Preparation method for abrasion resistant superhydrophobic surface

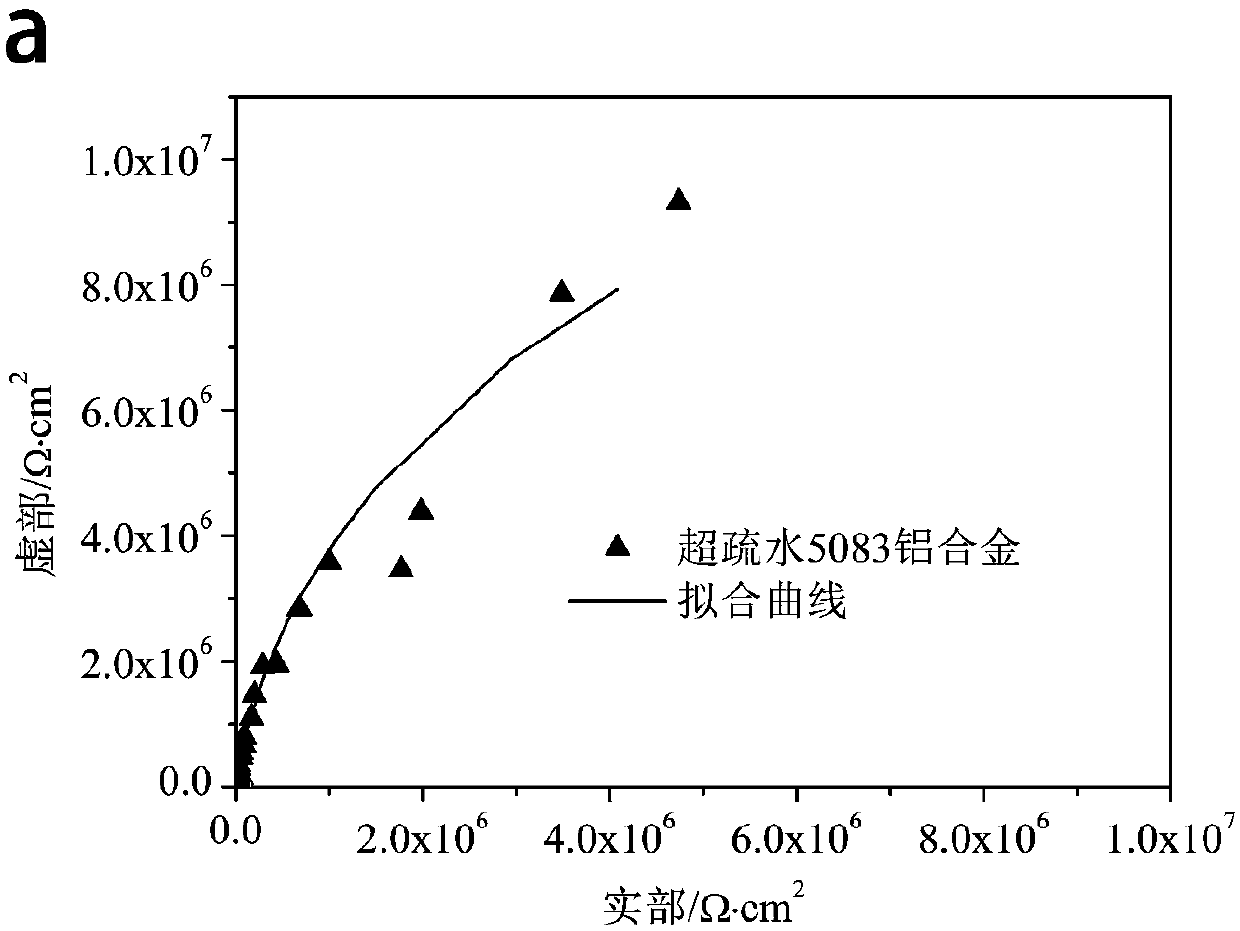

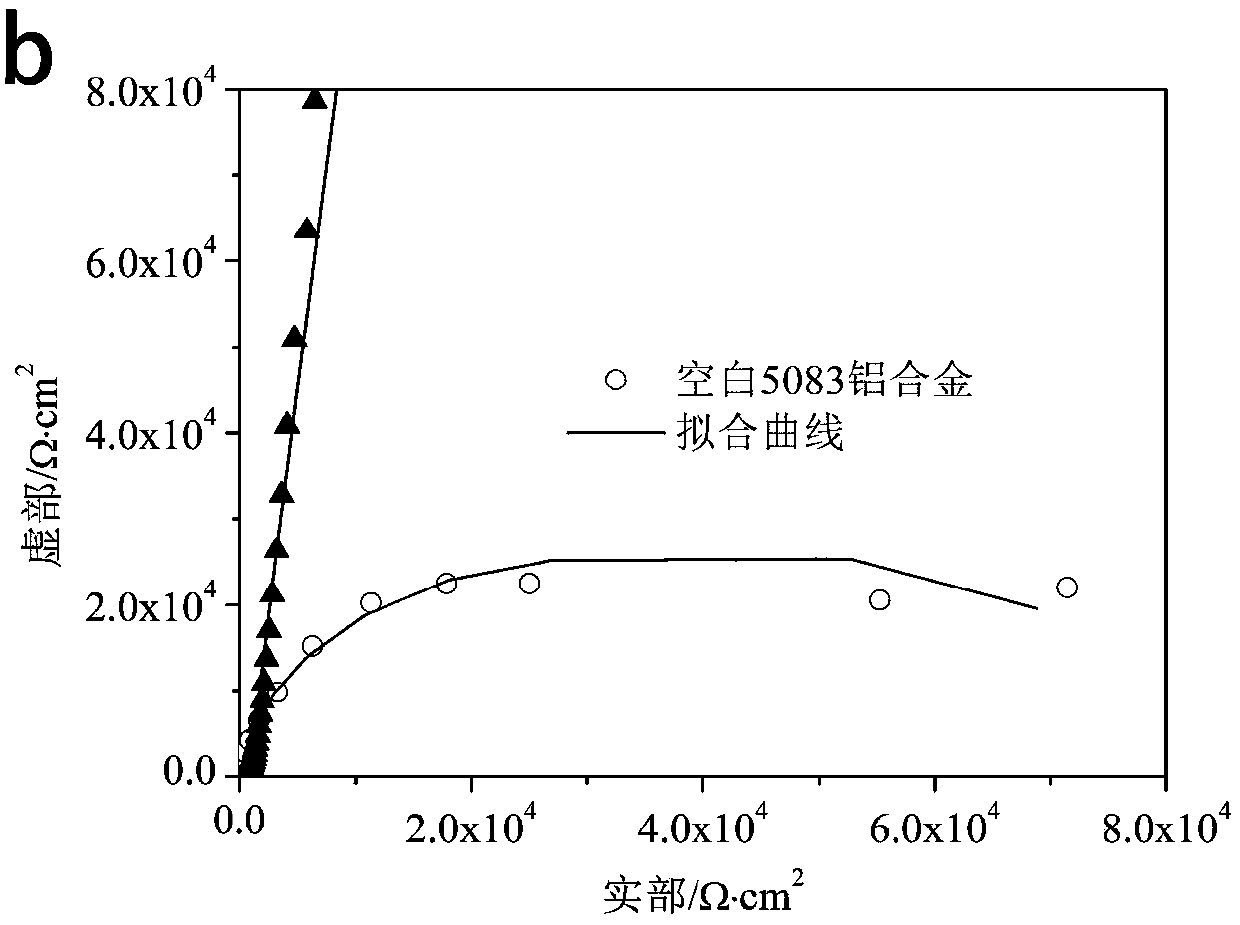

A super-hydrophobic surface, wear-resistant technology, applied in the direction of surface reaction electrolytic coating, electrolytic coating, coating, etc., can solve the problem of poor mechanical stability of super-hydrophobic surface, loss of surface super-hydrophobic properties, and microstructure susceptible to wear And damage and other problems, to achieve the effect of facilitating large-scale application, excellent mechanical stability, stable wear resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Pretreatment of the surface of 5083 aluminum alloy: firstly, the 5083 aluminum alloy sample was ultrasonically cleaned in absolute ethanol and deionized water, and then polished with SiC sandpaper of 200, 400, 800, 1200, and 2000 in sequence matrix;

[0029] (2) Constant pressure anodization of oxalic acid aqueous solution: Dissolve oxalic acid in deionized water to prepare a 0.3mol / L electrolyte solution, and then place the sample in a two-electrode anodic oxidation system, in which 5083 aluminum alloy is used as the anode, and the platinum electrode is For the cathode, the reaction system was anodized under the condition of 40V constant voltage, and the sample was taken out after 10 minutes of reaction, and washed several times with deionized water and absolute ethanol respectively to remove the residual electrolyte solution;

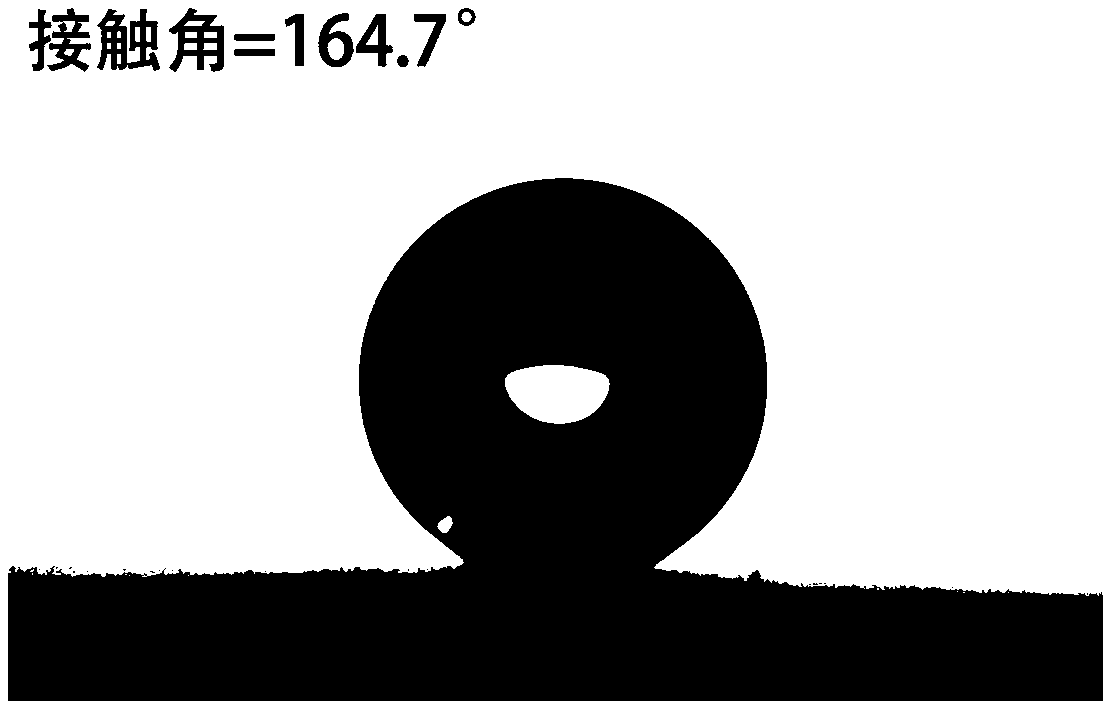

[0030] (3) Molecular modification with low surface energy: prepare an ethanol solution of perfluorodecyltriethoxysilane with a concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com