Break-in oil for internal-combustion engine of vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

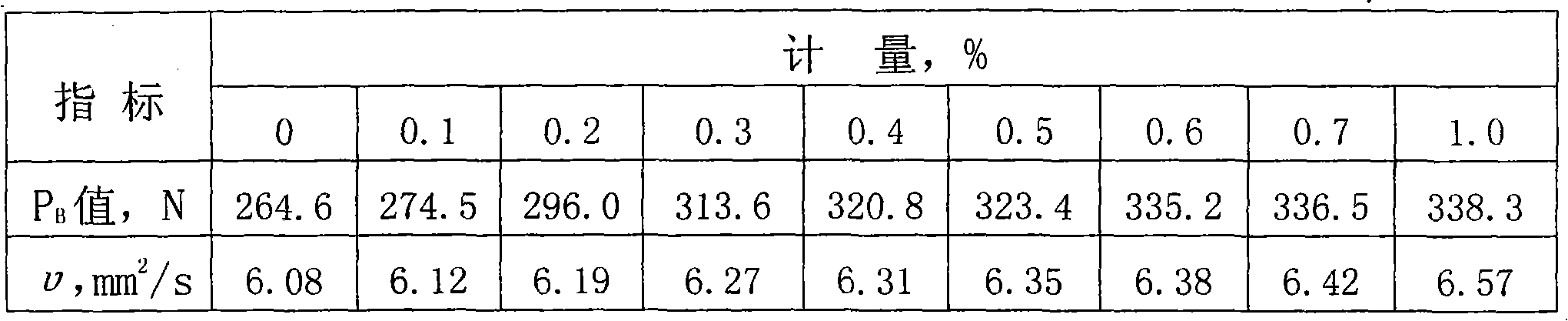

[0013] 1. Selection of base oil and additives

[0014] 1. Selection of base oil

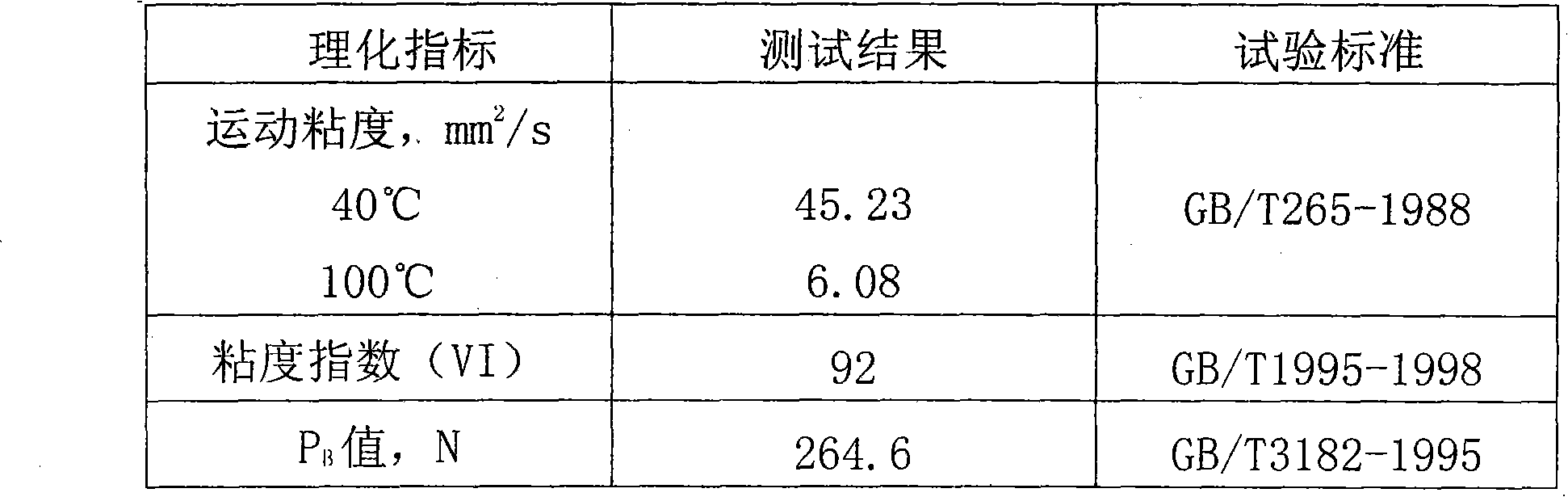

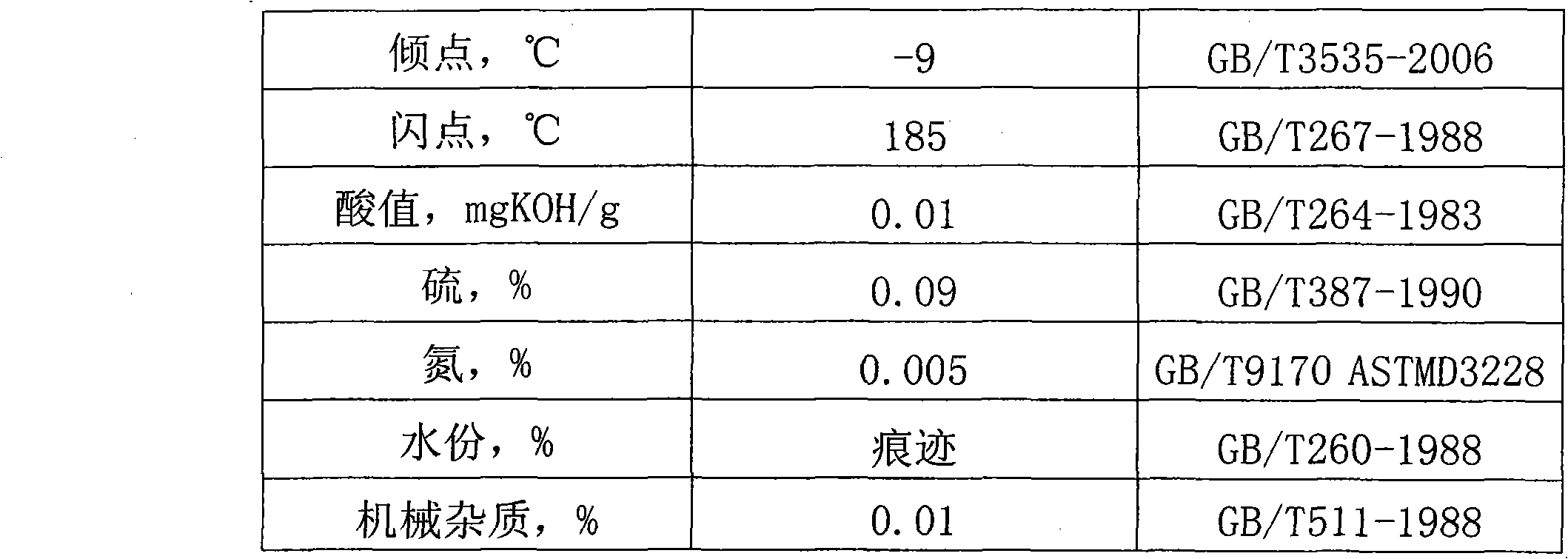

[0015] According to the working characteristics of the internal combustion engine, when preparing the internal combustion engine running-in oil, the running-in characteristics of the internal combustion engine for vehicles should be combined, and different models such as gasoline engines and diesel engines should be considered. Select 46 produced by Lanzhou Refinery # Machine oil is used as the base oil for blending, which is made from the second-line distillate oil after a series of refining. The results are shown in Table 1 through laboratory physical and chemical index determination.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com