Buckling deformation resisting impregnated film paper veneered plywood and production process thereof

A technology of impregnating adhesive film paper and production process, which is applied in the direction of paper/cardboard layered products, wood veneer bonding, layered products, etc. The effect of wear-resistant surface, stable structure and strong screw force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

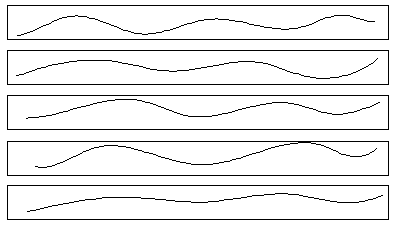

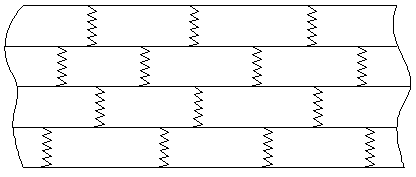

[0046] like Figure 1 to Figure 4 As shown in the figure, a warpage-resistant impregnated adhesive film paper facing plywood of the present invention comprises a core 1, a middle plate 2, a surface plate 3 and an impregnated adhesive film paper 4, a middle plate 2, a surface plate 3 and an impregnated adhesive film The paper 4 is adhered symmetrically to the upper and lower sides of the core 1 in turn, that is, on the upper and lower sides of the core, the middle plate 2 is glued to the core 1, the surface plate 3 is glued to the middle plate 2, and the impregnated film paper 4 is glued. It is attached to the surface plate 3, the thickness of the veneer of the core 1 and the middle plate 2 is 2.0-3.6mm, the thickness of the surface plate 3 is 0.4-0.6mm, the moisture content of the core 1 is less than 12%, the middle plate 2 and the surface plate The mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com