Check ring special die for wheel type engineering machinery cartwheel

A technology for construction machinery and wheels, which is applied in the field of special molds for retaining rings and special molds for wheel construction machinery wheels. It can solve the problems of easy cracking at welds, high process scrap rate, and high manufacturing costs, and achieve surface wear resistance. , the effect of high finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to enable those skilled in the art to better understand the solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

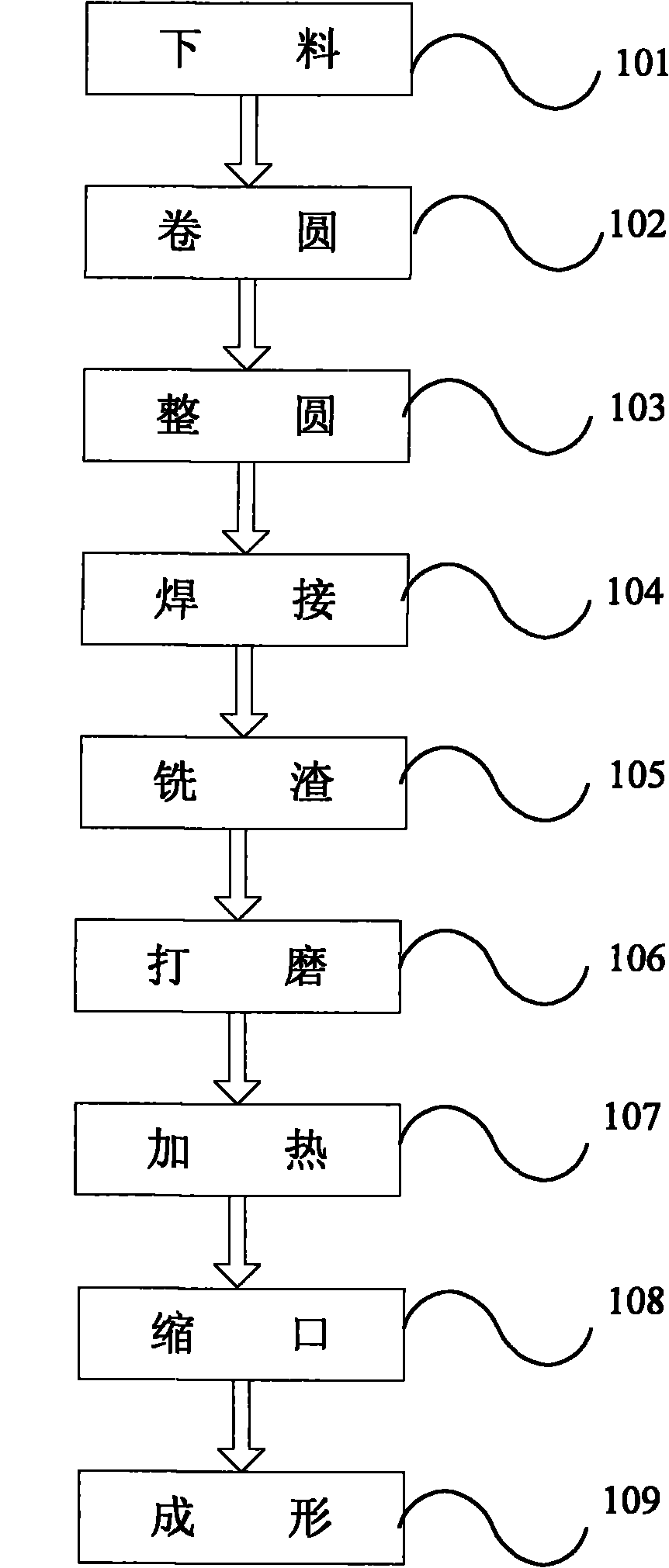

[0040] Such as figure 1 As shown, the wheeled engineering machinery wheel retaining ring manufacturing process provided by the invention includes the following steps:

[0041] S101 blanking cuts the prepared long strip according to the specifications of the prefabricated retaining ring to form a single-length strip;

[0042] S102 Rolling and rolling single-length strips into ring-shaped rings;

[0043] Use the existing rounding machine to roll the single-length strip into a ring-shaped ring.

[0044] S103 complete circle to round the ring-shaped material so that its two ends are aligned;

[0045] Utilize the existing shapi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com