Machining method for plunger of hydraulic plunger pump

A technology of a hydraulic plunger pump and a processing method, which is applied in the field of plunger processing, can solve problems such as short life, non-wear resistance, and sticking, and achieve the effects of prolonged service life, less contact surface, and no sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

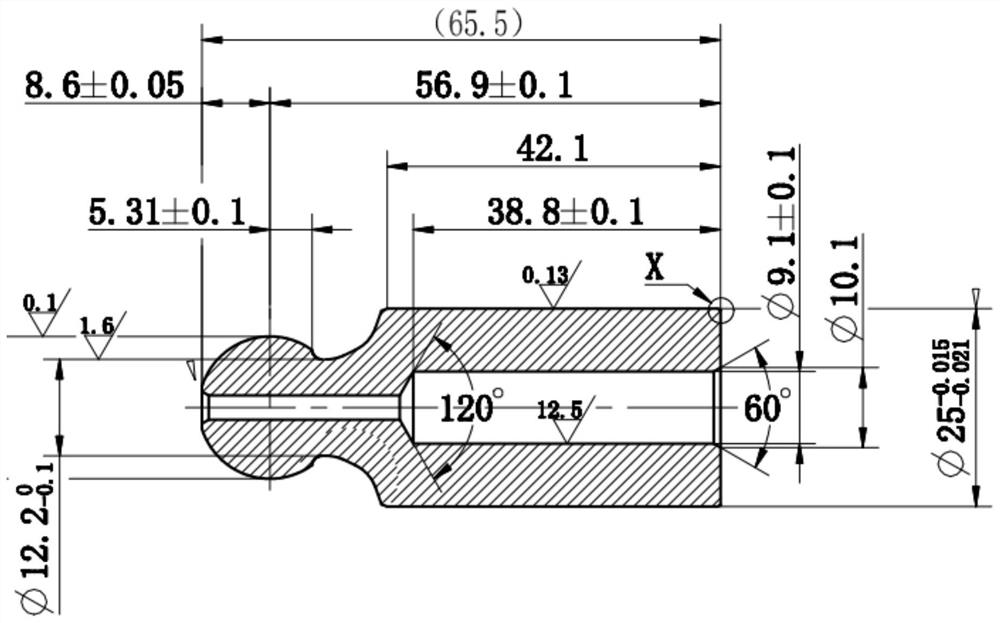

[0046] The processing method of the plunger of embodiment 1 hydraulic plunger pump

[0047] Raw material: 31CrMoV9 material is prepared from the following raw materials by weight percentage: C 0.27%, Si 0.2%, Mn0.4%, P 0.02%, S 0.02%, Cr 2.3%, Mo 0.15%, V 0.1%, the balance is iron.

[0048] S1. Car processing;

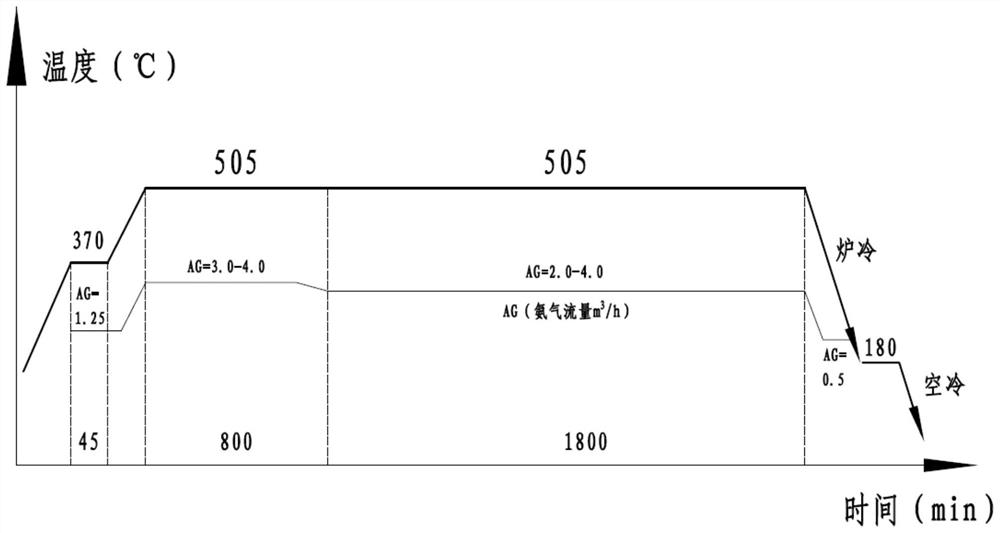

[0049] S2. Nitriding heat treatment, the instrument used is a heat treatment nitriding furnace;

[0050] include:

[0051] S201. Incoming material inspection, confirming that the model and quantity of the parts are consistent with the delivery note or circulation card, and there is no appearance defect;

[0052] S202. Cleaning, soak the parts in water-based cleaning agent for 2 minutes, and shake up and down, then soak in hydrocarbon cleaning agent for 2-3 minutes, and shake up and down, do not bump the parts, and finally dry them with compressed air;

[0053] The water-based cleaning agent is made by mixing the following raw materials in parts by weight: 10 parts ...

Embodiment 2

[0063] The processing method of the plunger of embodiment 2 hydraulic plunger pump

[0064] Raw material: 31CrMoV9 material is prepared from the following raw materials by weight percentage: C 0.34%, Si 0.1%, Mn0.7%, P 0.022%, S 0.035%, Cr 2.7%, Mo 0.25%, V 0.2%, the balance is iron.

[0065] S1. Car processing;

[0066] S2. Nitriding heat treatment, the instrument used is a heat treatment nitriding furnace;

[0067] include:

[0068] S201. Incoming material inspection, confirming that the model and quantity of the parts are consistent with the delivery note or circulation card, and there is no appearance defect;

[0069] S202. Cleaning, soak the parts in water-based cleaning agent for 2-3 minutes, and shake up and down, then soak in hydrocarbon cleaning agent for 2-3 minutes, and shake up and down, do not bump the parts, and finally dry them with compressed air;

[0070] The water-based cleaning agent is made by mixing the following raw materials by weight: 20 parts of so...

Embodiment 3

[0080] The processing method of the plunger of embodiment 3 hydraulic plunger pump

[0081] Raw material: 31CrMoV9 material is prepared from the following raw materials by weight percentage: C 0.3%, Si 0.3%, Mn0.6%, P 0.024%, S 0.03%, Cr 2.5%, Mo 0.2%, V 0.15%, the balance is iron.

[0082] S1. Car processing;

[0083] S2. Nitriding heat treatment, the instrument used is a heat treatment nitriding furnace;

[0084] include:

[0085] S201. Incoming material inspection, confirming that the model and quantity of the parts are consistent with the delivery note or circulation card, and there is no appearance defect;

[0086] S202. Cleaning, soak the parts in water-based cleaning agent for 2.5 minutes, and shake up and down, then soak in hydrocarbon cleaning agent for 2.5 minutes, and shake up and down, do not bump the parts, and finally dry them with compressed air;

[0087] The water-based cleaning agent is made by mixing the following raw materials in parts by weight: 15 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com