Patents

Literature

67results about How to "Wear-resistant surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

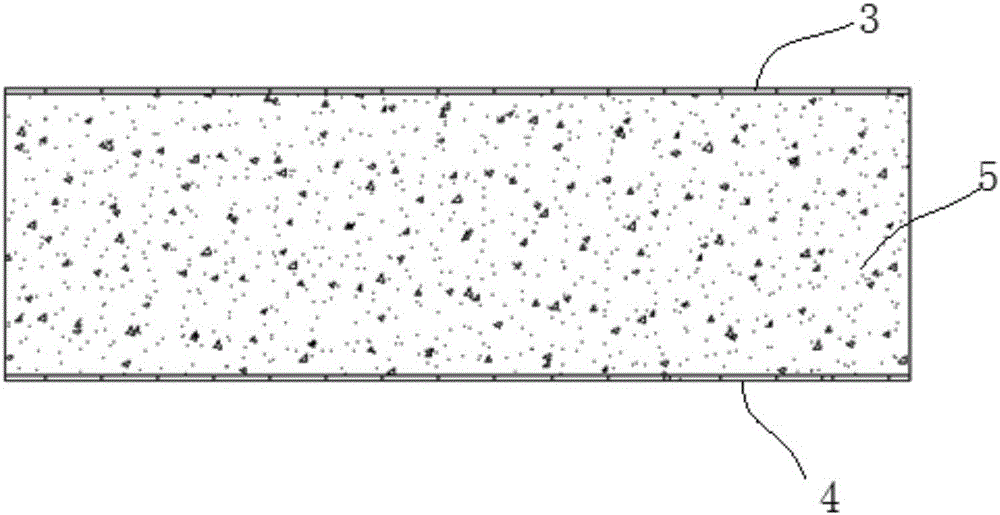

Preparation method for asphalt concrete with conduction function

InactiveCN101215124ALow costAlleviate problems such as insufficient aggregateSolid waste managementForeign matterMaterials preparation

The invention relates to a process for preparing asphaltic concrete with conducting function, which is characterized in that the process includes the procedures of 1), preliminary treatment of aggregates, which means washing away the foreign matters of the steel slag with water. 2), raw materials preparation, which means that the percentage by weight of each component is that rough aggregates is 55%-80%, fine aggregates is 13%-30%, mineral filler is 7%-15%, the rough aggregates, fine aggregates and mineral filler are selected to reserve as aggregates, consumption of asphalt cement is 6%-8% of the weight of the aggregates, consumption of fabric stabilizer is 0.1%-0.5% of the gross weight of the aggregates and the asphalt cement, consumption of conducting material is 10-30% of the weight of the asphalt cement, and gradation design of SMA mixture is employed. 3), mixture blending, which means charging fractionally and blending multitime, the temperature is kept not lower 150 DEG C when molding. The preparing process has simple technique and low cost. The prepared asphaltic concrete has good conducting function and pavement using property.

Owner:WUHAN UNIV OF TECH

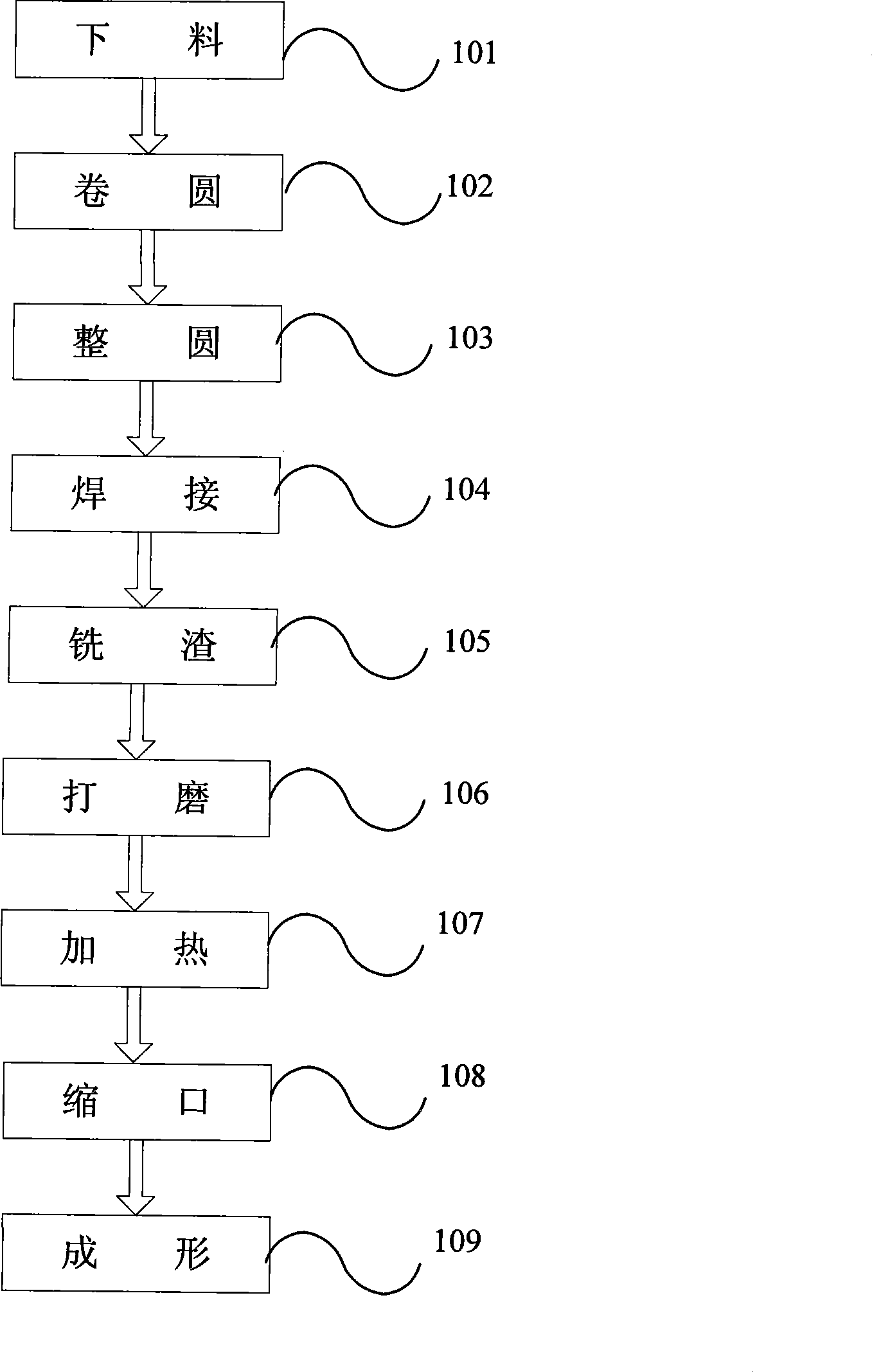

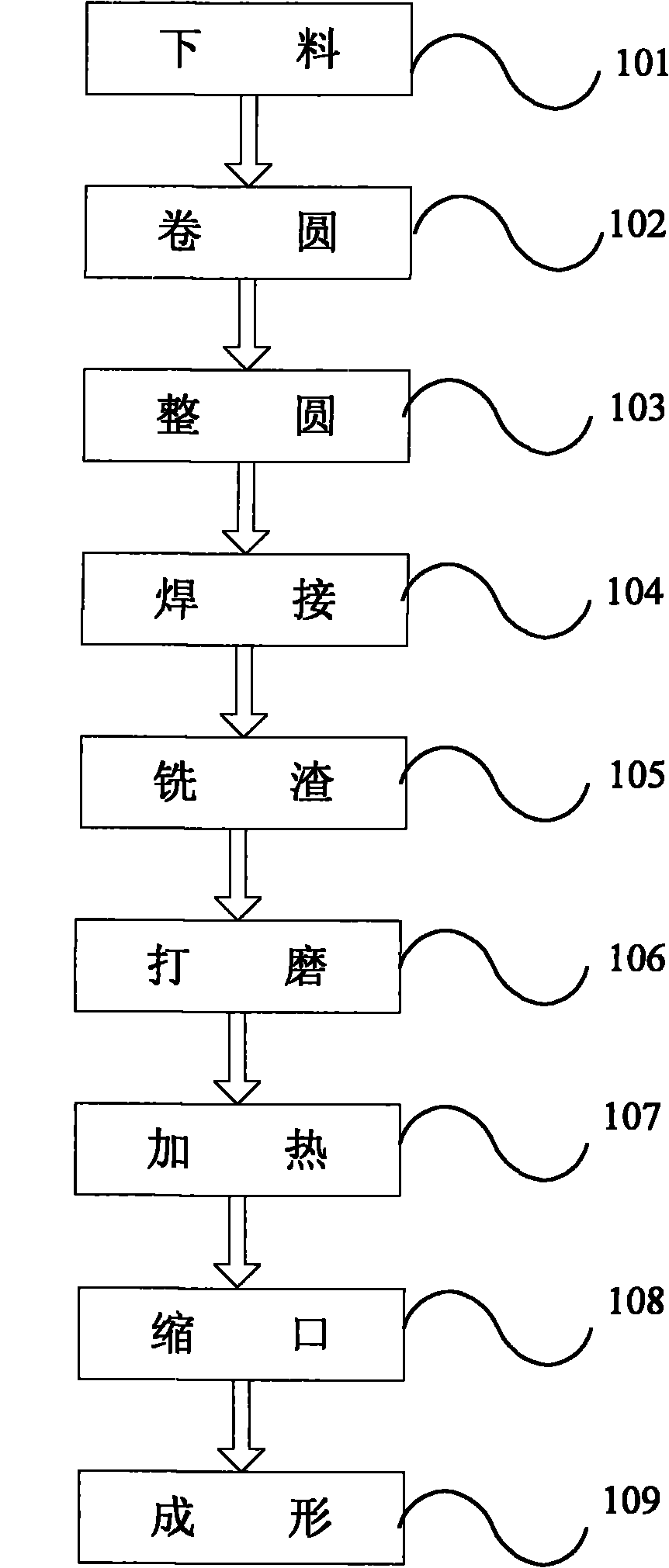

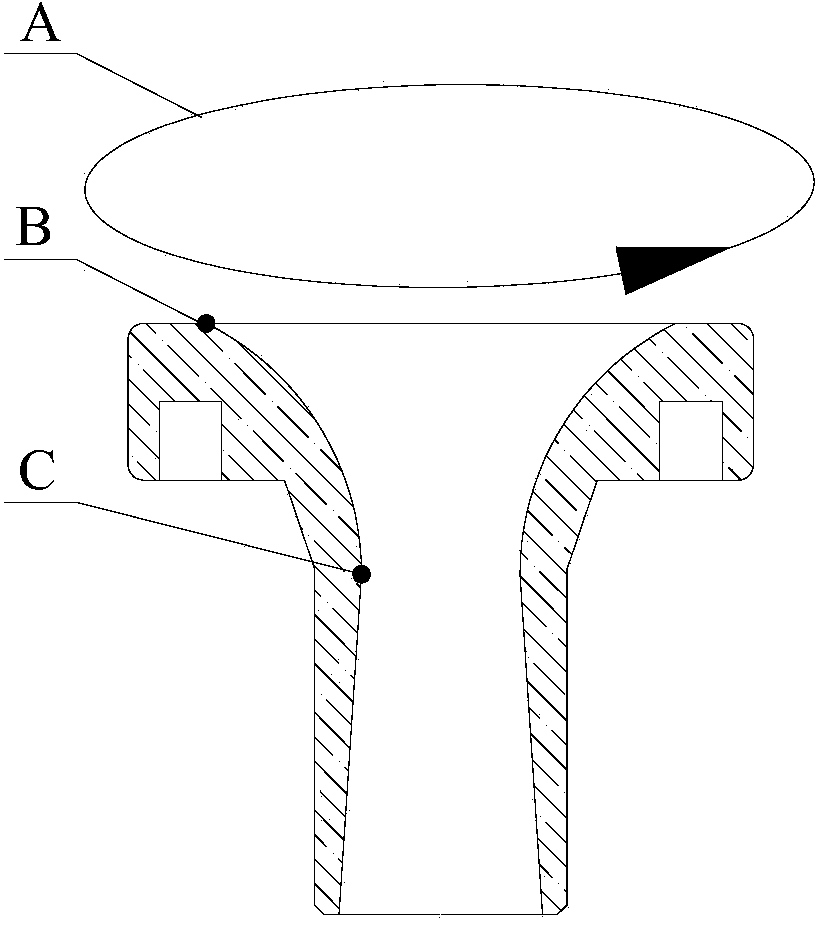

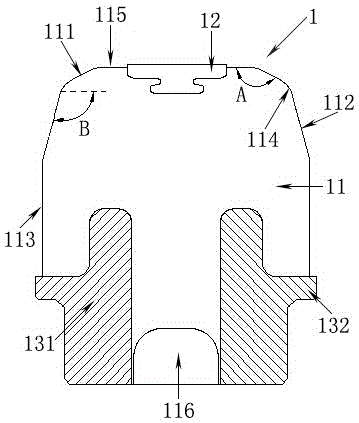

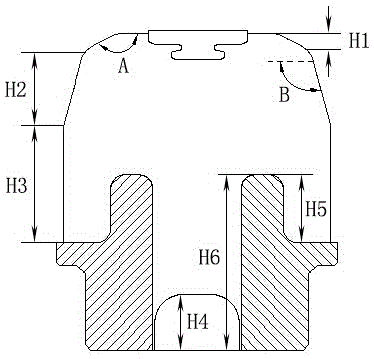

Technology for manufacturing retaining ring for wheel of wheeled engineering machinery and special-purpose mold thereof

The invention discloses a manufacturing process for a shield ring for a wheel type engineering machinery wheel and a special mould, and belongs to the technical field of engineering machinery. The manufacturing process comprises the following working procedures: heating, in which an annular ring blank is heated to be between 700 and 900 DEG C to form a heating workpiece; necking, in which the heating workpoece is subjected to necking and pressing by using a necking mould to prepare a necking workpiece; and forming, in which the necking workpiece is subjected to forming and pressing by using a forming mould to prepare a finished shield ring. The special mould comprises an upper mould body and a lower mould body, and the upper mould body comprises a necking upper mould body and a forming upper mould body. The manufacturing process and the special mould are applicable to manufacturing the shield ring for the wheel type engineering machinery wheel.

Owner:HONGYUAN JINGGONG WHEEL CO LTD

Medium density fiberboard with decorative surface covered by impregnated film adhesive paper and preparation method thereof

InactiveCN101767353AStrong three-dimensional senseImprove the decorative effectWood veneer joiningWood layered productsSurface layerAdhesive

The invention relates to wood processing field, in particular to a medium density fiberboard with decorative surface covered by impregnated film adhesive paper, wherein a surface layer film adhesive paper and a decorative layer film adhesive paper of the decorative surface film adhesive paper are sequentially adhered on the upper surface of the medium density fiberboard; the lower surface thereof is sequentially adhered with the surface layer film adhesive paper and the decorative layer film adhesive layer of the decorative surface film adhesive paper, or is adhered with a bottom layer film adhesive paper; a concave groove and / or a convex rib with depth more than and equal to 1.2mm is thermally pressed on the upper surface and / or the lower surface of the medium density fiberboard. The invention has good stereoscopic impression and can well satisfy the market demands.

Owner:费恺

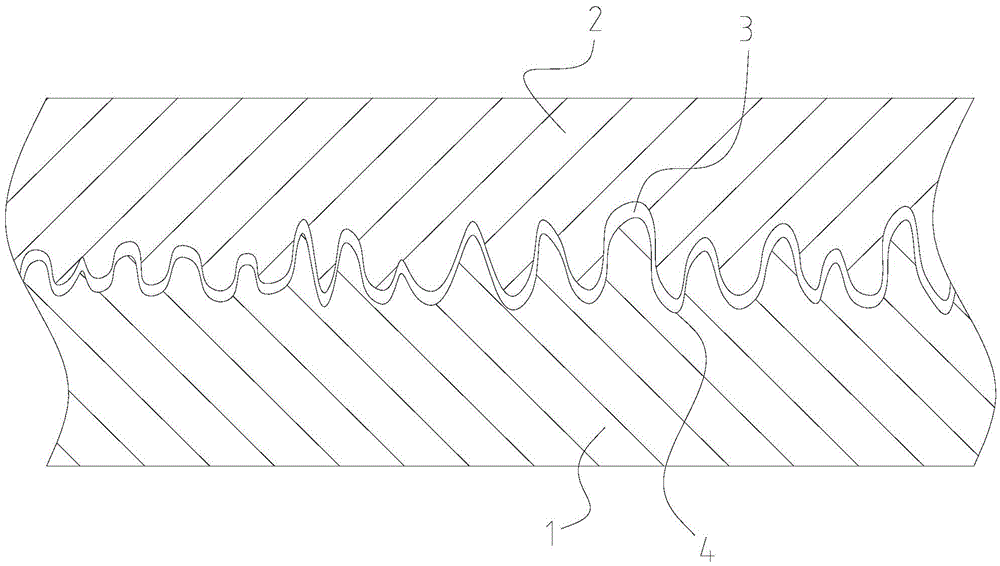

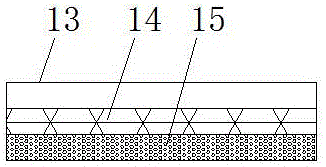

Production process of high-strength oxhide non-woven leather fabric

InactiveCN108068426AHigh tear strengthWear-resistant surfaceSynthetic resin layered productsLaminationScrapPolyester

The invention belongs to the technical field of textile, and in particular relates to a production process of a high-strength oxhide non-woven leather fabric. The production process comprises the following steps: mixing 20% of polyester fiber with 80% of nylon fiber, carrying out cross-laying by a lapping machine, and preparing a non-woven fabric through a spun-laced machine; mixing 93% of oxhidefibers with 7% of polyester fiber to form a mixed fiber layer, carrying out cross-laying by the lapping machine, putting the prepared non-woven fabric under the mixed fiber layer for transportation bya conveyor belt during cross-laying, and carrying out high-pressure spunlace on the mixed fiber layer and the non-woven fabric together through a spun-laced machine to form an oxhide non-woven leather fabric; shaping the prepared oxhide non-woven leather fabric in an oven, flattening and polishing the surface of the fabric, and passing the fabric through a hot roller; and finally, arranging a layer of PU on the surface of the fabric. According to the production process of the high-strength oxhide non-woven leather fabric, provided by the invention, the produced product has high tear strength,high wear resistance on the surface and high scratch resistance. Moreover, making full use of scraps of real leather to turn waste into valuables not only reduces the production cost, but also reduces the pollution to the environment.

Owner:FUZHOU JIADA TEXTILE TECH CO LTD

Treatment process for abrasion-resistant and corrosion-resistant metal substrate

InactiveCN105951147AImprove conductivityWear-resistant surfaceAnodisationAbrasive blastingMetallic substrate

The invention discloses a treatment process for an abrasion-resistant and corrosion-resistant metal substrate. The process comprises the following steps of S1, primary rust removing treatment, S2, primary cleaning, S3, leaching with acid liquor, S4, abrasive blasting treatment, S5, electroplating treatment, S6, anodic oxidation treatment, S7, coloring treatment and S8, drying treatment. The production process is simple, and the abrasion resistance and the corrosion resistance of the metal substrate can be effectively improved.

Owner:江苏国华电力器材有限公司

Scratch resistant environmental low-smoke halogen-free flame resistant sheath material for special optical cable

InactiveCN101702049AReduce pollutionReduce stimulationFibre mechanical structuresElastomerAntioxidant

The invention relates to a scratch resistant environmental low-smoke halogen-free flame resistant sheath material for a special optical cable. The sheath material comprises the following components by weight percent: 15-25% of ethylene-vinyl acetate copolymer, 5-10% of polyethylene, 5-10% of polyethylene elastomer, 45-60% of flame retardant, 5-10% of compatilizer, 0.5-2% of antiwear agent, 0.5-1.0% of lubricant and 0.1-0.5% of antioxidant. The material of the invention has no halogen, low pollution to the environment, good flame resistant performance, low smoke caused by burning and low irritation to human. The outer sheath of the cable prepared by the sheath material of the invention has excellent surface abrasion resistance and scratch resistant so that the surface of the outer sheath is not easy to scratch during construction and used processes and can maintain good appearance quality.

Owner:SUZHOU HENGLI COMM MATERIAL

Travertine-like arabesquitic vat and production technology thereof

The invention discloses a travertine-like arabesquitic vat. The forming material of the travertine-like arabesquitic vat mainly comprises a solid material, a blended solution and staple, wherein the solid material comprises the following components in percentage by weight: 30-45% of rapid-hardening sulphoaluminate cement, 45-65% of fine river sand, 1-3% of titanium dioxide, 1-3% of yellow powder and 0.01-0.15% of red powder; the blended solution comprises the following components in percentage by weight: 99-99.9% of water and 0.01-0.1% of polyacrylamide; and the staple is glass fiber of which the length is 5-10cm. The invention also discloses a production technology for the travertine-like arabesquitic vat, which comprises the following steps of: burdening, mixing, cleaning a mold, installing a material mold, installing the staple, demolding, nursing, trimming, repairing, brushing to be smooth, applying a surface coating and the like. The travertine-like arabesquitic vat disclosed by the invention has the advantages of clear and natural texture, good product intensity, light weight, hard surface layer, abrasion resistance, small possibility of delaminating and falling powder, low cost and good decoration effect, is convenient to produce on a large scale and is easy for stable control of product chromatic aberration, natural travertine in the natural world can be prevented from being mined on a large scale, and mine waste can be utilized to protect the ecological environment.

Owner:泉州市嘉利来石材工艺有限公司

Sweet and cool tipping paper gravure alcohol-soluble surface coating and tipping paper prepared therefrom

ActiveCN109610232AGuaranteed sweet and cool tasteGuaranteed not to fadeFlexible coversCoatings with pigmentsPolyvinyl butyralMomordica

The invention discloses a sweet and cool tipping paper gravure alcohol-soluble surface coating and tipping paper prepared therefrom. The sweet and cool tipping paper gravure alcohol-soluble surface coating comprises the following raw materials by weight: 0.1 to 0.3% of a sweetening agent prepared from neotame, mannitol, a rosvenor momordica fruit extract and fine moringa seed powder with a particle size of 1000 meshes, 15 to 20% of WS-23(N,2,3-trimethyl-2-isopropylbutanamide) cooling agent, 30 to 36% of polyvinyl butyral, 4 to 5% of castor oil, 1.6 to 2% of wax micropowder, 2.5 to 3% of whitecarbon black and 33.7 to 46.8% of edible ethanol. According to the invention, the tipping paper printed by using the sweet and cool tipping paper gravure alcohol-soluble surface coating provided by the invention is smoother, brighter, stain-resistant, water-resistant and wear-resistant in surface, has special sweet and cool tastes, and tastes cool and sweet; wear resistance, folding resistance andfunctionality of a printed product are reinforced to a great extent; and the reputation of he product is improved.

Owner:YUNNAN YUXI TIPPING PAPER FACTORY

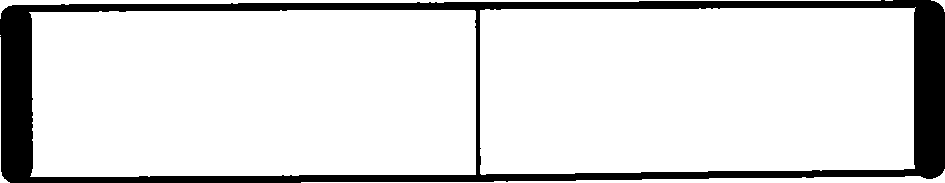

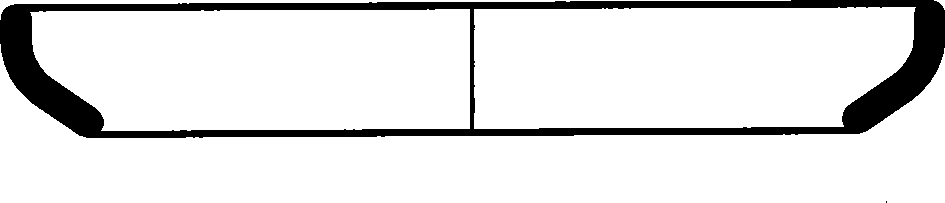

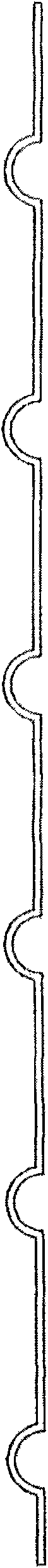

Check ring special die for wheel type engineering machinery cartwheel

InactiveCN101850382AWear-resistant surfaceImprove the finishShaping toolsMechanical engineeringEngineering

The invention discloses a check ring special die for a wheel type engineering machinery cartwheel, belonging to the technical field of engineering machinery. The die comprises an upper die body an a lower die body; the upper die body is composed of a necking upper die body and a forming upper die body; the necking upper die body is formed by fixed connection of an upper die seat, a necking die and a guide pillar; the underhorn of the interior of the necking die is provided with a necking groove; the forming upper die body is formed by fixed connection of an upper die seat, a forming die and a guide pillar; the underhorn of the interior of the forming die is provided with a forming groove; the lower die body comprises a cylindrical annular terrace die; the inner side surface of the terrace die is connected with a guide sleeve; the lower end surface of the terrace is fixedly connected with a lower die seat; the outer side surfaces of the terrace die and the lower die seat are in sliding connection with a stepped ejector plate which is in elastic connection with a positioning plate upwards; the outer surfaces of the positioning plate and the lower die seat are fixed with annular limit plates; and the lower die seat is fixedly connected with a baseplate downwards. The invention is suitable for preparing check rings for wheel type engineering machinery cartwheels.

Owner:HONGYUAN JINGGONG WHEEL CO LTD

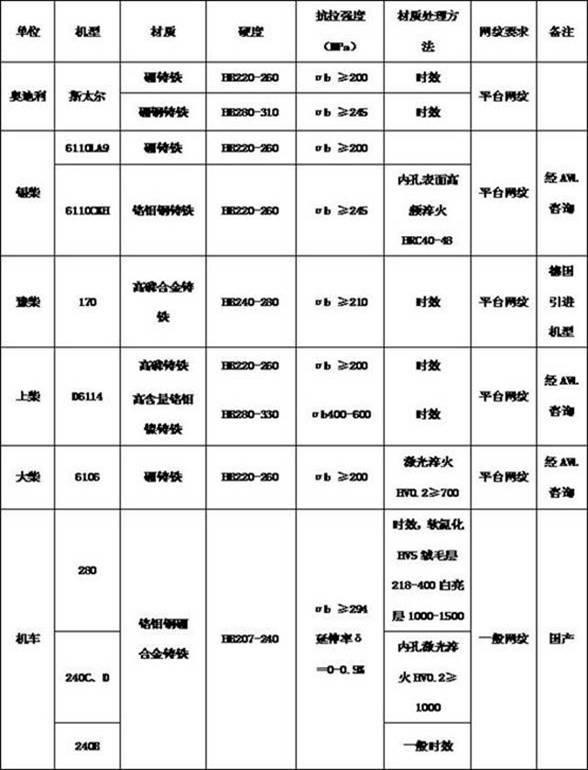

Method for producing austempered ductile iron (ADI) cylinder sleeve

The invention discloses a method for producing an austempered ductile iron (ADI) cylinder sleeve, belongs to metal materials, and in particular relates to the technical field of production processes for ADI supercharged engine cylinder sleeves. The method comprises the steps of casting an ADI cylinder sleeve casting blank, finely machining the cylinder sleeve casting blank, performing isothermal quenching treatment and shot blasting treatment and machining platform reticulate patterns. The method solves the problem that the fatigue property and the abrasion resistance of the conventional service materials such as boron cast iron, boron-copper cast iron, chromium-molybdenum-copper cast iron, high-phosphorus alloy cast iron, high-phosphorus cast iron, high-content chromium-molybdenum-nickel cast iron and chromium-molybdenum-copper-boron alloy cast iron cannot meet the service requirements of high strength engines.

Owner:扬州华铁机电集团有限公司

Ultraviolet (UV) curing ink screen printing technology for UV highlight veneer

The invention discloses ultraviolet (UV) curing ink screen printing technology for a UV highlight veneer, which relates to UV ink screen printing technology. Ink is printed on the surface of the UV highlight veneer, and a UV curing measure of ink is adopted, so that a pattern is firm and durable. The technology is characterized by comprising the following process steps of: stretching a screen; sizing; drying; printing down; developing; drying; cleaning and drying the UV highlight veneer; printing; and performing UV curing. The technology has the advantages that: environmentally-friendly high-polymer UV resin ink has the properties of fresh color, difficult breakage, acid resistance and alkali resistance; after the UV highlight veneer which is subjected to screen printing is used, a clear pattern, high adhesion, surface wear and flexible and plain tone are realized; and impurities in resin can be filtered better through the screen in the printing process, so that a printed pattern has a bright and flexible color, and the problems of unavailable UV ink printing on the UV highlight plate in the prior art and making of UV on a UV surface are solved.

Owner:陈增金

Nano TiO2-containing cellulose-based low-temperature phase change energy storage microcapsule and preparation method thereof

ActiveCN105754554AImprove thermal conductivityPrevent leakageHeat-exchange elementsMicroballoon preparationCelluloseHeat conducting

The invention discloses a nano TiO2-containing cellulose-based low-temperature phase change energy storage microcapsule and a preparation method thereof; the low-temperature phase change energy storage microcapsule comprises a capsule core and a capsule wall, wherein the capsule core is a core-shell structure composite phase change material formed by wrapping the surface of paraffin with ethylene glycol, and the capsule wall is formed by a carboxymethyl cellulose membrane doped with nano TiO2 particles; the preparation method comprises the steps of firstly, preparing a composite phase change material by using an aqueous phase ethylene glycol solution and oil phase liquid paraffin through a micro-emulsion method; then, preparing the capsule wall by using a carboxymethyl cellulose water solution containing tetrabutyl titanate and a silane coupling agent through a sol-gel reaction to obtain the microcapsule; the microcapsule has average particle size of 3-10 microns, phase-transition temperature of minus 12 to 5 DEG C and an enthalpy value of 170-200J / g; furthermore, the microcapsule also has good heat-conducting property; the microcapsule is simple in preparation technology and easy in large-scale production, and products of the preparation method do not contain inorganic salt and an organic solvent which can easily corrode a container, so that the preparation method is green and environment-friendly.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +1

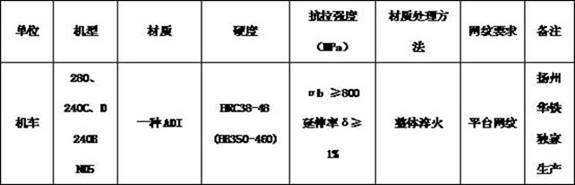

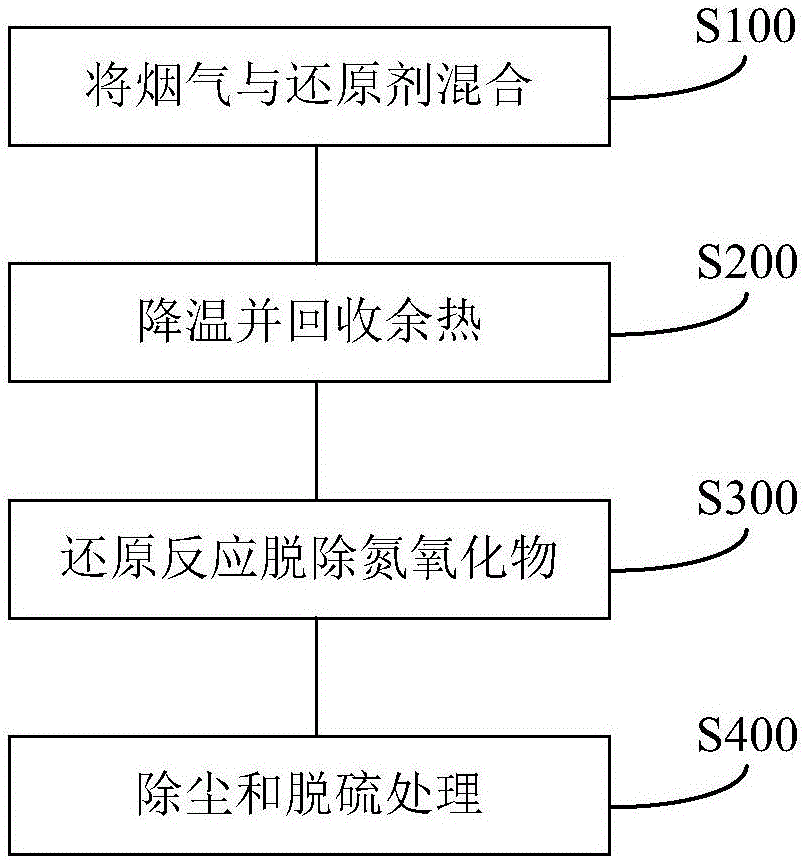

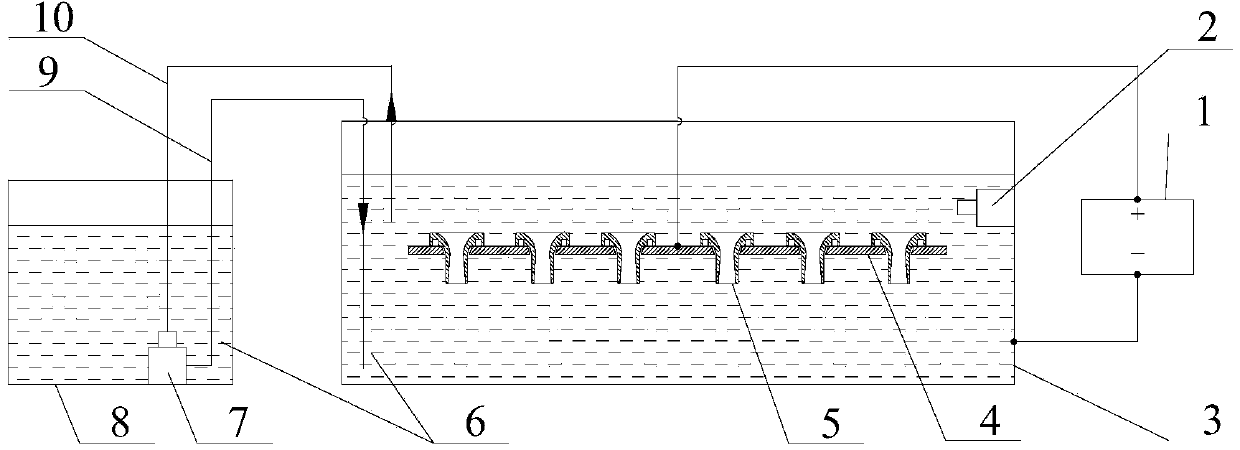

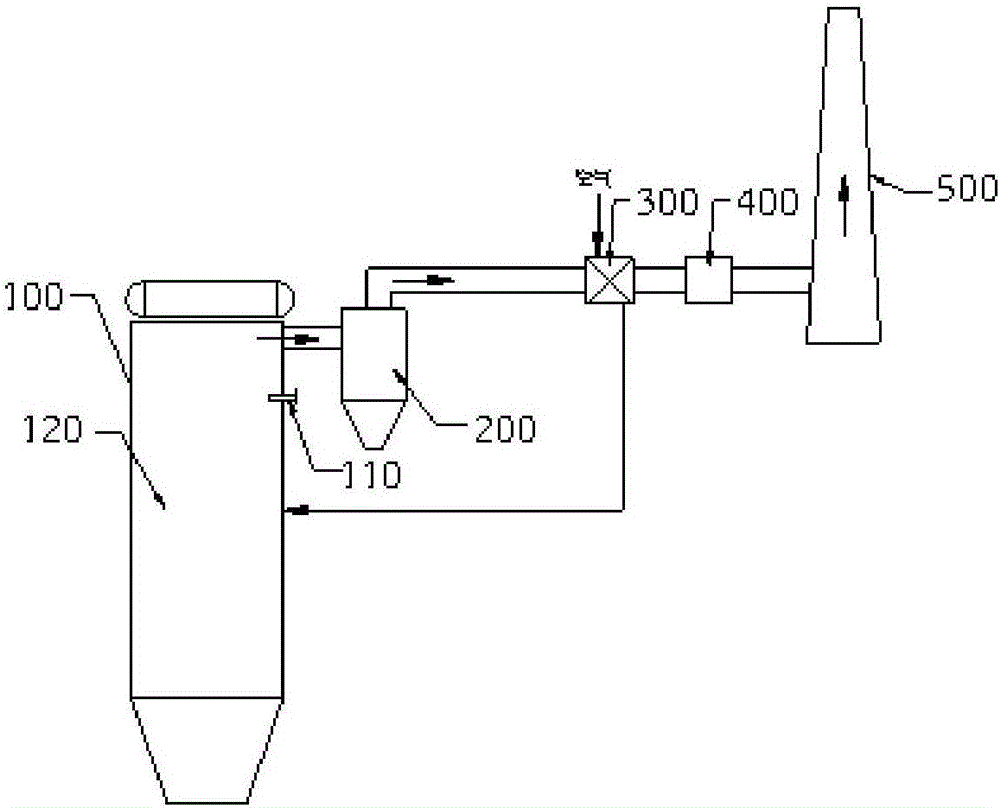

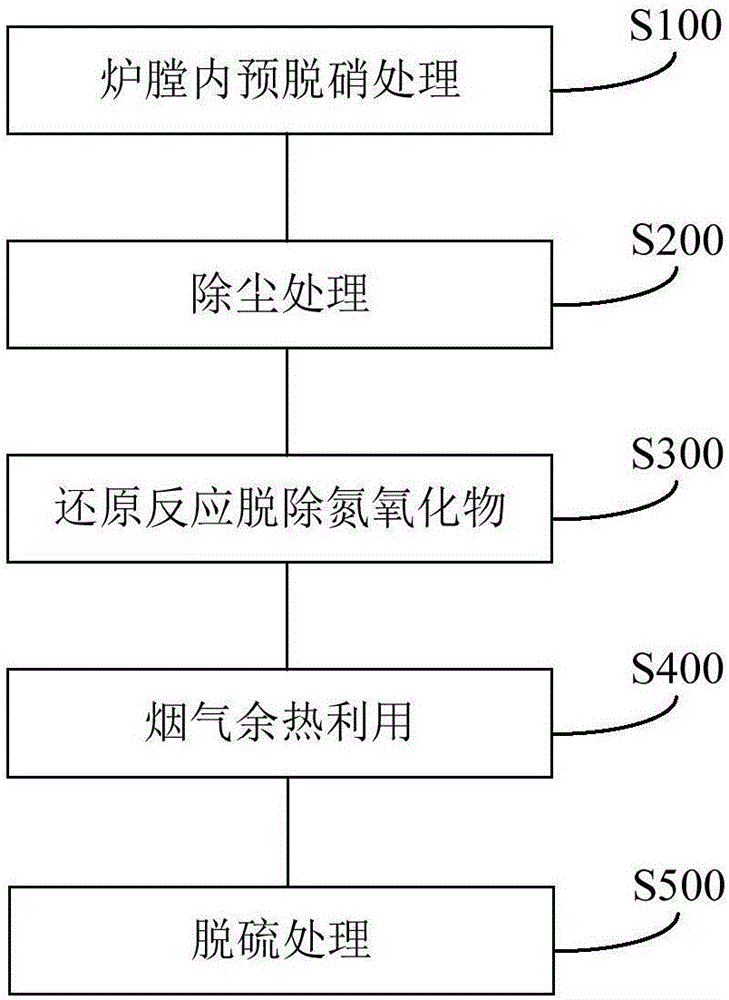

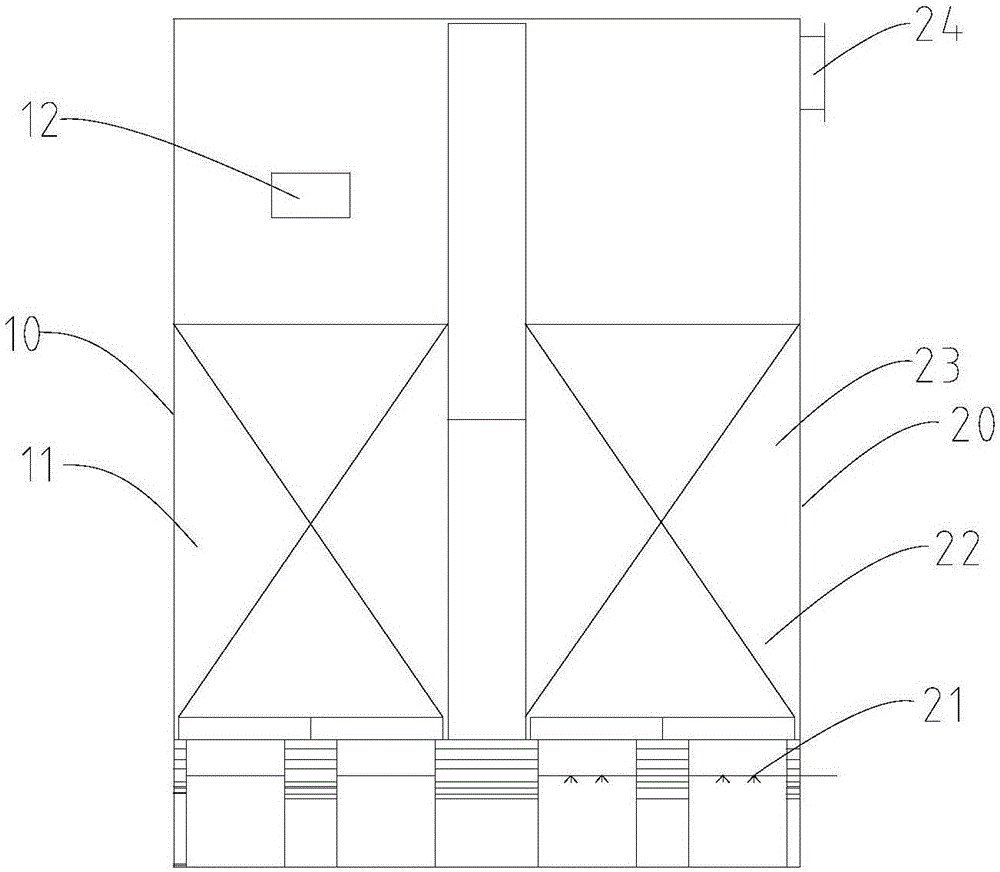

Flue gas denitrification system and denitrification method for particle material industrial boiler

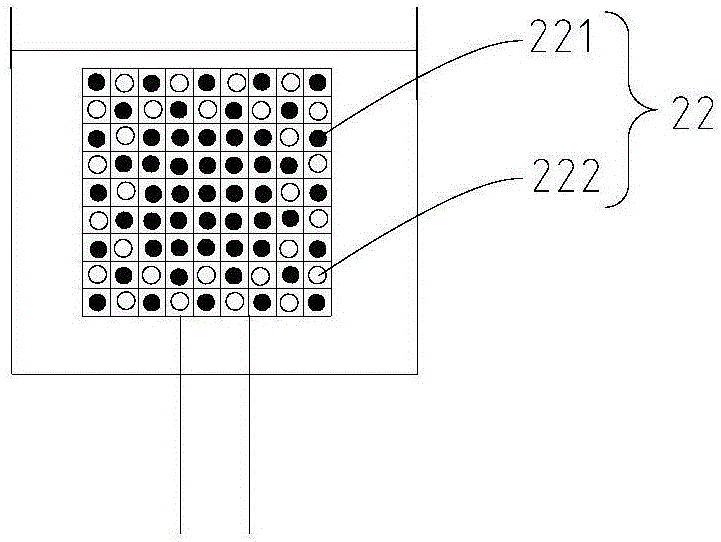

PendingCN106731798AFlat surfaceWear-resistant surfaceGas treatmentDispersed particle separationFlue gasProcess engineering

The invention discloses a flue gas denitrification system and denitrification method for a particle material industrial boiler. The denitrification system comprises an exhaust pipeline, a heat accumulator, a denitrification heat accumulator, a cyclone separation device, a desulfurization device and a chimney, wherein the exhaust pipeline is connected to a flue gas outlet of the particle material industrial boiler, and a reducer nozzle is arranged on the exhaust pipeline; the heat accumulator is arranged in the exhaust pipeline and is located in the downstream of the reducer nozzle, and the heat accumulator is suitable for pre-recovering waste heat of the flue gas; the denitrification heat accumulator is arranged in the exhaust pipeline and is located at the downstream of the heat accumulator, and the denitrification heat accumulator is suitable for recovering the waste heat of the flue gas and denitrifying the flue gas; the cyclone separation device is connected to a gas outlet of the exhaust pipeline and is suitable for dedusting the flue gas; the desulfurization device is connected to the cyclone separation device and is suitable for removing sulfur oxides in the flue gas; and the chimney is connected to the desulfurization device. By using the denitrification system, a denitrification reaction can be performed on the flue gas without dedusting, so that the denitrification system is simple to operate and high in denitrification efficiency.

Owner:SHENWU TECH GRP CO LTD

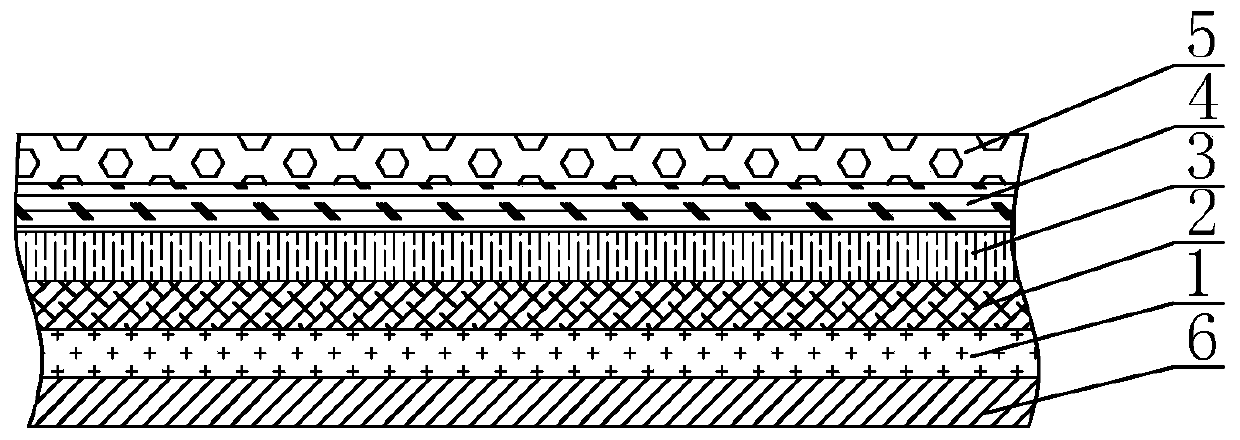

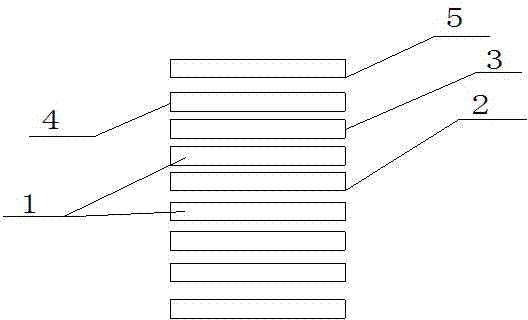

Buckling deformation resisting impregnated film paper veneered plywood and production process thereof

InactiveCN110341001AStable structureStrong screw forcePaper/cardboard layered productsWood veneer joiningPulp and paper industryAir pollution

The invention discloses a buckling deformation resisting impregnated film paper veneered plywood and a production process thereof. The plywood comprises a board core, a middle board, a surface board and impregnated film paper. The production process comprises the production of the board core and the production of the plywood, and the production of the plywood comprises the steps of gluing, assembling, cold press forming, hot pressing, pressure relief, putty maintenance, fixed-thickness sanding, gluing and pasting of the surface board, cold press forming, hot pressing, sanding, edge sawing, andpressing and pasting of the impregnated film paper. The buckling deformation resisting impregnated film paper veneered plywood and the production process thereof solve the problems of deformation ofkitchen and cabinet door boards in furniture decoration, and harm of formaldehyde in plywood to air pollution and human bodies.

Owner:NANNING KETIAN SHUIXING TECH LTD CO +1

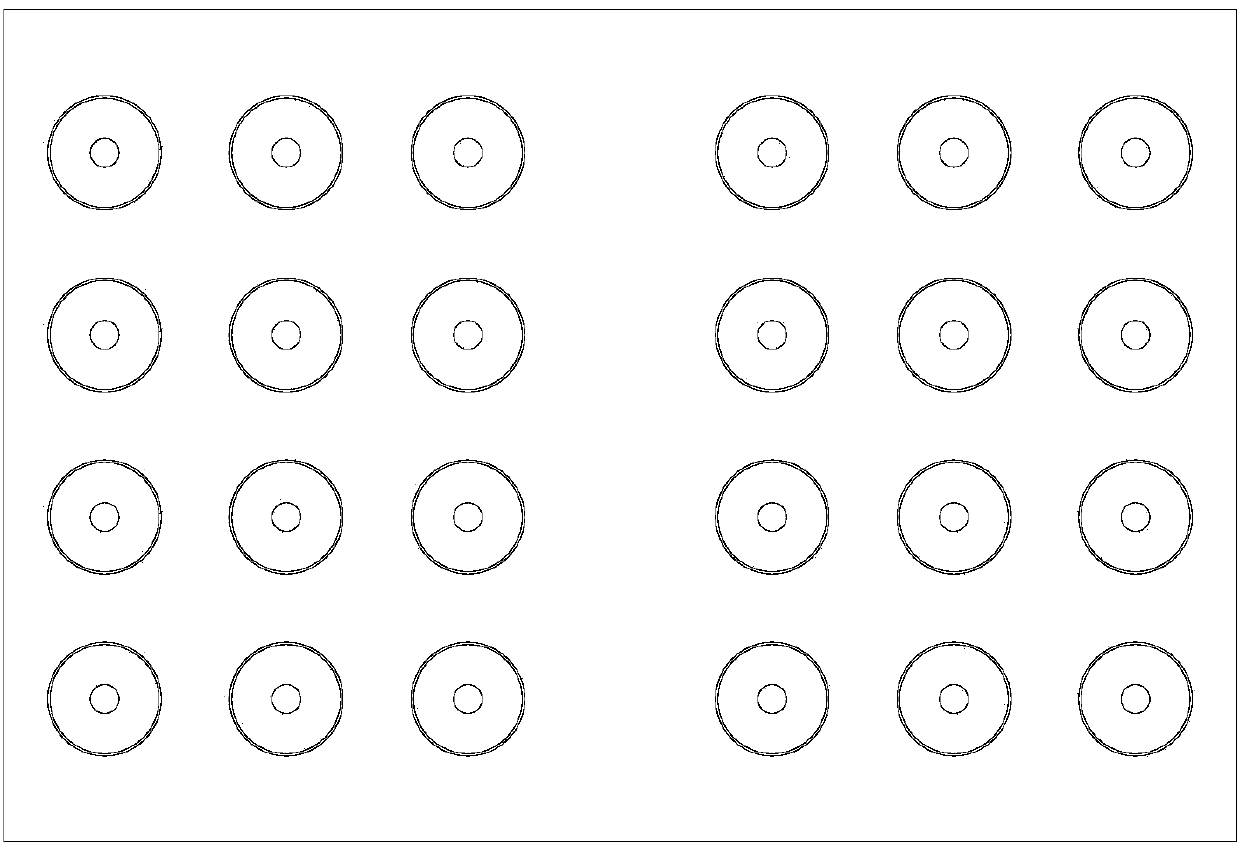

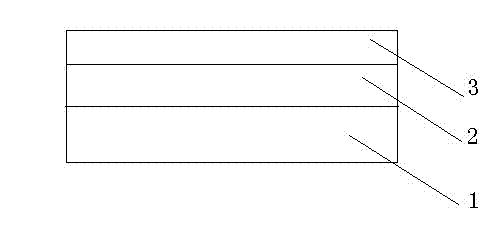

High-strength steel-based copper alloy sliding plate

InactiveCN104553135AStrong impact resistanceImprove carrying capacityMetal layered productsCopper atomSheet steel

The invention relates to a high-strength steel-based copper alloy sliding plate which comprises a base sheet plate, a copper alloy plate and an alloy film layer, wherein the alloy film layer is arranged between the base sheet plate and the copper alloy plate; the copper alloy plate, the alloy film layer and the steel plate are combined together by adopting an iontophoresis method; at least one binding groove for improving the binding strength of the steel plate and the alloy film layer is also formed in the steel plate; exchanging is carried out among atoms of the steel plate and the alloy film layer as well as atoms of the alloy film layer and the copper alloy plate; meanwhile, iron atoms penetrate through the film to be exchanged with copper atoms, or the copper atoms penetrate through the film to be exchanged with the iron atoms, so that the copper alloy plate is combined with the steel plate by adopting the iontophoresis method; and the at least one combining groove for improving the binding strength of the steel plate and the copper alloy plate is also formed in the steel plate.

Owner:PINGHU KAIFENG MACHINERY MFG FACTORY

Travertine-like arabesquitic vat and production technology thereof

The invention discloses a flower vat imitating travertine. The molding material is mainly composed of solid materials, blending solution and short fibers. The weight percentage of the solid materials: 30-45% rapid hardening sulfoaluminate cement, 65% fine river sand, 1-3% titanium dioxide, 1-3% yellow powder, 0.01-0.15% red powder; the weight percentage of the blended solution: 99-99.9% water, 0.01-0.1% polyacrylamide; The staple fibers described above: glass fibers with a length of 5 to 10 cm; the present invention also discloses a process for producing the above-mentioned imitation travertine flower vats, including batching, mixing, mold cleaning, feeding molds, upper staple fibers, and demoulding. , Maintenance, trimming, repairing, brushing, surface coating and other steps. The imitation travertine flower vat of the present invention has clear and natural texture, good product strength, light weight, hard surface, wear-resistant, not easy to delaminate and powder, convenient for mass production, low cost, easy to control product color difference stably, The decorative effect is good, and at the same time, it can avoid a large amount of mining of natural travertine in nature, and can digest mine waste to protect the ecological environment.

Owner:泉州市嘉利来石材工艺有限公司

Anhydrous low-cost imitation electroplating film and surface treatment method thereof

InactiveCN111411332ANo Wastewater ProblemsNo emissionsVacuum evaporation coatingSputtering coatingWastewaterSilicon oxide

The invention relates to a metal or non-metal anhydrous low-cost imitation electroplating film and a surface treatment method thereof. The method comprises the following steps that a formed workpieceis subjected to hydrocarbon ultrasonic cleaning, oil removal and wax removal, then UV paint with a high hydroxyl value is sprayed on a workpiece, leveling, drying and curing are carried out, then theworkpiece is placed in a vacuum furnace for plasma glow treatment, then vacuum coating treatment is carried out, the UV paint with a high hydroxyl value is sprayed on the workpiece plated with the film, then the workpiece is enabled to enter the vacuum furnace again to sputter the silicon target, and the oxygen content is gradually increased. And finally, the workpiece plated with the gradient silicon and the silicon dioxide is immersed into a low-surface-energy solution, and the hydrophobic and corrosion-resistant imitation electroplating coating is obtained through drying at a low temperature. The imitation electroplating film can be widely applied to the fields of hardware, household appliances, bathroom accessories, automobile accessories and the like, and has the advantages of no wastewater discharge, low cost, excellent performance and the like.

Owner:厦门大锦工贸有限公司

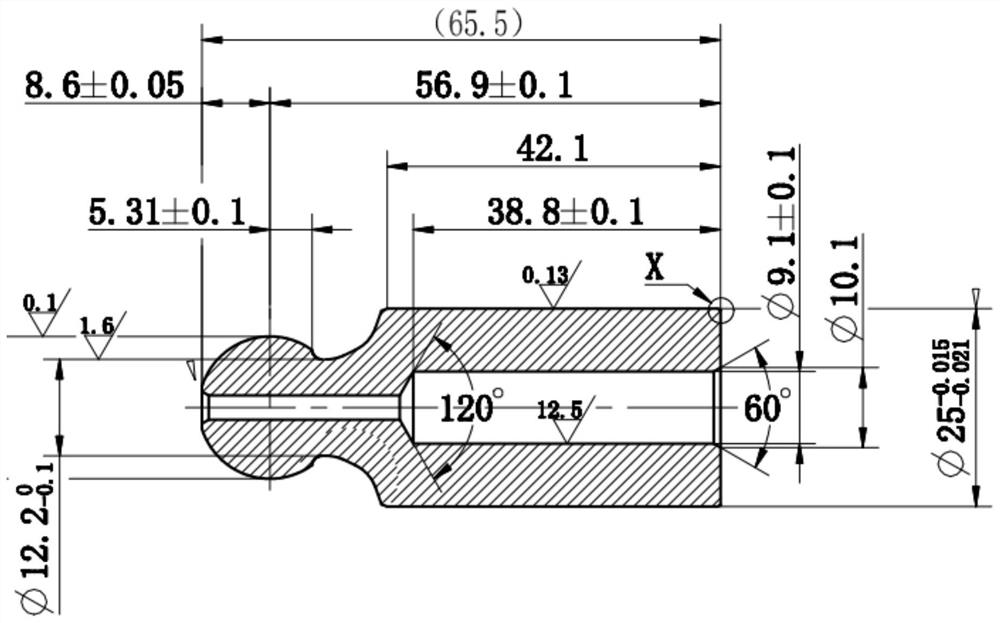

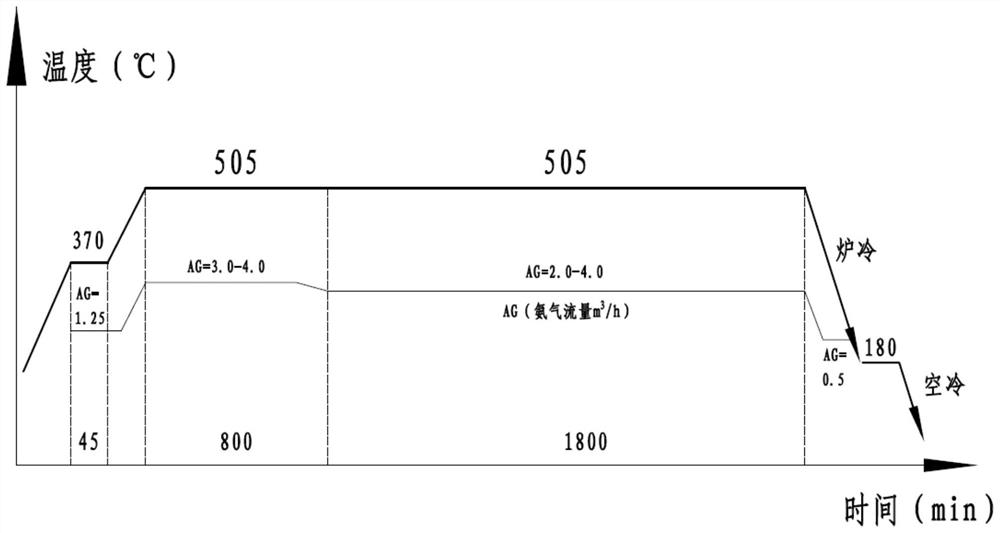

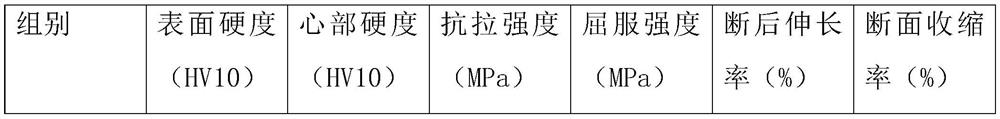

Machining method for plunger of hydraulic plunger pump

The invention discloses a machining method for a plunger of a hydraulic plunger pump. The machining method is used for machining a 31CrMoV9 material and includes the following steps of: S1, turning; S2, nitriding heat treatment, including the following steps of: S201, inspection; S202, cleaning; S203, clamping; S204, pre-oxidation; S205, exhausting; S206, nitrocarburizing; S207, cooling; S208, discharging; and S3, crushing grinding. According to the machining method disclosed by the invention, a 31CrMoV9 material is nitrided to replace the original carburization and quenching treatment of a 20CrMo material; grinding after heating is carried out by a crushing grinding machine instead of the original through-type penetrating grinding machine, so that the surface hardness of a product is high and the product is more wear-resistant; the surface of the outer circle protrudes slightly; the positions, the 4-8 mm positions of the two ends are subjected to edge collapse; a contact surface is smaller and smoother during working; operation is more stable; chucking is avoided; and the machined products are enabled to meet the technical requirements of drawings.

Owner:WUXI YINGBEI PRECISION BEARING

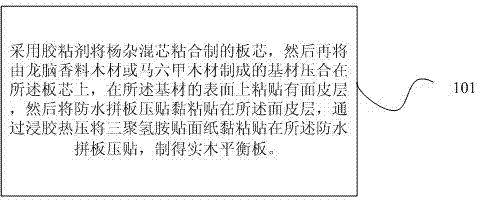

Environment-friendly waterproof solid wood balance plate and preparation method thereof

ActiveCN102922567AReduce pollutionEnvironmentally friendlyLaminationLamination apparatusSolid woodHazardous substance

The invention discloses an environment-friendly waterproof solid wood balance plate and a preparation method thereof. The environment-friendly waterproof solid wood balance plate comprises a base material made of dipterocarpaceae wood or Falcata wood. A board core is arranged in the base material and is a poplar mixed core. A face skin layer is arranged on the surface of the base material, a waterproof jointed board press paster is arranged on the face skin layer, and melamine veneering paper undergoing wear-resisting technology processing is arranged on the waterproof jointed board press paster. The solid wood balance plate is produced by selecting and using the best ring adhesive, the base material and the process, the release amount of harmful substances such as methanol and formaldehyde is zero, cracking, foaming and delamination and the like are avoided, and the environment-friendly waterproof solid wood balance plate has the advantages of being environment-friendly, waterproof, wear-resisting in surface and resistant to cracking and the like and can be applied to the fields of furniture, cupboards and bathrooms and the like.

Owner:GUANGDONG SUNCOO TECH

Ceramic rotor spinning false twisting disc and ceramic processing method for inner surface of false twisting disc

InactiveCN104005125ANo impuritiesDense surfaceAnodisationContinuous wound-up machinesOxide ceramicChemical composition

The invention discloses a ceramic rotor spinning false twisting disc and a ceramic processing method for the inner surface of the false twisting disc and belongs to the field of spinning machinery equipment. The ceramic rotor spinning false twisting disc and the ceramic processing method for the inner surface of the false twisting disc are aimed to solve the problems of non-uniform surface coating distribution, poor quality and short service life of a traditional chrome plated false twisting disc and problems of high production cost and complex technique of a powder sintering ceramic false twisting disc. The inner surface of the ceramic rotor spinning false twisting disc is plated with a layer of ceramic film. The ceramic processing method for the inner surface of the false twisting disc includes that preparing an oxide ceramic layer at the surface of the false twisting disc, wherein the chemical ingredient of the generated ceramic layer is oxide which is same with the chemical ingredient of the false twisting disc produced through a ceramic powder pressing sintering technique; remelting and refining the ceramic layer, wherein the refined surface is uniform and wearable, and the service time of the false twisting disc on equipment is prolonged. The ceramic rotor spinning false twisting disc is suitable for spinning various materials.

Owner:HARBIN INST OF TECH

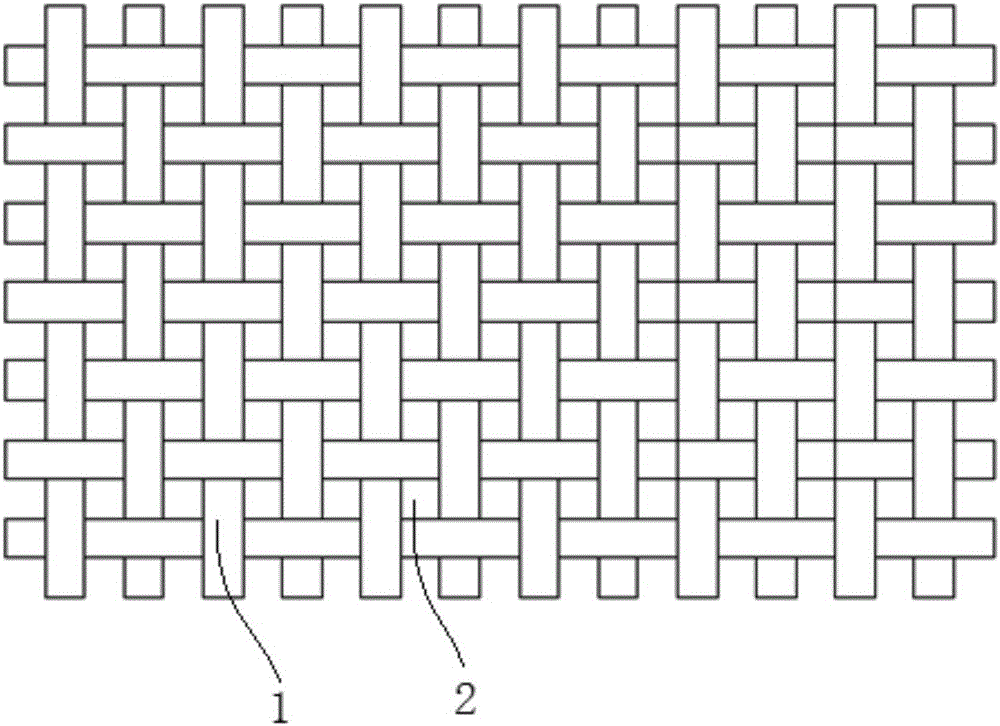

Pine and bamboo particle recombination board and manufacturing method thereof

InactiveCN106042105AIncrease profitImprove surface bonding strengthCane mechanical workingReed/straw treatmentHigh pressureComposite plate

The invention belongs to the technical field of composite plates, and relates to a pine and bamboo particle recombination board and a manufacturing method thereof. The manufacturing method comprises the following steps: weaving bamboo skin strips in a staggering manner to form a bottom mesh grid and a surface mesh grid; placing a pine particle blended sizing material between the bottom mesh grid and the surface mesh grid in a filling manner, performing high-temperature and high-pressure treatment to obtain a pine and bamboo particle recombination board blank, grinding and polishing the bottom and the surface of the pine and bamboo particle recombination board blank, and cutting to obtain the pine and bamboo particle recombination board finished product. According to the pine and bamboo particle recombination board and the manufacturing method thereof, the problem that the conventional multilayer bonded board is easy to degum and open is thoroughly solved, and the surface bonding strength of the board is greatly enhanced.

Owner:江西达森家私有限公司

Denitration system and denitration method for fuel gas of pulverized coal industrial boiler

PendingCN106669393AFlat surfaceWear-resistant surfaceGas treatmentLighting and heating apparatusCombustion chamberFlue gas

The invention discloses a denitration system and a denitration method for fuel gas of a pulverized coal industrial boiler. The denitration system comprises the pulverized coal industrial boiler, a cyclone separation device, a denitration heat accumulator, a desulfurization device and a chimney, wherein a reducing agent nozzle is formed in the side wall of a combustion chamber of the pulverized coal industrial boiler; the reducing agent nozzle is suitable for spraying a reducing agent into the combustion chamber, mixing the reducing agent and the flue gas of the pulverized coal industrial boiler in the combustion chamber and carrying out pre-denitration treatment; the cyclone separation device is connected with a flue gas outlet of the pulverized coal industrial boiler; the denitration heat accumulator is connected with the cyclone separation device; the denitration heat accumulator is suitable for recycling waste heat of the flue gas and carrying out denitration treatment of the flue gas; the desulfurization device is connected with the denitration heat accumulator; the chimney is connected with the desulfurization device. By utilizing the denitration system disclosed by the invention, the denitration treatment can be effectively carried out on the flue gas of the pulverized coal industrial boiler, and the denitration efficiency is remarkable.

Owner:SHENWU TECH GRP CO LTD

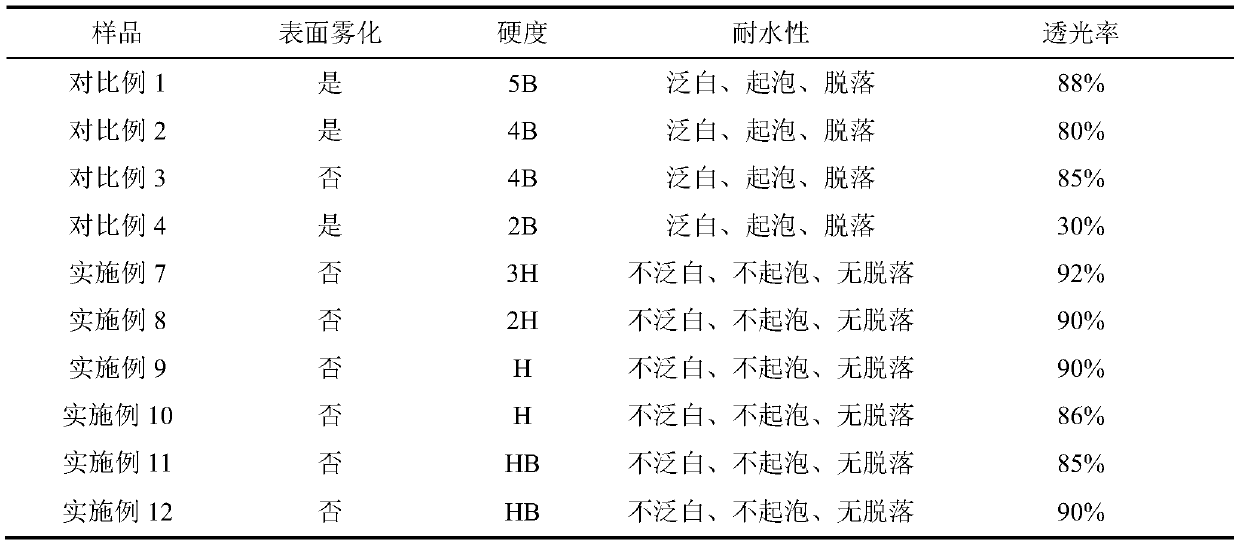

Thermosetting abrasion-resistant polyurethane type anti-fog film and preparation method thereof

The invention provides a thermosetting abrasion-resistant polyurethane type anti-fog film and a preparation method thereof and belongs to the technical field of high polymer materials. The anti-fog film comprises silicon dioxide microspheres with isocyanate terminated macromolecular chains and a multifunctional curing agent, wherein the weight ratio is 100 to (5-50), the silicon dioxide microspheres with the isocyanato-terminated macromolecular chains mainly comprise isocyanate or isocyanate polymer, polyoxyethylene ether and silicon dioxide microspheres, wherein the weight ratio is 100 to (10-80) to (5-50). The anti-fog film has a lasting anti-fog effect, high surface hardness, abrasion resistance, scratch resistance, excellent water resistance, adjustable performance and structure, low cost and mature technology and is suitable for production.

Owner:JIANGNAN UNIV

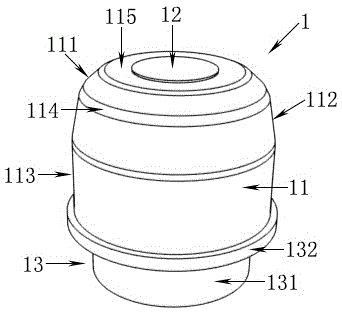

Vertical stop catch with wear plate and method for preventing fracture of steel spring

The invention discloses a vertical stop catch with a wear plate and a method for preventing fracture of a steel spring. The wear plate is embedded to the top of a rubber body, and the rigidity of the vertical stop catch can be adjusted by adjusting the diameter or height of the wear plate; a base is embedded into the rubber body and is used for limiting the rubber body of the vertical stop catch, and the rigidity of the vertical stop catch can be adjusted by adjusting the height of the base; the upper end of the rubber body is configured to have two or more annular flat-straight sections, and the variable rigidity of the vertical stop catch can be adjusted by adjusting an included angle between the annular flat-straight sections and a horizontal plane; and by adjusting the rigidity, the variable rigidity and a limiting position of the vertical stop catch, the vertical load born by the steel spring can be reduced, and metal fatigues generated by the steel spring during running of a locomotive can be reduced, thereby preventing the fracture of the steel spring. The vertical stop catch also has the characteristics that the structure is firm and cannot be damaged easily, the wear plate, the rubber body and the base are combined compactly and cannot be loosened and divorced easily, and the vertical stop catch is wide in application range and strong in universality.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

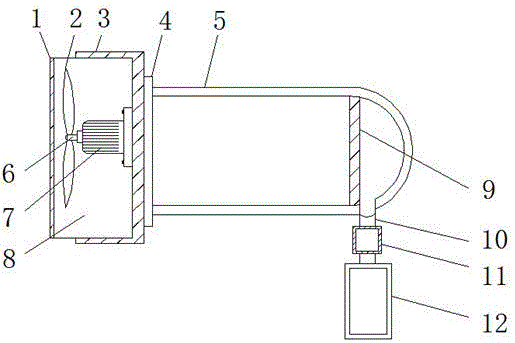

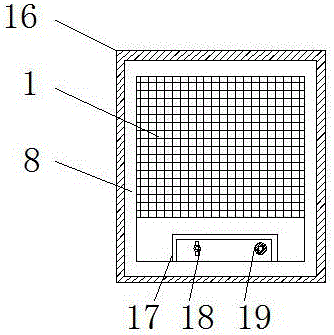

Filtering bag device for air purifier

InactiveCN106492559ASolve corrosionWear-resistant surfaceDispersed particle filtrationImpellerEngineering

The invention discloses a filtering bag device for an air purifier. The filtering bag device comprises a device body, fixing faceplates are connected around the device body in a clamped manner, a control panel is arranged in the middle of the bottom end of the device body, the middle on the right side of the device body is fixedly connected with a motor through bolts, the motor is in sleeving connection with a rotating shaft through a connecting bearing, an impeller is connected on the left side of the rotating shaft in a clamped manner, an air outgoing groove is formed in the right side of the device body, the right side of the air outgoing groove is in threaded connection with a sealing ring, the right side of the sealing ring is in sleeving connection with a filtering bag, an inner layer of the filtering bag is provided with a primary filtering layer while an outer layer of the same is provided with a secondary filtering layer, and an iron wire net is woven between the primary filtering layer and the secondary filtering layer. The motor and the impeller are arranged inside the device body to play a role in gas exchange, and by arranging the primary filtering layer and the secondary layer in the filtering bag, dust particles in air can be filtered effectively.

Owner:JIANGSU FUSHENG ENVIRONMENTAL PROTECTION GROUP

Wearable alloy block

InactiveCN102886931AMaintain heat resistanceStay strongMolten spray coatingMetal layered productsHeat resistanceToughness

The invention provides a wearable alloy block, and belongs to the technical field of compound. The alloy comprises a base body, a nickel-cadmium alloy layer and a cobalt-based alloy layer, wherein the nickel-cadmium alloy layer is coated on the surface of the base body; and the cobalt-based alloy layer is coated on the surface of the nickel-cadmium alloy layer. The wearable alloy block provided by the invention has the advantages that the heat resistance and toughness of an iron base body are remained, and the surface wearable characteristic is achieved, therefore, the service life of iron parts is greatly prolonged; and meanwhile, the wearable alloy layer is thin, so the alloy materials which are high in cost can be saved.

Owner:SHENYANG CHUANGDA TECH TRADE MARKET

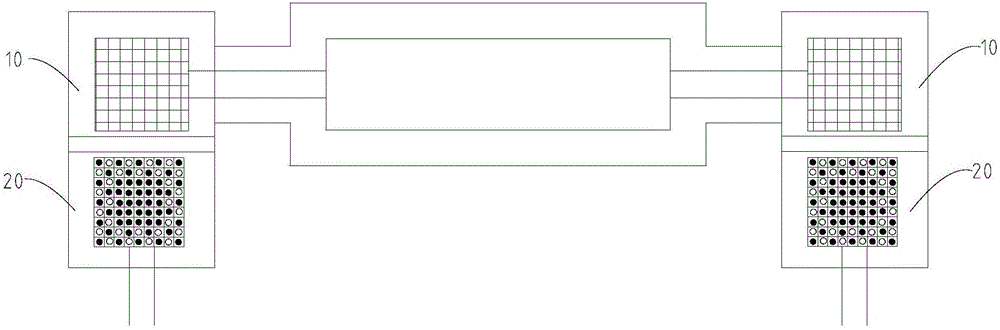

Flue gas heat accumulation and denitrification device and denitrification method for industrial furnace

PendingCN106731555AExtended service lifeReduce usageGas treatmentChemical industryCombustion systemFlue gas

The invention discloses a flue gas heat accumulation and denitrification device and a denitrification method for an industrial furnace. The flue gas heat accumulation and denitrification device comprises a first heat accumulation portion and a second heat accumulation portion, wherein a high-temperature heat accumulator is arranged in the heat accumulation portion, and a first opening is formed in the upper portion of the heat accumulation portion; and the second heat accumulation portion is successively divided into an ammonia spraying region and a denitrification and heat accumulation region from bottom to top, a reducer nozzle is arranged in the ammonia spraying region, a denitrification and heat accumulator is arranged in the denitrification and heat accumulation region, a second opening is formed in the upper portion of the second heat accumulation portion, and the bottom end of the second heat accumulation region is communicated with the bottom end of the first heat accumulation portion. The flue gas heat accumulation and denitrification device for the industrial furnace integrates a heat accumulating combustion system and the flue gas denitrification system, so that the denitrification treatment on the flue gas is realized while flue gas waste heat is recovered. The flue gas heat accumulation and denitrification device has double functions of heat accumulation and denitrification.

Owner:SHENWU TECH GRP CO LTD

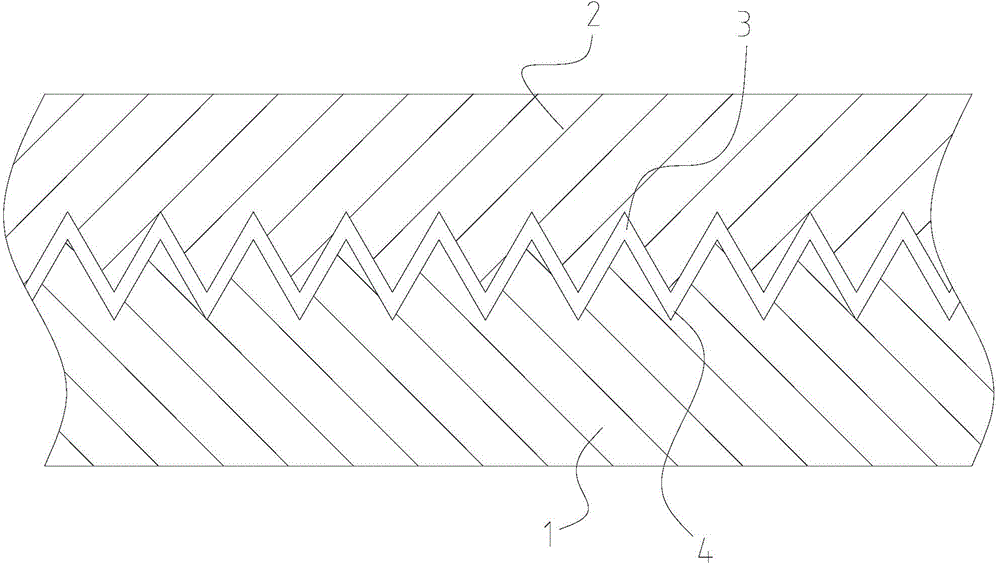

Fireproof antibacterial special functional flexible board and preparation method thereof

PendingCN113249049AWear-resistant surfaceFireproofFilm/foil adhesivesDoor leavesAnti bacteriaMechanical engineering

The invention discloses a fireproof antibacterial special functional flexible board and a preparation method thereof. The fireproof antibacterial special functional flexible board comprises release paper, an adhesive layer, a balance layer, a core layer, a decorative layer and a wear-resistant layer which are sequentially bonded from bottom to top. The preparation method comprises the steps that the core layer is prepared, the balance layer, the core layer, the decorative layer and the wear-resistant layer are sequentially stacked, an obtained blank is put into a press to be pressed and formed, and a semi-finished product obtained in the press is coated with the release paper after the adhesive layer coats one side of the balance layer. Compared with the prior art, the fireproof antibacterial special functional flexible board provided by the invention has the advantages that the combustion grade of the board can reach grade A, the surface of the board is more wear-resistant, the mildew-proof and antibacterial properties of the board are outstanding, formaldehyde is not contained, construction is easy, flexible bending can be realized, a minimum angle is R1.5, and the fireproof antibacterial special functional flexible board can be used for decoration of various cambered surfaces.

Owner:中复(常州)新材料有限公司

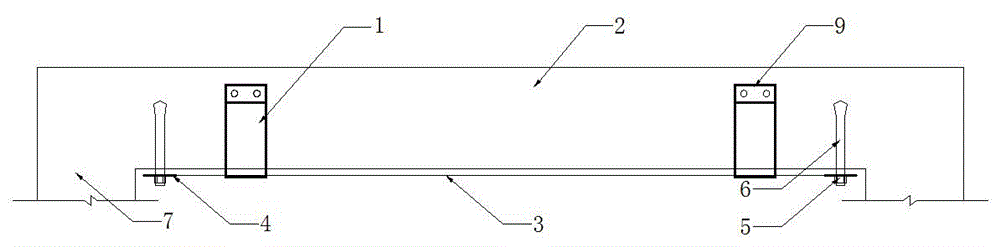

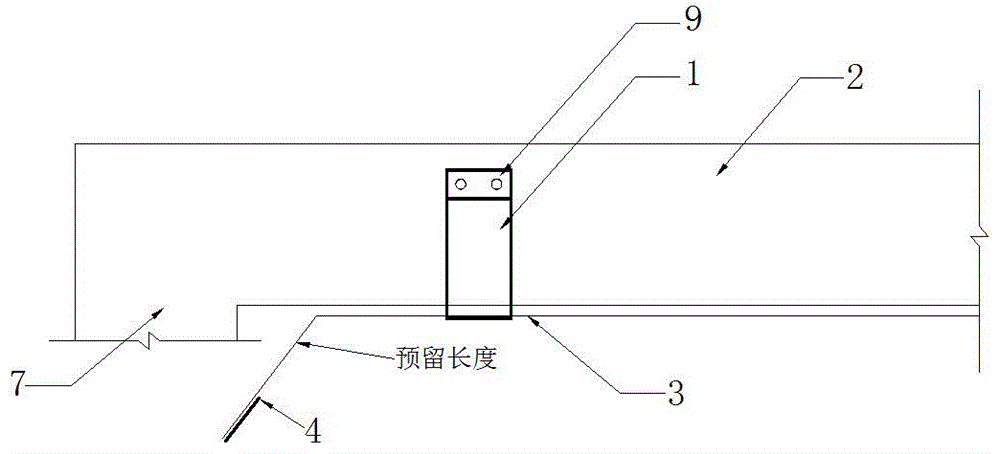

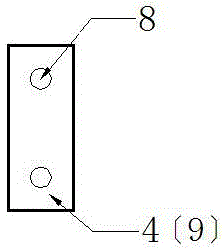

Reinforced Concrete Beam Strengthened by Carbon Fiber Sheet and Its Strengthening Method

ActiveCN103603509BImprove flexural strengthImprove seismic performanceBuilding repairsFiberSheet steel

The invention discloses a reinforced concrete beam reinforced with carbon fiber cloth and a strengthening method, comprising a reinforced concrete beam, the bottom tension surface of the reinforced concrete beam is provided with a carbon fiber cloth evenly pasted as a whole, and the two ends of the carbon fiber cloth are It is connected with the steel plate, and the steel plate is provided with a steel plate connection hole, and the steel plate is connected with both ends of the reinforced concrete beam through the steel plate connection hole, nuts and chemical bolts. The structure and construction are simple, and the end is fixed reliably, which effectively improves the tensile strength of the concrete beam, improves the flexural bearing capacity of the concrete beam, improves the seismic performance of the building structure and the repair effect and efficiency of the damaged structure after the earthquake, and guarantees The safety of people's lives and property.

Owner:SHANDONG SHUANGDELI CONSTR TECH

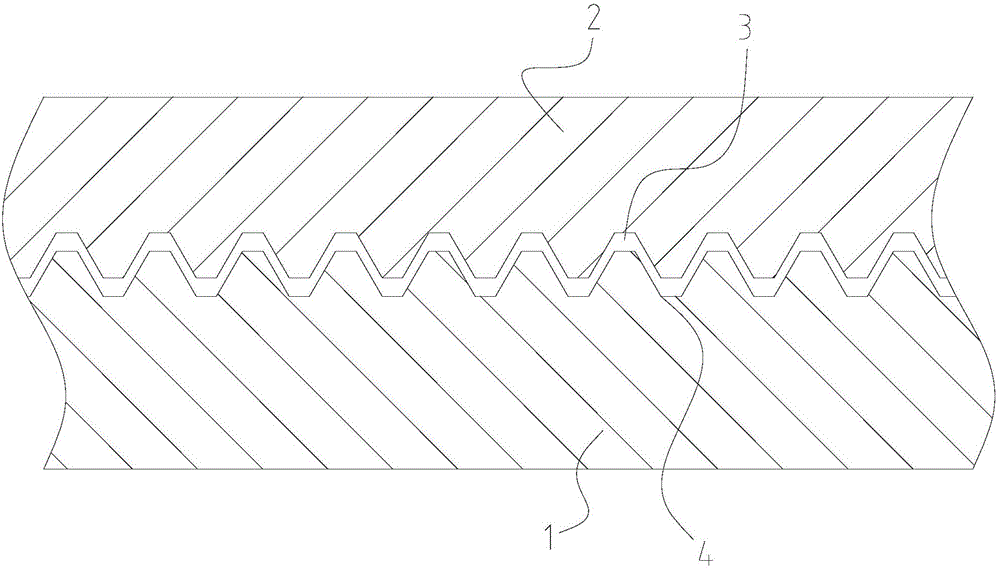

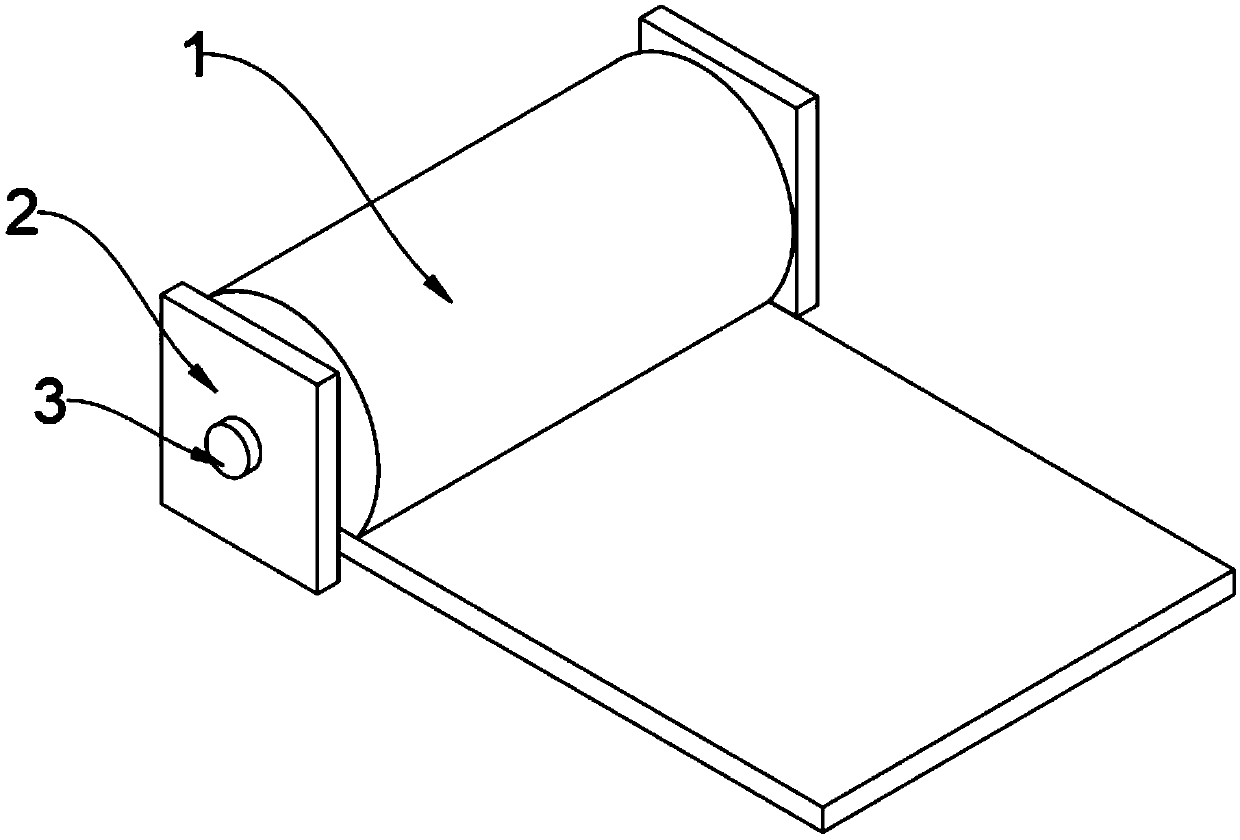

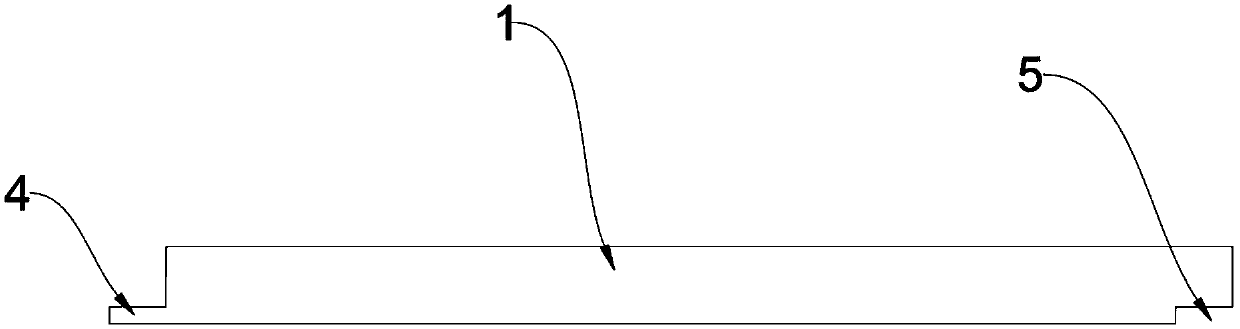

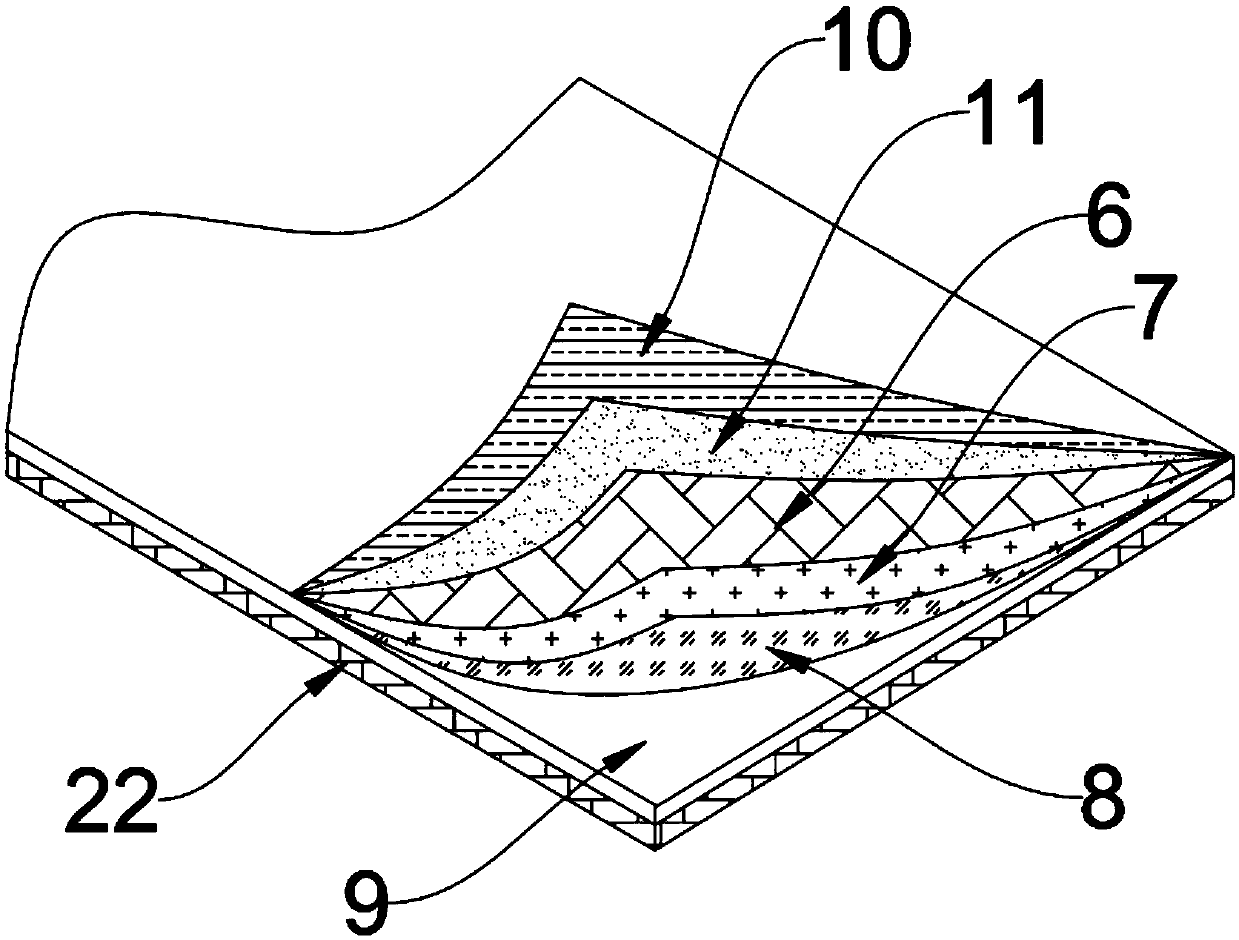

Modified asphalt waterproof roll for tunnel engineering

ActiveCN109677023AEasy to let goEasy to plug inUnderground chambersConstructions elementsBituminous waterproofingArchitectural engineering

The invention discloses a modified asphalt waterproof roll for tunnel engineering. The modified asphalt waterproof roll comprises a special roll, wherein a roller shaft is mounted inside the special roll; square supporting plates are mounted at the two ends of the roller shaft; a roll side bulge is arranged on the bottom surface of one side of the special roll; a roll side groove is formed in thebottom surface of the other side of the special roll; the special roll comprises a lining base layer, an anticorrosive layer, a buffer layer, a second isolating membrane, a surface waterproof layer, afireproof layer and a waterproof thick adhesive layer; the second isolating membrane is mounted above the waterproof thick adhesive layer; the buffer layer is mounted on the upper end surface of thesecond isolating membrane; the anticorrosive layer is mounted on the upper end surface of the buffer layer; the lining base layer is mounted on the upper end surface of the anticorrosive layer; the fireproof layer is mounted on the upper end surface of the lining base layer; the surface waterproof layer is mounted on the outer surface of the fireproof layer. The modified asphalt waterproof roll isstrong in waterproofness, has fireproof, cold-resistant and buffering performance and the like and is high in safety.

Owner:中油佳汇(广东)防水股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com