Medium density fiberboard with decorative surface covered by impregnated film adhesive paper and preparation method thereof

A technology of impregnated film paper and medium density, which is applied in the direction of manufacturing tools, wood layered products, and the joining of wooden veneers. surface cost, the effect of not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

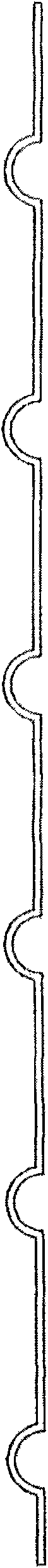

[0035] Preparation of medium-density fiberboard covered with impregnated film paper for "V"-shaped facing:

[0036] Medium density fiberboard is 3mm thick and 80mm wide (manufactured by Daya Wood Industry). The impregnated film paper used for facing includes: the surface film paper of the film paper used for facing, the decorative film paper and the bottom film paper (They are all produced in Shenyang Fulong Decoration Material Factory). The mold is a "V"-shaped upper and lower matching mold with concave and convex opposite, and the softened medium density fiberboard is placed in the middle. Second;

[0037] Pressure 8mPa / cm 2 Press the medium-density fiberboard plain board at a mold temperature of 120°C for 30 seconds. After the plain board is shaped, it will become a base fiber board and then cover with impregnated film paper for the finish. Place the surface layer of film paper and the decorative layer of film paper on the top of the base fiber board. Put the bottom layer...

Embodiment 2

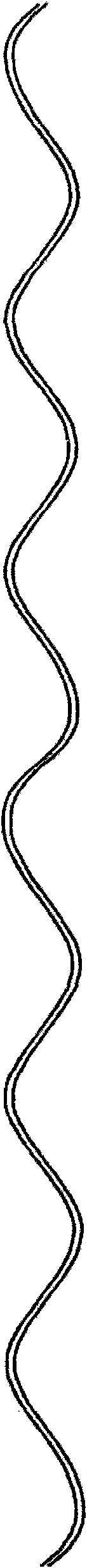

[0039] Preparation of medium density fiberboard covered with impregnated film paper for semi-circular facing:

[0040]The thickness of medium density fiberboard is 4.75mm (produced by Daya Wood Industry), and the impregnated film paper used for facing includes: the surface film paper of the film paper used for decoration, the decorative film paper and the bottom film paper (they All produced in Shenyang Fulong Decoration Material Factory), the mold is a concave-convex "semi-arc" upper and lower matching mold, and the softened medium density fiberboard is placed in the middle, and the softening method of the medium density fiberboard is steaming for 5 minutes;

[0041] Pressure 9mPa / cm 2 Press the medium-density fiberboard plain board at a mold temperature of 130°C for 5 minutes. After the plain board is shaped, it will become a base fiber board and then be covered with impregnated film paper. Place the bottom layer of adhesive film on the surface, and the covering pressure is...

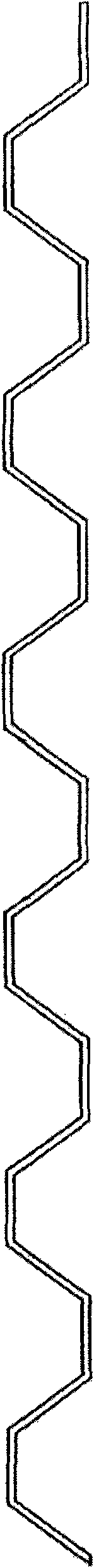

Embodiment 3

[0043] Preparation of medium-density fiberboard covered with impregnated film paper for embossed decorative finish with a molding depth of 50% of the plate thickness:

[0044] The thickness of the medium density fiberboard is 6mm (manufactured by Daya Wood Industry). Produced in Shenyang Fulong Decoration Material Factory), the mold is a counter-pressure mold with a single-sided punch and a flat mold, and a softened medium density fiberboard is placed in the middle. The deepest point of the punch is 3mm. The softening method of the medium density fiberboard Steam for 6 minutes;

[0045] Pressure 10mPa / cm 2 Press the medium density fiberboard plain board at a mold temperature of 170 °C for 50 seconds. After the plain board is shaped, it will become a base fiber board and then cover with impregnated film paper for the finish. Place the surface layer of film paper and the decorative layer of film paper on the top of the base fiber board. Put the bottom layer of adhesive film on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com