Method for producing austempered ductile iron (ADI) cylinder sleeve

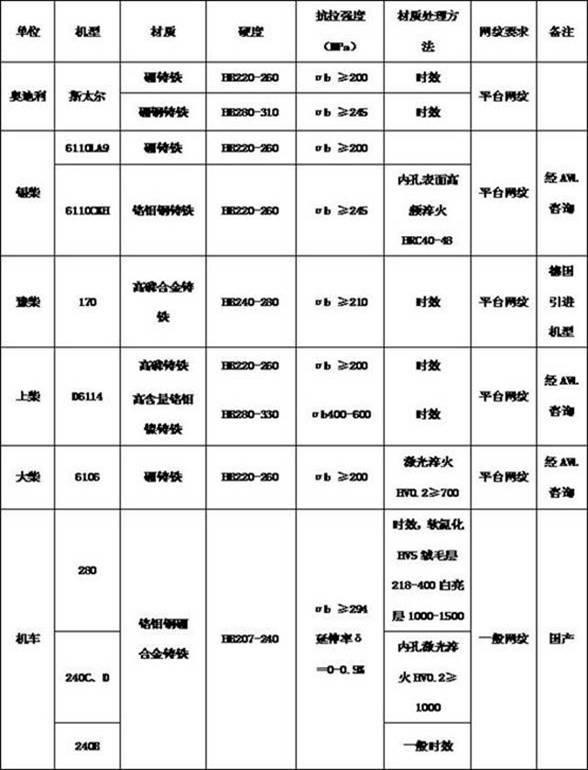

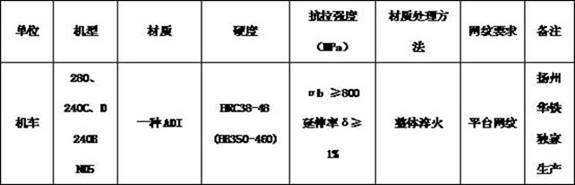

A production method and cylinder liner technology, applied in the field of ADI supercharged engine cylinder liner and production, can solve problems such as poor emission index, fatigue performance and wear resistance that cannot meet the requirements of high-enhanced engine service, and environmental impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] 1. Production steps:

[0016] 1. Pouring ADI cylinder liner slab:

[0017] Select synthetic cast iron or high-purity nodular iron pig iron carbonized by scrap steel as the main metal material for the production of ADI cylinder liners, and strictly control the addition of alloying elements; melt molten iron in an intermediate frequency electric furnace, purify the molten iron by blowing argon; 1480 ~ 1560 ° C, Spheroidization treatment and secondary inoculation treatment are adopted.

[0018] Addition of alloying elements (%), the rest is Fe:

[0019] C Si mn P S Mg Re 3.1-3.9 2.0-3.0 <0.31 <0.03 <0.02 0.039-0.062 ≥0.02

[0020] 2. Analysis: The number of graphite nodules of the formed ADI (rare earth Aubey ductile iron) cylinder liner slab is grade 1-4 of GB9441-88; the size of graphite is grade 5 not thicker than GB9441-88; the matrix structure The total amount of medium phosphorus eutectic cementite is ≤5%; the ratio of pearlite and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com