High-strength steel-based copper alloy sliding plate

A copper alloy plate, copper alloy technology, applied in the direction of metal layered products, layered products, chemical instruments and methods, etc., can solve the problems of high use cost, complex sliding plate structure, poor bonding strength, etc., to achieve low manufacturing cost, The effect of surface wear resistance and large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

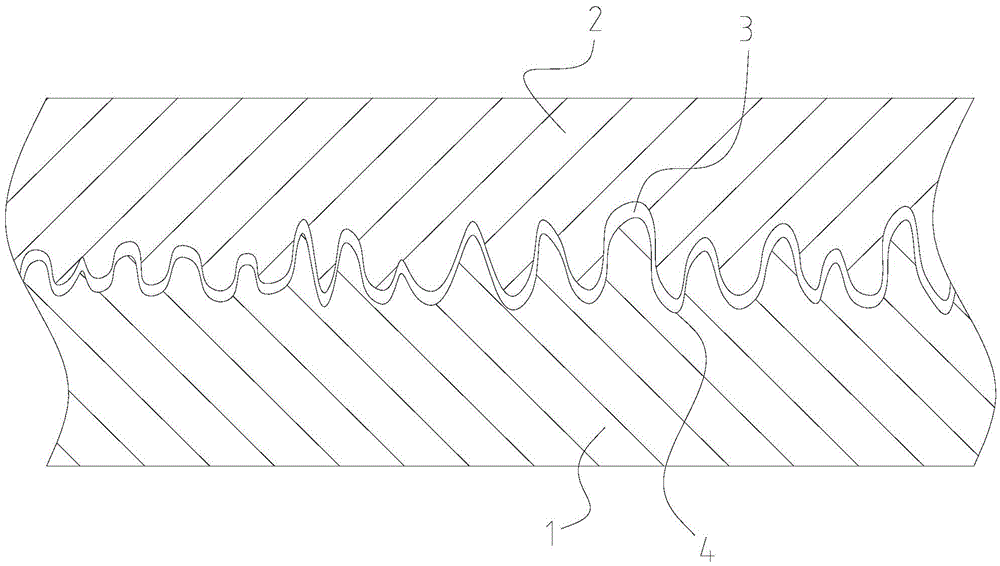

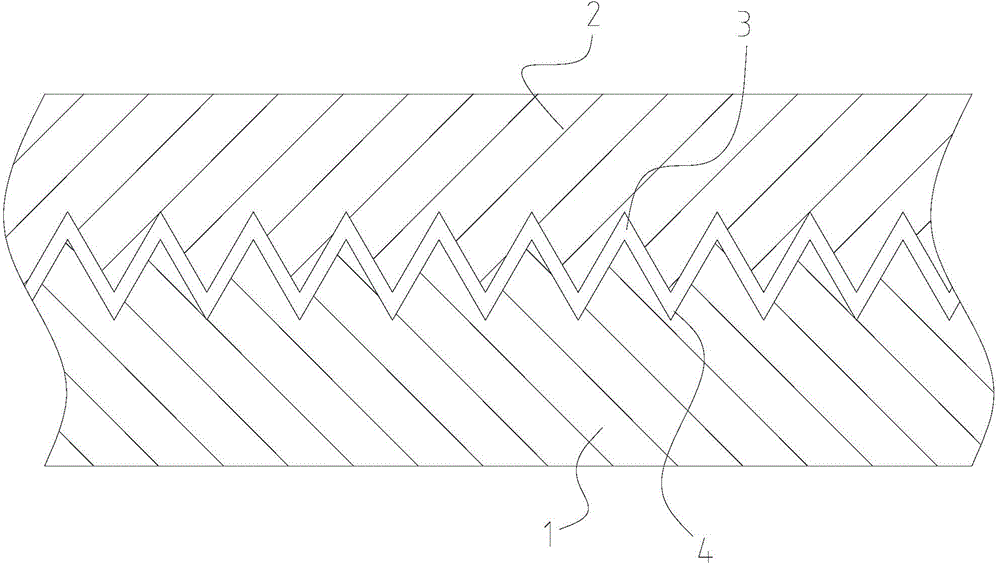

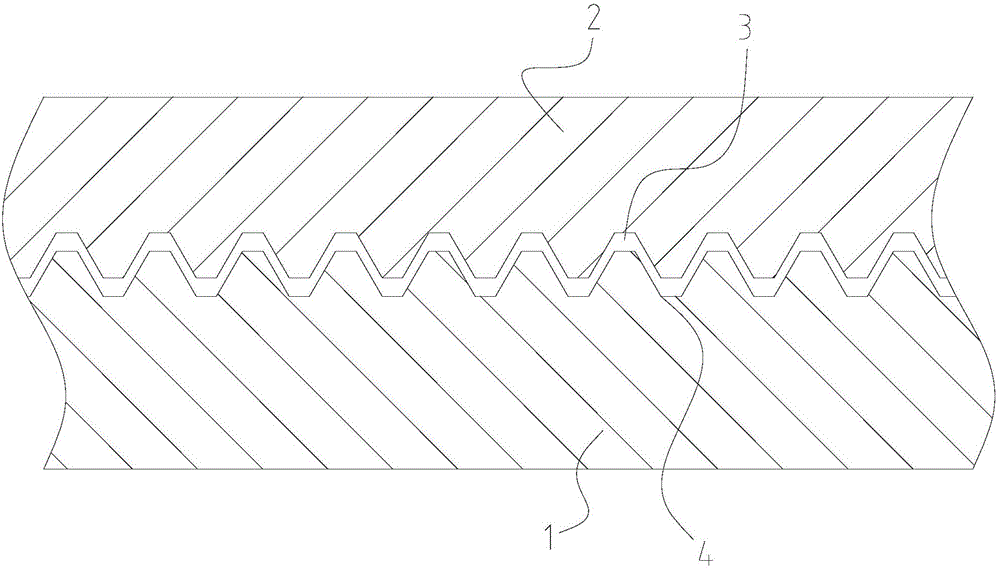

[0019] The manufacturing process of the high-strength steel-based copper alloy skateboard of the present invention is: processing the surface of the steel plate 1 into irregular shallow grooves, or processing into shallow grooves with regular grids, or regular processing in one direction Shallow grooves, and clean the surface to remove the oil; then coat a layer of alloy film layer 3 on the surface of the steel plate 1, and at the same time spray the liquid copper alloy on the alloy film layer 3 at high speed under high temperature infiltration; , At the boundary of the alloy film layer 3: the steel plate 1 and the alloy film layer 3, the copper alloy plate 2 and the alloy film layer 3, their atoms are fully exchanged with each other, and iron atoms pass through the film to exchange with copper atoms, or copper atoms pass through the film Exchange with iron atoms and fully exchange atoms at the boundary to form a very strong metallurgical bonding force. The measured bonding stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com