Anhydrous low-cost imitation electroplating film and surface treatment method thereof

A surface treatment, low-cost technology, applied in the field of anhydrous and low-cost imitation electroplating film and its surface treatment, can solve the problems of easily corroded metal layer, affect the appearance and use function, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

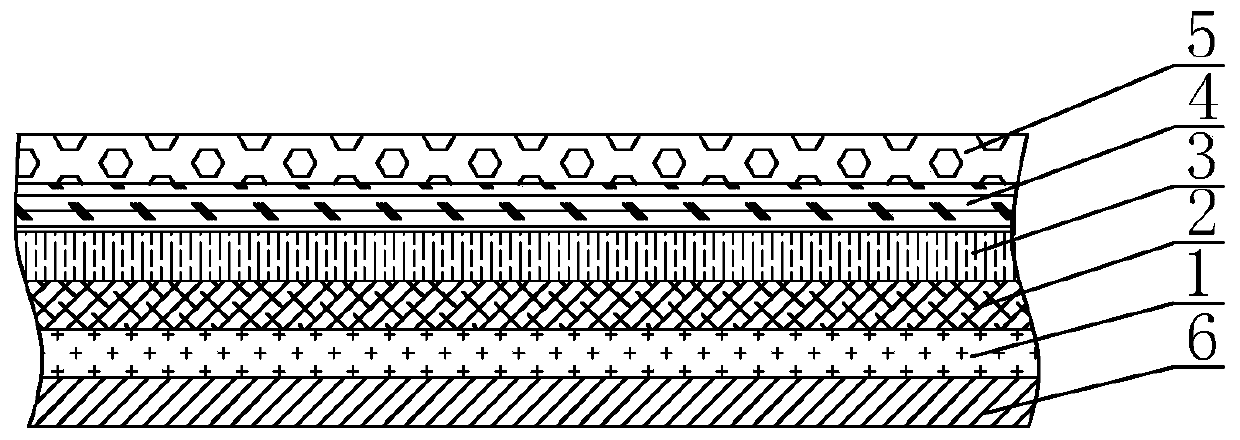

[0054] Specific embodiment one ABS plastic substrate surface anhydrous low-cost anti-corrosion imitation electroplating surface treatment

[0055] Step 1), cleaning: the direct molding or in-film drawing ABS workpiece is subjected to hydrocarbon ultrasonic cleaning to remove oil and wax;

[0056] Step 2), UV bottom layer: Spray the coated workpiece with acrylic polyurethane UV paint with a hydroxyl value of 4.8, level it for 1.5 minutes, dry it at 50°C for 4 minutes, and spray it at 1100mJ / cm 2 Under curing 30s. ;

[0057] Step 3), alloy coating layer: place the cleaned workpiece in a vacuum furnace for plasma glow treatment, the plasma glow treatment process conditions are ion source current 0.5A, bias voltage 60V, duty cycle 60%, Argon gas flow rate 80SCCM, time 8min. Then carry out the vacuum coating treatment, the above-mentioned coating treatment process conditions are high-power DC power supply, the target material is silicon chromium target, current 100A, voltage 700...

Embodiment 2

[0063] Example 2 Anhydrous and low-cost corrosion-resistant imitation electroplating surface treatment on the surface of zinc alloy substrate

[0064] Step 1), Cleaning: Carry out ultrasonic cleaning of carbon and hydrogen to remove oil and wax on the direct forming or in-film wire drawing zinc alloy workpiece;

[0065] Step 2), UV bottom layer: Spray the coated workpiece with acrylic polyurethane UV paint with a hydroxyl value of 5.5, level it for 2 minutes, dry it at 50°C for 5 minutes, and spray it at 1100mJ / cm 2 Under curing 30s. ;

[0066] Step 3), alloy coating layer: place the cleaned zinc alloy workpiece in a vacuum furnace for plasma glow treatment, the plasma glow treatment process conditions are ion source current 0.4A, bias voltage 40V, duty cycle 70 %, argon flow rate 80SCCM, time 7min. Then carry out vacuum coating treatment, and the above coating treatment process conditions are high-power DC power supply, current 120A, voltage 600V, bias voltage 50V, duty cy...

Embodiment 3

[0072] Embodiment 3 PET plastic substrate surface anhydrous low-cost corrosion-resistant imitation electroplating surface treatment

[0073] Step 1), Cleaning: Carry out ultrasonic cleaning of the direct molding or in-film drawing PET workpiece to remove oil and wax;

[0074] Step 2), UV bottom layer: Spray the coated workpiece with acrylic polyurethane UV paint with a hydroxyl value of 4.5, level it for 1.5 minutes, dry it at 50°C for 4 minutes, and spray it at 1100mJ / cm 2 Under curing 30s. ;

[0075] Step 3), plating alloy paint film layer: place the cleaned PET workpiece in a vacuum furnace for plasma glow treatment, the plasma glow treatment process conditions are ion source current 0.4A, bias voltage 90V, duty cycle 70% , argon flow rate 80SCCM, time 8min. Then carry out the vacuum coating treatment, the above-mentioned coating treatment process conditions are high-power DC power supply, the target material is silicon chromium target, current 100A, voltage 700V, bias v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com