Pine and bamboo particle recombination board and manufacturing method thereof

A manufacturing method and particle board technology, applied in the field of composite boards, can solve the problems of easy degumming, easy opening, and insufficient combination of the core board and the surface board, achieving simple formula, improving compression resistance, and solving the problem of easy multi-layer sticking. The effect of degumming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

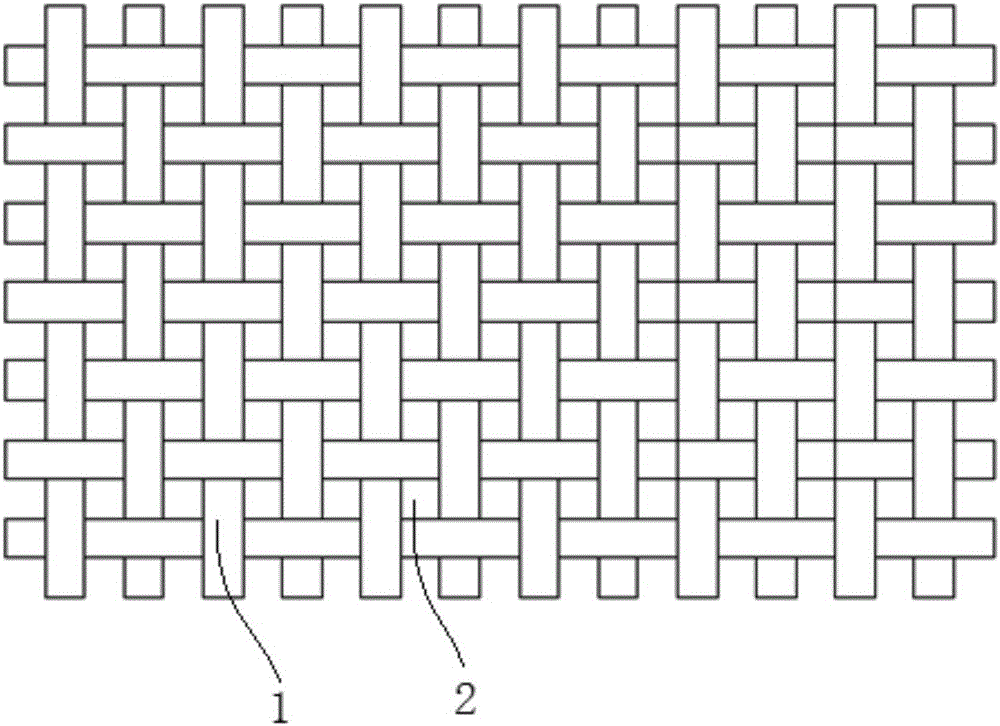

[0029] Step 1: Refer to figure 1 First, the bamboo with a length of 2500mm is rotary-cut into 0.3mm thick sheets, and then the 0.3mm bamboo sheets are divided into wide 3mm strip bamboo strips 1 for use.

[0030] Step 2: Refer to figure 2 , weaving bamboo strips 1 interlacedly into (2450*1250*0.3) mm mesh bottom grid 4 and mesh surface grid 3 for use, the mesh size is: 3mm×3mm.

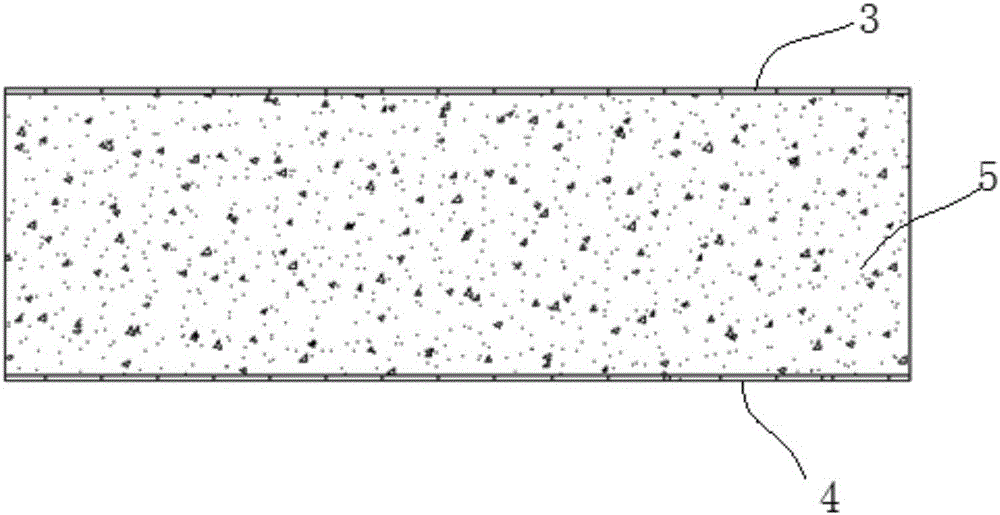

[0031] Step 3: Rotate cut or mash the pine wood and branch wood from which the epidermis and spoilage sources have been removed into loose particles with a diameter of 1-2 mm, and then dry, degrease and bleach the loose particles. Fill the loose particle board with the formaldehyde-free resin glue between the mesh bottom grid 4 and the mesh surface grid 3, the loose particle board core 5 is formed between the mesh bottom grid 4 and the mesh surface grid 3, and the loose particle board core 5 is formed. It is also filled in the meshes of the mesh bottom grid 4 and the mesh surface grid 3, and after ...

Embodiment 2

[0033] Step 1: Rotate the bamboo with a length of 2500mm into 0.2mm thick sheets, and then divide the 0.2mm bamboo sheets into 2mm wide strips of bamboo strips 1 for use.

[0034] Step 2: Weave bamboo strips 1 interlacedly into (2450*1250*0.3) mm mesh bottom grid 4 and mesh surface grid 3 for use, and the size of mesh 2 is: 3mm×3mm.

[0035] Step 3: Fill loose particles with formaldehyde-free resin glue between the mesh bottom grid 4 and the mesh surface grid 3, the distance between the mesh bottom grid 4 and the mesh surface grid 3 is 10mm, after high temperature After the high-pressure treatment, the pine and bamboo granule recombined board rough is obtained, and then the bottom and the surface of the pine and bamboo granule recombined board rough are polished, and after cutting, the finished pine and bamboo granule recombined board is obtained.

Embodiment 3

[0037] Step 1: Rotate the bamboo with a length of 2500mm into 0.4mm thick sheets, and then divide the 0.4mm bamboo sheets into 4mm wide bamboo strips 1 for use.

[0038] Step 2: Weave the strips of bamboo strips 1 interlacedly into (the mesh bottom grid 4 and the mesh surface grid 3 for use, the size of the mesh 2 is: 5mm×5mm.

[0039] Step 3: Fill loose particles with formaldehyde-free resin glue between the mesh bottom grid 4 and the mesh surface grid 3, the distance between the mesh bottom grid 4 and the mesh surface grid 3 is 25mm, after high temperature After the high-pressure treatment, the pine and bamboo granule recombined board rough is obtained, and then the bottom and the surface of the pine and bamboo granule recombined board rough are polished, and after cutting, the finished pine and bamboo granule recombined board is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com