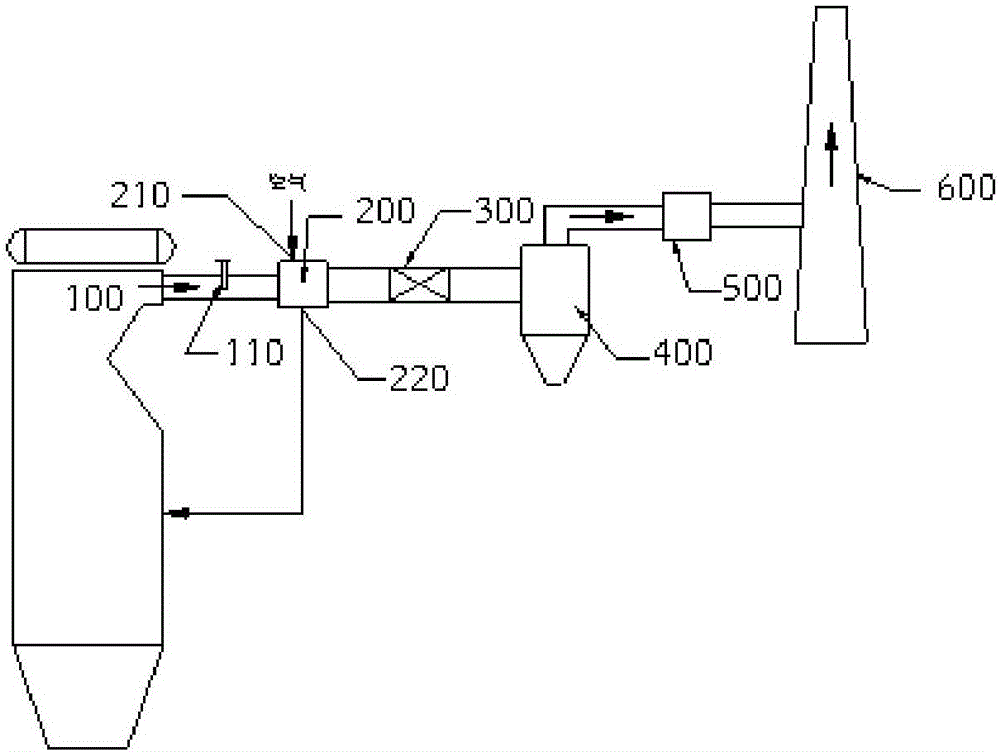

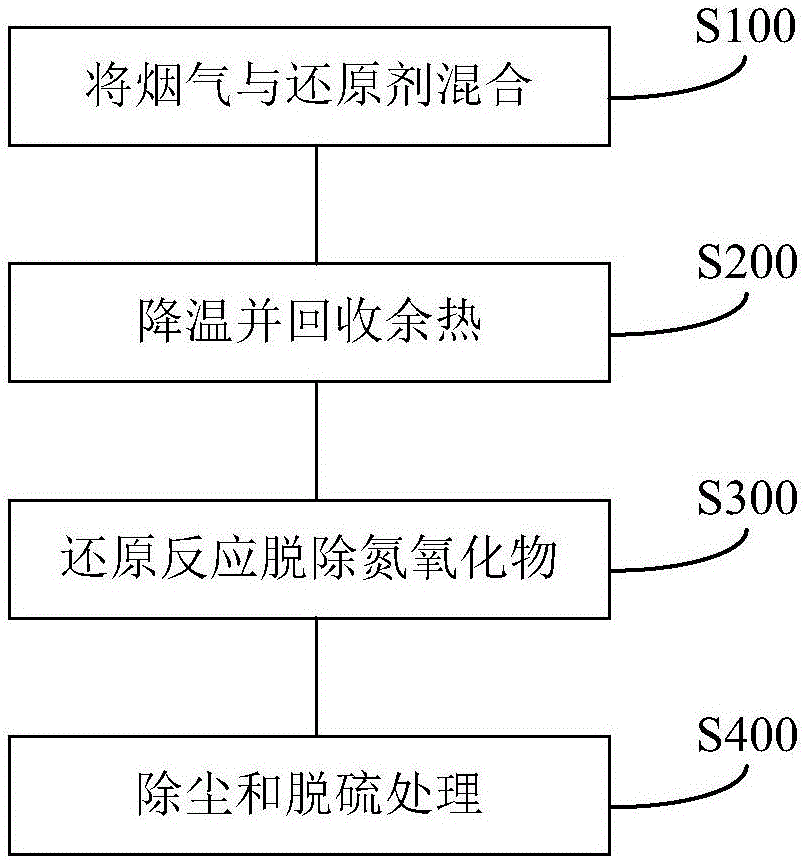

Flue gas denitrification system and denitrification method for particle material industrial boiler

A technology for industrial boilers and granular materials, which is applied in the field of flue gas denitrification and can solve the problems that other methods are in the experimental research stage or pilot test stage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0096] According to a specific embodiment of the present invention, the preparation method of the denitration heat storage body specifically includes:

[0097] (1) Refining of heat storage body embryo body

[0098] Mix an appropriate amount of inorganic powder, ceramic powder, binder, plasticizing moisturizing agent, and lubricant, and add an appropriate amount of deionized water for kneading and refining to obtain mud material for use.

[0099] The mud block is aged, the temperature of the aging environment is 15-25°C, and the aging time is 24h-48h. After vacuum refining and vacuum extrusion, it is made into a honeycomb body blank of the required specification.

[0100] Then, the honeycomb body blank is sent to a dryer for shaping, drying, and firing at a temperature of 1200°C to 1400°C to obtain a finished product.

[0101] (2)TiO 2 -Al 2 o 3 Preparation of composite oxides

[0102] Take a certain amount of titanyl sulfate and aluminum chloride, dissolve them in an appr...

Embodiment

[0120] Anthracite crushed to less than 6mm is sprayed into the furnace of the boiler through the nozzle, mixed with the air sent into the furnace by the blower, and then burned. The temperature in the furnace can reach 1250°C. The high-temperature flue gas produced by combustion passes through the convection tube bundle installed at the flue gas outlet of the furnace to heat and demineralize the water. The flue gas lowered to 950°C enters the flue connected to the heat storage denitrification system, and the atomized reducing agent nozzle installed in it sprays ammonia water droplets, and the flue gas mixes with it quickly and uniformly before entering the heat storage system. , the temperature drops to 450°C and enters the regenerative denitrification system. Under the action of the denitrification heat storage body, while recovering the waste heat of the flue gas, the nitrogen oxides in the flue gas undergo a reduction reaction with ammonia water, and the nitrogen oxides are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com