Thermosetting abrasion-resistant polyurethane type anti-fog film and preparation method thereof

A polyurethane-based and thermosetting technology, applied in the field of thermosetting wear-resistant polyurethane anti-fog films and their preparation, can solve the problems of fogging, short anti-fog persistence, poor water resistance and adhesion, etc. Excellent anti-fog effect and long-lasting anti-fog effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

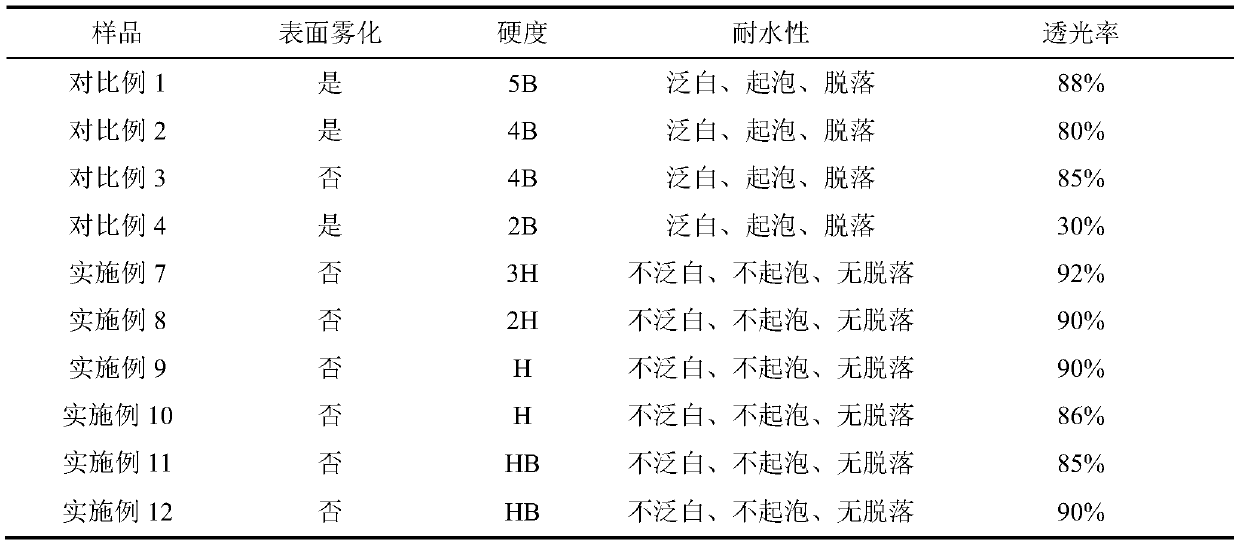

Examples

Embodiment 1

[0028] Put 100 parts of isophorone diisocyanate in a flask, add an appropriate amount of acetone to dissolve, put 10 parts of dehydrated polyoxyethylene ether (molecular weight is about 200g / mol) in a constant pressure dropping funnel, pass nitrogen to remove oxygen, Under the action of the initiator dibutyltin dilaurate, raise the temperature to 50°C and stir mechanically, and react for 1h; then add 50 parts of 50nm silica microsphere dispersion, stir and react at 60°C for 2h, stop the heating reaction, and obtain Modified silica microspheres 1 .

Embodiment 2

[0030] Put 100 parts of hexamethylene diisocyanate in a flask, add an appropriate amount of acetone to dissolve, put 20 parts of dehydrated polyoxyethylene ether (molecular weight is about 600g / mol) in a constant pressure dropping funnel, pass nitrogen to remove oxygen, Under the action of the initiator dibutyltin dilaurate, raise the temperature to 50°C and stir mechanically, and react for 1 hour; then add 40 parts of 50nm silica microsphere dispersion liquid, stir and react at 60°C for 2 hours, stop the heating reaction, and obtain Modified silica microspheres 2 .

Embodiment 3

[0032] Put 100 parts of toluene diisocyanate in a flask, add an appropriate amount of acetone to dissolve, put 40 parts of polyoxyethylene ether (molecular weight is about 1000g / mol) dehydrated in a constant pressure dropping funnel, pass nitrogen to remove oxygen, in the initiator Under the action of dibutyltin dilaurate, heat up to 50°C and stir mechanically, and react for 1h; then add 30 parts of 100nm silica microsphere dispersion, stir and react at 60°C for 2h, stop the heating reaction, and obtain Modified silica microspheres 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com