Steam inlet valve of a steam turbine

A steam inlet valve, steam turbine technology, applied in the direction of lift valve, valve detail, valve device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

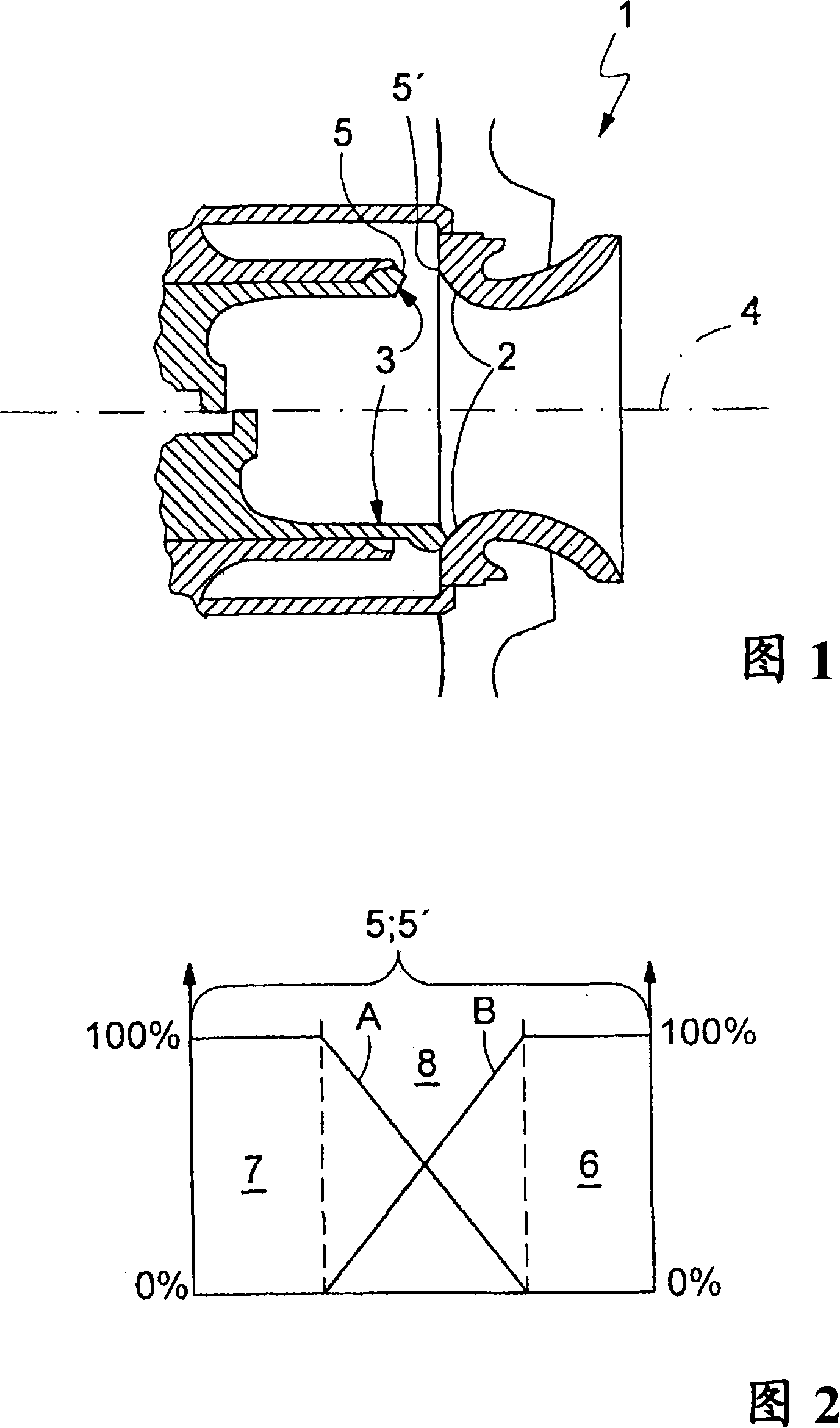

[0030] As shown in FIG. 1, according to the present invention, a steam turbine inlet valve 1, which is not shown, has a valve seat 2 and an associated valve body 3. In this way, the part of the inlet valve 1 above the dividing line 4 indicates an open state, and below the dividing line 4 is a closed state. When the inlet valve 1 is closed, the valve body 3 sealingly abuts on the contact area 5'of the valve seat 2 through the contact area 5. In this case, at least one of the two contact regions 5 or 5'is configured to be multi-layered, and has the configuration shown in FIG. 2 or FIG. 3, for example.

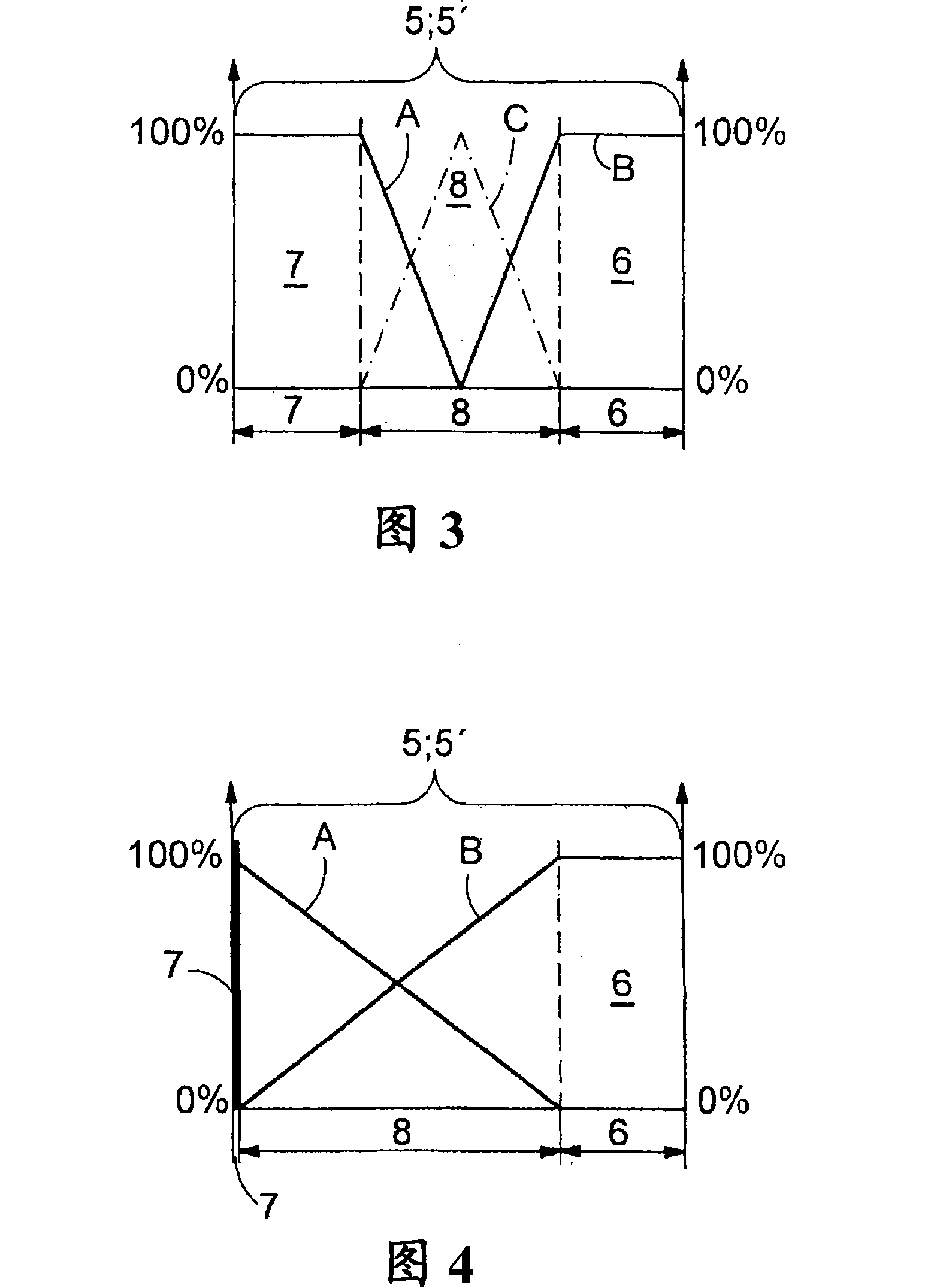

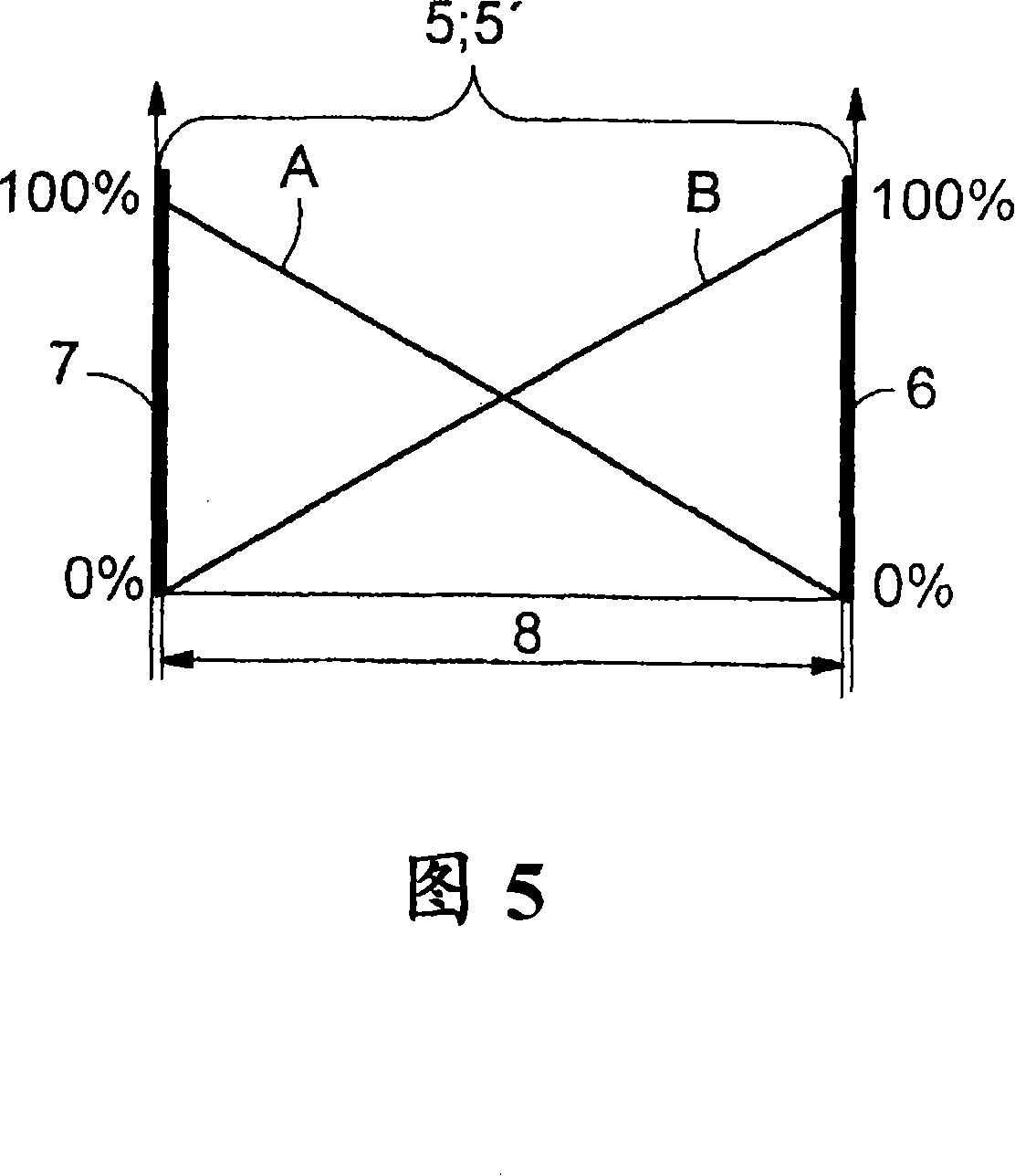

[0031] Figure 2 is a graphical depiction of the concentrations of materials A and B in the contact areas 5, 5'. In this case, in principle, the contact area 5, 5'according to FIG. 2 has at least one sealing area 6 facing the other contact area 5, 5', and a base area 7 facing away from this sealing area 6, And the transition area 8 between the sealing area 6 and the base area 7. The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com