Ceramic rotor spinning false twisting disc and ceramic processing method for inner surface of false twisting disc

A technology of false twisting disc and inner surface, which is applied in spinning machine, anodizing, textile and papermaking, etc., can solve the problems of uneven distribution of coating, high production cost, complicated process, etc., so as to reduce production cost and simplify production process. , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

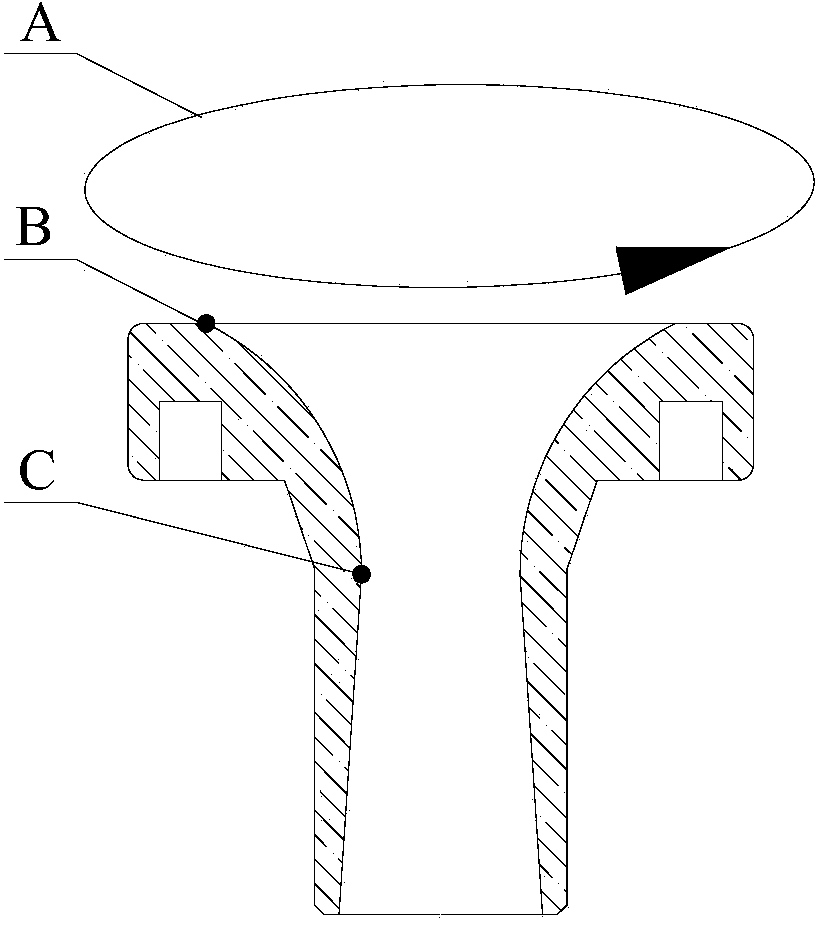

[0026] Embodiment 1: In the air-spinning ceramic false-twist disc described in this embodiment, the inner surface of the false-twist disc is coated with a layer of ceramic film, and the material of the layer of ceramic film contains a volume fraction of 80% to 90%. Al between 2 O 3 , the thickness of this layer of ceramic film is between 20μm and 70μm, the hardness is between HV1500 and HV1600, and the roughness is between Ra2μm and Ra3μm.

[0027] In this embodiment, the ceramic membrane removes 80% to 90% of the Al contained 2 O 3 , with a surplus of SiO 2 and impurities.

specific Embodiment approach 2

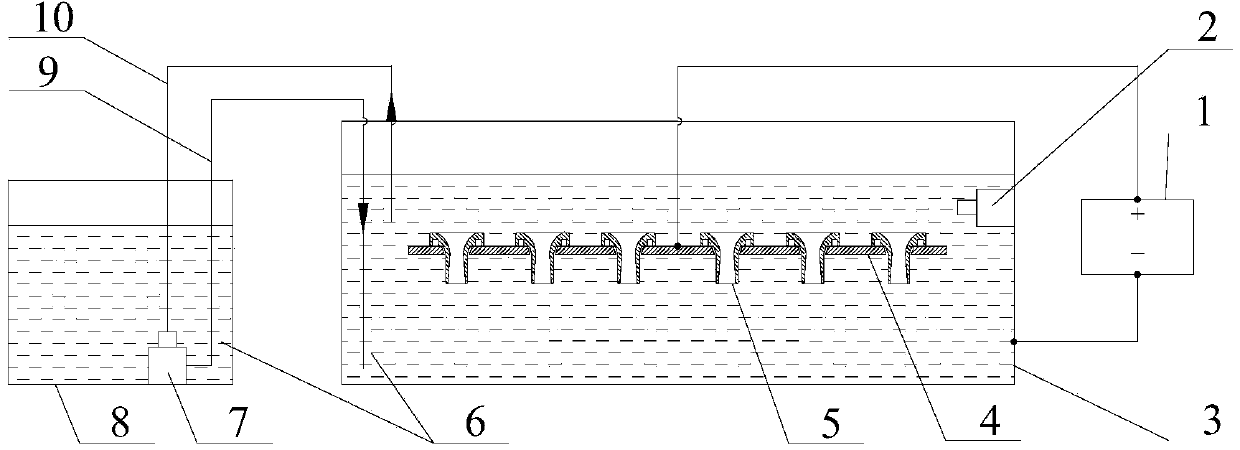

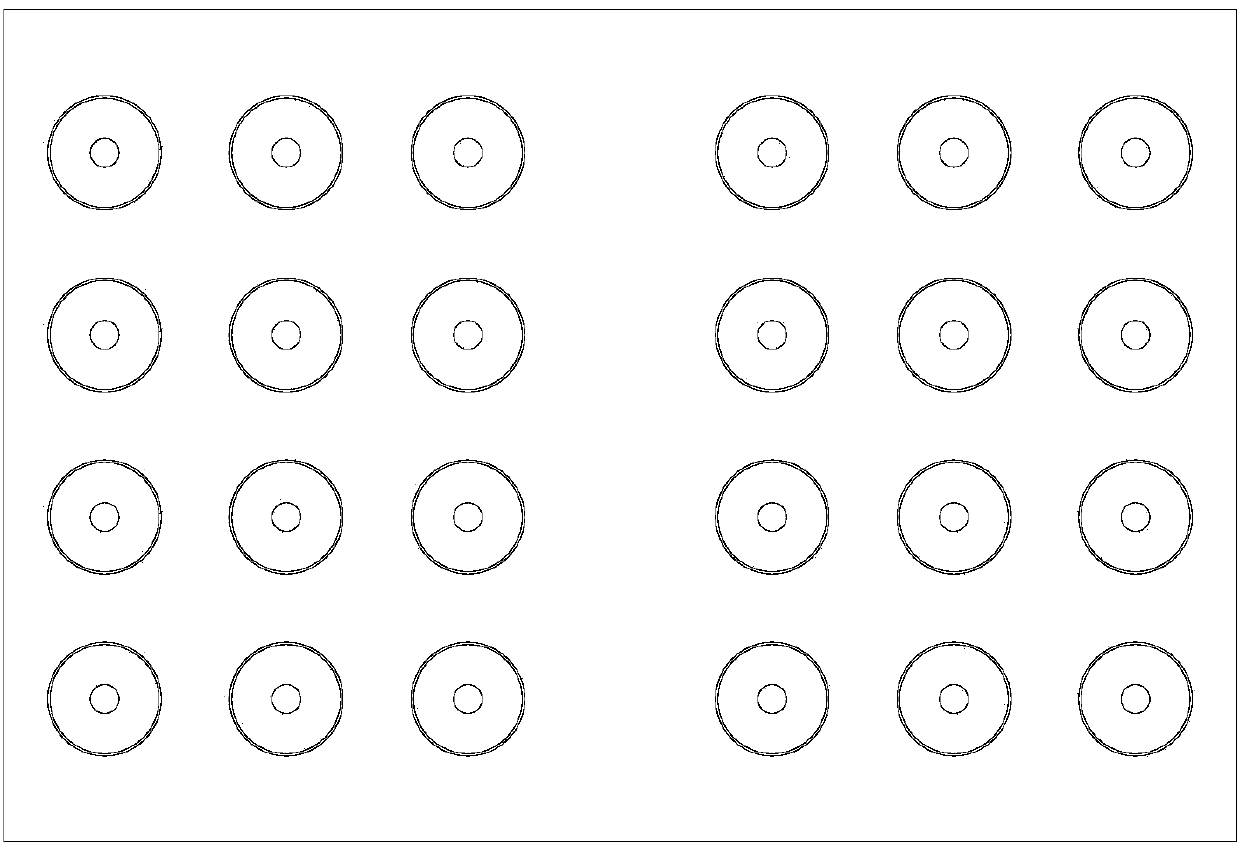

[0028] Specific implementation two: refer to figure 1 , figure 2 and image 3 Specifically describe this embodiment, the method for ceramizing the inner surface of the false twist disc described in this embodiment, which includes the following steps:

[0029] Step 1: Prepare an oxide ceramic layer on the surface of the false twist disc 5, and the specific process is as follows:

[0030] Fix the false twist disc 5 to be processed on the bracket 4, then immerse the false twist disc 5 and the bracket 4 into the reaction tank 3 filled with the working liquid 6 as a whole, and ensure that the opening of the false twist disc 5 to be processed is the same as the one. The working fluid level is parallel;

[0031] According to the thickness of the film layer of the false twist disc 5 to be obtained, the voltage of the DC pulse power supply 1 is set, and then the DC pulse power supply 1 is used to apply a DC pulse between the bracket 4 and the reaction tank 3;

[0032] Use the inne...

specific Embodiment approach 3

[0044] Embodiment 3: This embodiment further describes the method for ceramizing the inner surface of the false-twist disc described in Embodiment 2. In this embodiment, before step 1, the false-twist disc 5 to be treated is firstly processed. Cleaning, the cleaning method is:

[0045] First, use deionized water to clean the false twisting disc 5 to be treated, and then use alcohol solution to clean the false twisting disc 5 after deionized water cleaning to obtain a false twisting disc 5 with surface dust and oil stains removed.

[0046] Specific implementation four: refer to Figure 4 This embodiment is specifically described. This embodiment further describes the method for ceramicizing the inner surface of the false-twisting disc described in the third embodiment. A periodic process of applying a DC pulse to the reaction tank 3 is:

[0047] At time t0, the DC pulse power supply 1 outputs a positive pulse with an amplitude of Vzi and a pulse width of Tz; at the end of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com