New type of ceramic triple change valve

A three-way reversing valve, ceramic technology, used in multi-way valves, valve devices, engine components, etc., can solve the problems of loss of sealing performance, wear resistance, valve internal leakage, etc., to reduce self-wear and reduce wear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

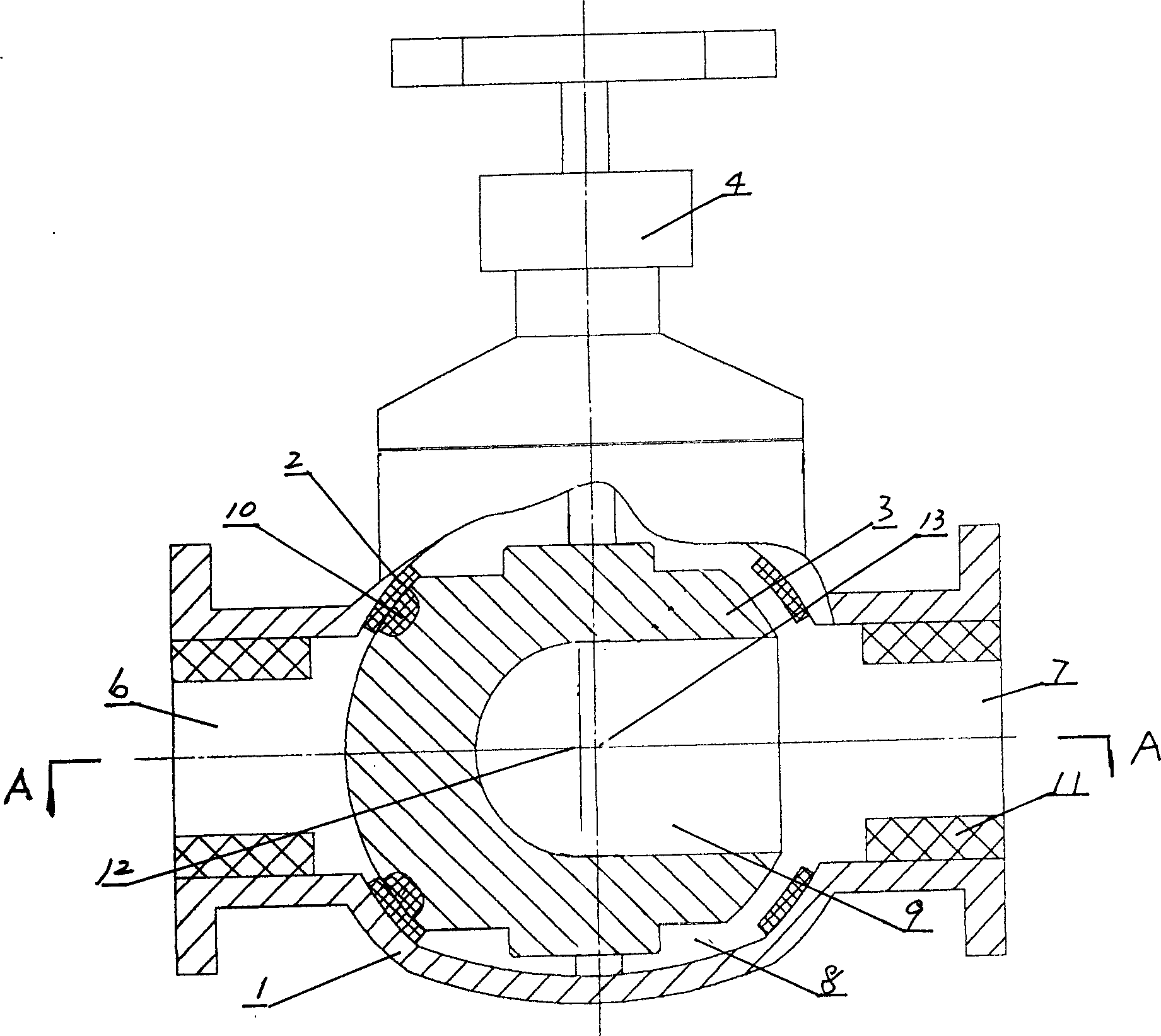

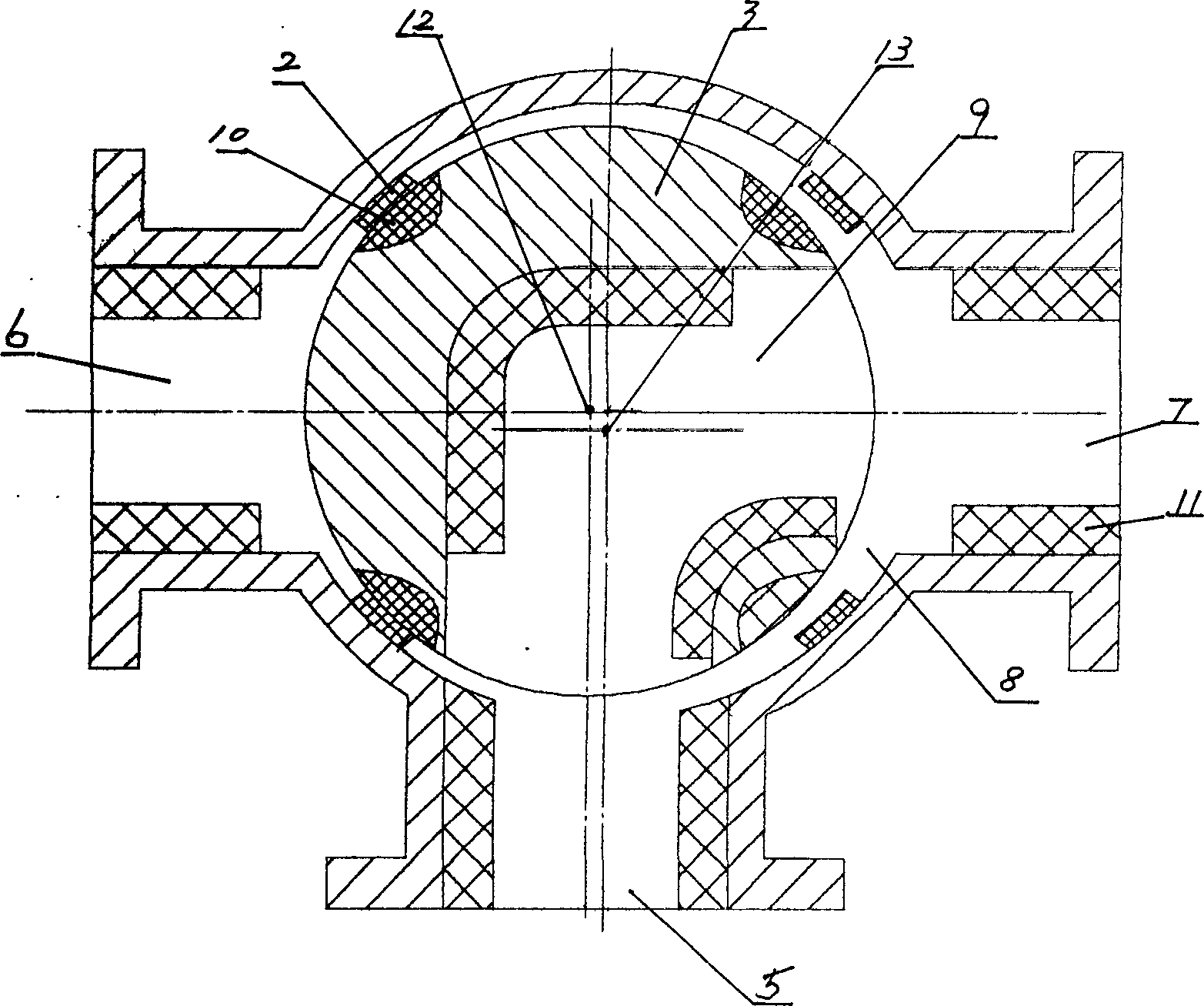

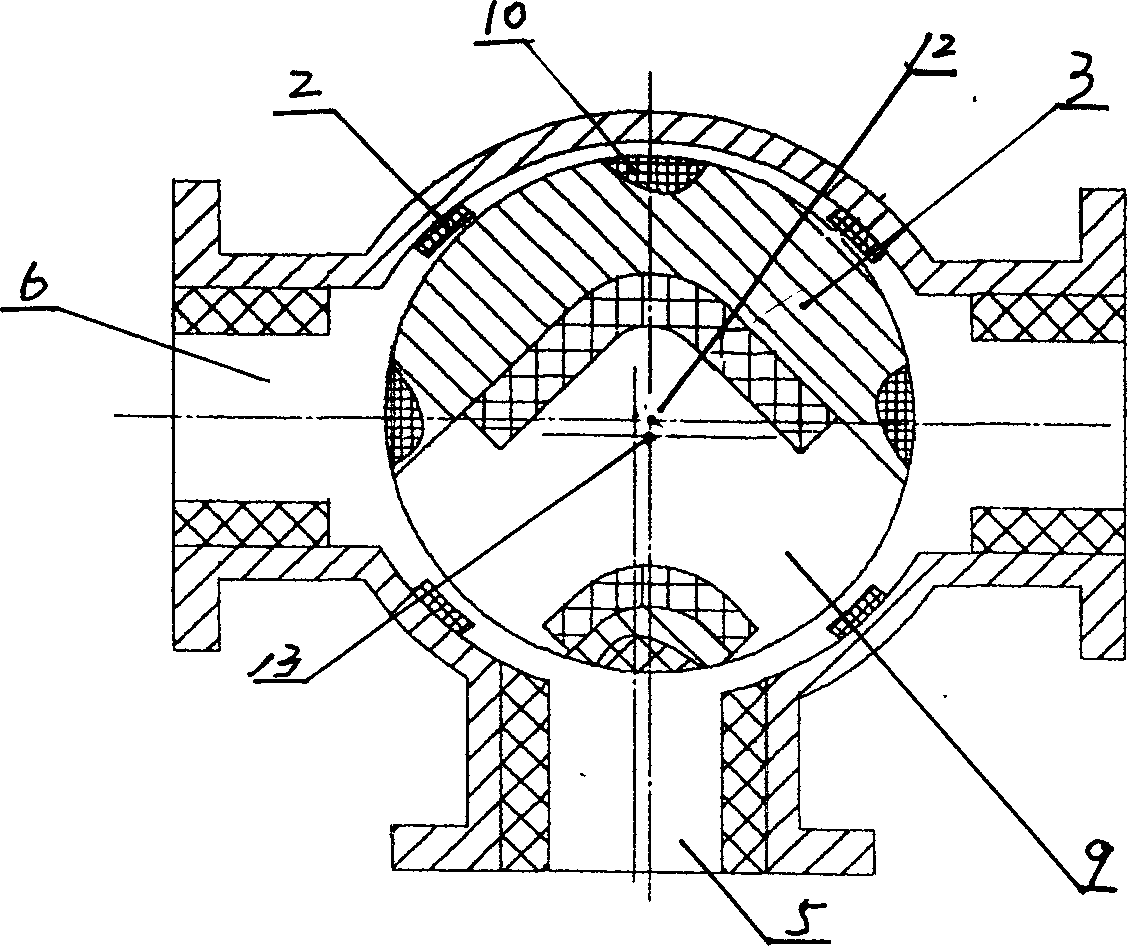

[0018] The invention is used in a dry ash discharge system of a power plant. Adopt nominal diameter DN: 150mm, nominal pressure PN: 1.6Mpa; make the eccentricity 3mm in the horizontal direction and 3mm in the vertical direction; the outlet A6 and the outlet B7 form an angle of 180° each other,

[0019] The inlet 5 of the valve body 1 of the present invention, the outlet A6, and the outlet B7 are respectively installed in the inlet pipeline and two outlet pipelines in opposite directions, and the passage 9 on the cock 3 is communicated with the outlet B7, and the valve seat 2 at the outlet A6 is It fits with the cock 3 and is in a sealed state. The medium flowing in from the inlet 5 passes through the channel 9 and then flows out from the outlet B7.

[0020] When the flow direction needs to be changed, the rotating mechanism 4 is rotated to drive the cock 3 to rotate around the axis 13 of the valve body, and the cock 3 is separated from the valve seat 2. When the cock 3 rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com