High-power diesel engine cylinder sleeve surface functional phosphating technology

A high-power diesel engine, functional technology, applied in the direction of metal material coating process, etc., can solve the problems of long run-in test period, difficult formation of lubricating oil film, high oil purchase cost, etc., so as to reduce the probability of cylinder scuffing accidents, avoid High adhesion to molten metal, and the effect of reducing cylinder scuffing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with embodiment the present invention is described in further detail:

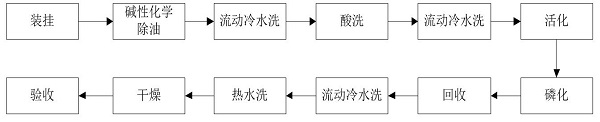

[0038] Such as figure 1 As shown, a high-power diesel engine cylinder liner surface functional phosphating process includes the following steps (the relevant parameters can be adjusted according to the steel substrate material):

[0039] S1, installation and hanging

[0040] Hang the high-power diesel engine cylinder set on the hanger.

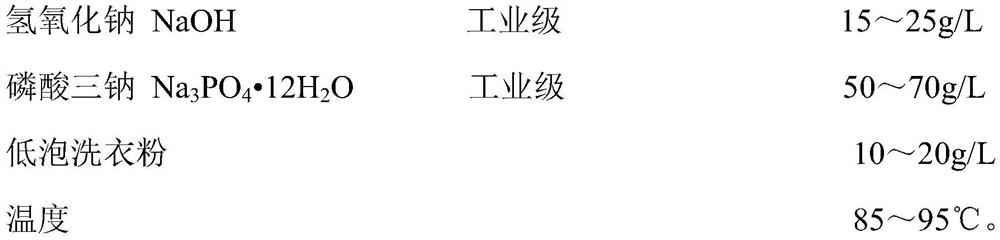

[0041] S2, alkaline chemical degreasing

[0042] Degreasing fluid composition and process specifications:

[0043]

[0044] When the cylinder liner enters and leaves the degreasing tank, the hanger drives the cylinder liner to reciprocate up and down in the degreasing liquid for many times, generally 4 to 5 times.

[0045] S3, washing with flowing cold water

[0046] The cylinder liner that has been degreased is cleaned several times by multiple immersion methods until it is cleaned. The degreasing effect of the cylinder liner depends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com