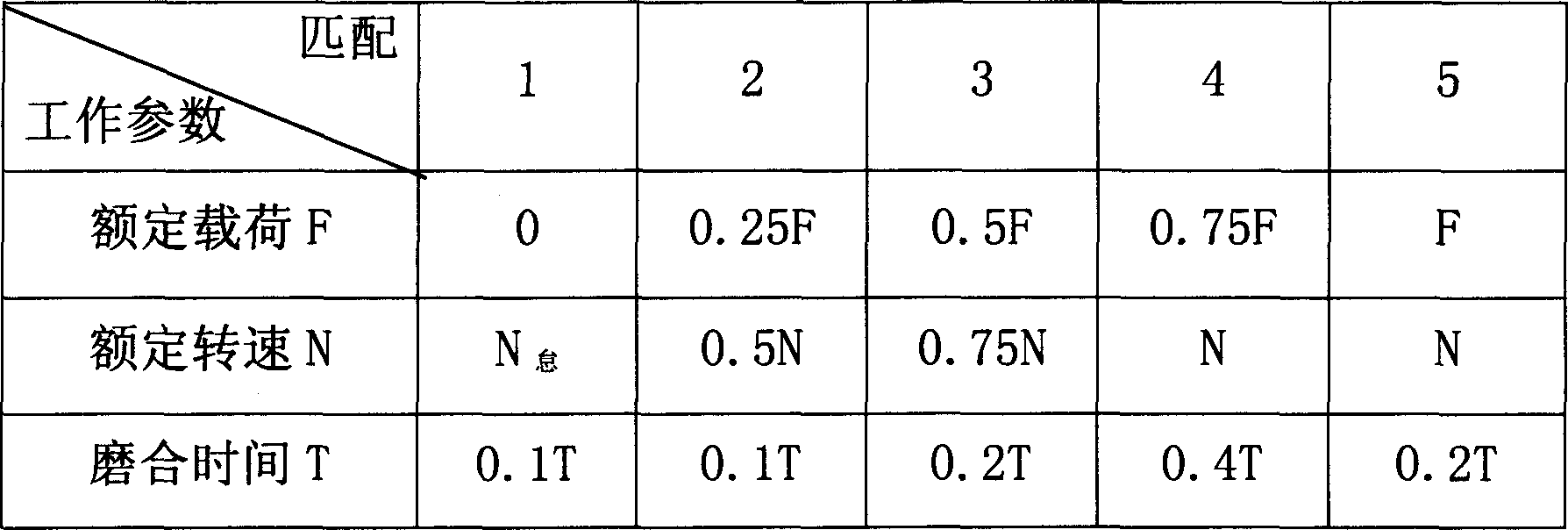

[0050] In order to exert its maximum special effect, the running-in lubricating oil must be properly matched with the main parameters of the actual diesel engine and gasoline engine: load, speed, and time. The selection of matching par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com