High occlusion cylinder liner and preparation method thereof

A cylinder liner and fitting technology, which is applied in the direction of cylinders, cylinder heads, mechanical equipment, etc., can solve the problems of difficulty in meeting the requirements of cylinder liner strength, wear resistance and cost, high production cost of cylinder liners, and long running-in time. Achieve the effects of shortening the running-in time, low manufacturing cost and improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

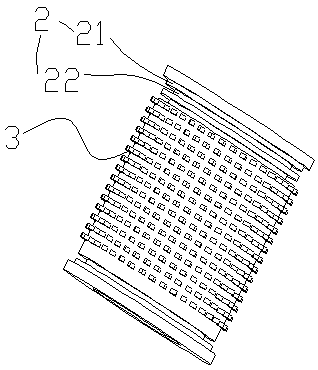

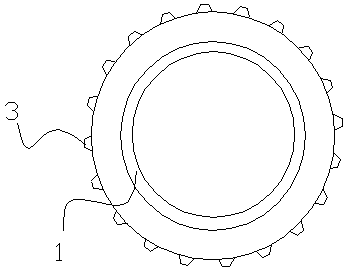

[0026] Such as Figure 1-2 As shown, this embodiment discloses a high-occlusion cylinder liner, including a cylinder liner body, the inner surface of the cylinder liner body is coated with an inner coating 1, the surface roughness of the inner coating 1 is 80 μm, and the thickness is 0.2 mm; Both ends of the outer surface of the sleeve body are provided with an annular groove body 2, and the depth of the annular groove body 2 is 0.1mm; a burr 3 structure is arranged in the middle area of the outer surface of the cylinder body; the height of the burr 3 is 0.1m.

[0027] The chemical composition of the cylinder liner body includes Si content of 5wt.%, Ti content of 7wt.%, Fe content of 0.3wt.%, Mn content of 0.6wt.%, Pd content of 0.05wt.%. The Sr content is 2.3wt.%, and the rest is Al.

Embodiment 2

[0029] Such as Figure 1-2 As shown, this embodiment discloses a high-occlusion cylinder liner, including a cylinder liner body, the inner surface of the cylinder liner body is coated with an inner coating 1, the surface roughness of the inner coating 1 is 100 μm, and the thickness is 0.3 mm; Both ends of the outer surface of the sleeve body are provided with an annular groove body 2, and the depth of the annular groove body 2 is 0.3mm; a burr 3 structure is arranged in the middle area of the outer surface of the cylinder body; the height of the burr 3 is 0.2mm.

[0030] The annular groove body 2 has a stepped structure, including a first annular groove body 21 and a second annular groove body 22 ; the depth of the second annular groove body 22 is greater than that of the first annular groove body 21 .

[0031] The depth of the first annular groove body 21 is 0.1mm; the depth of the first annular groove body 21 is 0.2mm.

[0032] The chemical composition of the cylinder lin...

Embodiment 3

[0034] Such as Figure 1-2 As shown, this embodiment discloses a high-occlusion cylinder liner, including a cylinder liner body, the inner surface of the cylinder liner body is coated with an inner coating 1, the surface roughness of the inner coating 1 is 120 μm, and the thickness is 0.4 mm; Both ends of the outer surface of the sleeve body are provided with an annular groove body 2, and the depth of the annular groove body 2 is 0.4mm; a burr 3 structure is provided in the middle area of the outer surface of the cylinder body; the height of the burr 3 is 0.5mm.

[0035] The annular groove body 2 has a stepped structure, including a first annular groove body 21 and a second annular groove body 22 ; the depth of the second annular groove body 22 is greater than that of the first annular groove body 21 .

[0036] The depth of the first annular groove body 21 is 0.15mm; the depth of the first annular groove body 21 is 0.25mm.

[0037] The chemical composition of the cylinder l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com