Cylinder jacket based on scale structure

A technology based on scale and cylinder liner, applied in the direction of cylinder, cylinder head, engine components, etc., can solve the problem of not meeting the needs of use, and achieve the effect of extending service life, reducing wear and enhancing oil storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

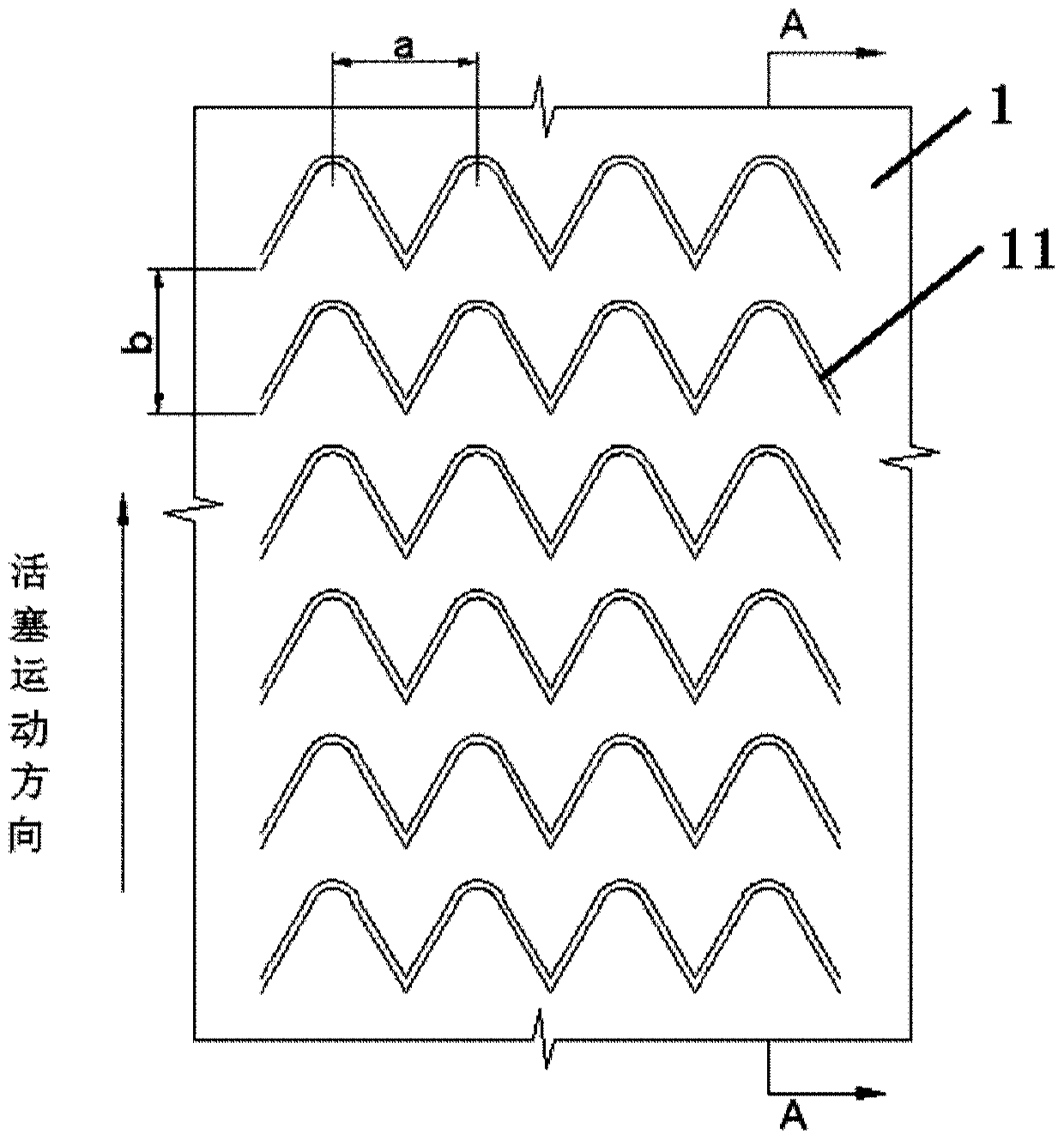

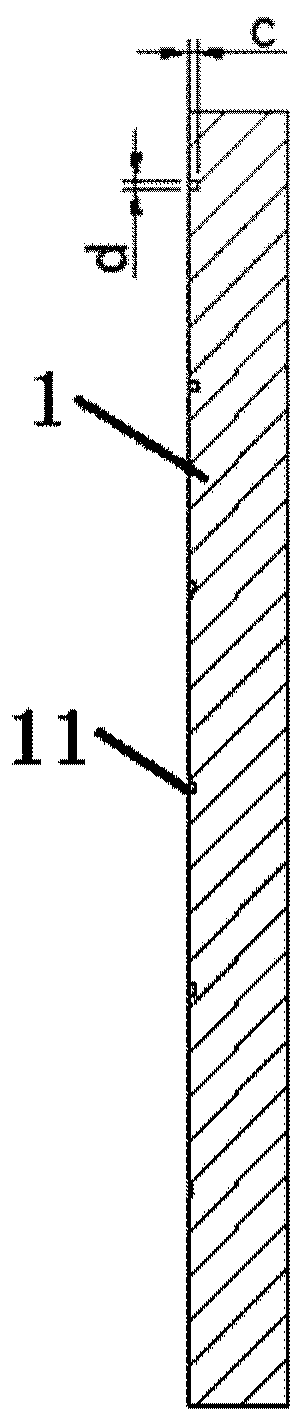

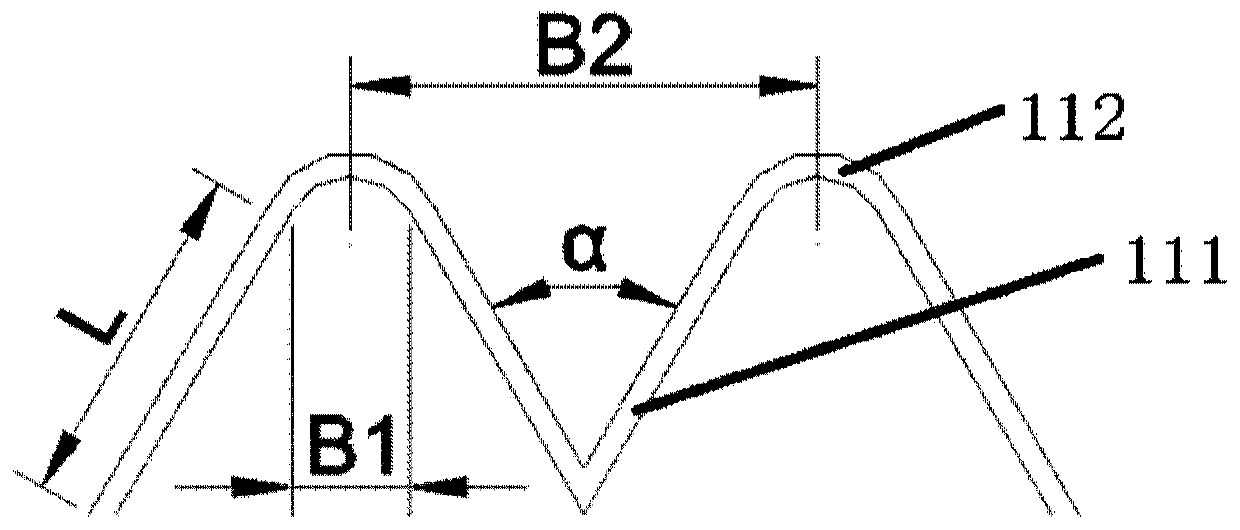

[0028] The disclosure provides a cylinder liner based on a scale structure. The inner surface of the cylinder liner includes: multiple sets of V-shaped grooves, which are evenly distributed along the moving direction of the piston and have a scale structure. In the present disclosure, multiple groups of scale-shaped V-shaped groove groups are designed on the surface of the cylinder liner, which is beneficial to oil storage, reduces wear and tear, and prolongs the service life of the engine.

[0029] In order to make the purpose, technical solutions and advantages of the present disclosure clearer, the present disclosure will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0030] Certain embodiments of the present disclosure will be described more fully hereinafter with reference to the accompanying drawings, in which some but not all embodiments are shown. Indeed, various embodiments of the disclo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Chord length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com