Processing method for composite lubricating structure of sliding bearing based on electron beam curing

An electron beam curing and sliding bearing technology, applied in the field of friction and drag reduction, can solve the problems of ineffective curing, poor filling effect of cured materials, poor friction and anti-wear effects, etc., to avoid uneven release, surface vibration and Improved lubrication and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

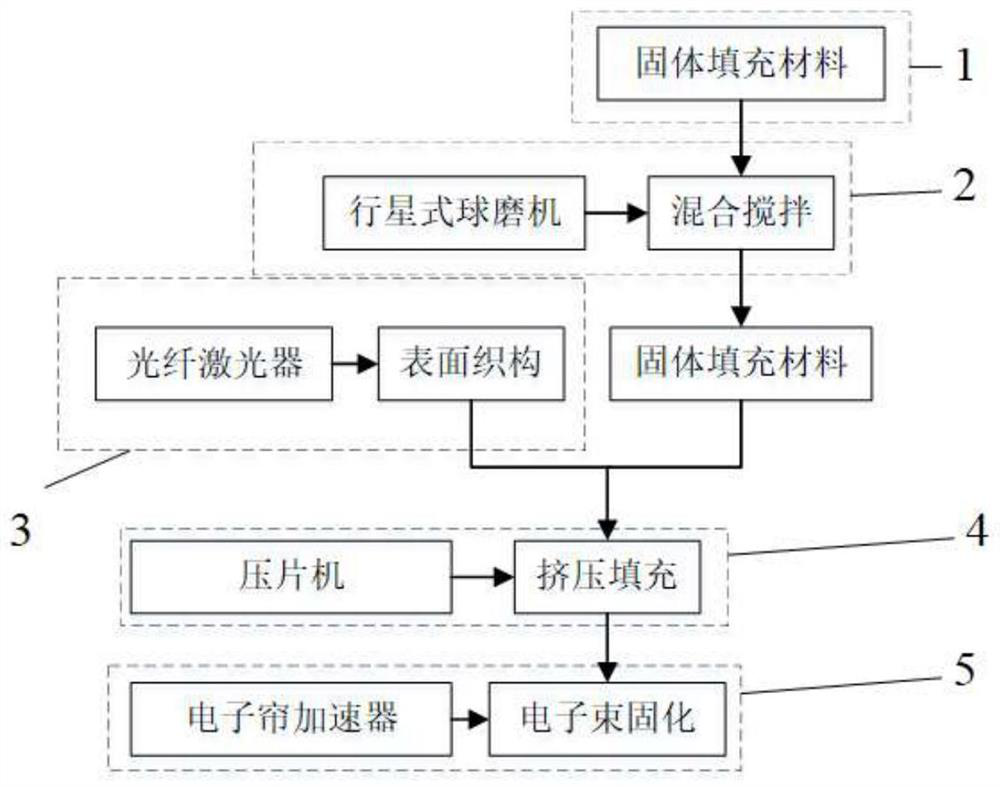

[0047] Such as figure 1 As shown, a method for processing the composite lubrication structure of sliding bearings based on electron beam solidification, the steps are as follows:

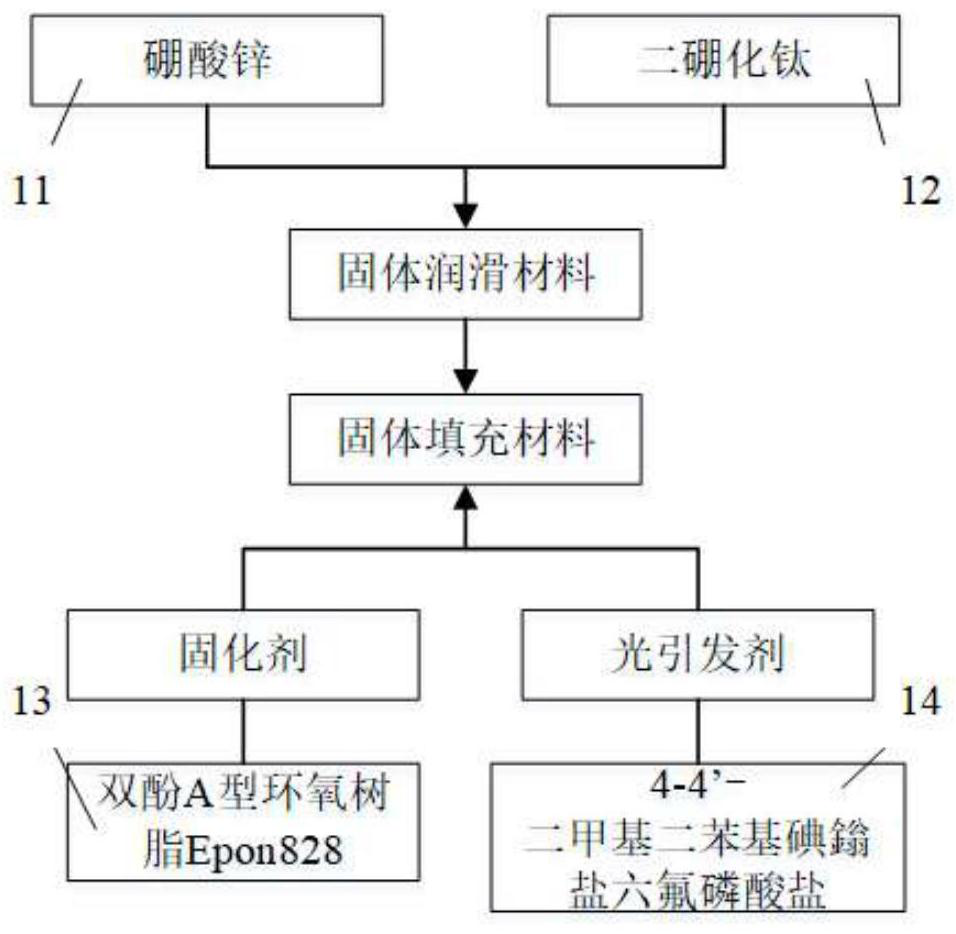

[0048] (1) Selection of solid filling materials: Titanium diboride with a particle size of 1 μm and a Mohs hardness of 2 and zinc borate with a particle size of 2 μm and a Mohs hardness of 2 are used as solid lubricating materials, and the ratio of the two is 2: 3; Take bisphenol A epoxy resin Epon828 as the curing agent, and take 4-4'-dimethyldiphenyliodonium hexafluorophosphate as the photoinitiator.

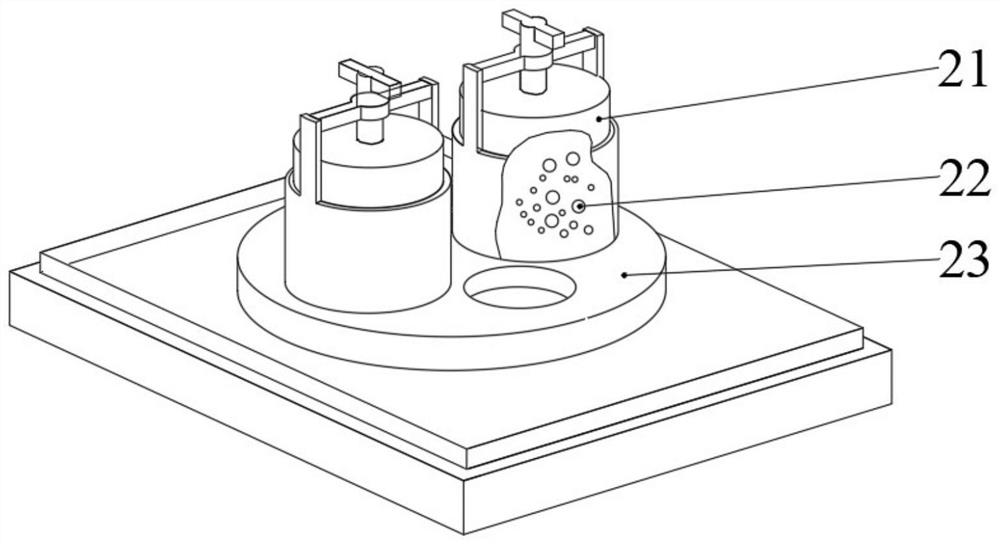

[0049] (2) Mixing and stirring of solid filling materials: according to the mass fraction ratio of 50% solid lubricating material, 48% curing agent, and 2% photoinitiator, each material is packed in the ball mill tank 21 of the planetary ball mill, and zirconia ceramics are added Grinding balls 22 (mixed according to the number ratio of 6mm, 10mm, and 15mm diameters of the grinding balls is 25:10:1...

Embodiment 2

[0053] Example 2: Use the composite lubricating structure obtained in Example 1 above to conduct a friction and wear test to investigate its anti-friction and anti-wear performance and compressive performance, and compare the ordinary texture without filling with the composite lubrication obtained by using traditional hot filling structure for comparison.

[0054] The test conditions are: room temperature; rotational speed 120r / min; load 100N; test time 1h, the obtained results are as follows Figure 7 and Figure 8 shown. The results show that the composite lubricating structure obtained by the electron beam curing method is smaller than the ordinary texture or the composite lubricating structure obtained by the traditional thermal curing method in terms of friction coefficient and bearing pad sample wear, indicating that the composite lubricating structure obtained by the electron beam curing method has Better anti-friction and anti-wear properties.

Embodiment 3

[0055] Embodiment 3: Using the composite lubricating structure obtained in the above-mentioned embodiment 1, a friction and wear test was carried out to investigate its compressive bearing performance, and a composite lubricating structure obtained by using traditional hot filling was used as a comparison.

[0056] The test conditions are: room temperature; speed 120r / min; loads 100N, 200N, 300N, 400N; test time 1h, the obtained results are as follows Figure 9 shown. The results show that under different loads, the friction coefficient of the composite lubrication structure obtained by the electron beam curing method is lower than that of the thermal curing method, indicating that the composite lubrication structure obtained by the electron beam curing method has better compressive bearing capacity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com